Comprehensive performance test bench for planetary roller screw

A comprehensive performance test and planetary roller technology, which is applied in the direction of machine gear/transmission mechanism test, etc., can solve the problems of single performance test of planetary roller screw pair and inability to simulate actual working conditions, and achieve high loading accuracy and flexibility Strong, scalable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

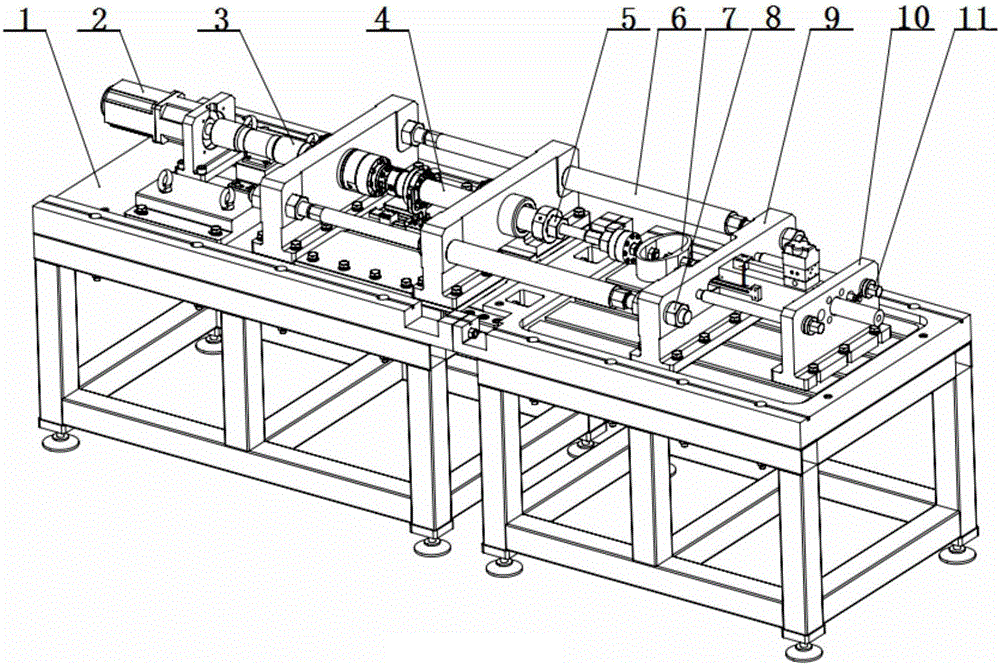

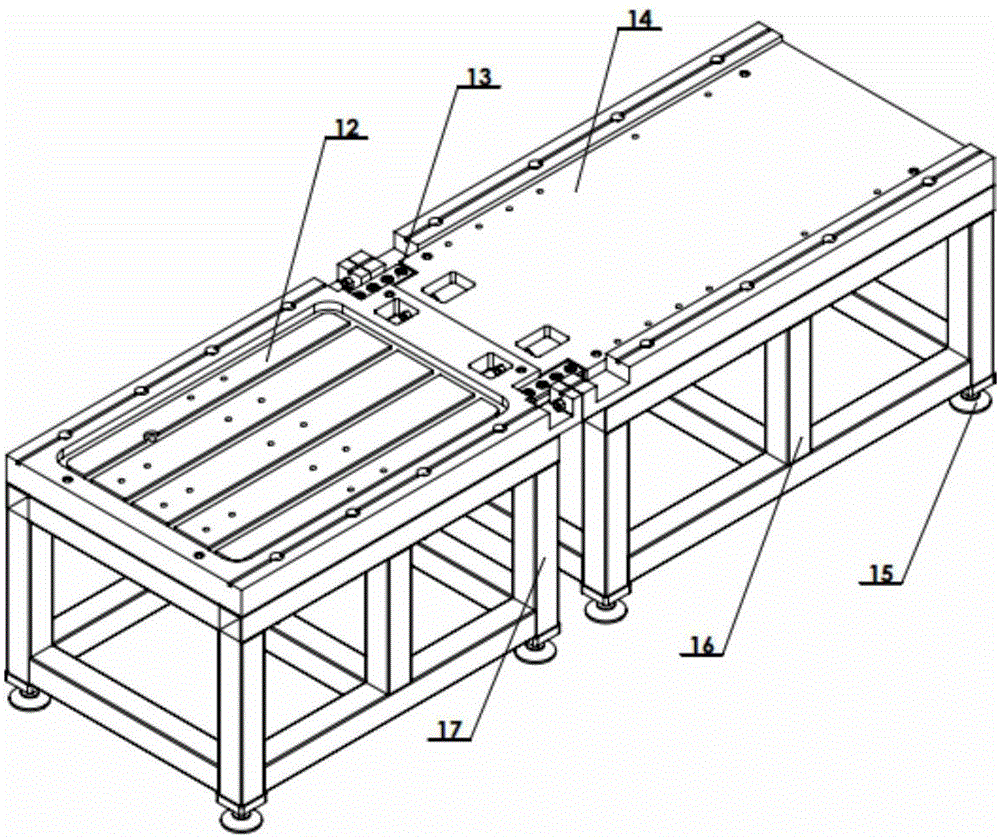

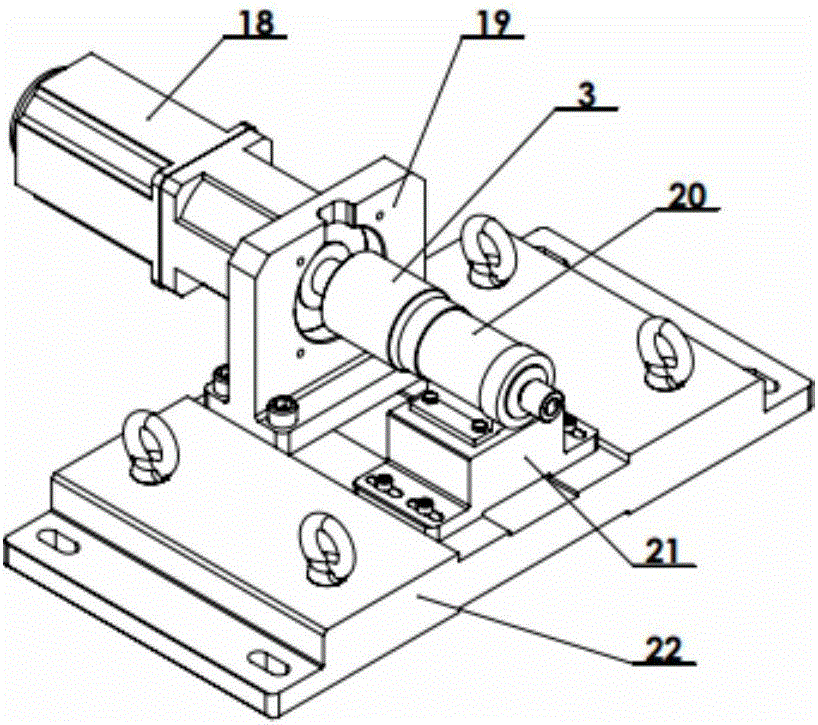

[0024] This embodiment is a comprehensive performance test bench for a planetary roller screw pair.

[0025] refer to Figure 1 to Figure 6, the comprehensive performance test bench of the planetary roller screw pair in this embodiment consists of a test bench bottom plate assembly 1, a drive assembly 2, a coupling 3, a test assembly 4, a threaded push rod nut 5, an internal force rod 6, and a hydraulic loading assembly 7. The internal force rod nut 8, the hydraulic loading base 9, the hydraulic loading rear base 10, and the hydraulic cylinder fixing screw 11 are composed. The drive assembly 2 is used to drive the planetary roller screw pair to drive the screw to rotate. Test assembly 4 is used to install different types of planetary roller screw pairs. The hydraulic loading assembly 7 is used to provide load for the planetary roller screw pair to simulate its actual working condition. The bottom plate assembly 1 of the test bench is used to support parts connected to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com