Omnibearing high-precision detection device and method for defects of notebook computer shell

A notebook computer and detection device technology, which is applied in the direction of measuring devices, optical testing flaws/defects, image data processing, etc., can solve the problems of decreased accuracy, long detection time, high cost, etc., and achieve expansion of dimension diversity and high precision The effect of detection and improvement of detection accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

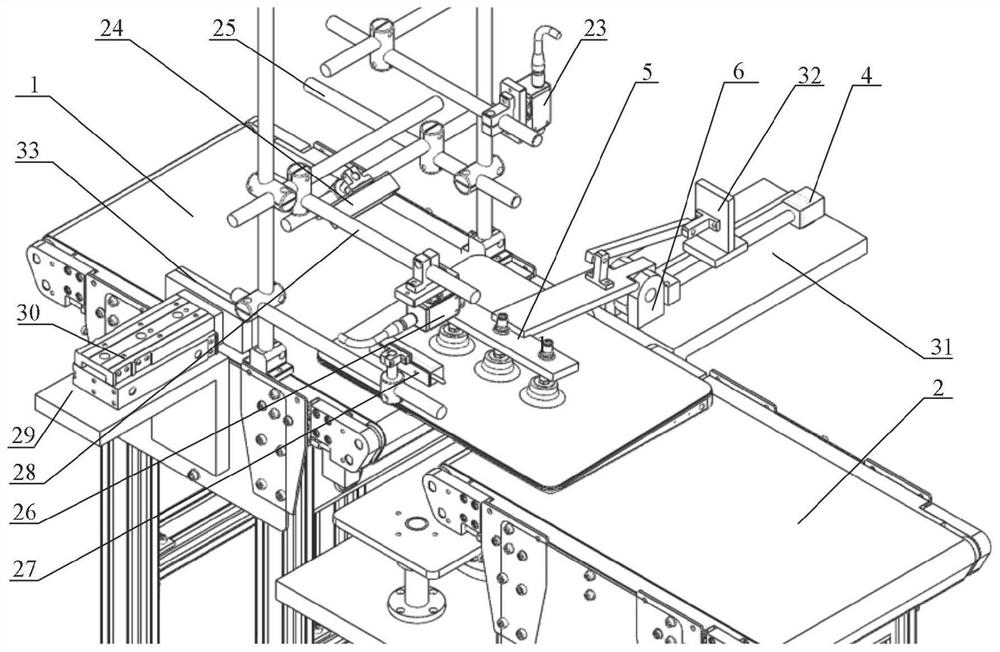

[0048] In this embodiment, an all-round high-precision detection device for defects in a notebook computer casing, such as image 3 As shown, a conveyor belt is provided, and the conveyor belt is sequentially provided with a first conveyor belt 1 and a second conveyor belt 2 along the conveying direction;

[0049] One side of the first conveyor belt 1 is provided with a push rod assembly 29, and the push rod assembly 29 is provided with a rubber block 33 at the movable end of the push rod cylinder 30, which is used to carry out the initial position of the notebook computer on the first conveyor belt 1 Adjust so that the notebook computer is in the middle position on the first conveyor belt 1, so that the notebook computer can be accurately moved to the detection station;

[0050] like Figure 4 As shown, the same side of the first conveyor belt 1 and the second conveyor belt 2 is provided with a flip mechanism 3, and the flip mechanism 3 is provided with a support plate 31 be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com