Scraper detection device for omnidirectional detection

A kind of testing equipment, all-round technology, applied in measuring devices, optical testing flaws/defects, instruments etc problems, to achieve the effects of low purchase and storage management costs, stable and reliable operation and adjustment, and ingenious and reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

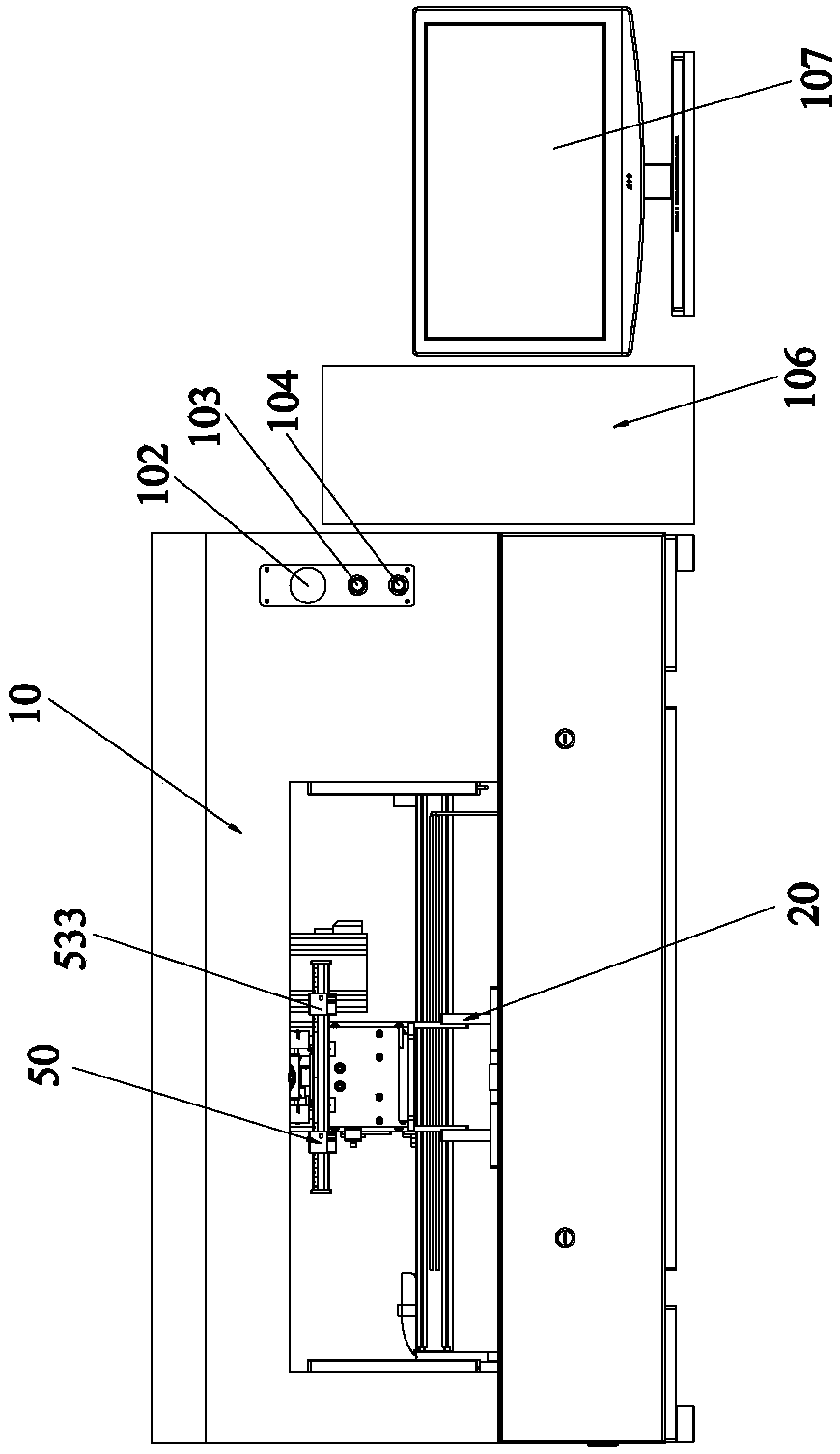

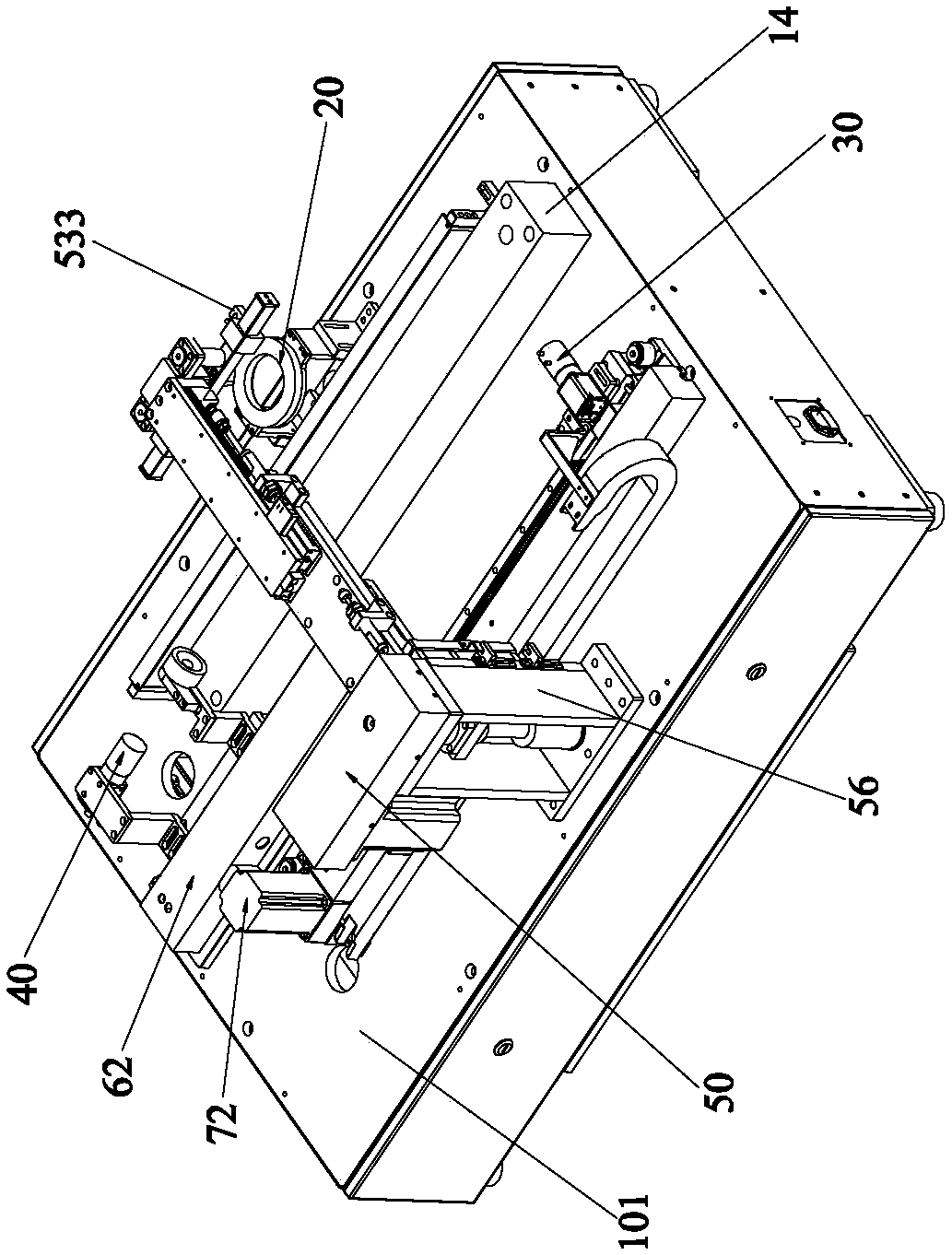

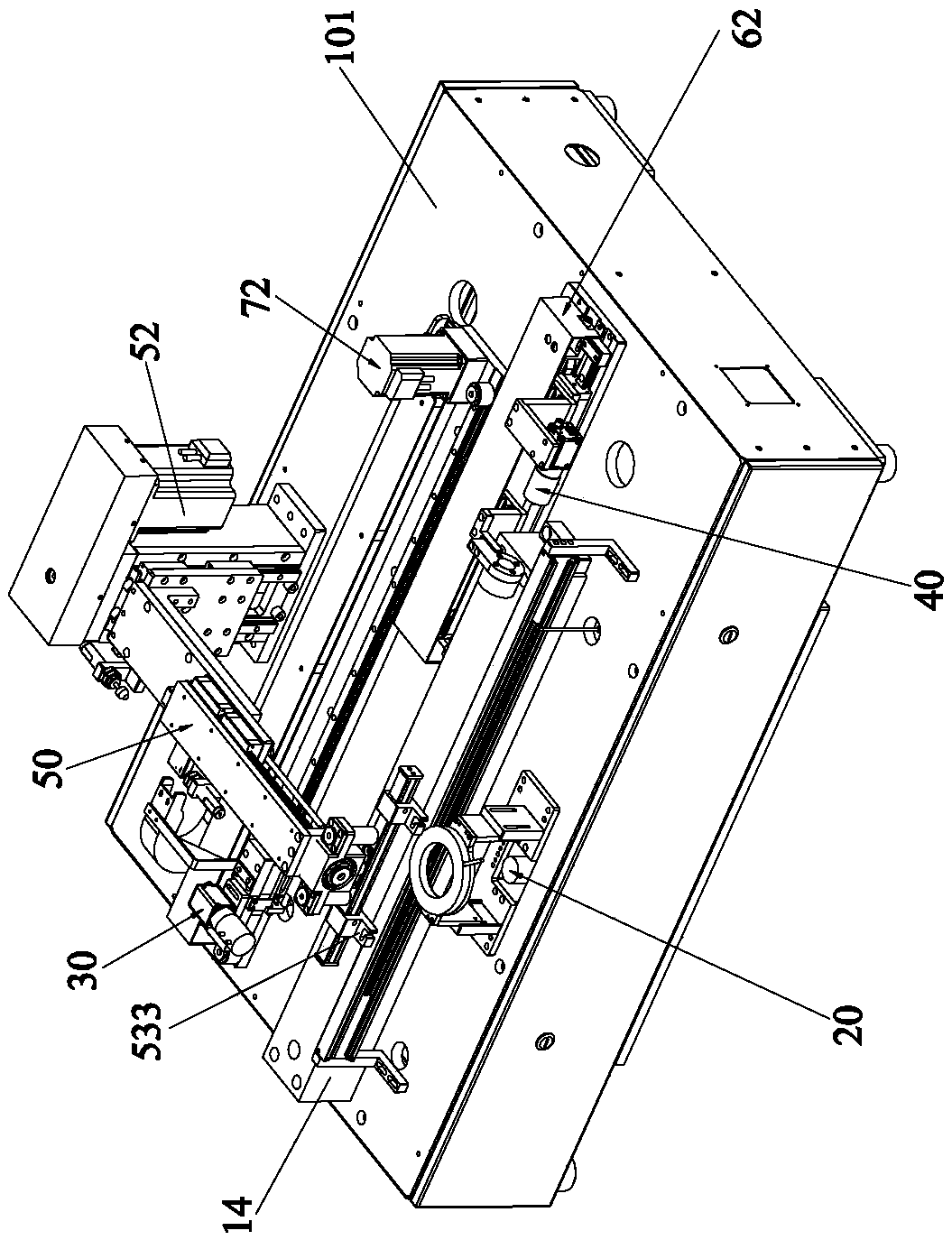

[0077] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the embodiment of the present invention, a scraper detection equipment for omnidirectional detection, including a frame 10, a main console (not shown in the figure) and a detection device installed on the frame 10 Module; the frame 10 has a horizontal workbench 101, and the detection module is installed on the horizontal workbench 101, wherein:

[0078] The detection module includes a first X-axis translation sliding seat 61, a second X-axis translation sliding seat 71, a vertically adjustable scraper blade surface defect detection device 20, and a scraper installation unit 50 for installing a scraper 80 to be tested. , the second X-axis translation drive mechanism 72 for driving the second X-axis translation slide seat 71 to move along the X-axis direction, the first X-axis translation drive mechanism 72 for driving the first X-axis translation slide seat 61 to move along the X-axis dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com