Automatic detecting equipment for appearance defects of mobile phone lens

An automatic detection and lens technology, which is applied in sorting and other directions, can solve the problems of manual detection form performance and efficiency that cannot meet the demand, measurement accuracy impact, and low efficiency, so as to improve efficiency and stability, improve production efficiency, and realize automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

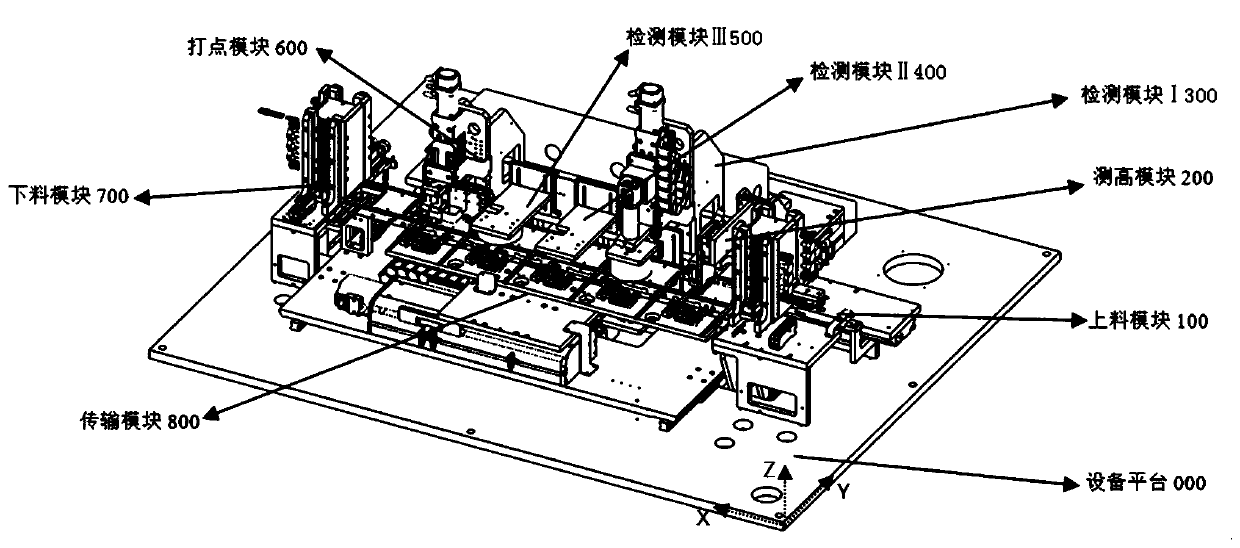

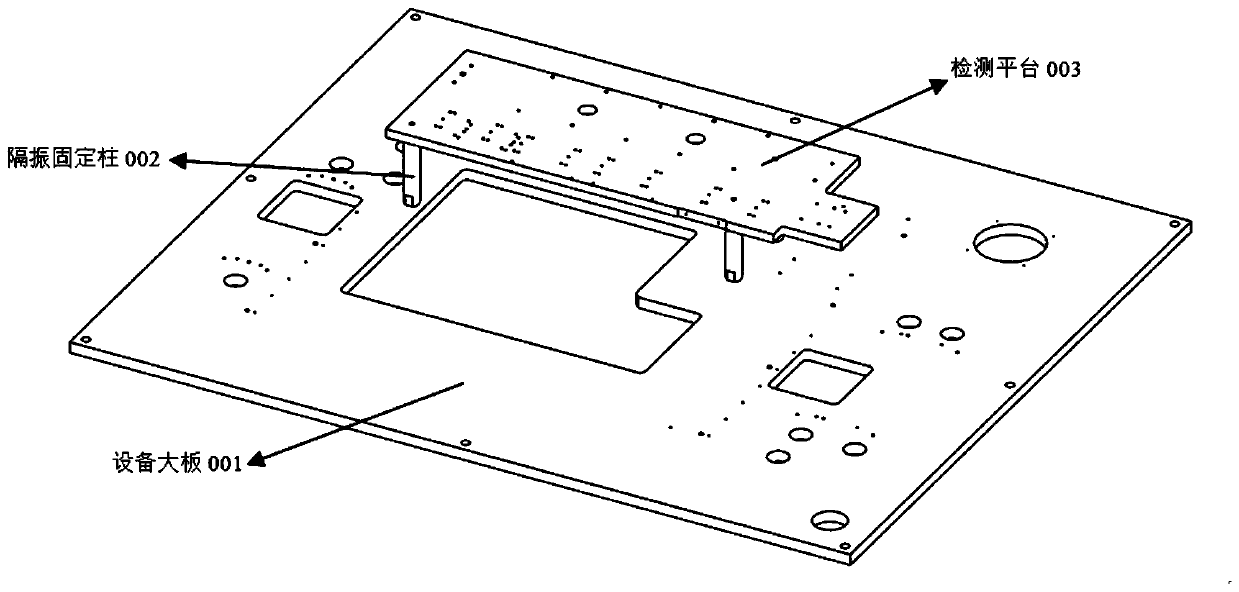

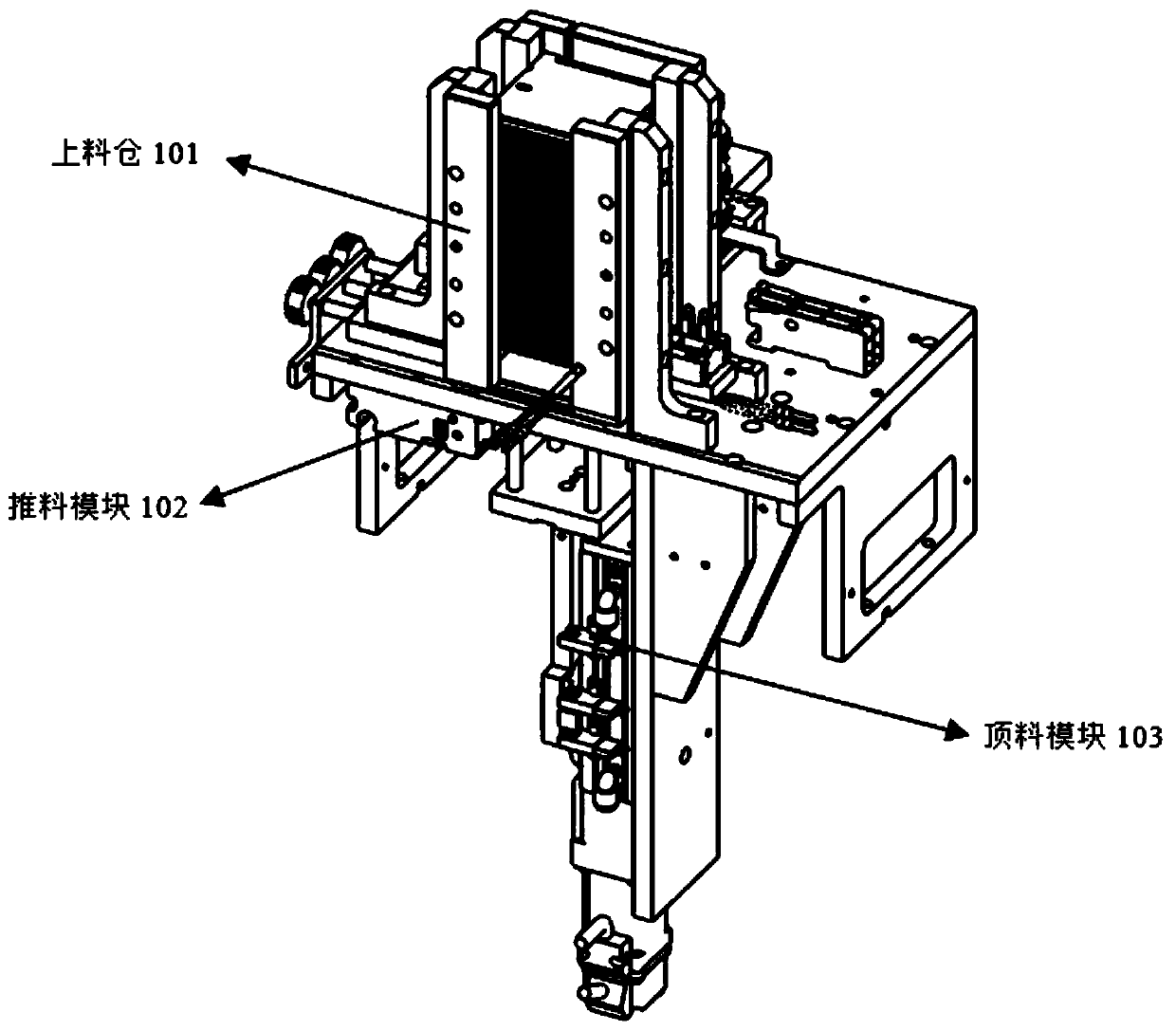

[0044] In general, the present invention provides an automatic detection device with a reasonable structure design and a remarkable test effect rate. The detection device can be automatically controlled by a built-in / external integrated upper computer. The upper computer may preferably include hardware structures and calculation programs and / or firmware that drive the mechanical / electronic / mechatronic actions of these hardware structures and their electrical connection components, such as digital signal processors (DSP), programmable logic circuits (ASIC) or FPGA array components. The accompanying drawings vividly depict the three-dimensional structure of the preferred embodiment of this detection device in a simplified manner as much as possible, wherein the coordinate axes (such as X-o-Y or Z axis) can be defined according to the perspective shown in the diagram, and the description in the context In , for example, "X coordinate axis" may sometimes be simply referred to as "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com