Antibacterial pipe material and preparation method thereof

A technology of pipes and antibacterial agents, applied in the field of antibacterial pipes and their preparation, can solve the problems of polyethylene pipes with weak antibacterial performance, difficulty in achieving antibacterial effects, and affecting water quality, so as to improve product use effect, excellent antibacterial effect, and perfect operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

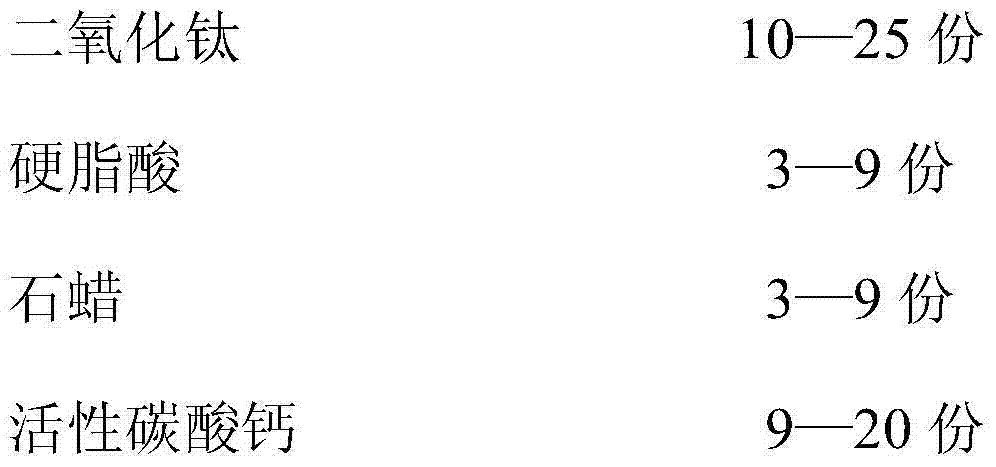

Method used

Image

Examples

example 1

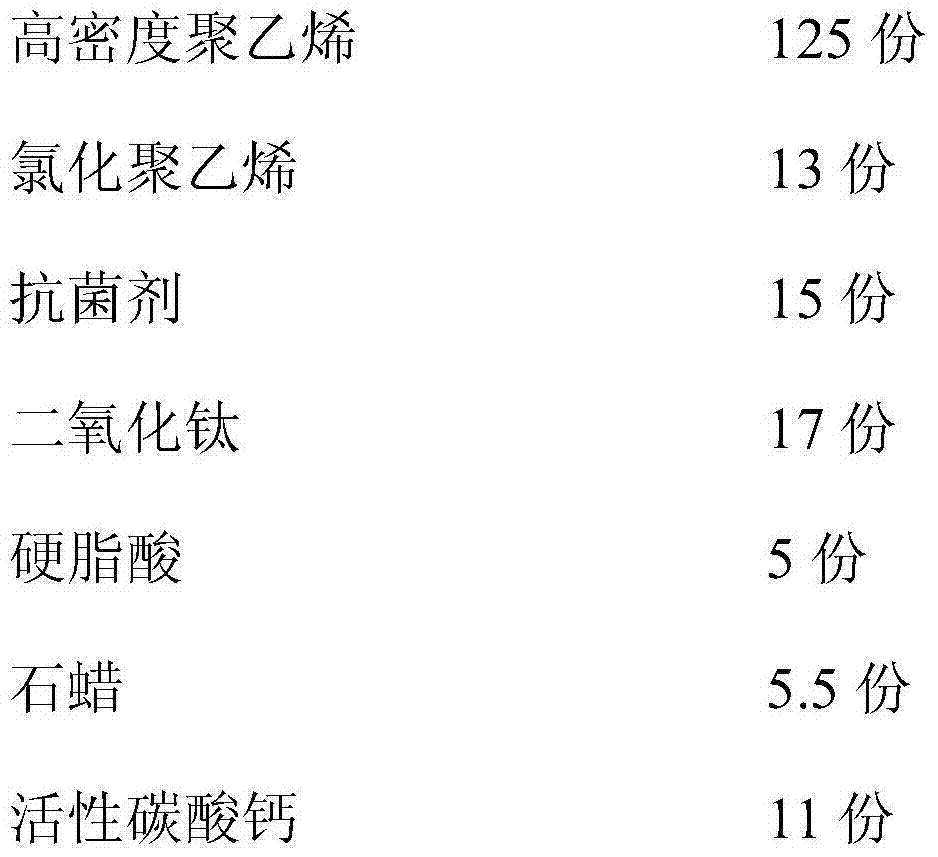

[0023] An antibacterial pipe and a preparation method thereof, the preparation method of which is as follows: firstly configure an antibacterial agent, mix nanoscale silver powder, nanoscale copper powder and nanoscale zinc powder with a mass ratio of 20:9:5 to obtain an antibacterial agent . Then put 125 parts of high-density polyethylene, 13 parts of chlorinated polyethylene, 15 parts of antibacterial agent, 17 parts of titanium dioxide, 5 parts of stearic acid, 5.5 parts of paraffin, and 11 parts of active calcium carbonate into the mixer in sequence, stirring time: 15min , with a stirring rate of 590r / min; then, put the stirred mixture into a twin-screw extruder for blending and granulation, and the temperature range of each section of the extruder is: 180°C—220°C; finally, the granulated particles The finished pipe is extruded through a single-screw extruder, the temperature of the barrel of the single-screw extruder is 170°C, the temperature of the mold is 195°C, and the...

example 2

[0028] An antibacterial pipe and a preparation method thereof, the preparation method of which is as follows: firstly configure an antibacterial agent, mix nanoscale silver powder, nanoscale copper powder and nanoscale zinc powder with a mass ratio of 20:9:5 to obtain an antibacterial agent . Then put 140 parts of high-density polyethylene, 15 parts of chlorinated polyethylene, 19 parts of antibacterial agent, 13 parts of titanium dioxide, 7 parts of stearic acid, 6 parts of paraffin, and 18 parts of active calcium carbonate into the mixer in turn, stirring time: 25min , the stirring rate is 590r / min; then, put the stirred mixture into a twin-screw extruder for blending and granulation, and the temperature range of each section of the extruder is: 180°C-220°C; finally, the granulated particles The finished pipe is extruded through a single-screw extruder, the temperature of the barrel of the single-screw extruder is 175°C, the temperature of the mold is 200°C, and the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com