Piston surface defect detection method and system based on deep learning

A technology of defect detection and deep learning, which is applied in the field of piston surface defect detection based on deep learning, to achieve all-round detection, the best image acquisition effect, and the effect of improving detection accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

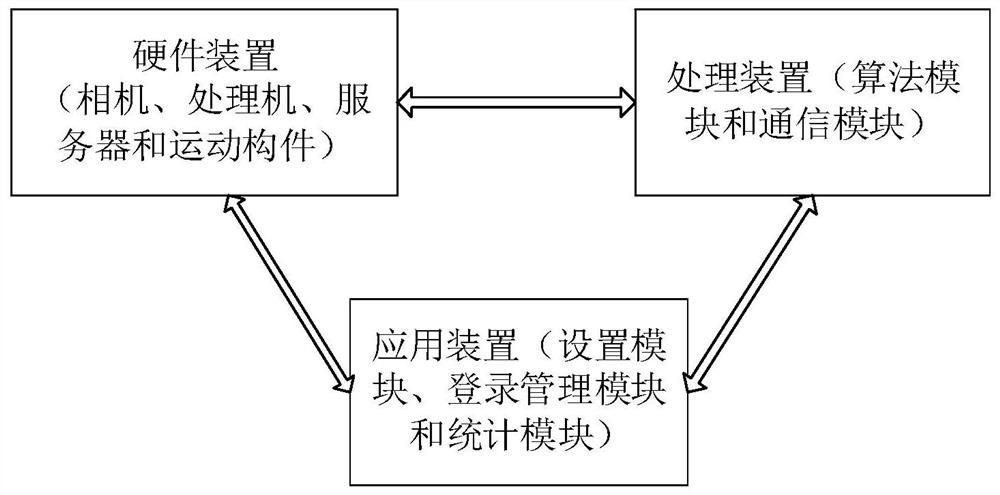

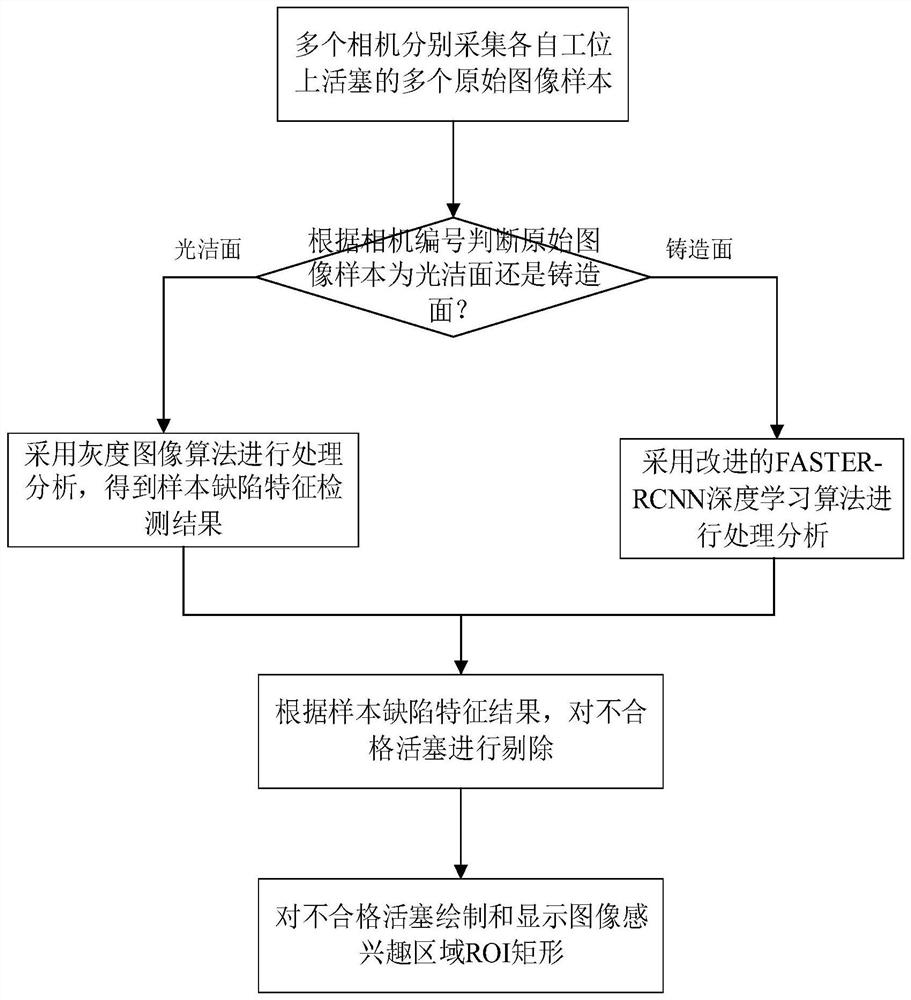

[0156]According to a specific implementation of the piston surface defect detection system based on deep learning of the present invention, combined with the attachedPicture 8 , The present invention will be described in detail. The invention adopts a plurality of cameras and different angle waveband end light sources to collect images at different image collecting stations.

[0157]The invention provides a piston surface defect detection system based on deep learning, including:

[0158]AttachedPicture 8 Middle 1-9 are cameras, the above cameras collect images of different parts of the piston; processor 1 connects camera 2, camera 4 and camera 7, processor 2 connects camera 3 and camera 8, processor 3 connects camera 5 and camera 6, Processor 4 connects camera 1 and camera 9; the total number of connected cameras is 9. The transmission protocol between processors 1, 2, 3 and 4 and the server is Socket TCP / IP. Processors 1 to 4 communicate with the server and PLC, the camera solution is s...

Embodiment 2

[0194]According to a specific implementation of the piston surface defect detection system based on deep learning of the present invention, combined with the attachedPicture 8 , The present invention will be described in detail.

[0195]The present invention provides a method for detecting defects on the surface of a piston based on deep learning. Taking the camera 2 connected to the camera workstation 2 as an example, the camera 2 collects a smooth and clean image, including the following steps:

[0196]The camera 2 collects multiple original image samples of the piston of the camera station;

[0197]For the smooth face image, the gray-scale image algorithm is used for processing and analysis, and the sample defect feature detection result is obtained;

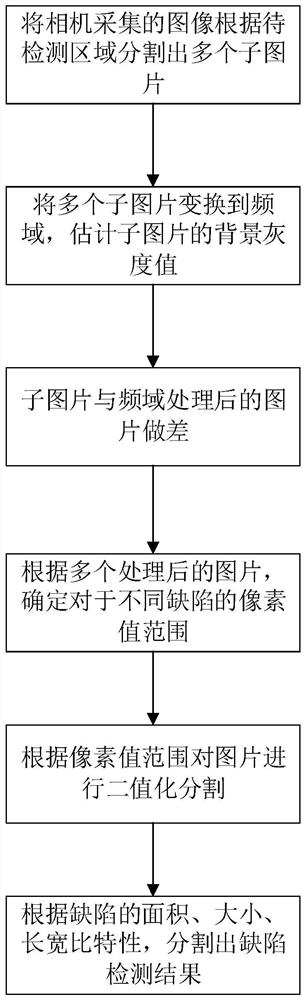

[0198]The body includes:

[0199]Segment the image collected by the camera into multiple sub-pictures according to the area to be detected;

[0200]Transform multiple sub-pictures into the frequency domain, and estimate the background gray value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com