Patents

Literature

58results about How to "The direction of movement is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

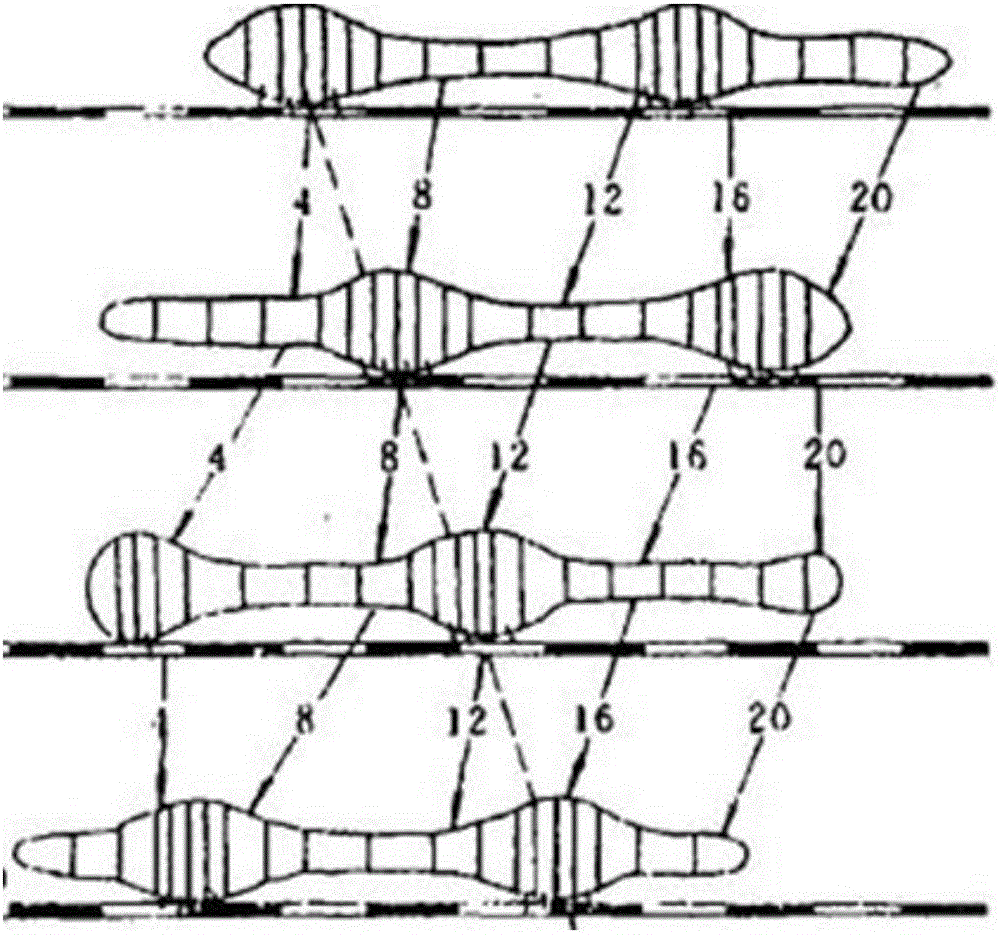

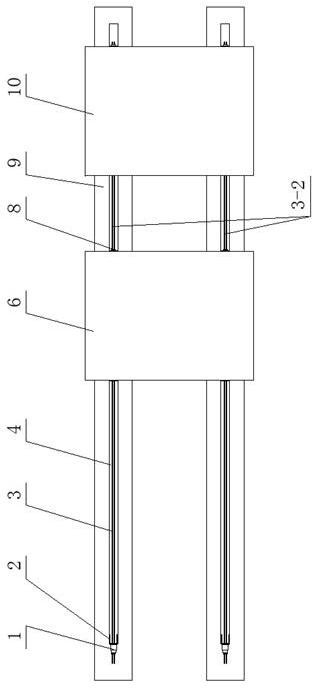

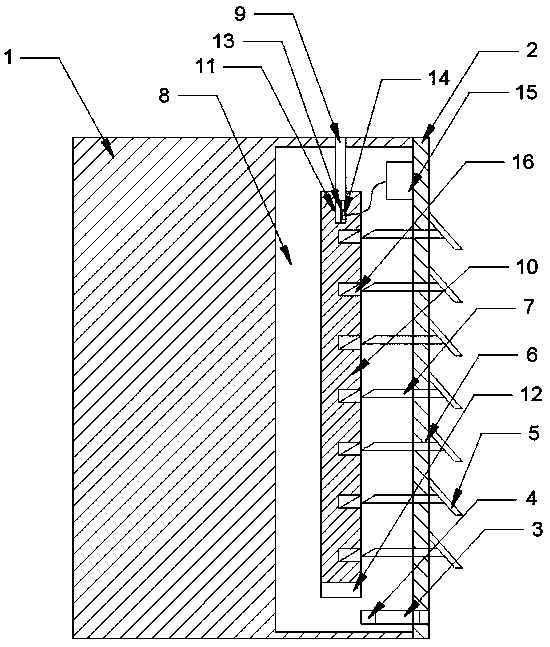

Pneumatic type soft motion robot based on earthworm motion principle

The invention provides a pneumatic type soft motion robot based on an earthworm motion principle. The robot comprises a first body part, a second body part and a third body part, wherein the first body part is connected with the second body part through a first telescopic part, the second body part is connected with the third body part through a second telescopic part, and the first body part and the second body part are controlled by a controller arranged on the second body part to stretch and retract; and mechanical steel bristles are arranged at the lower portion of the first body part and the lower portion of the third body part. By the adoption of the robot, a robot motion model is established according to the earthworm motion mechanism, and through the mechanical steel bristles, pneumatic control replacement and simulation of stretching and retracting of transverse muscles and longitudinal muscles of an earthworm, the robot can conduct complex actions of walking straightly, making a turn, crossing an obstacle and the like in a severe environment. Through intelligent control, the robot can be used in industrial pipeline exploration and disaster search and rescue.

Owner:SHANGHAI INST OF TECH

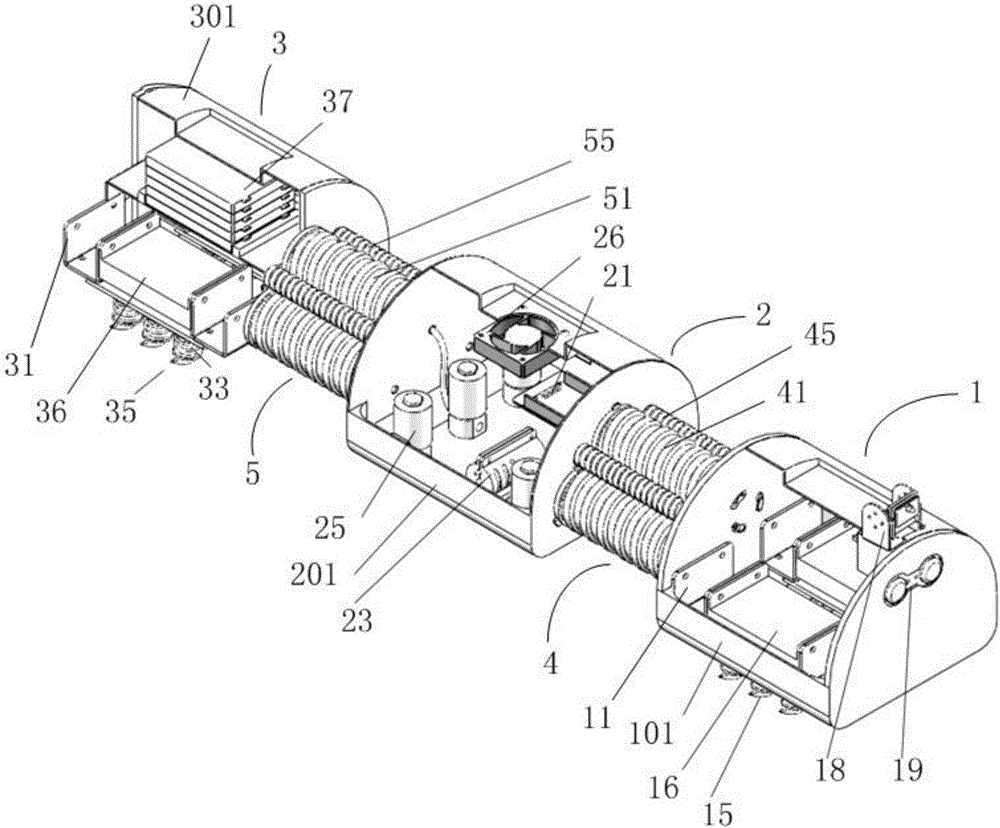

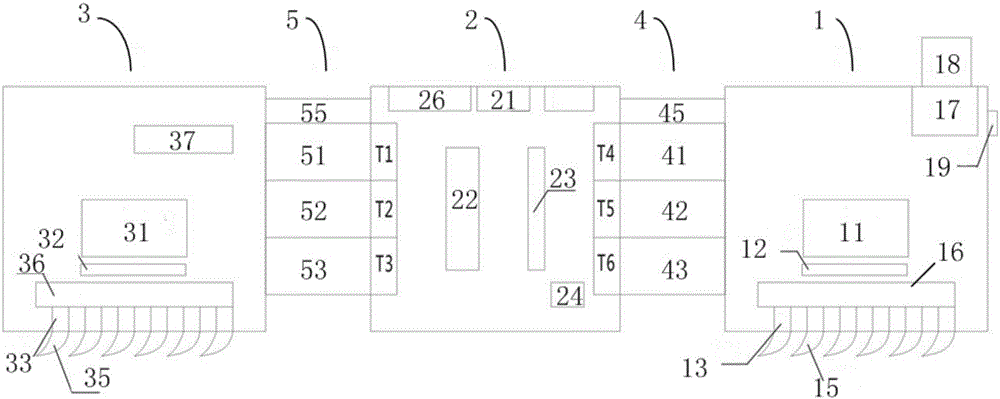

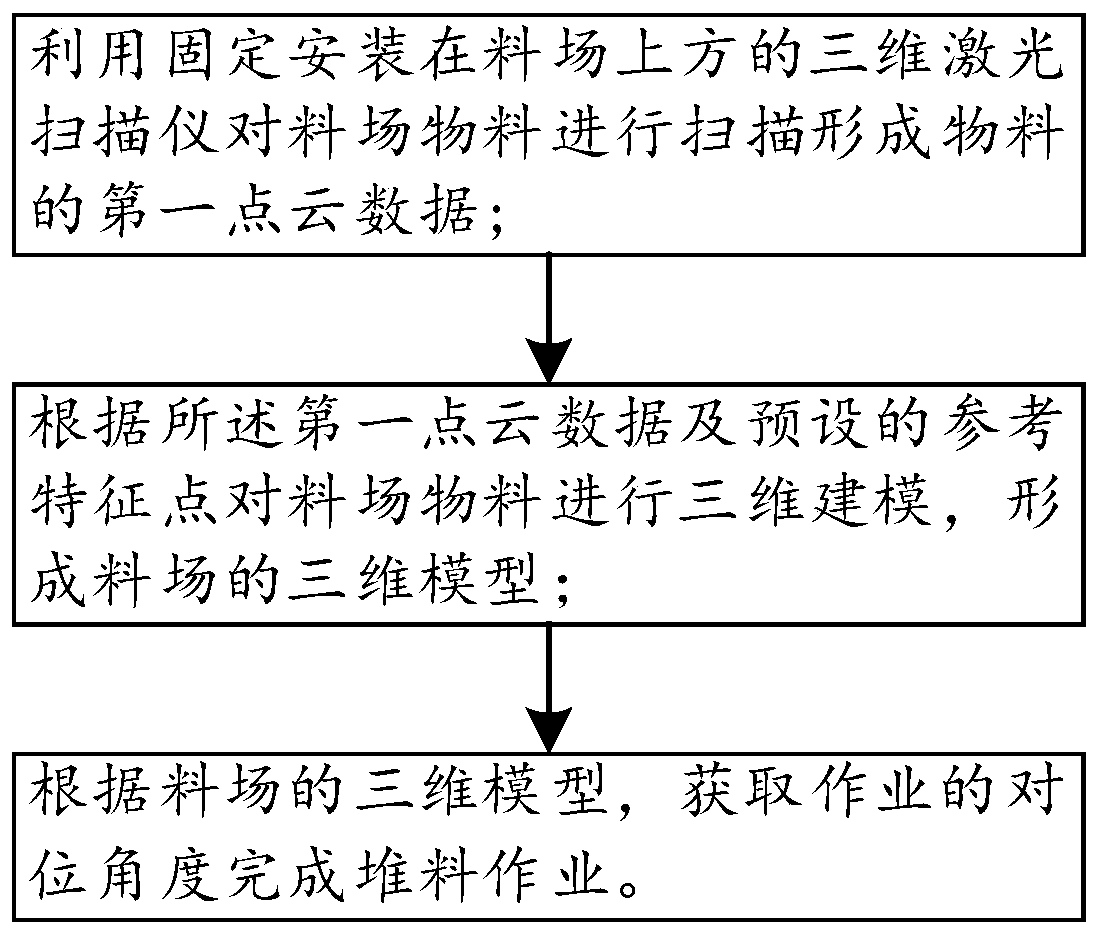

Automatic material stacking, material taking and material stacking and taking method and system for material yard

ActiveCN110194375AReduce empty runsRealize fully automatic operationUsing optical meansLoading/unloadingPoint cloudStack machine

The invention relates to an automatic material stacking and material taking method for a material yard. The method comprises the steps of scanning materials in the material yard by using a three-dimensional laser scanner fixedly installed above the material yard to form point cloud data of the materials, and carrying out three-dimensional modeling according to the point cloud data of the materialsand preset reference characteristic points and finishing material stacking and material taking operations, wherein forming of a three-dimensional model of the material yard comprises a cleaning step,a splicing step, a removing step, a filling step and a modeling step. The invention further discloses an automatic material stacking, material taking and material stacking and taking system. The three-dimensional laser scanner fixed above the material yard is used for scanning the point cloud data of the materials in the material yard, no material stacking and material taking machine participatesin the scanning process, the three-dimensional laser scanner can independently run in real time, working time is saved, and material stacking and material taking operations can be more accurately carried out by acquiring the alignment angle of a material stacking machine or acquiring a starting point and an ending point of a material taking machine.

Owner:BEIJING ZHONGSHENG BOFANG ENVIRONMENTAL PROTECTION ENG TECH

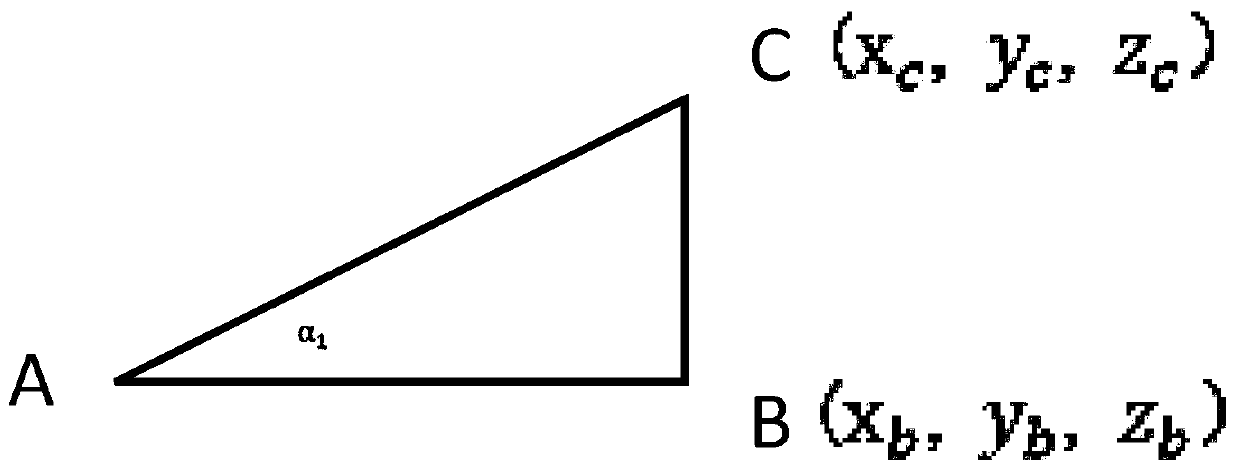

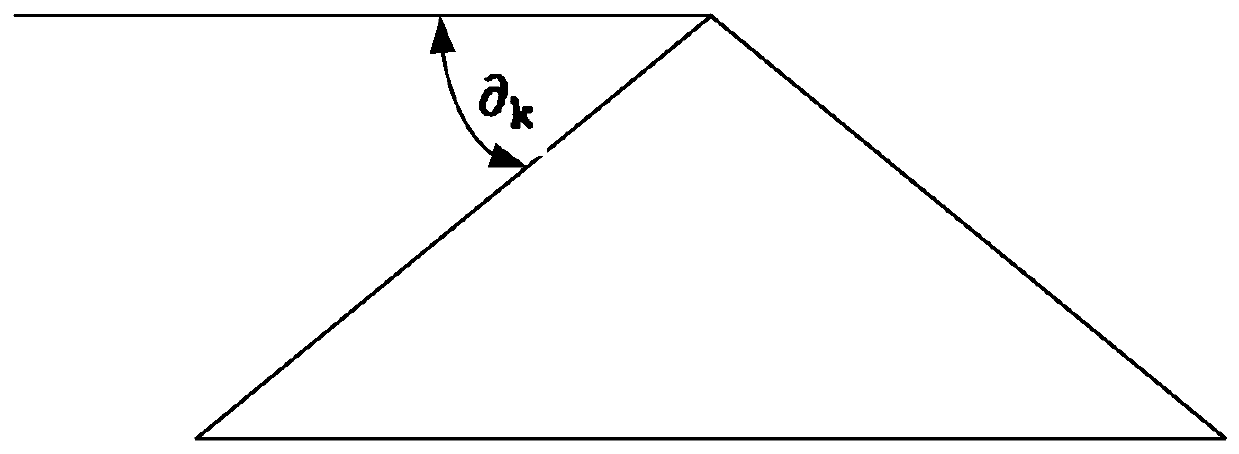

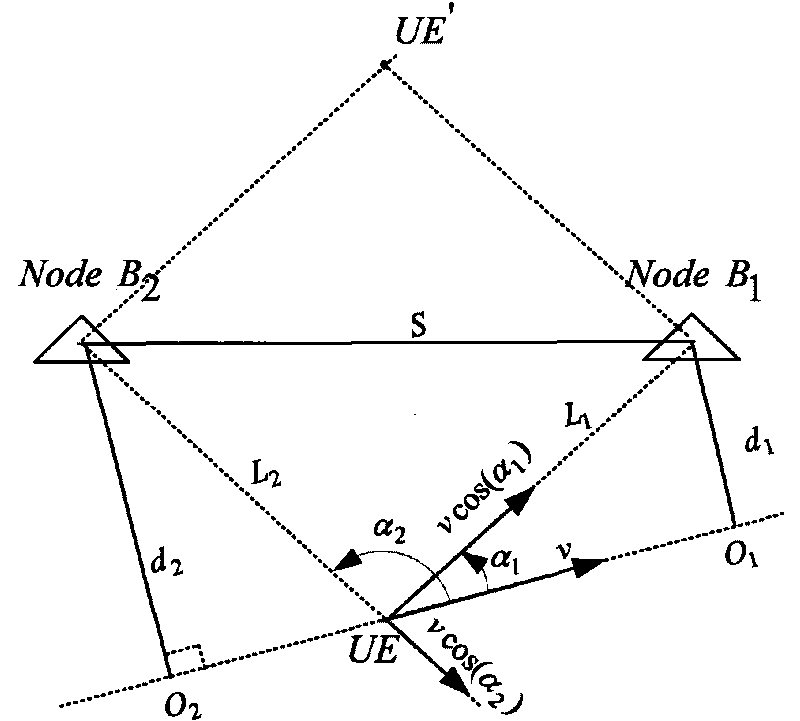

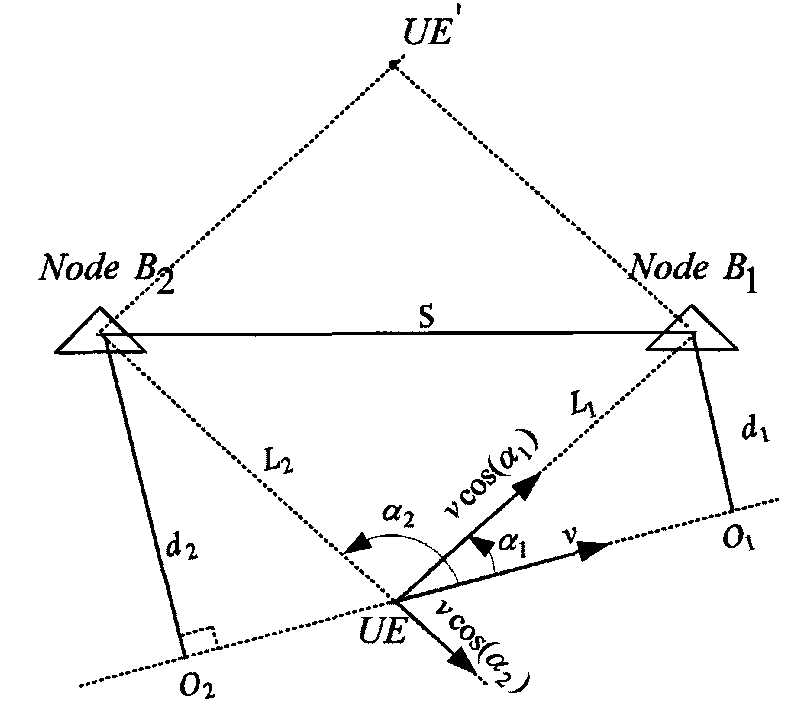

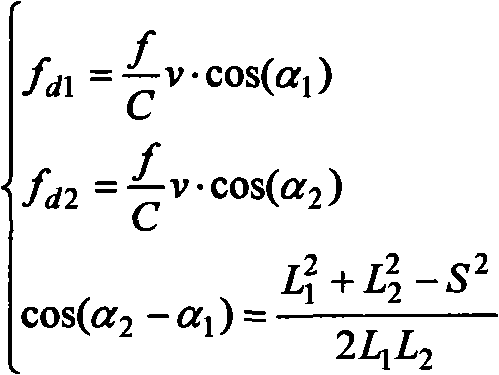

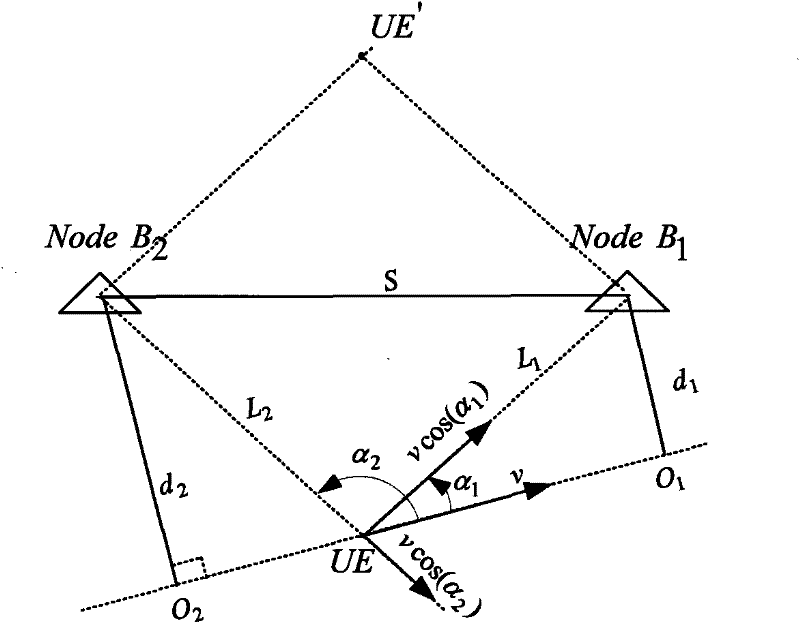

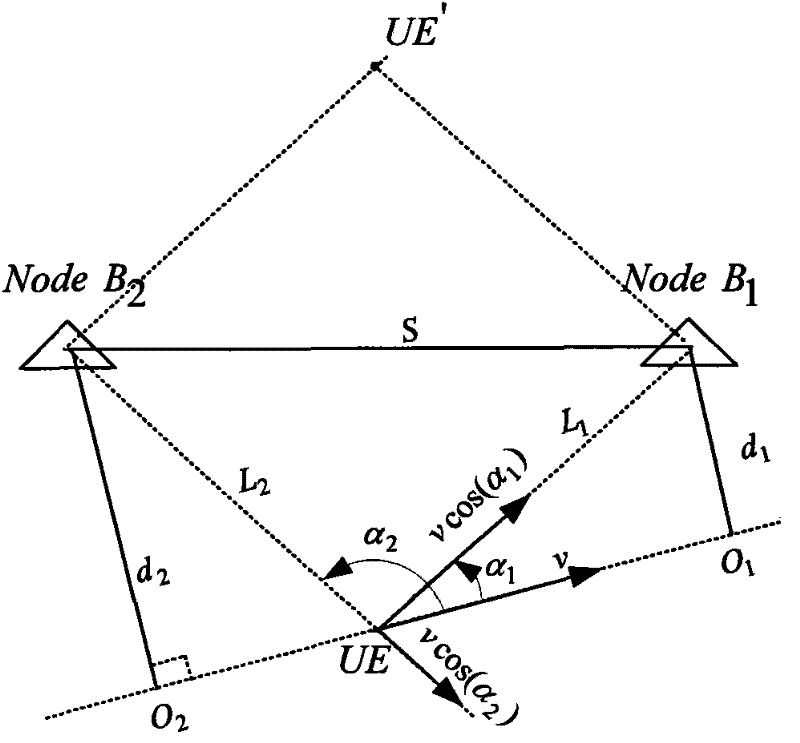

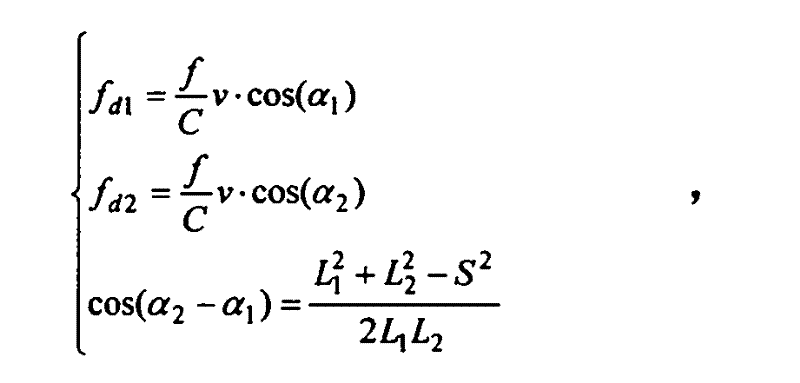

Multi-base station frequency shift synthesized positioning method for mobile terminal

InactiveCN101707805AThe positioning method is scientific and reasonableAccurate locationWireless communicationMotion parameterDynamic positioning

The invention discloses a multi-base station frequency shift synthesized positioning method for a mobile terminal. The positioning method uses the own Doppler effect of the mobile terminal to synthesize the Doppler effects produced by multiple base stations relative to the mobile terminal to acquire a kinematic parameter of the mobile terminal, and further acquire the position, moving speed and moving direction of the mobile terminal by combining cell information, thereby implementing continuous and dynamic positioning of the mobile terminal. The positioning method is scientific and reasonable.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

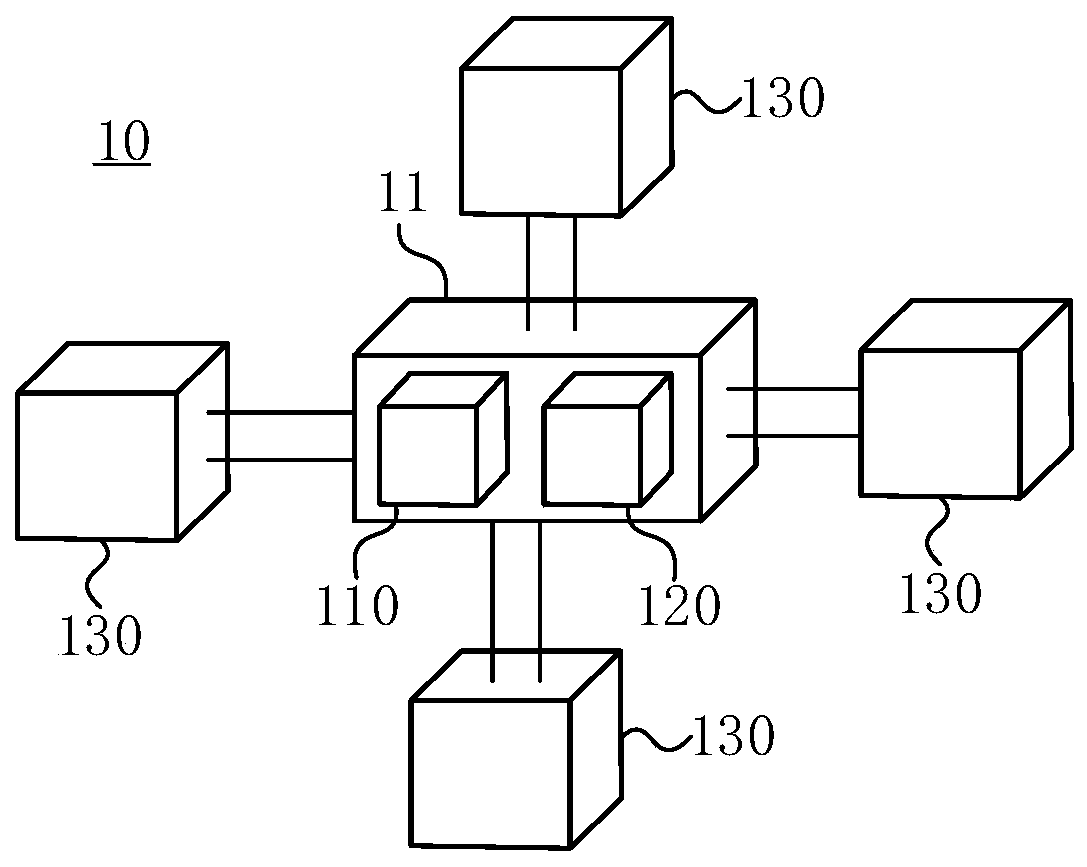

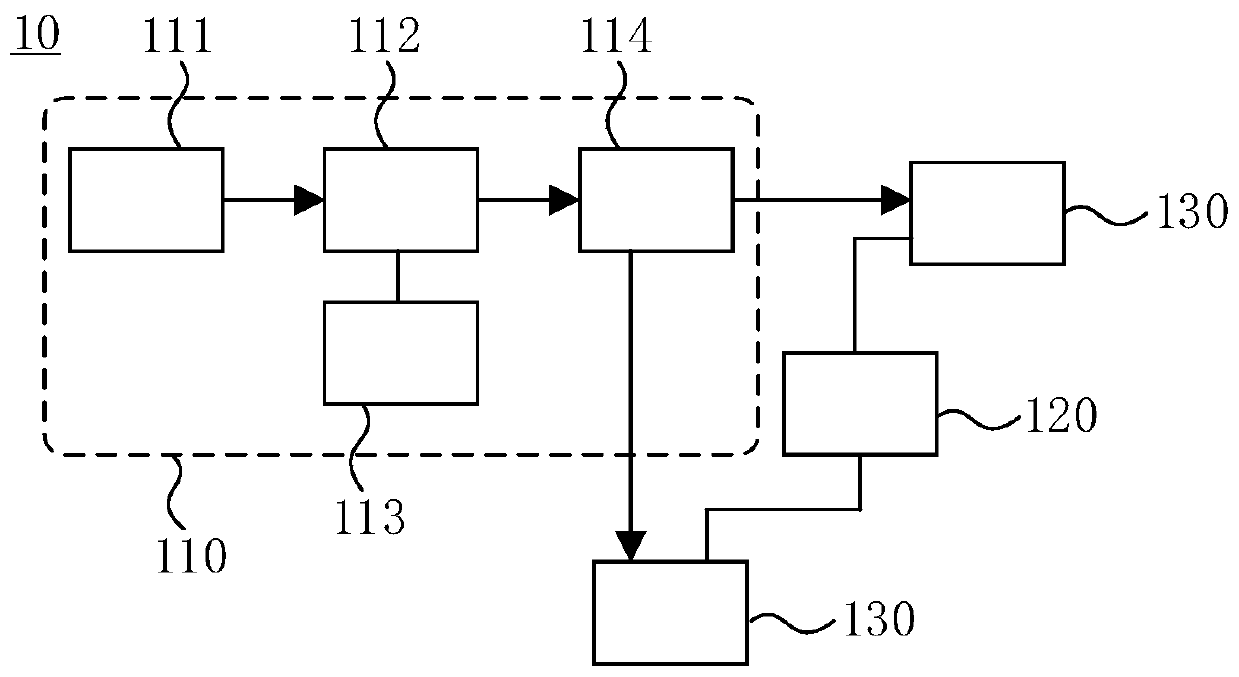

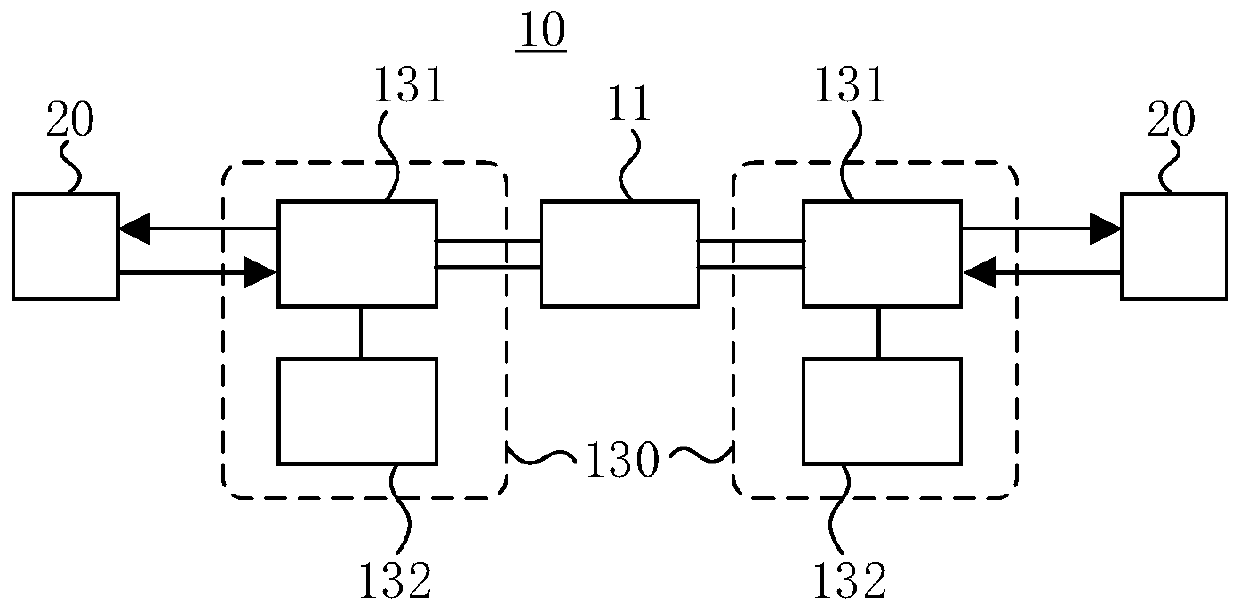

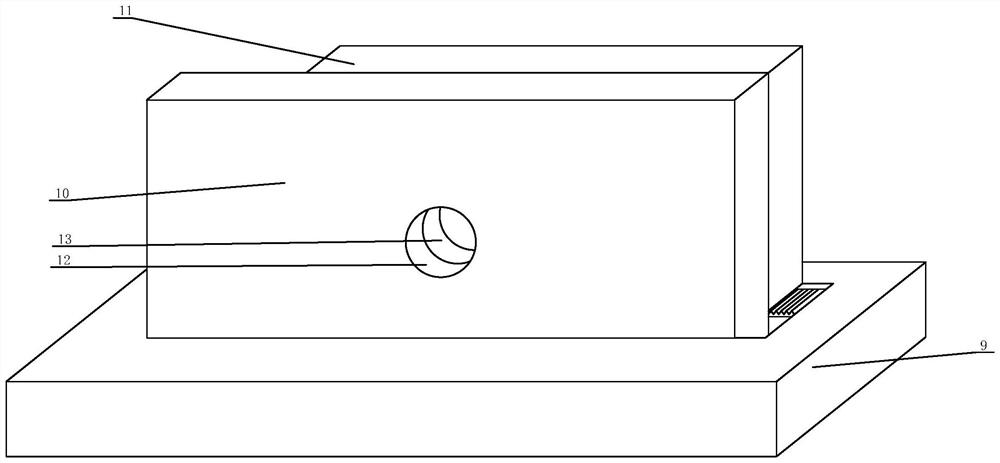

Distributed laser radar

PendingCN109991623AAccurate measurementThe direction of movement is accurateOptical rangefindersElectromagnetic wave reradiationMain processing unitInformation processing

The invention discloses distributed laser radar. The distributed laser radar includes: a light generating unit, an information processing unit and a plurality of detection scanning units; the light generating unit is used for generating frequency modulation continuous waves and splitting the frequency modulation continuous waves to each detecting scanning unit for the first time; each detection scanning unit is used for splitting the frequency modulation continuous waves after primary splitting again to form a detection light beam and a reference light beam, emitting the detection light beam,receiving an echo light beam reflected by a target object in a target area, and determining relevant information of the target area according to the reference light beam and the echo light beam; and the information processing unit is used for integrating the relevant information of each target area to obtain a point cloud picture of the peripheral area of the distributed laser radar. The technicalscheme provided by the embodiment of the invention can enhance the detection real-time performance of the target objects in the target areas and can improve the speed measurement precision.

Owner:LEISHEN INTELLIGENT SYST CO LTD

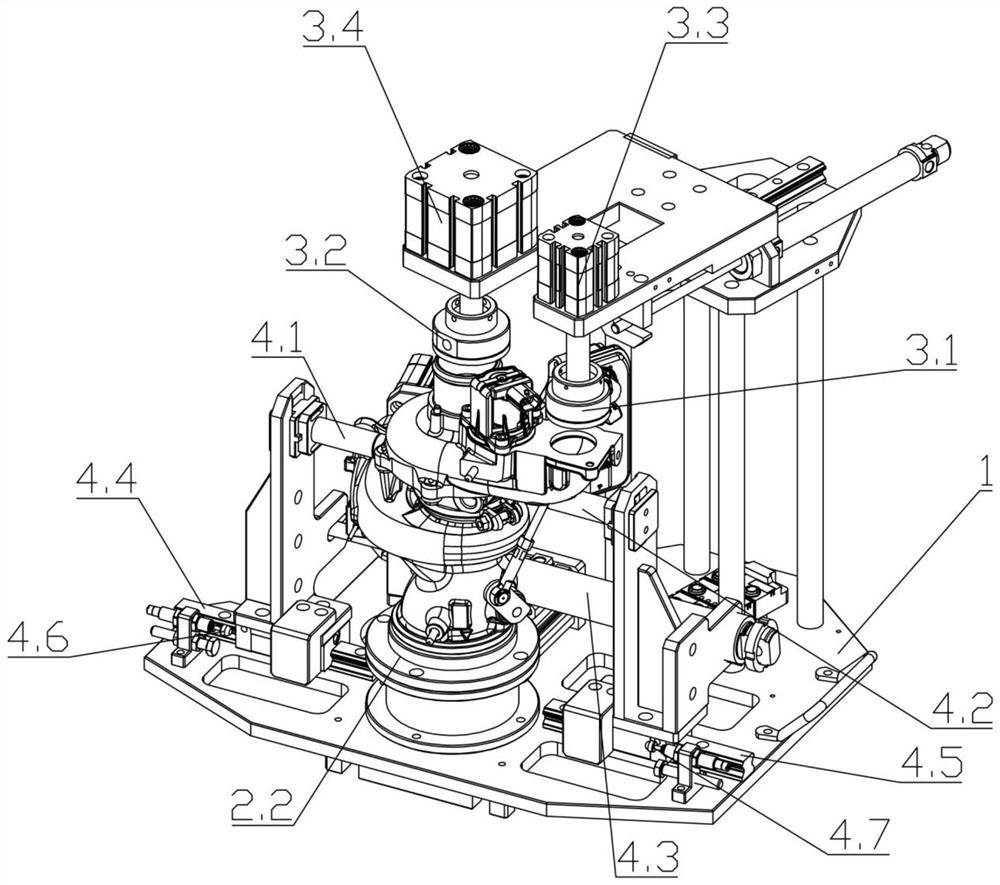

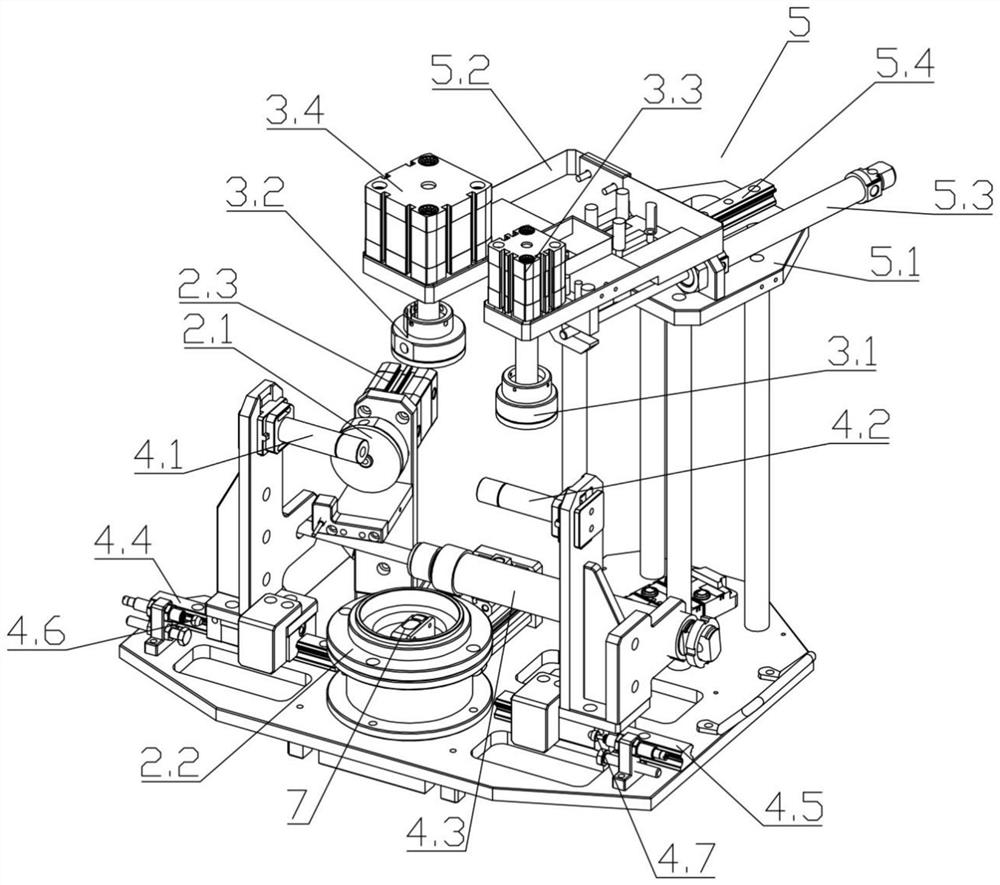

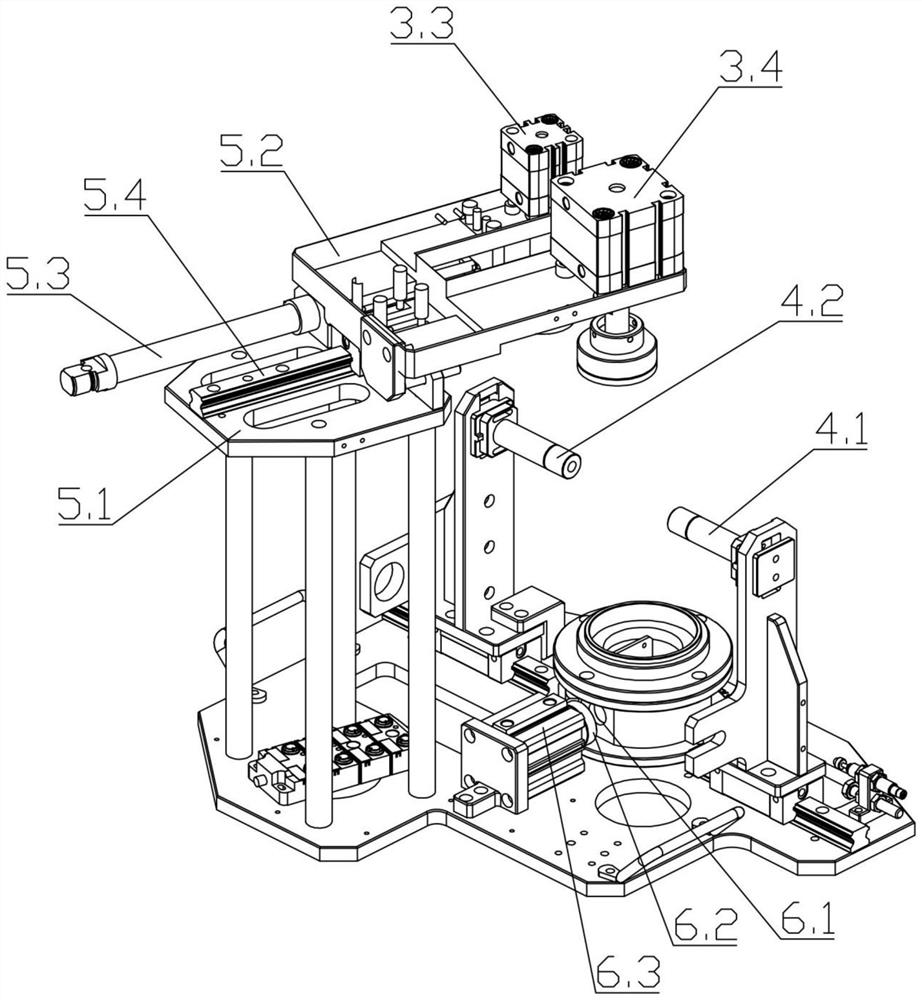

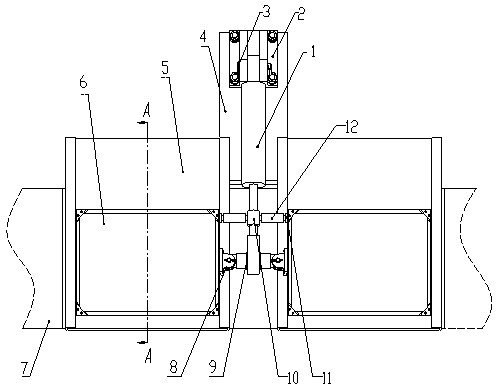

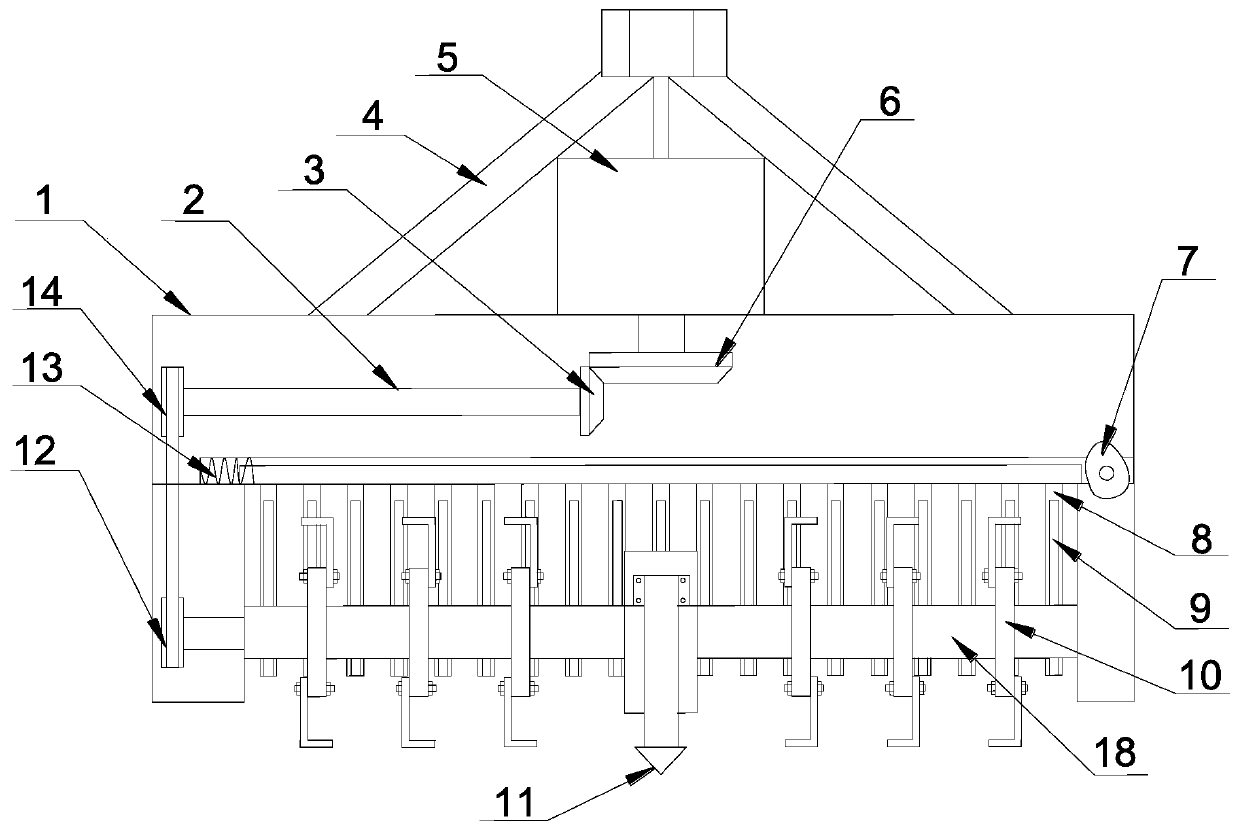

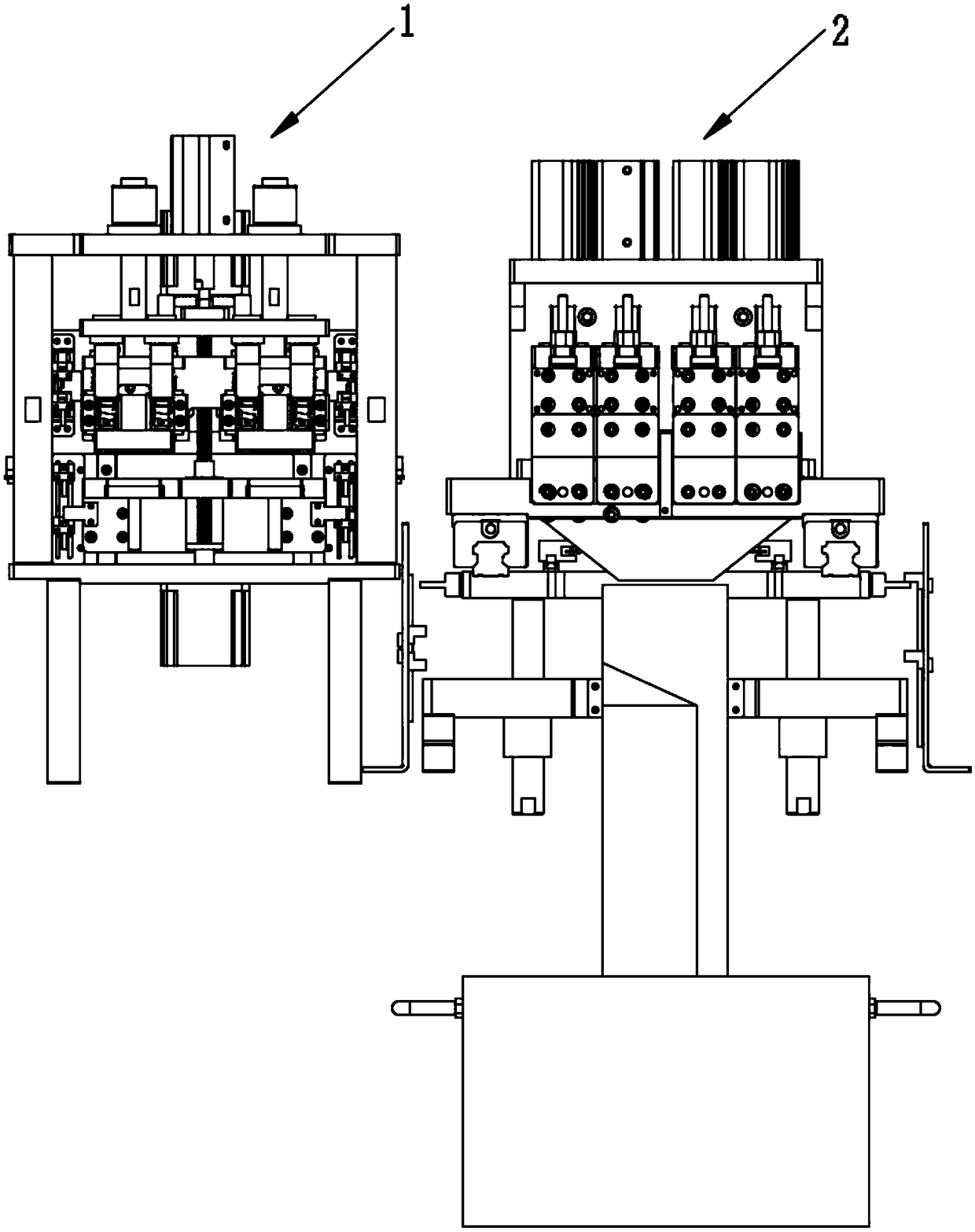

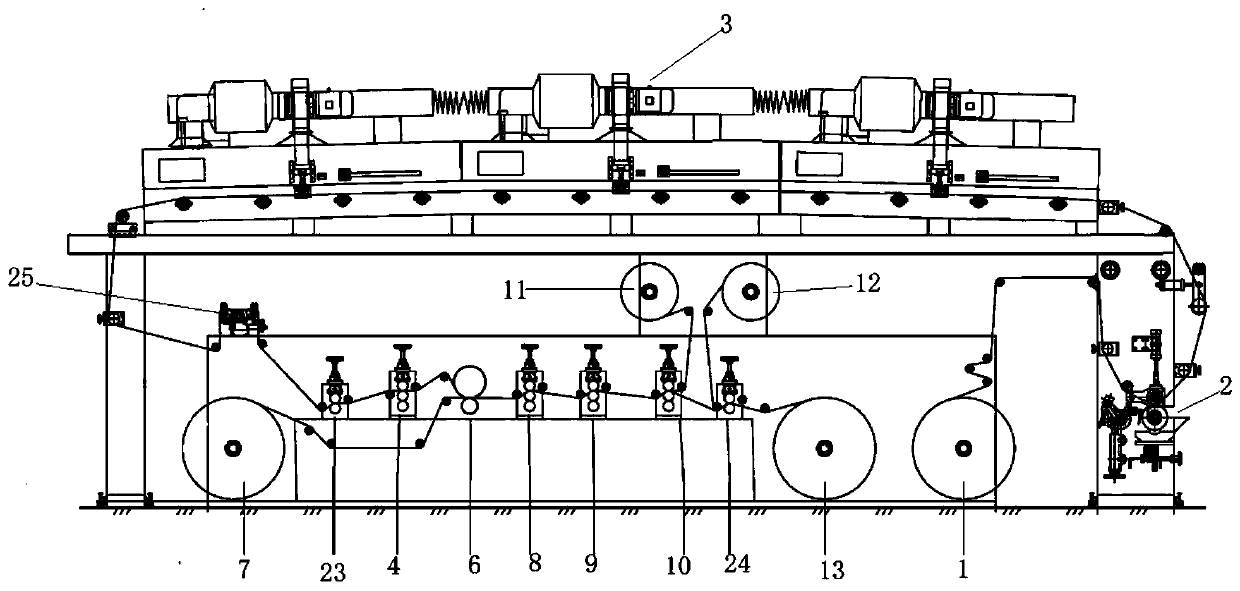

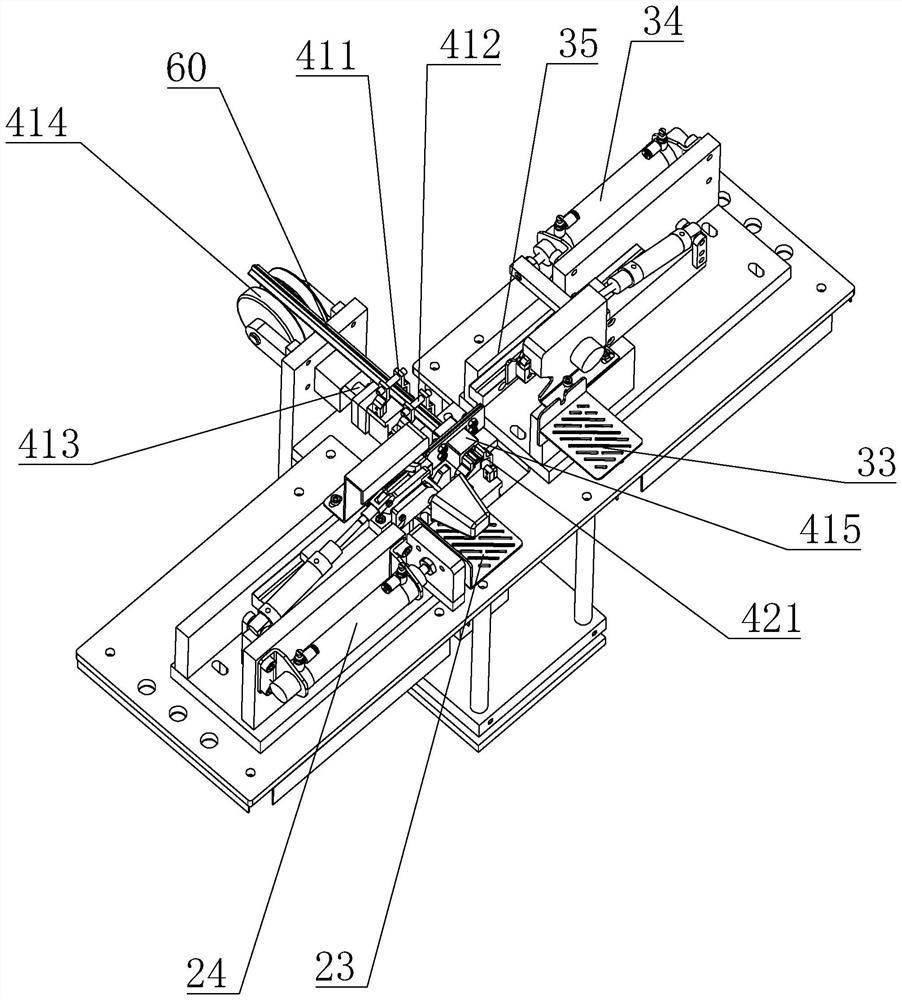

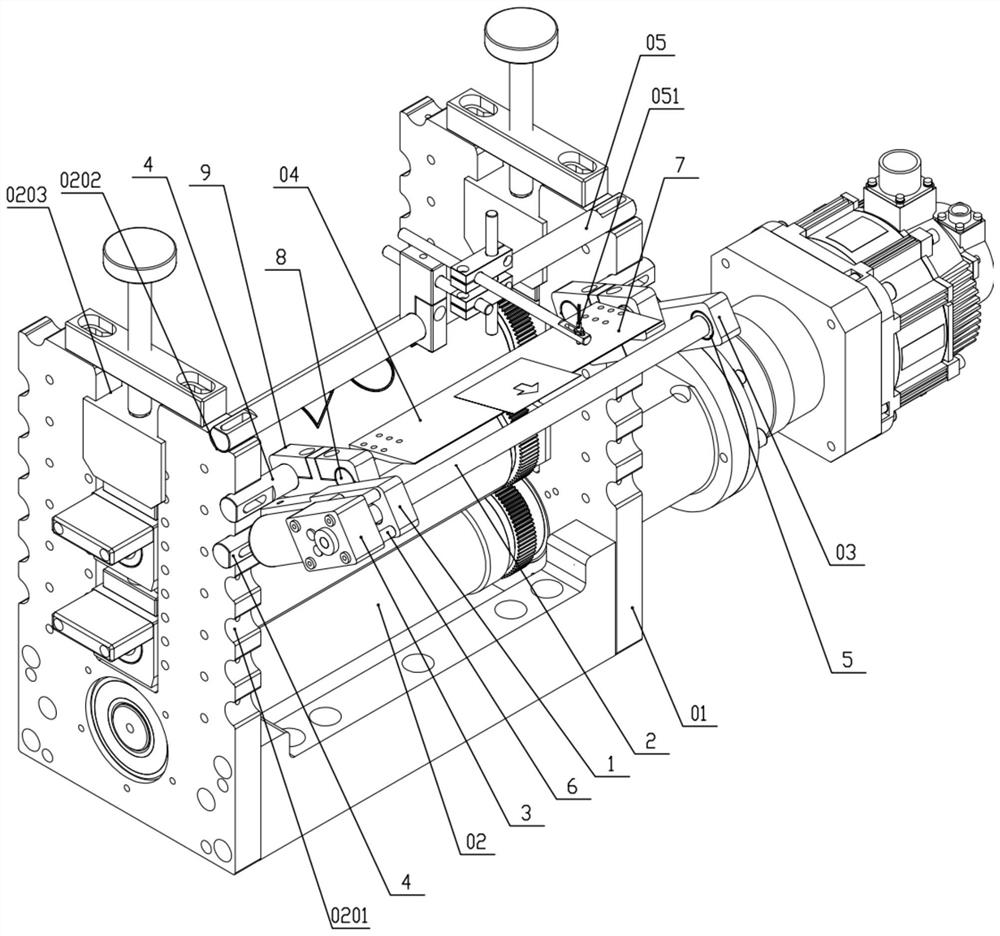

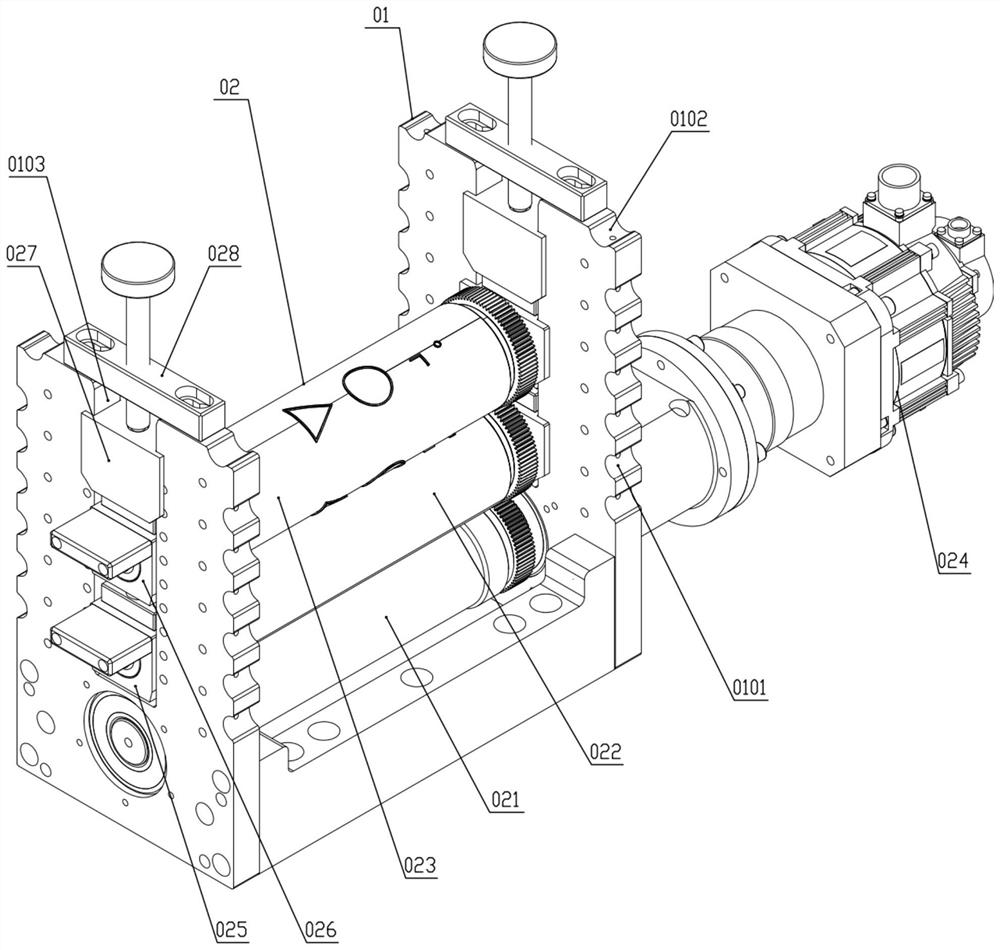

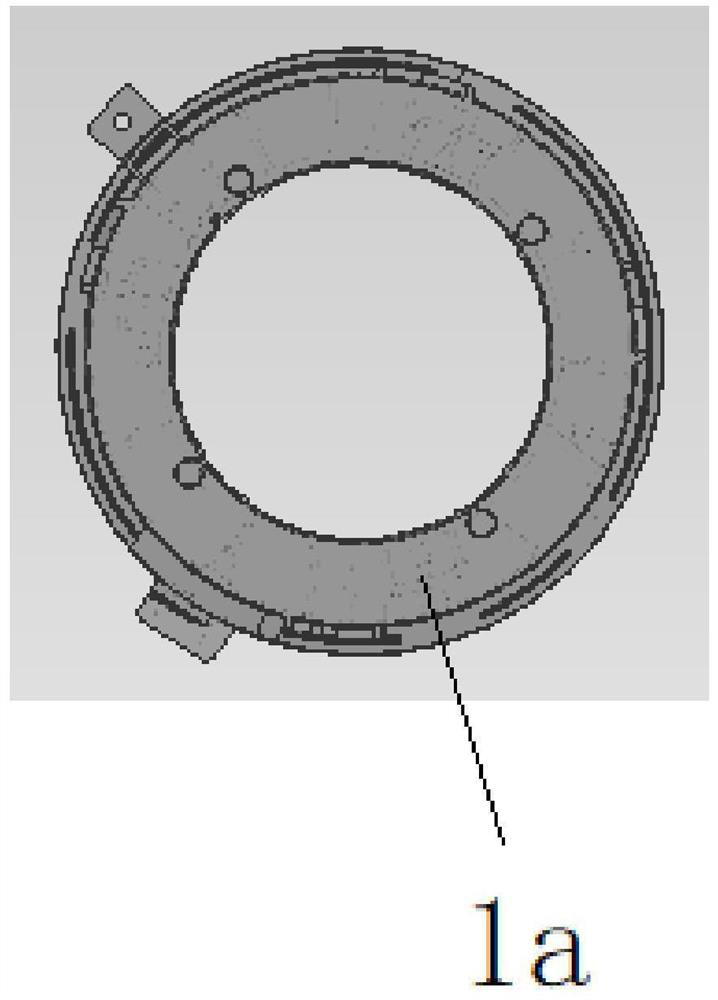

Full-automatic testing tool for turbocharger

PendingCN111678644AGuaranteed detection accuracyReduce mistakesMachine part testingLinear/angular speed measurementTurbochargerEngineering

The invention discloses a full-automatic testing tool for a turbocharger. The tool comprises a bottom plate, a volute sealing part and a pressure shell sealing part, the volute sealing part comprisesa first volute sealing mechanism and a second volute sealing mechanism; the volute second sealing mechanism is connected with the bottom plate, the pressure shell sealing part is arranged above the volute sealing part, the pressure shell sealing part comprises a pressure shell first sealing mechanism and a pressure shell second sealing mechanism, the pressure shell second sealing mechanism is connected with the first leakage instrument channel, and the volute second sealing mechanism is connected with the second leakage instrument channel. After the structure is adopted, the volute is positioned and sealed by the volute sealing part, and the gas leakage amount of the volute end can be obtained by detecting the second leakage instrument channel connected with the second volute sealing mechanism; the pressure shell sealing part positions and clamps the pressure shell and seals the pressure shell, the gas leakage amount of the pressure end can be measured by detecting the first leakage instrument channel connected with the second sealing mechanism of the pressure shell, and the turbocharger leakage test is completed.

Owner:BORGWARNER AUTOMOTIVE COMPONENTS (NINGBO) CO LTD

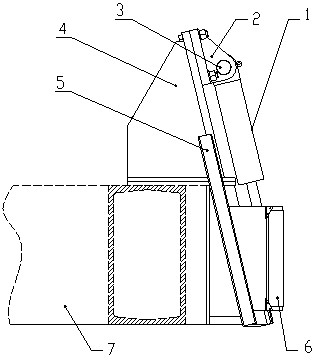

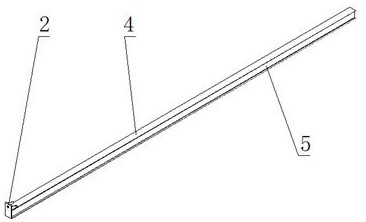

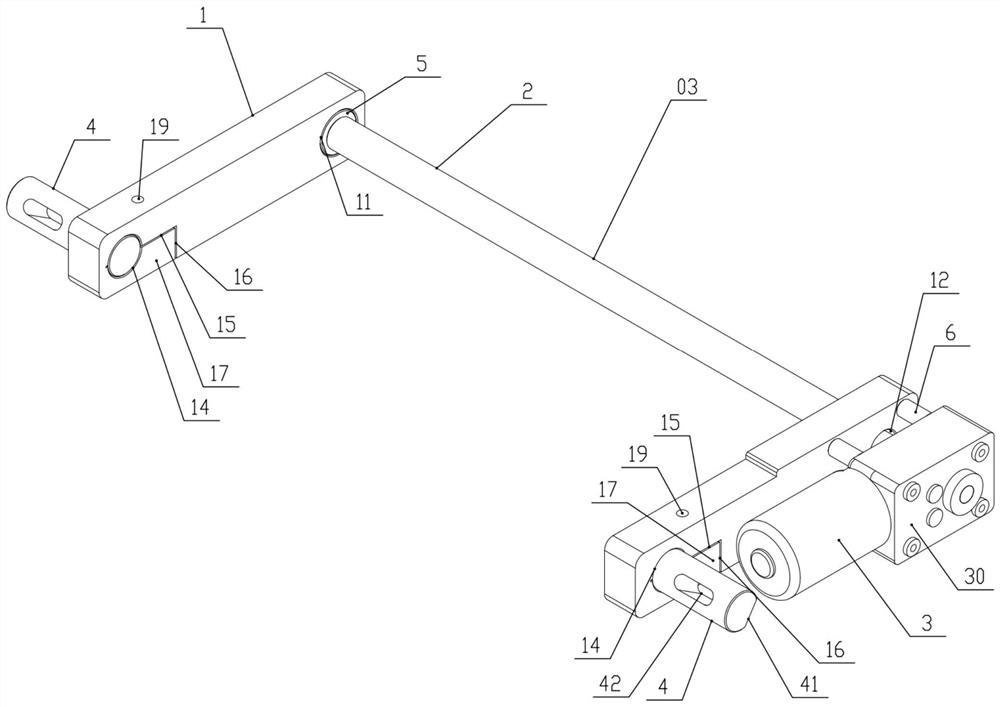

Telescopic boom of walking hanging scaffold

InactiveCN102562073AThe direction of movement is accurateAvoid damageShaft liningHydraulic cylinderEngineering

A telescopic boom of a walking hanging scaffold mainly consists of a slide wedge component and a power component providing power for the slide wedge component. The power component comprises a wedge corner connecting seat fixed on a ring beam, the wedge corner connecting seat is provided with a single-lug support, and a hydraulic cylinder is fixed on the single-lug support via a hinge pin; the slide wedge component comprises guide grooves which are symmetrically arranged on two sides of the wedge corner connecting seat, sliding wedge blocks are respectively arranged in the guide grooves, hinge supports are respectively disposed on two opposite surfaces of the two sliding wedge blocks, a double-lug slide sleeve is penetratingly sleeved on a piston rod of the hydraulic cylinder, a double-lug shaft penetrates in a single-lug hole of the piston rod, two single lugs of the double-lug shaft are respectively hinged with the hinge supports welded on the two sliding wedge blocks via hinge pins, an opposite screwing lead screw, a positioning lead screw and the double-lug slide sleeve form an opposite screwing component, the hydraulic cylinder drives the wedge blocks to move on a guide track so as to control a gap between each wedge block and a well wall, deformation of the well wall can be adapted conveniently, walking positioning is omitted, a large quantity of precisely prefabricated beam pits are omitted, complexity of wall building process is reduced, and damage to the integral well wall is avoided.

Owner:CHINA UNIV OF MINING & TECH

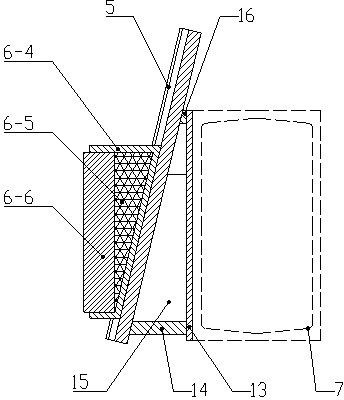

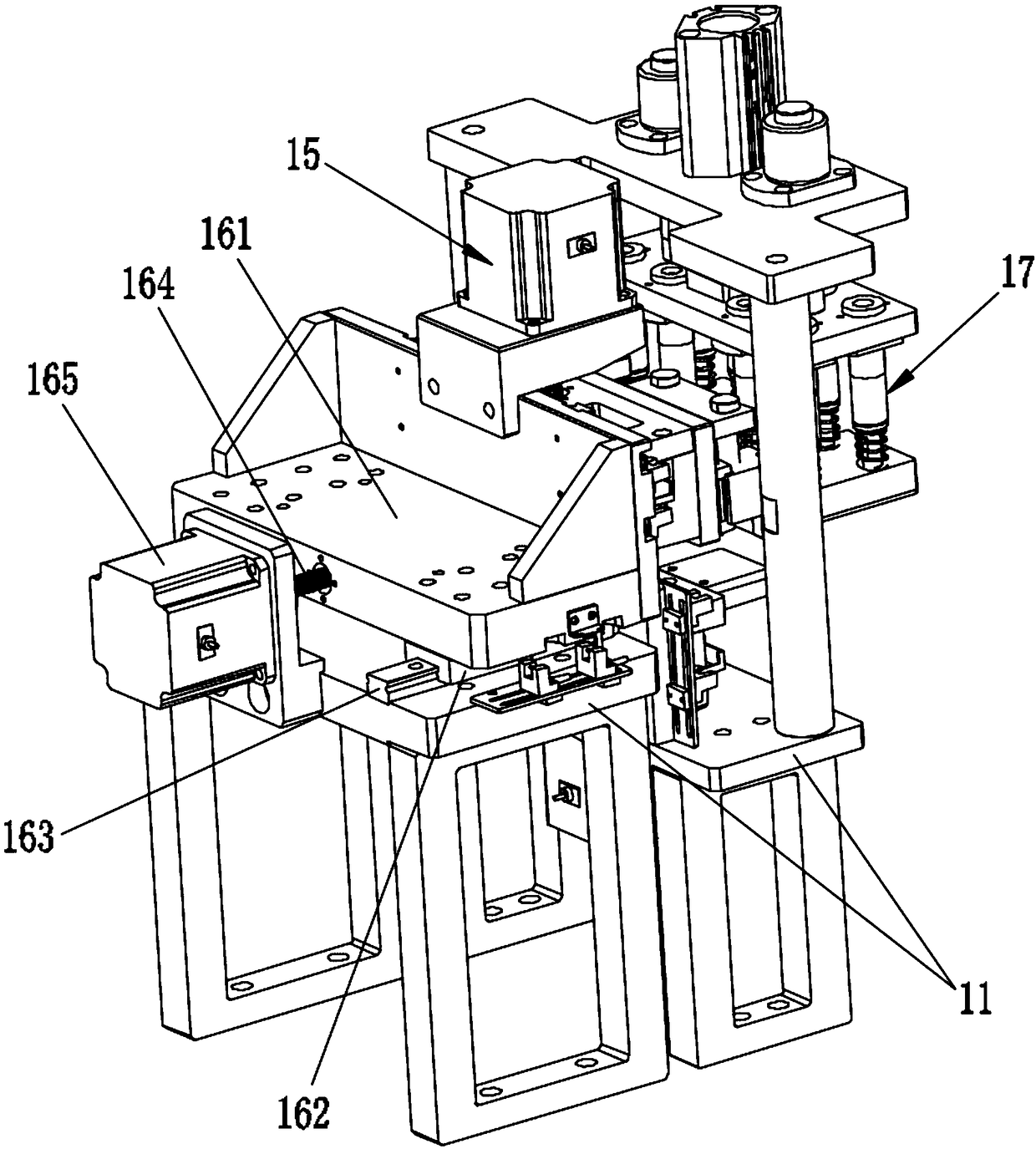

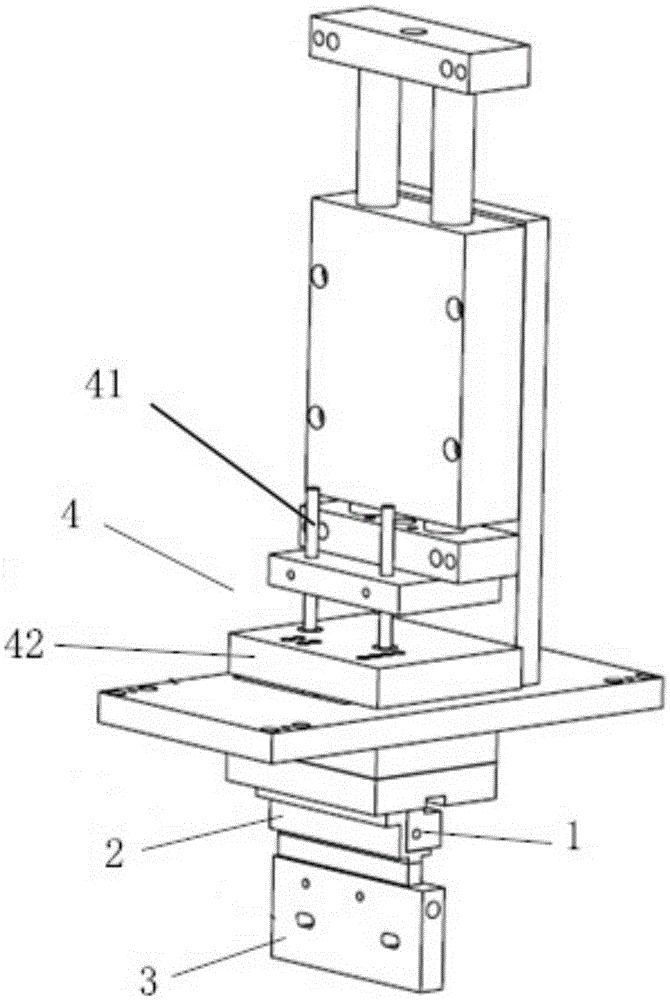

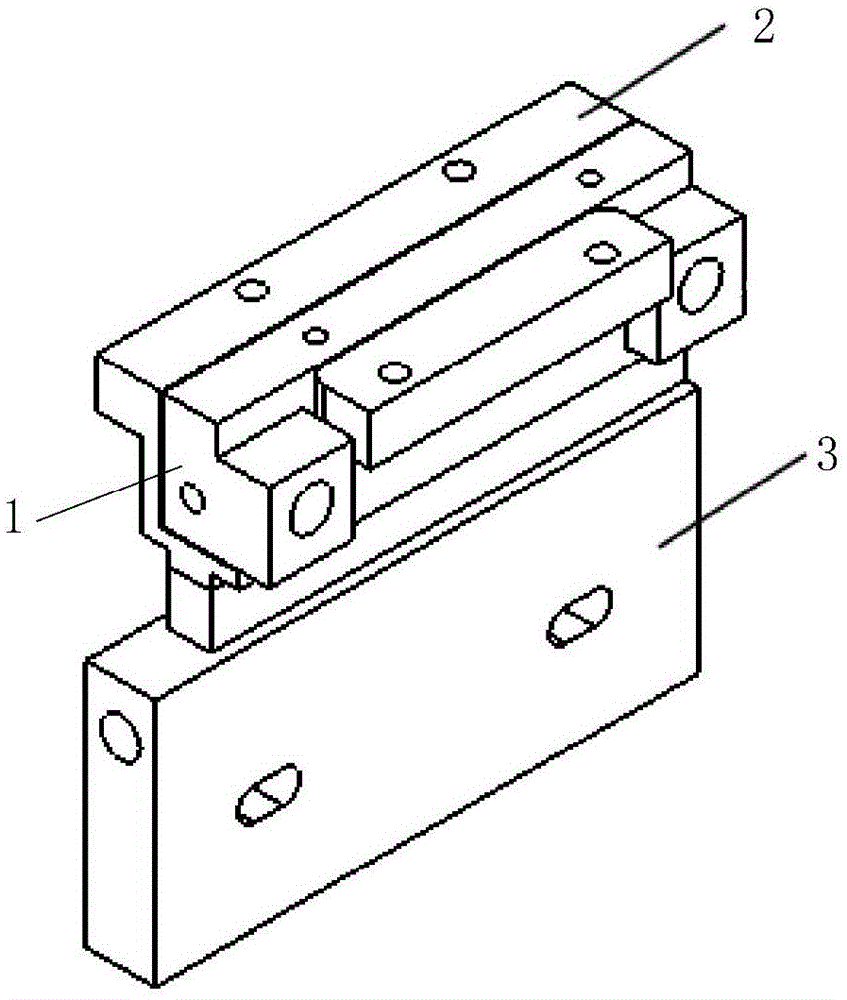

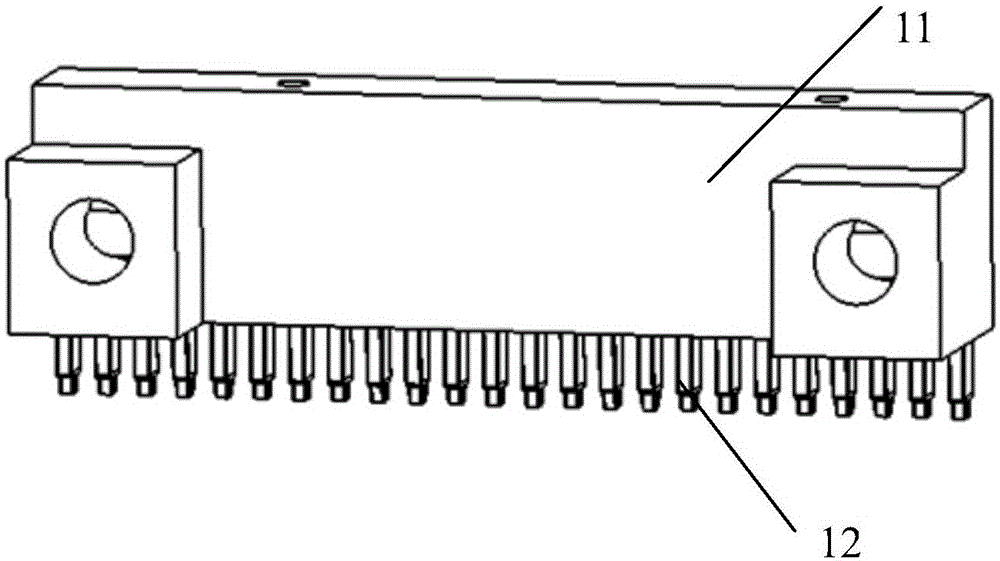

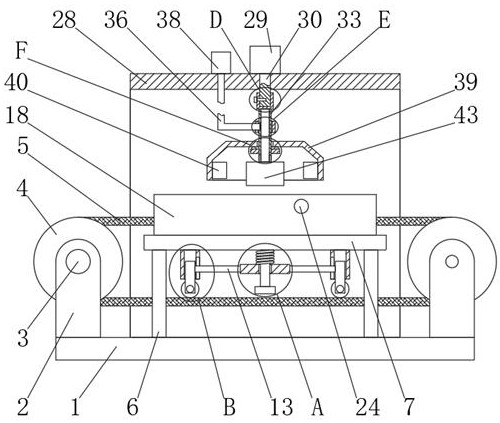

Clamping and positioning device for blanking machine

InactiveCN104416611AAvoid vibrationThe direction of movement is accurateMetal-working feeding devicesMetal working apparatusInstabilityIndustrial engineering

The invention provides a clamping and positioning device for a blanking machine. The clamping and positioning device comprises a clamping unit, a guide rail and a support frame, wherein the guide rail and the clamping unit are respectively arranged on the support frame, the clamping unit comprises a movable baffle plate and a fixed baffle plate, the movable baffle plate is glidingly arranged on the guide rail, the fixed baffle plate is arranged on the support frame, the clamping and positioning device also comprises a hydraulic mechanism and a positioning mechanism, the hydraulic mechanism is connected with the bottom end of the movable baffle plate, and the positioning mechanism is in parallel arrangement to the clamping unit. Due to the adoption of the hydraulic mechanism, the problems of clamping instability of conventional machinery and great noise generated by the clamping of a pneumatic clamping mechanism are solved, the clamping reliability is ensured, meanwhile, good operation environment is also maintained, and the work efficiency is improved. Through the arrangement of the positioning mechanism, the maintenance of a correct moving direction before a workpiece enters a clamping mechanism is ensured, the workpiece can also be fixed during the cutting, and the workpiece is prevented from generating vibration of great amplitude.

Owner:熊凌聪

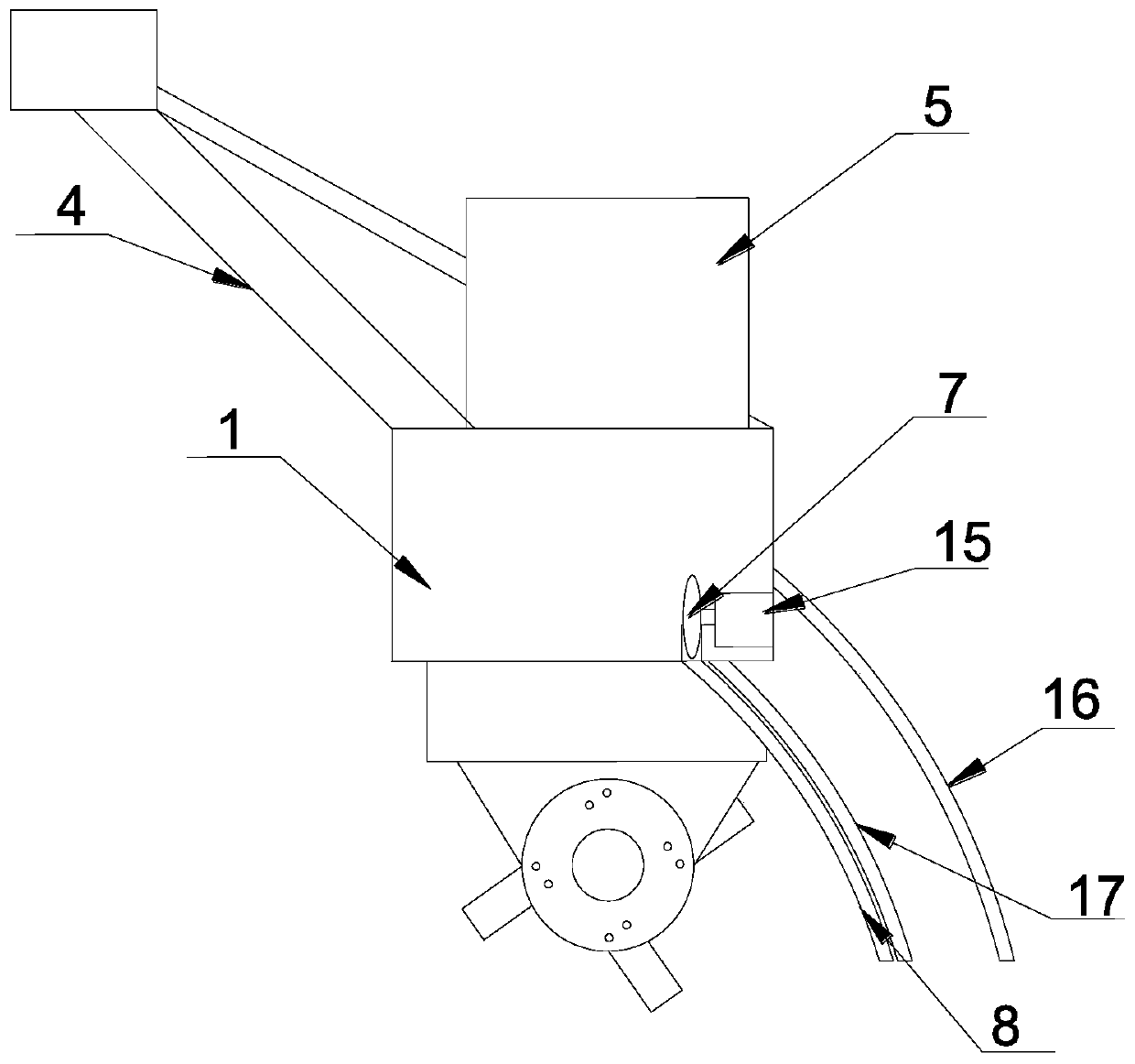

Rotary tillage stubble cleaner

The invention relates to the technical field of agricultural devices, and discloses a rotary tillage stubble cleaner which comprises a shell. A knife roller assembly is rotationally arranged in the shell. A driving mechanism is arranged on the shell and in transmission connection with the knife roller assembly. A traction mechanism is arranged on the shell. A grass blocking fence and a cover shellare arranged on the shell. A stubble removal fence is slidingly arranged on the shell and is located between the knife roller assembly and the grass blocking fence and close to the grass blocking fence. An adjusting mechanism is arranged on the shell and can be used for driving the stubble removal fence to reciprocate. Strip-shaped holes are formed in a fence plate of the stubble removal fence. The aims of preventing root stubbles from getting stuck in the grass blocking fence in the stubble removal process and improving the soil layer covering effect can be realized.

Owner:WUWEI PENGKAI MACHINERY

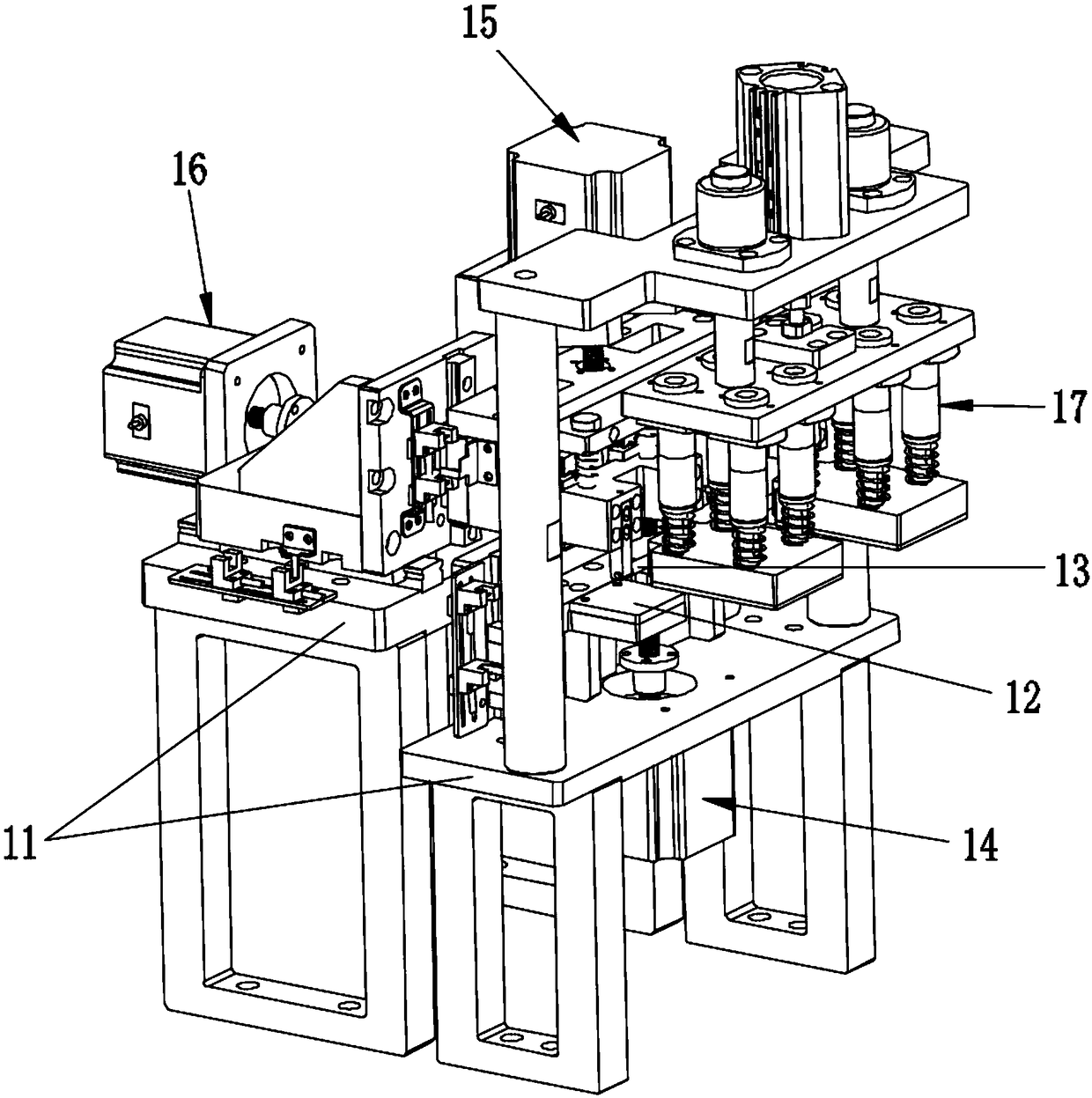

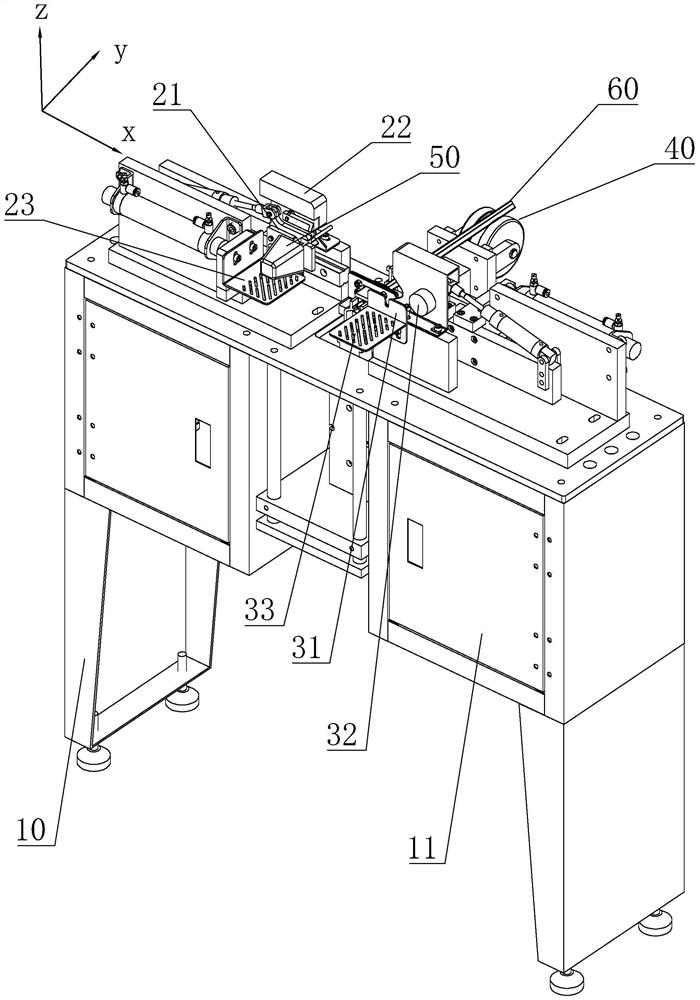

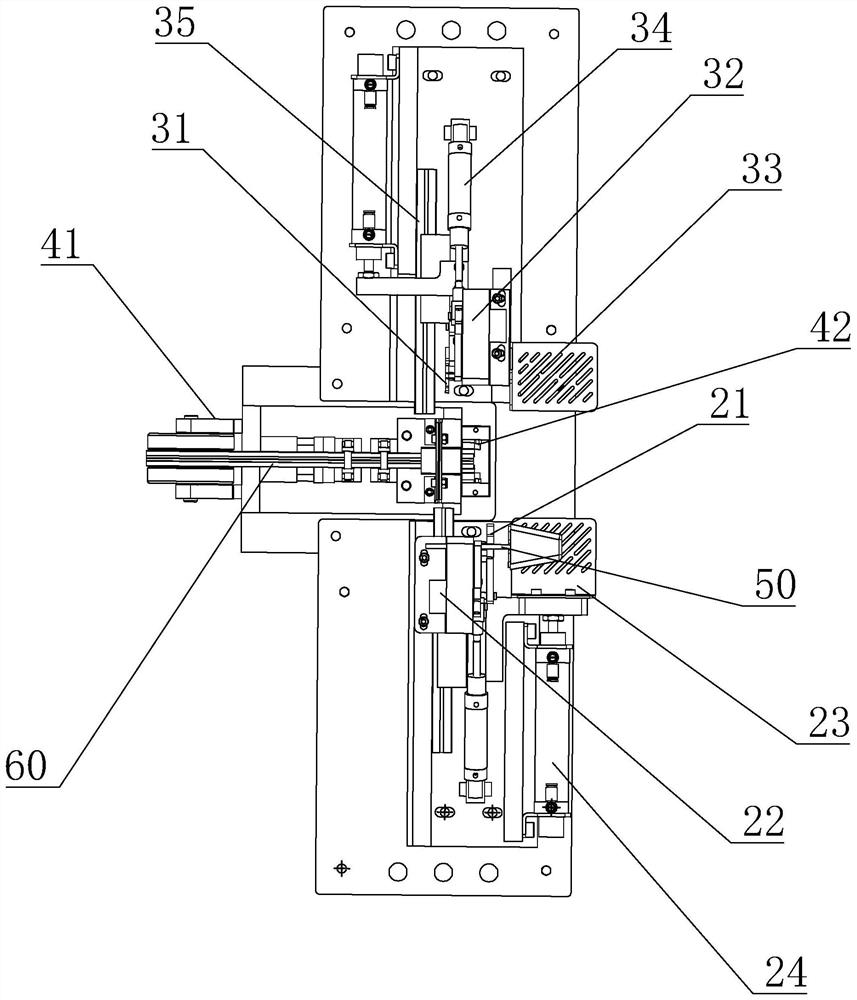

A machining apparatus for an electrode ear of an electric cell

PendingCN109103417APrevent tamperingSimple structureElectrode manufacturing processesFinal product manufactureEar shapingEngineering

The invention relates to the field of lithium battery equipment, in particular to a machining apparatus for an electrode ear of an electric cell, which comprises an electrode ear shaping mechanism andan electrode ear cutting mechanism. The electrode lug shaping mechanism comprises a work table, a bearing table, a pressing roller, a first driving assembly, a second driving assembly, a third driving assembly and a cell pressing device. The first driving assembly, the third driving assembly and the cell pressing device are all arranged on the work table. The second driving assembly comprises a first driving member, a first top pressing plate, a first connecting block and a plurality of first elastic members. When the pole ear is shaped by the present application, a rolling mode is adopted instead of a scraping mode, thereby avoiding scratches on the pole ear. As the kpressing roller is rotating all the time when the pole ear surface has aluminum chips, the pressing roller will not drivethe aluminum chips to move together, thereby avoiding scratch on the pole ear surface, preventing the pole ear from being damaged, and increasing the eligibility rate of the pole ear.

Owner:东莞仕能机械设备有限公司

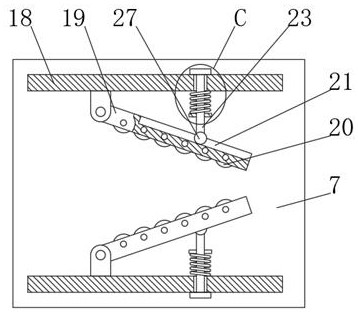

Rod clamping mechanism

InactiveCN103801962AThe direction of movement is accurateAvoid vibrationWork clamping meansLarge fixed membersIndustrial engineeringOperating environment

The invention discloses a rod clamping mechanism which comprises a clamping unit, a sliding way and a machine frame. The sliding way and the clamping unit are both arranged on the machine frame, the clamping unit comprises a movable plate and a fixed plate, the movable plate is arranged on the sliding way in a sliding mode, and the fixed plate is arranged on the machine frame. The rod clamping mechanism further comprises a driving mechanism and a positioning mechanism, the driving mechanism is connected with the bottom end of the movable plate, and the positioning mechanism and the clamping unit are arranged in parallel. The problems of the instability of traditional mechanical clamping and large noise caused by clamping of a pneumatic clamping mechanism are solved through the adoption of the driving mechanism, the good operating environment is maintained while the clamping reliability is guaranteed, and the working efficiency is improved; due to the arrangement of the positioning mechanism, it is guaranteed that a rod can be kept in the correct movement direction before entering the clamping mechanism, and the rod can further be fixed when being cut, so that large-amplitude vibration of the rod is avoided.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

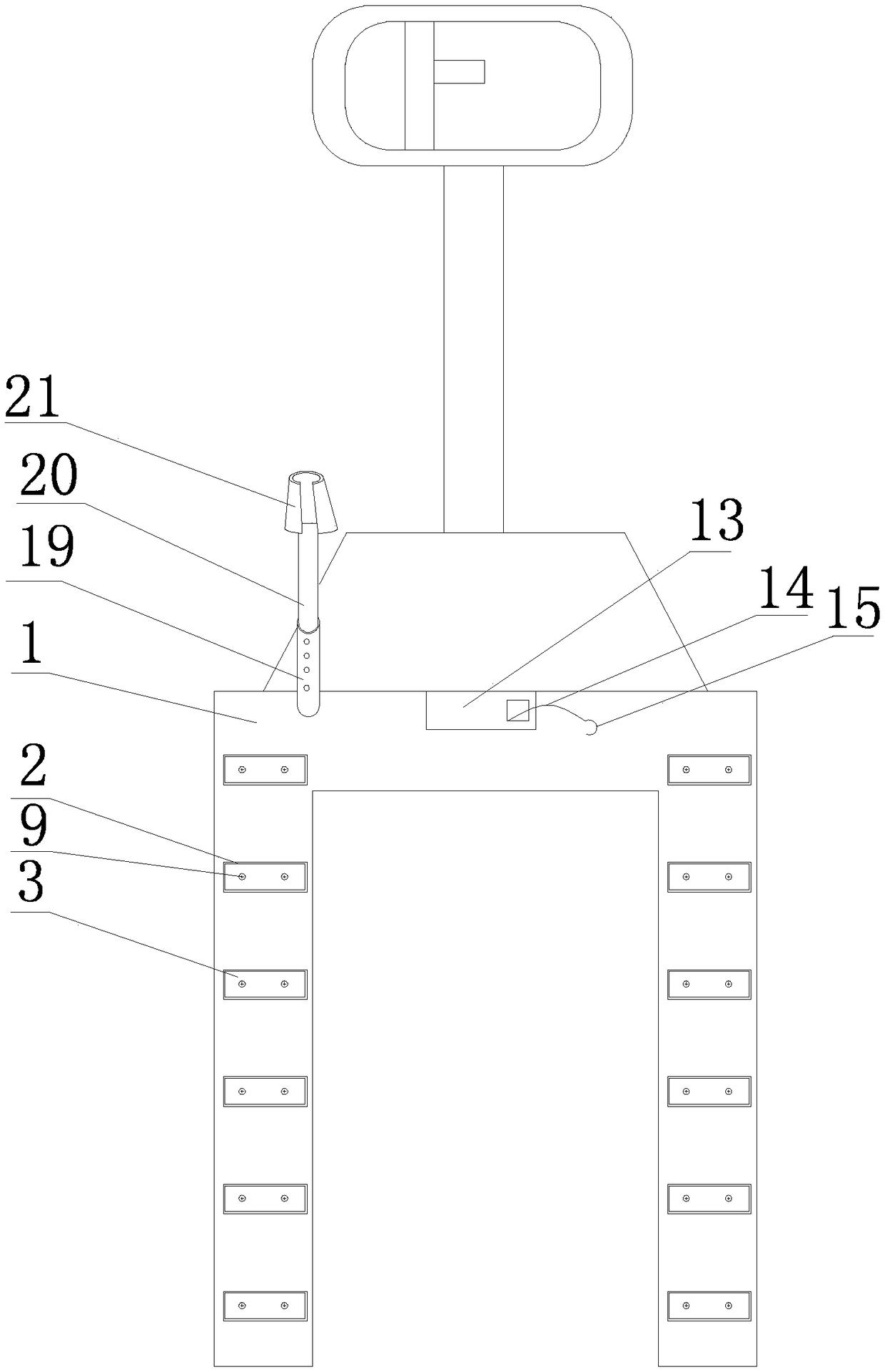

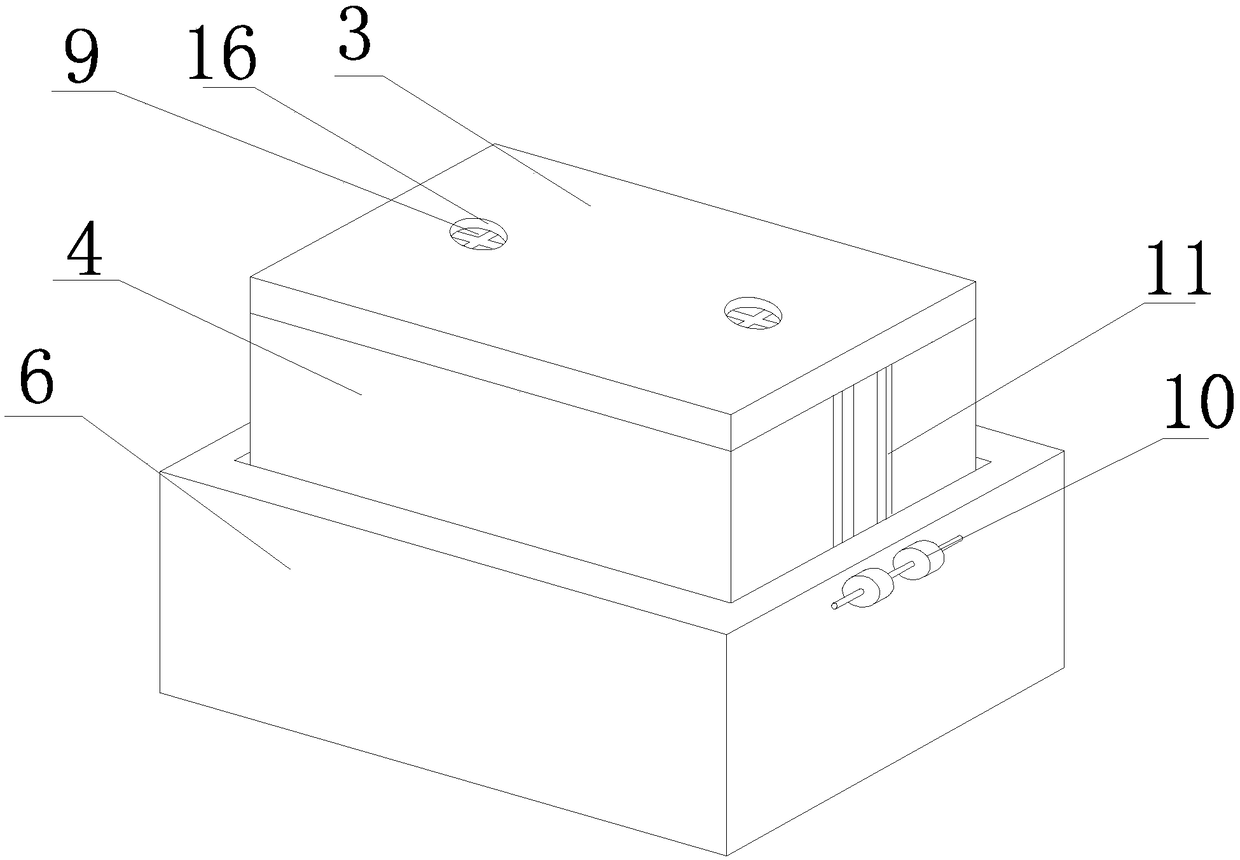

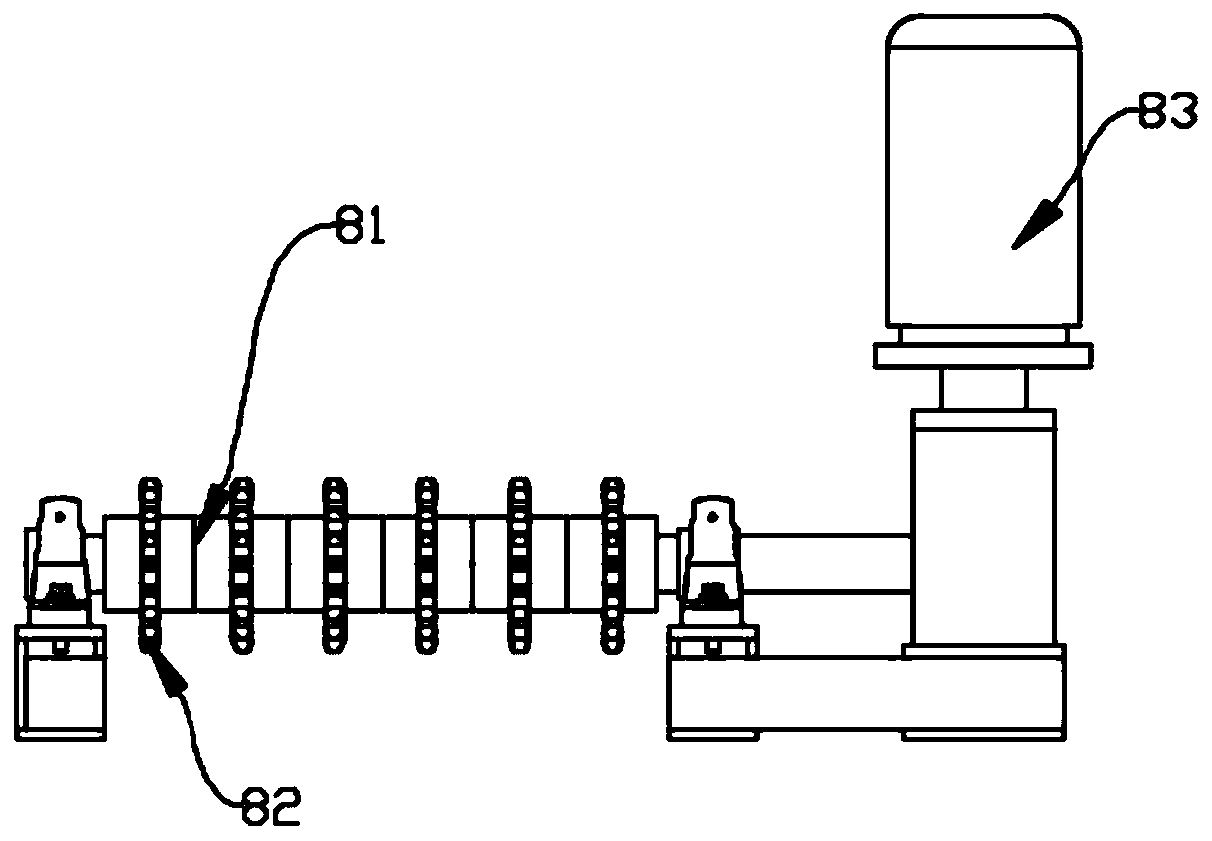

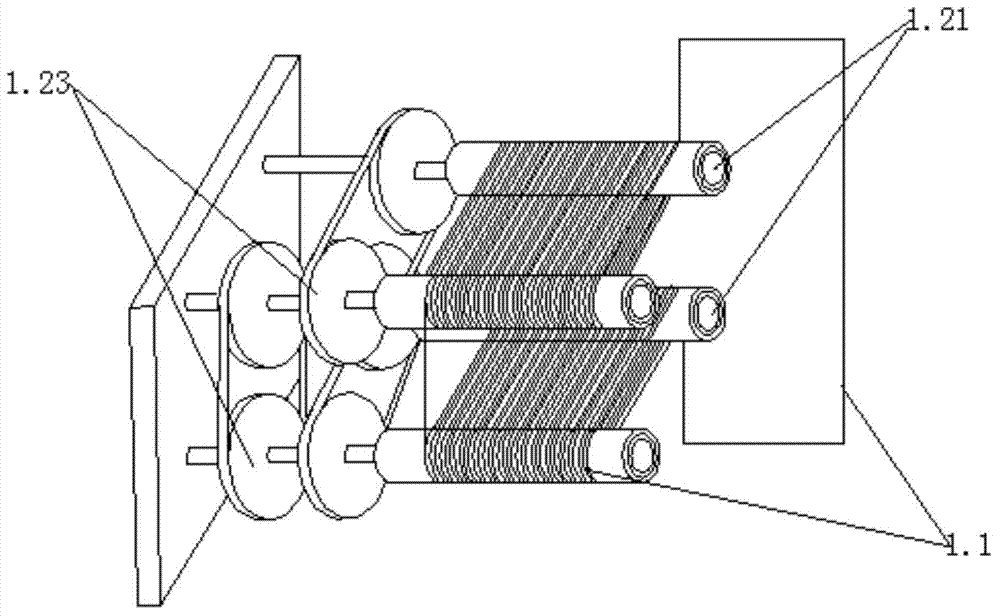

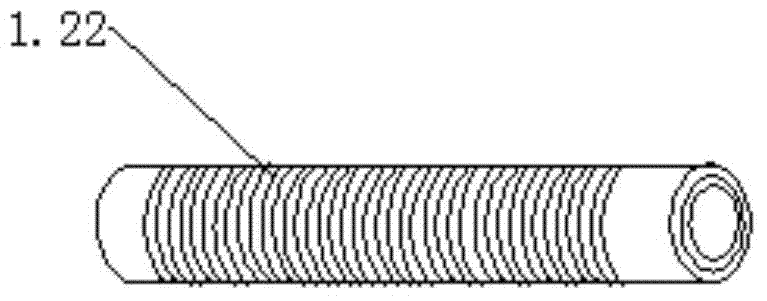

Doubling winder

ActiveCN114737283AImprove winding qualityGuaranteed tensionTextile disintegration and recoveryTextiles and paperYarnElectric machinery

According to the doubling winder, the tension adjusting mechanism is arranged on the doubling winder, the winding tension can be adjusted in real time according to the winding position, and the machining efficiency is high. The device comprises a bottom plate, a rotating seat, a tension adjusting mechanism, a speed reducing mechanism, a yarn guiding mechanism and a winding mechanism are sequentially arranged on the bottom plate, and the winding mechanism comprises a mounting seat, a roller and a first motor; the yarn guide mechanism comprises a mounting plate, a sliding groove is formed in the upper surface of the mounting plate, a lead screw is horizontally arranged in the sliding groove, a sliding block is fixed to the lead screw, a yarn guide ring is fixed to the top of the sliding block, and a second motor is fixed to the side face of the mounting plate; the speed reducing mechanism comprises a base, a fixed plate, a movable plate and a driving assembly; the number of the tension adjusting mechanisms is four, and every two tension adjusting mechanisms are symmetrically distributed.

Owner:陈定洲

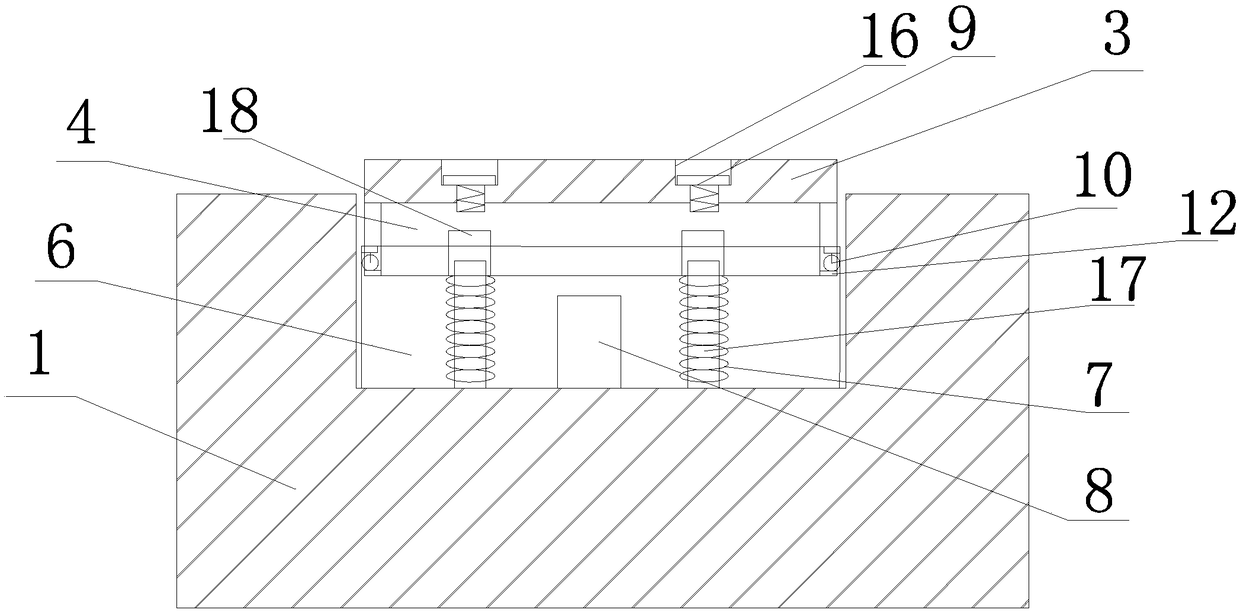

Hydraulic fork truck

InactiveCN108658008AEasy to replaceReduce impact damageLighting applicationsMechanical apparatusEngineeringMechanical engineering

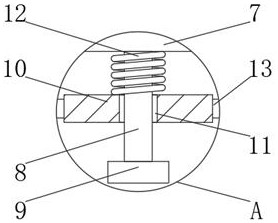

The invention provides a hydraulic fork truck. Antiskid components on the hydraulic fork truck are convenient to replace, impacting damage and crushing damage on the antiskid components when objects are inserted and taken can be reduced simultaneously, and the service lives of the antiskid components are prolonged. The hydraulic fork truck comprises a hydraulic fork truck part; a plurality of grooves uniformly distributed in the length direction of a truck plate are formed in the truck plate of the hydraulic fork truck part; a rubber block and a buffering mechanism are arranged in each groove;each buffering mechanism is used for exerting the buffering effect after each rubber block is under the pressure; each buffering mechanism comprises an upper housing body, a lower housing body, springs, guide columns and guide holes; each upper housing body and each lower housing body movably sleeve with each other; the springs are arranged in each lower housing body and exert the buffering effect; the guide columns are arranged in each lower housing body; the guide holes fitting with the guide columns are formed in the bottom of each upper housing body; the springs sleeve the guide columns;the lower ends of the springs are bonded with the inner bottom surface of each lower housing body; the upper ends of the springs are bonded with the bottom of each upper housing body; each rubber block is detachably fixed to the upper surface of each upper housing body through bolts; a supporting column is arranged in each lower housing body; and an illuminating device is arranged on the truck plate of the hydraulic fork truck part further.

Owner:海宁市高级技工学校

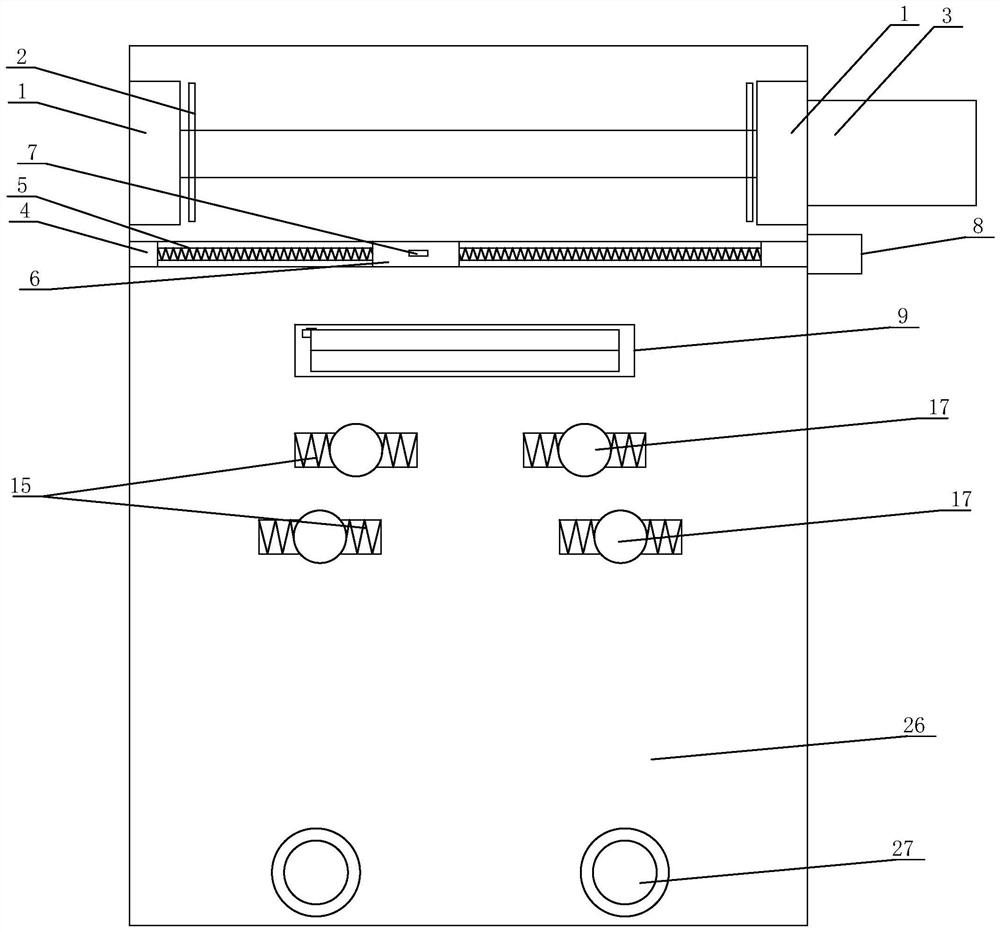

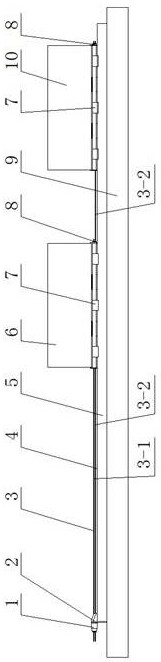

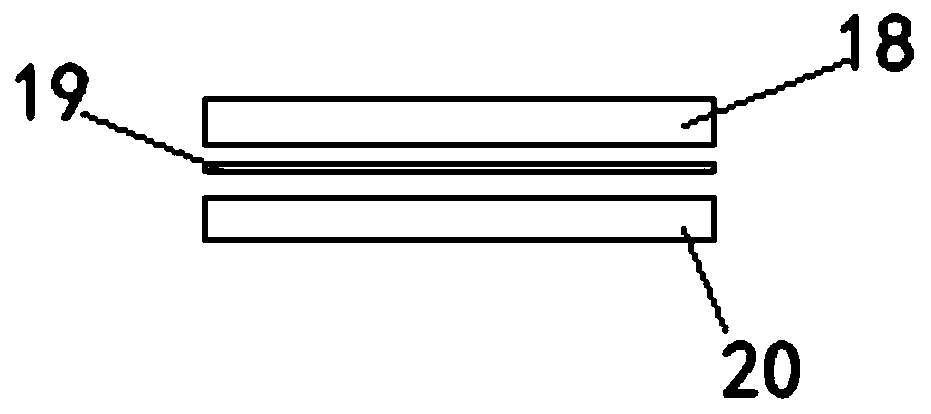

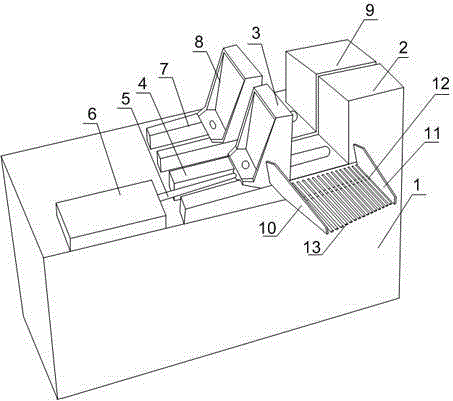

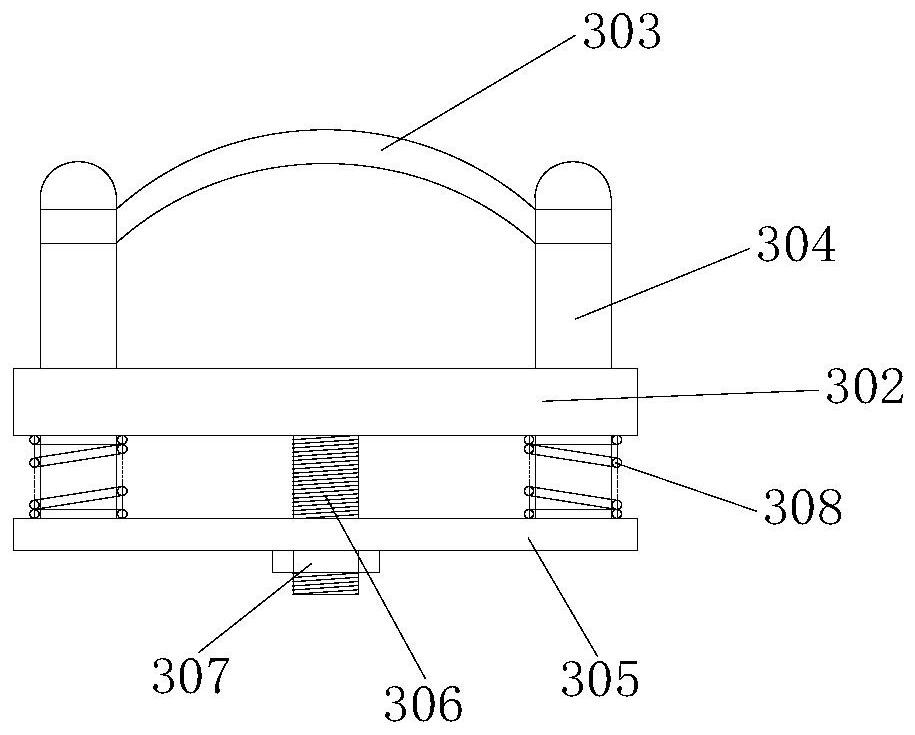

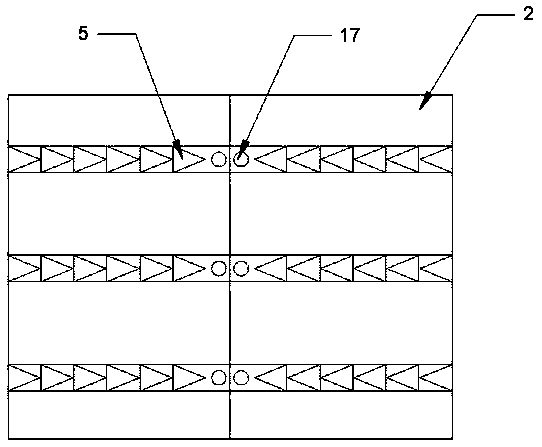

Carrier band forming device and method

ActiveCN105058756ALow manufacturing costImprove product qualityBeltsElectrical and Electronics engineeringEngineering

The invention provides a carrier band forming device. The carrier band forming device comprises a rack, a gas input unit, an upper forming die, a lower forming die and a clamping unit, wherein the upper forming die, the lower forming die and the clamping unit are connected with the rack. The clamping unit is opposite to the lower forming die in position. The distance between the clamping unit and the lower forming die can be adjusted. The upper forming die comprises an upper die base body and a plurality of forming cylinders. The lower forming die is provided with a plurality of lower die holes corresponding to the forming cylinders in position. The upper die base body is connected with the rack through an upper die driving unit. Gaps are reserved between all the forming cylinders and the hole walls of the lower die holes. The gas input unit is connected with the lower forming die so that compressed gas can be input. By the adoption of the carrier band forming device, product quality can be improved, carrier band deformation is avoided, narrow center wall deep cavity carrier bands can be manufactured, and the manufacturing cost of the carrier bands is reduced. The invention further provides a carrier band forming method capable of lowering machining difficulty of the carrier bands, improving machining efficiency, avoiding carrier band deformation and achieving manufacturing of the narrow center wall deep cavity carrier bands.

Owner:广东昭信平洲电子有限公司

Translation device for synchronously replacing new and old components and construction method thereof

PendingCN112796230AShort construction periodThe direction of movement is accurateBridge erection/assemblyBridge strengtheningEngineeringFriction force

The invention discloses a translation device for synchronously replacing new and old components and a construction method thereof. The translation device comprises a slide way and a sliding structure formed by connecting two sliding shoe assemblies, one sliding shoe assembly supports the old component, and the other sliding shoe assembly supports the new component; a counter-force seat is fixed at one end of the slide way and is connected with a traction end, so that the slide way, the counter-force seat and the traction end are connected into a whole; when a traction driving component pulls or pushes a traction component, the old component and the new component are moved together. During construction, the new component is prefabricated beside the old component, after the new component is prefabricated, the prefabricated new component and the old component are placed on the corresponding sliding shoe assemblies respectively, and the new component and the old component are horizontally moved in place through a traction device. The device has the advantages that the counter-force device and the sliding device are connected into a whole, so that sliding friction force (or rolling friction force) between the counter-force device and the sliding device belongs to internal force between the devices, the old component is moved out and the new component is translated in place at the same time through one-time traction, the overall manufacturing cost is low, the construction occupied area is small, and the bridge construction period is short.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

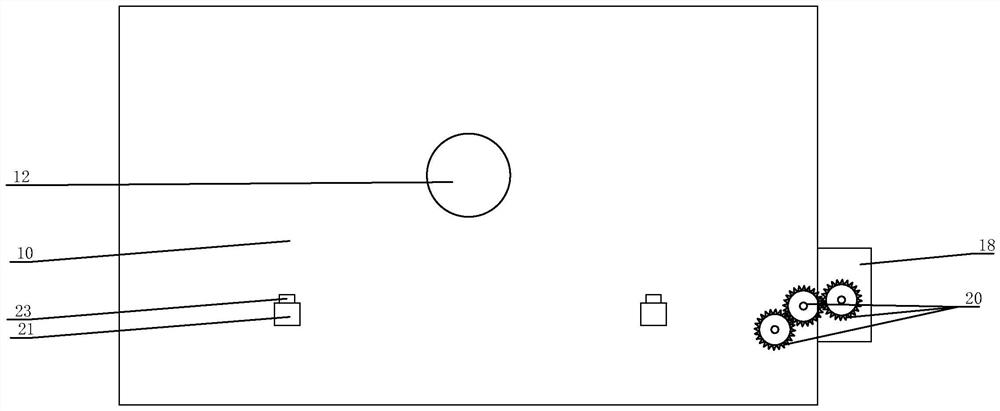

Barcode recognition device of sorting machine for artificial intelligence electronic component processing

InactiveCN112633032AThe direction of movement is accurateBarcode surface is clean and unobstructedCleaning using gasesSensing by electromagnetic radiationBarcodeElectric machinery

The invention discloses a barcode recognition device of a sorting machine for artificial intelligence electronic component processing, which comprises a bottom plate, a support is welded at the upper end of the bottom plate, a motor is arranged on the support, a support roller is arranged on the support, a conveyor belt is arranged on the support roller, and supporting legs are welded at the upper end of the bottom plate. Supporting plates are welded to the supporting legs, a frame is welded to the bottom plate, an air cylinder is fixedly installed at the end, away from the bottom plate, of the frame, an air cylinder rod is arranged at the lower end of the air cylinder, an air cylinder rod is slidably sleeved with the frame, a connecting sleeve is sleeved with the outer side of the end, away from the air cylinder, of the air cylinder rod, and an air pump is fixedly installed on the frame. A hose is arranged at the lower end of the air pump, and a hose is slidably connected into the frame in a sleeved mode. The invention relates to the barcode recognition device of a sorting machine for artificial intelligence electronic component processing. The barcode recognition device has the advantages that the electronic component moving direction is accurate, and the bar code surface is clean and unshielded.

Owner:XUCHANG UNIV

Expanding excavation device for replacing cutter on cutter head and cutter replacing method

ActiveCN112593953AThe direction of movement is accurateEasy to useTunnelsStructural engineeringMechanical engineering

The invention discloses an expanding excavation device for replacing a cutter on a cutter head and a cutter replacing method. The expanding excavation device comprises a cutter head expanding excavation assembly and an auxiliary installation assembly, wherein the cutter head expanding excavation assembly can be assembled at a cutter assembly installation position on the cutter head; the cutter head expanding excavation assembly comprises an expanding excavation body and an expanding excavation cutter cylinder, and the expanding excavation body is installed at one end of the expanding excavation cutter cylinder; and the auxiliary installation assembly comprises a base and a driving component, the base can be fixedly installed on the cutter head, and the driving component can push out or pull back the expanding excavation cutter cylinder. According to the expanding excavation device, firstly, the cutter assembly is replaced with the cutter head expanding excavation assembly, expanding excavation of the cutter head expanding excavation assembly is used for expanding excavation of a rock surface to meet n installation size requirement of a new cutter assembly, use is convenient, through arrangement of the auxiliary installation assembly, it is guaranteed that a moving direction of the cutter head expanding excavation assembly is accurate, the driving force of the driving part is used, assembly of the cutter head expanding excavation assembly is finished, the device is convenient to operate, high in precision, capable of achieving automatic operation, capable of avoiding manualwarehouse entering treatment and high in safety.

Owner:CHINA RAILWAY CONSTR HEAVY IND

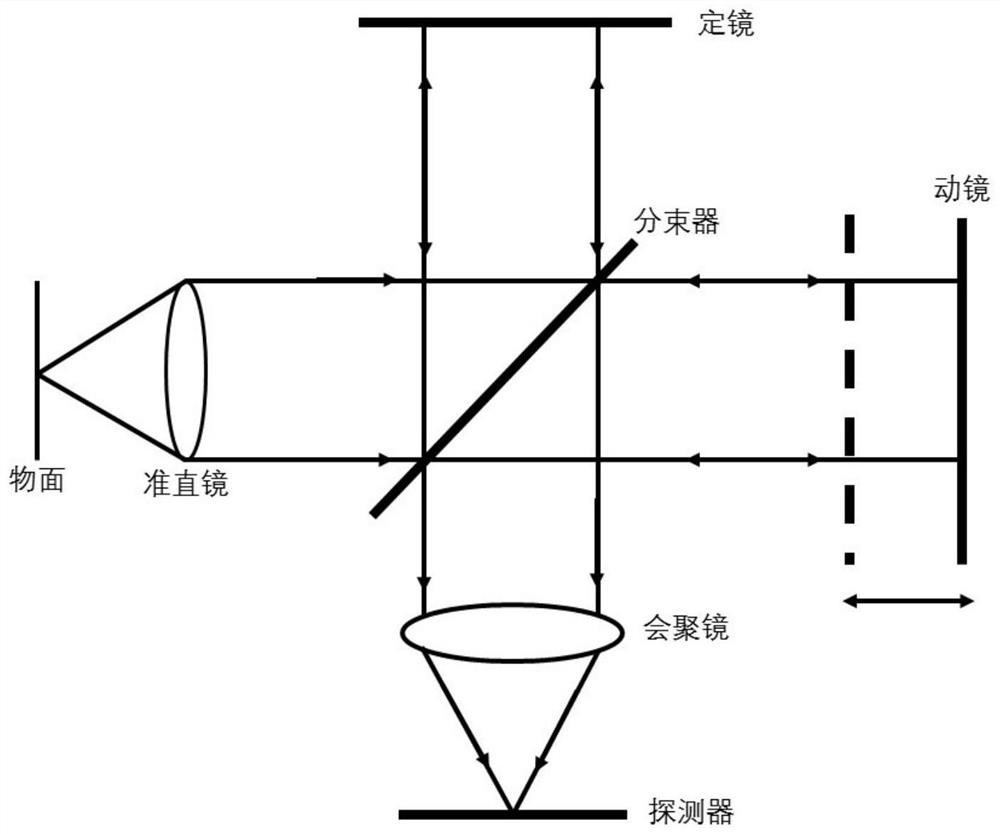

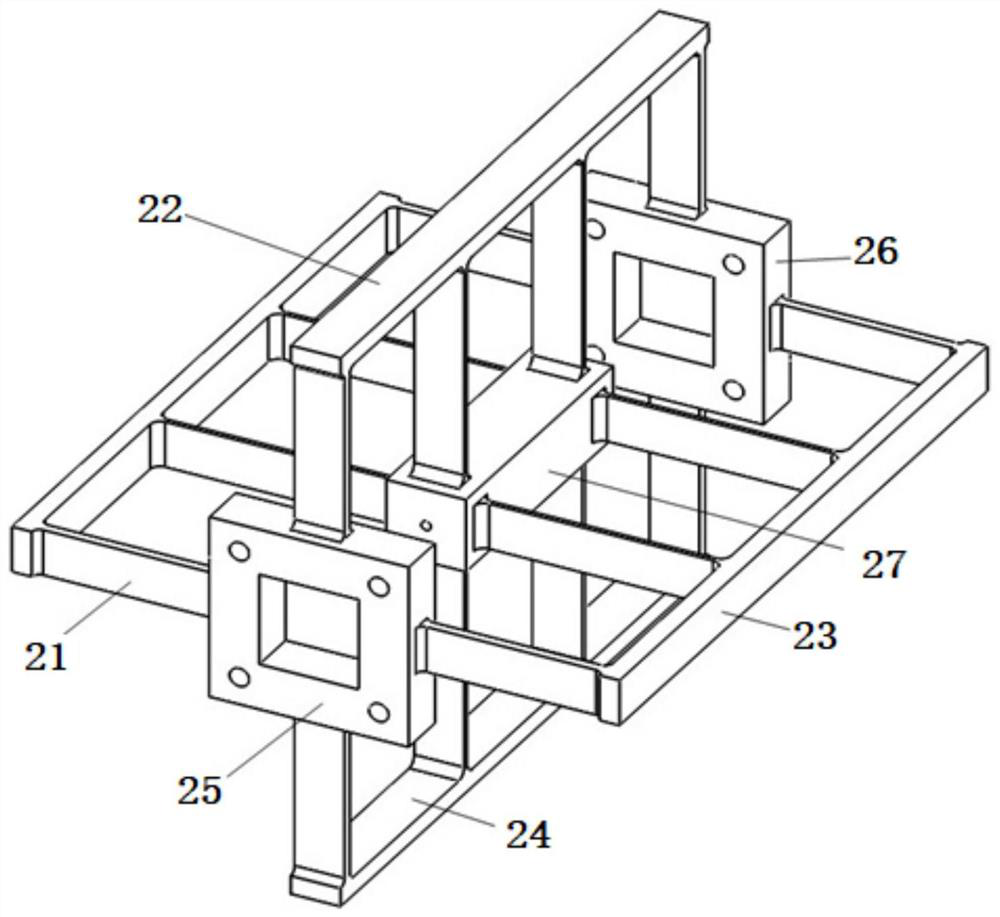

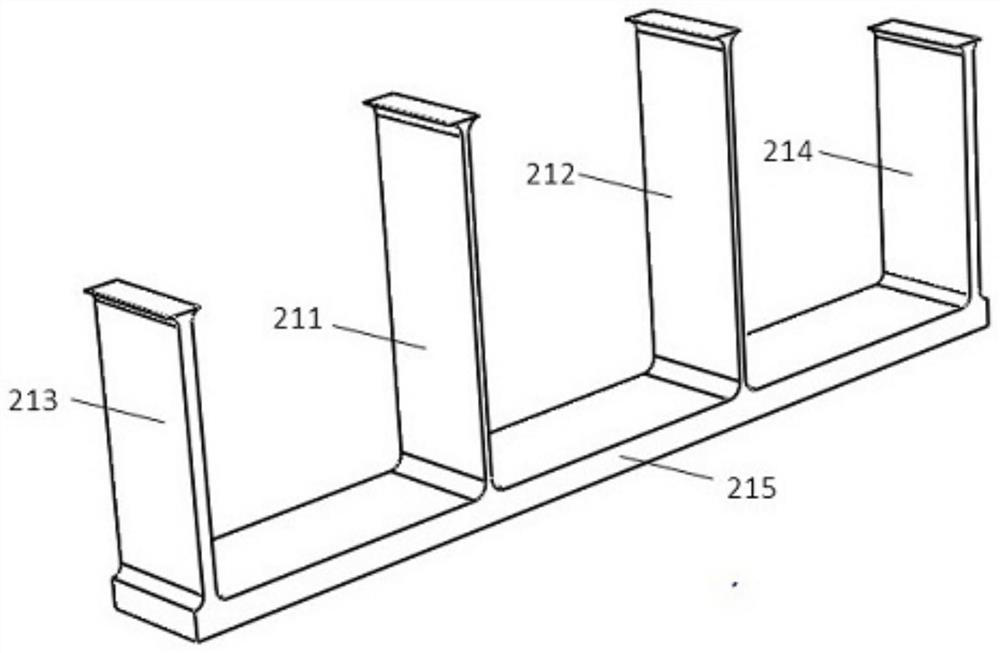

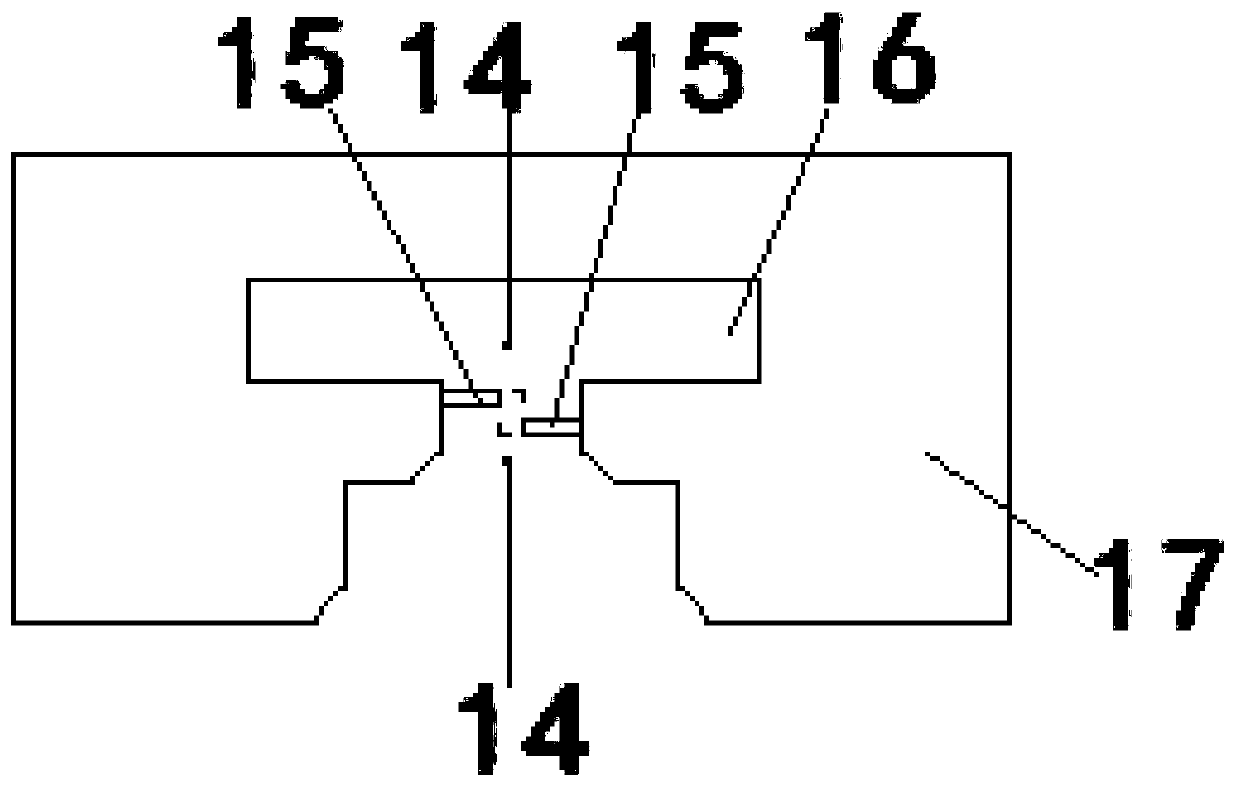

Symmetrical flexible supporting mechanism

PendingCN113532642AGuaranteed motion accuracyFrictionlessRadiation pyrometrySpectrum investigationOptical spectrometerImage resolution

In order to overcome the defects that a traditional movable mirror supporting mechanism is short in service life, large in coupling displacement, prone to inclination of a displacement output end face and small in movement stroke, the invention provides a symmetrical flexible supporting mechanism which comprises four movable arms, two fixed bodies and a movable body. The four movable arms are the same in structural size, are connected with the movable body through two connecting bodies in the middle of each movable arm and are connected with the two fixed bodies through compensation bodies at the two ends of each movable arm, the four movable arms are symmetrically arranged in the space relative to the center of the movable body, and every two adjacent movable arms are spaced by 90 degrees; the connecting body and the compensation body on each movable arm are flexible hinges, movement transmission is achieved through the flexible hinges, the advantages of zero-clearance transmission, zero friction and the like are achieved, and the movement precision of the mechanism is effectively guaranteed; and a double-parallelogram nested structure is formed in each movable arm, so that the movement stroke of a movable mirror can be effectively increased, a compensation function is achieved, and the spectral resolution of an imaging spectrometer can be improved. The symmetrical flexible supporting mechanism of the invention has the advantages of simple and compact structure, low cost and long service life.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

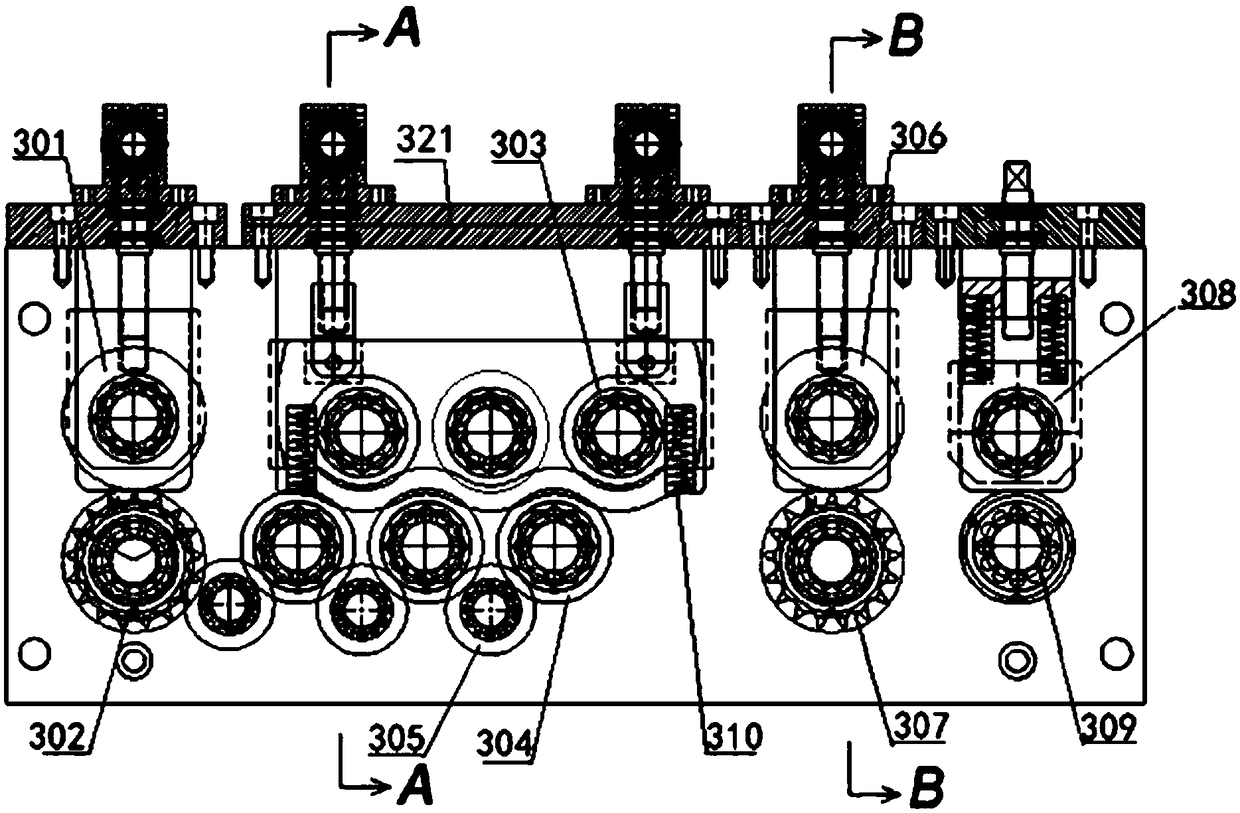

Composite and multi-station full-die-cutting ultrahigh-frequency tag antenna machining equipment and method

PendingCN111185961AReduce pollutionDoes not affect the processing effectPretreated surfacesCoatingsTag antennaElectronic tagging

The invention provides composite and multi-station full-die-cutting ultrahigh frequency tag antenna machining equipment and method, and relates to an ultrahigh frequency tag antenna. An antenna body is provided with a chip binding positioning point formed in a die cutting mode and a chip binding point formed in the die cutting mode. A second base material layer or a first base material layer and the second base material layer are pasted on one side of an antenna layer of the antenna body. The machining equipment is characterized by comprising a first die cutting mechanism, a second die cuttingmechanism and a traction mechanism. The machining equipment and method solve the problem of, in the prior art, 1, how to avoid the problem of using an etching process to produce a chip binding pointand a chip binding positioning point of an ultra-high frequency electronic tag antenna; 2, how to completely avoid the use of an etching process in the production process of the ultra-high frequency electronic tag antenna; 3, how to prevent the antenna layer from shifting during movement or driving in the machining process; and 4, how to help the antenna layer to move or drive better while maintaining the tension.

Owner:黄光伟

Multi-base station frequency shift integrated positioning method for mobile terminals

InactiveCN101707805BThe positioning method is scientific and reasonableAccurate locationWireless communicationMotion parameterComputer terminal

The invention discloses a multi-base station frequency shift comprehensive positioning method for a mobile terminal. The positioning method utilizes the Doppler effect existing in the mobile terminal itself, and synthesizes the Doppler effect generated by the mobile terminal relative to multiple base stations to obtain the mobile terminal's Motion parameters, combined with the cell information to further obtain the position, speed and direction of the mobile terminal, to achieve continuous and dynamic positioning of the mobile terminal, and the positioning method is scientific and reasonable.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

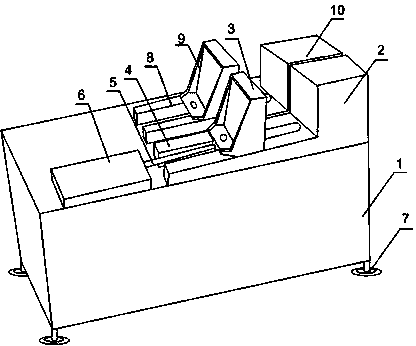

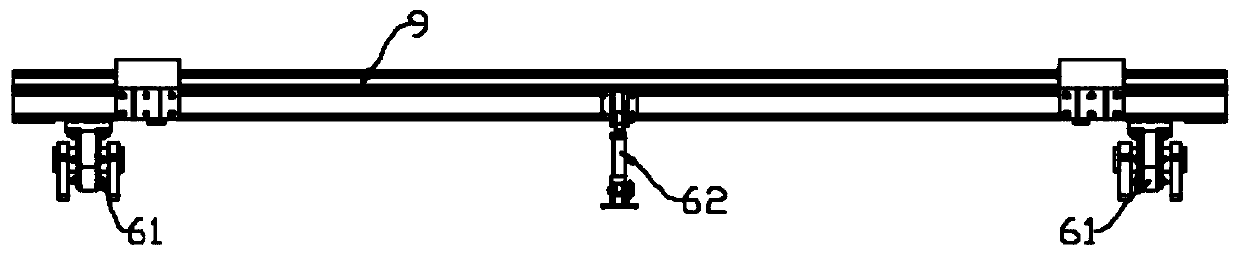

Back-and-forth seaming machine, use method of back-and-forth seaming machine and air pipe production line

InactiveCN109277447APrecise hem shapeAvoid affecting the accuracy of foldingShaping toolsMetal-working feeding devicesProduction lineMachining

The invention discloses a back-and-forth seaming machine, a use method of the back-and-forth seaming machine and an air pipe production line and belongs to the field of air pipe manufacturing. The seaming machine comprises a rack, a seaming device which is installed on the rack and is capable of moving in the direction perpendicular to the feeding direction, and a material conveying device which can move in the feeding direction. The material conveying device comprises a material pressing mechanism and a material clamping mechanism. Rollers are arranged on the two sides of the moving directionof the seaming device. By means of the seaming machine, the opposite two sides of a plate are machined in one process through back-and-forth motion of the seaming device, and accuracy of the folded edge shape of the machined plate is high. By means of the use method of the back-and-forth seaming machine, the plate with the accurate folded edge shape can be obtained, the two edges of the plate aremachined in one process, and the machining efficiency is high. By means of the air pipe production line, the above back-and-forth seaming machine is adopted as the seaming machine, the air pipe machining efficiency is high, and the quality of a manufactured air pipe is good.

Owner:安徽开天重工机械制造有限公司

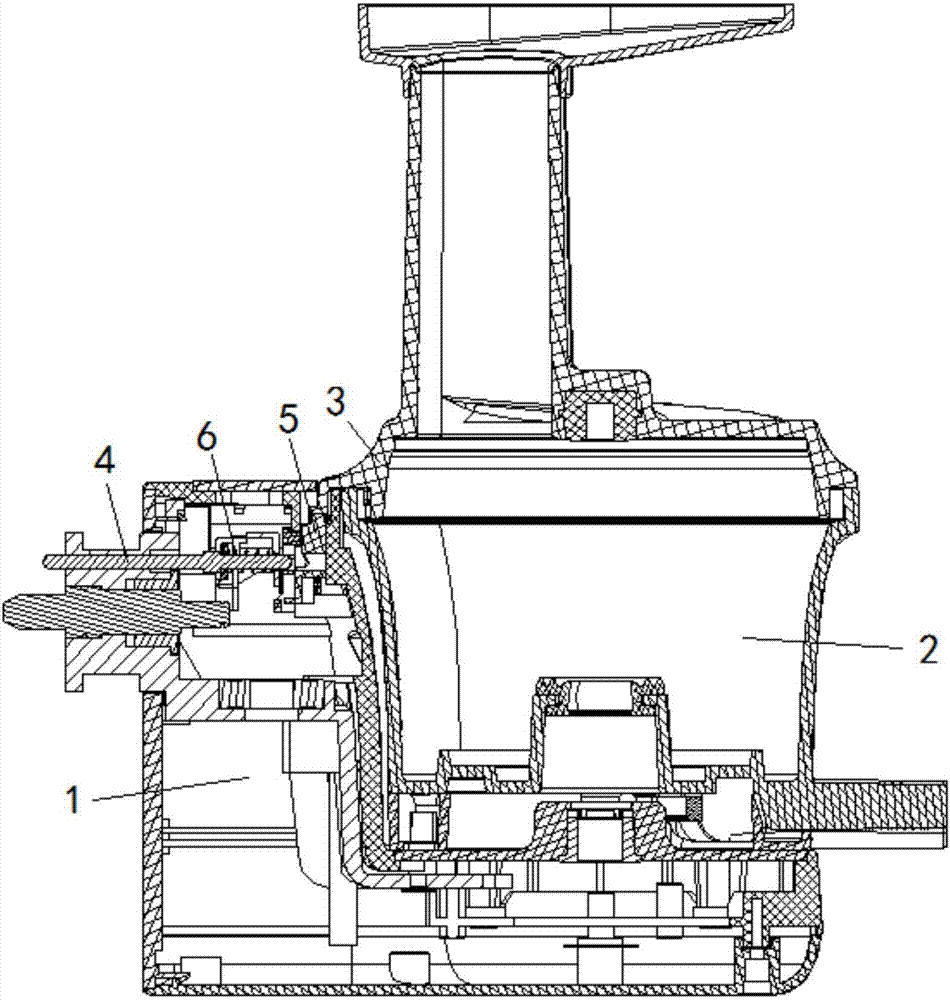

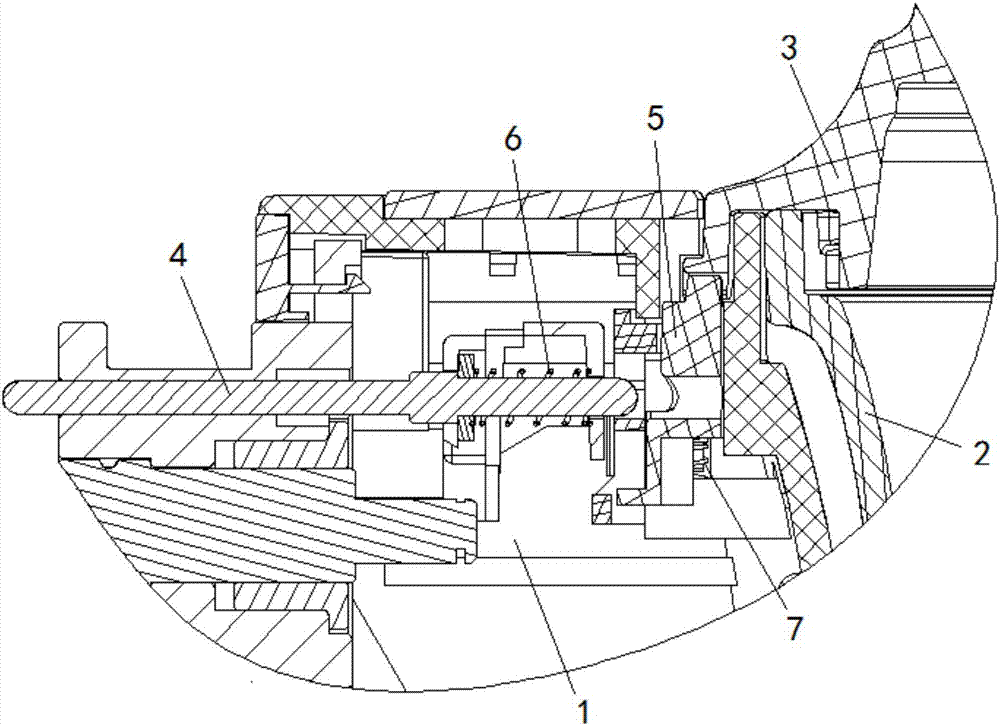

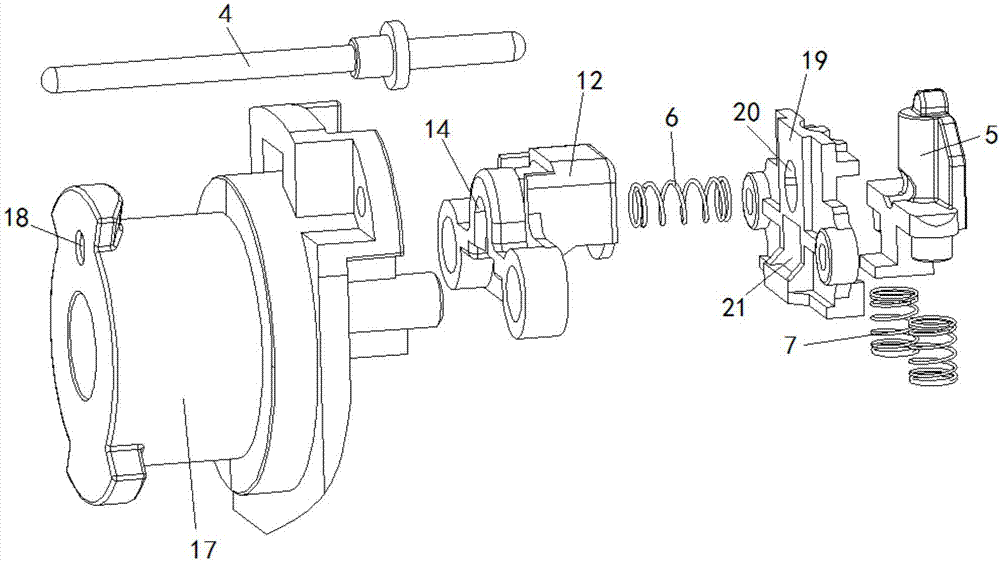

Food processing assembly with safety lock

PendingCN107095599AAvoid disassemblyImprove securityKitchen equipmentType safetyMechanical engineering

The invention relates to the technical field of food processing assemblies, in particular to a food processing assembly with a safety lock. The food processing assembly comprises a large body and a cup body arranged on the big body and used for processing food. A cup cover is detachably arranged on the cup body, and a locking part, a release part, an elastic part and a reset part are arranged in the large body; the first end of the locking part can extend out of or retract into the mounting surface of the large body, and the second end of the locking part is matched with the release part; the elastic part is located on the locking part so as to drive the first end of the locking part to keep the state of extending out of the mounting surface of the large body; the release part is matched with the locking part, and when the cup cover is arranged on the cup body, the cup cover drives the release part to move so that the locking part can freely retract; when no cup cover is arranged on the cup body, the release part can prevent the locking part from being retracted. A pure mechanical type safety lock structure is adopted so that it can be guaranteed that the assembly can be installed on a host only after the cover is installed, when the assembly is installed on the host, the cover cannot be opened, and accordingly the use safety is improved.

Owner:GUANGDONG BARSETTO ELECTRIC IND CO LTD

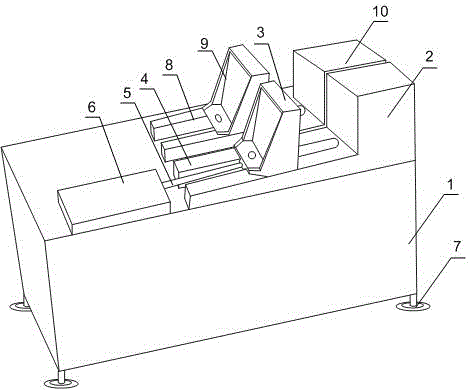

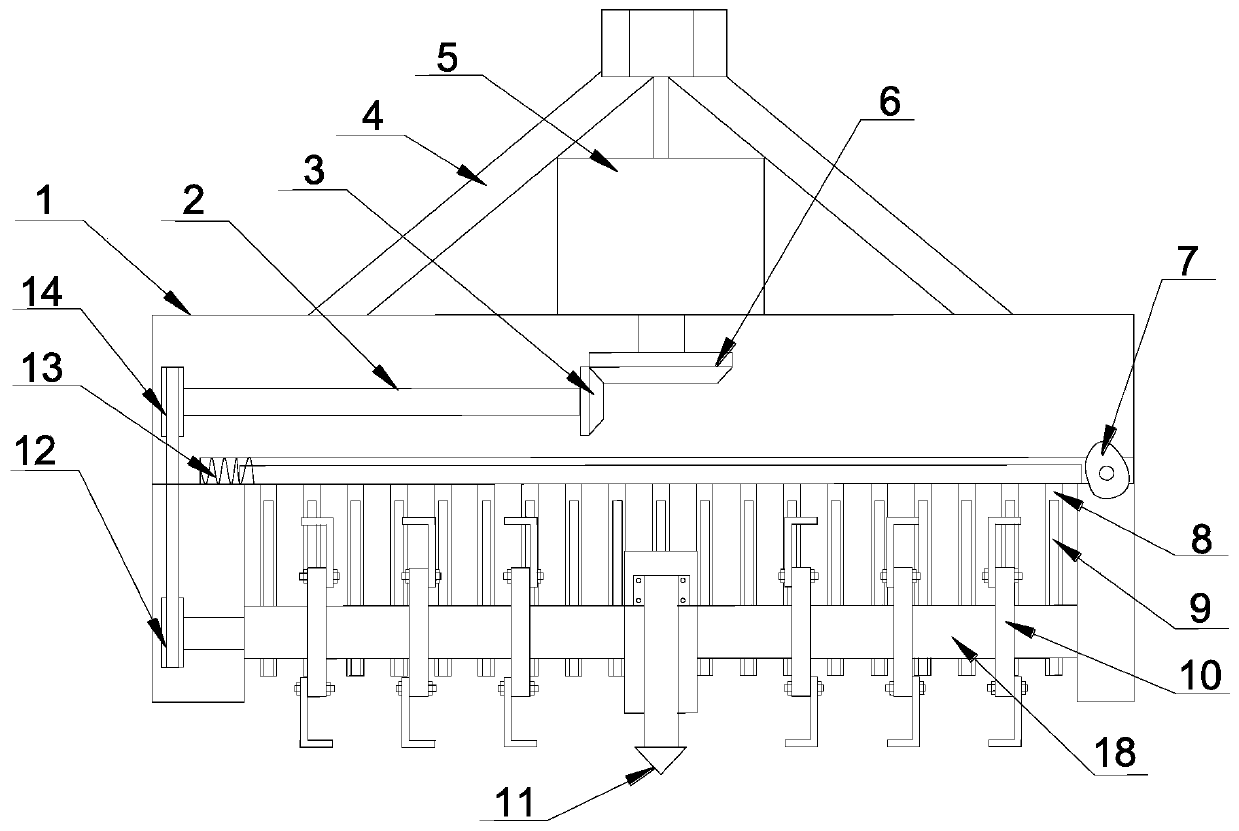

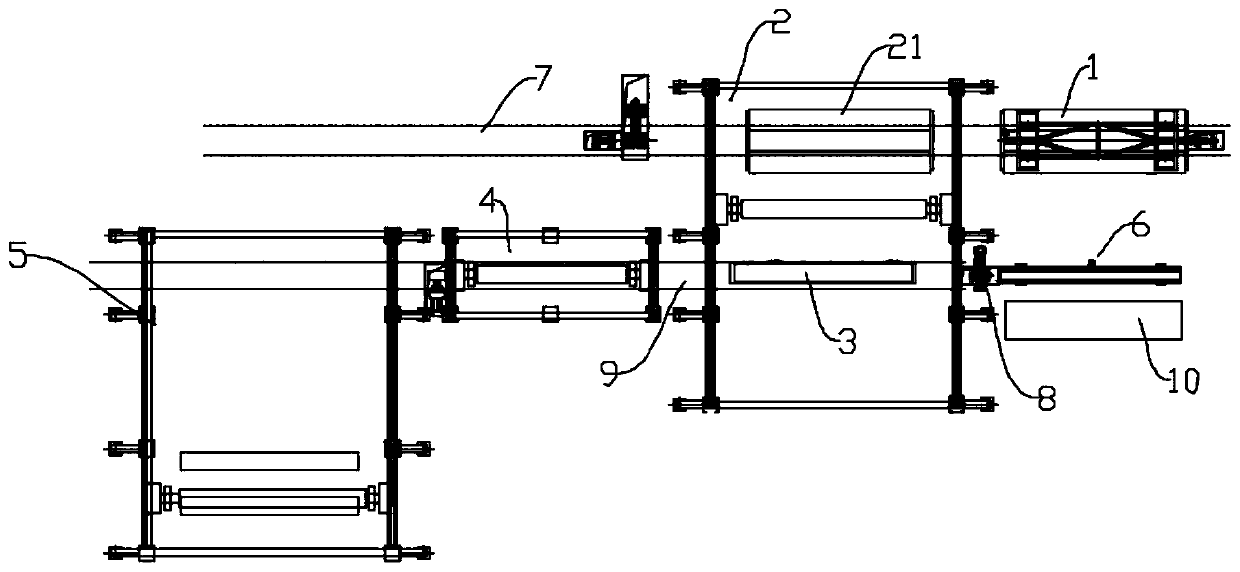

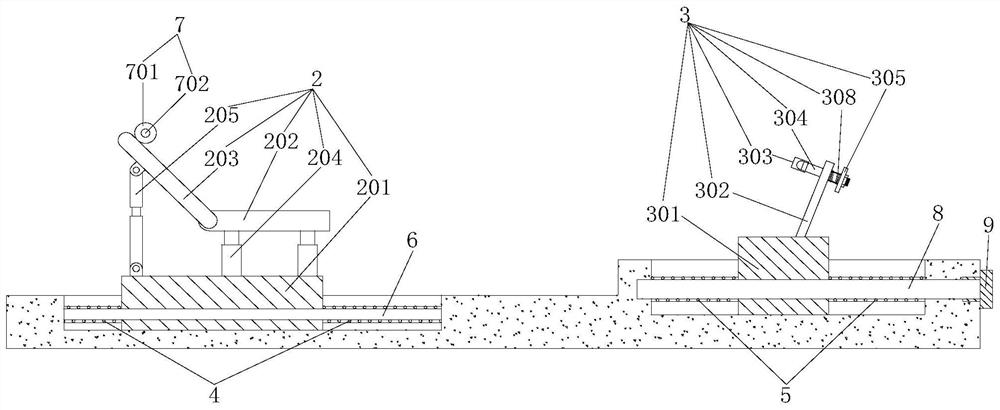

Waste removal equipment and technology of aerated concrete green body

ActiveCN111331725AAvoid damage and deformationEasily deformed and damagedAuxillary shaping apparatusProcess engineeringWaste management

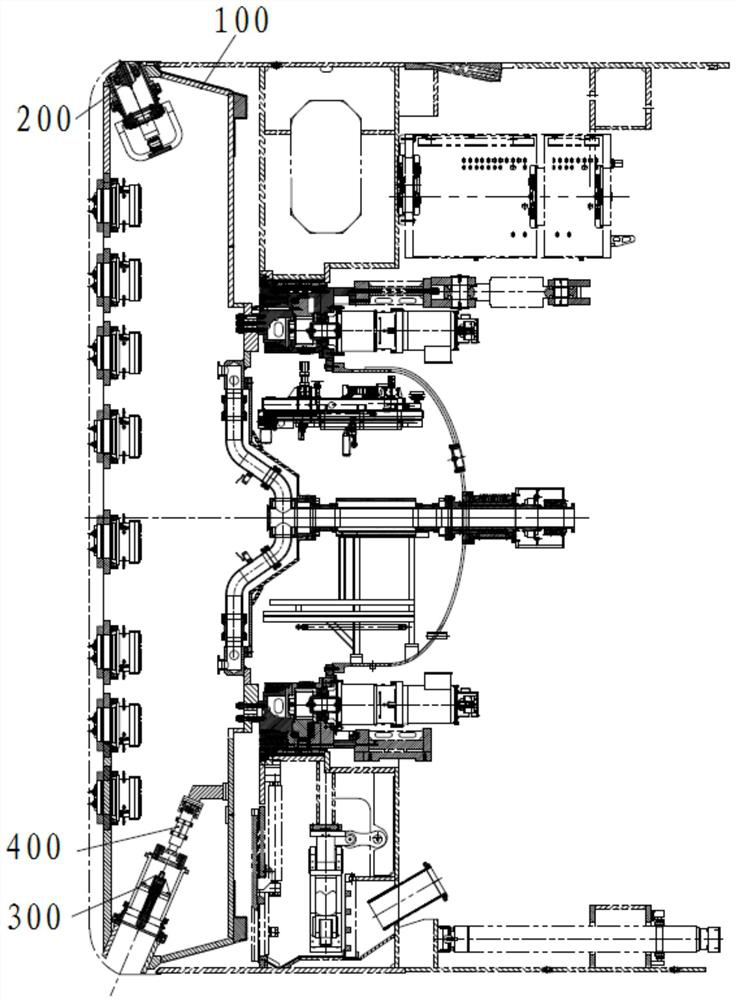

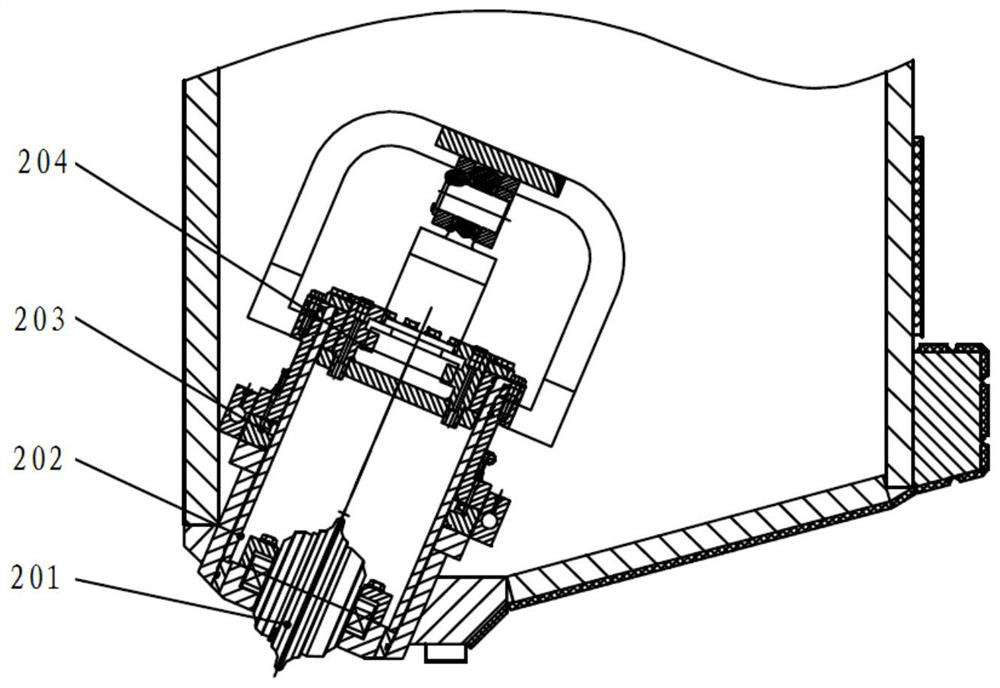

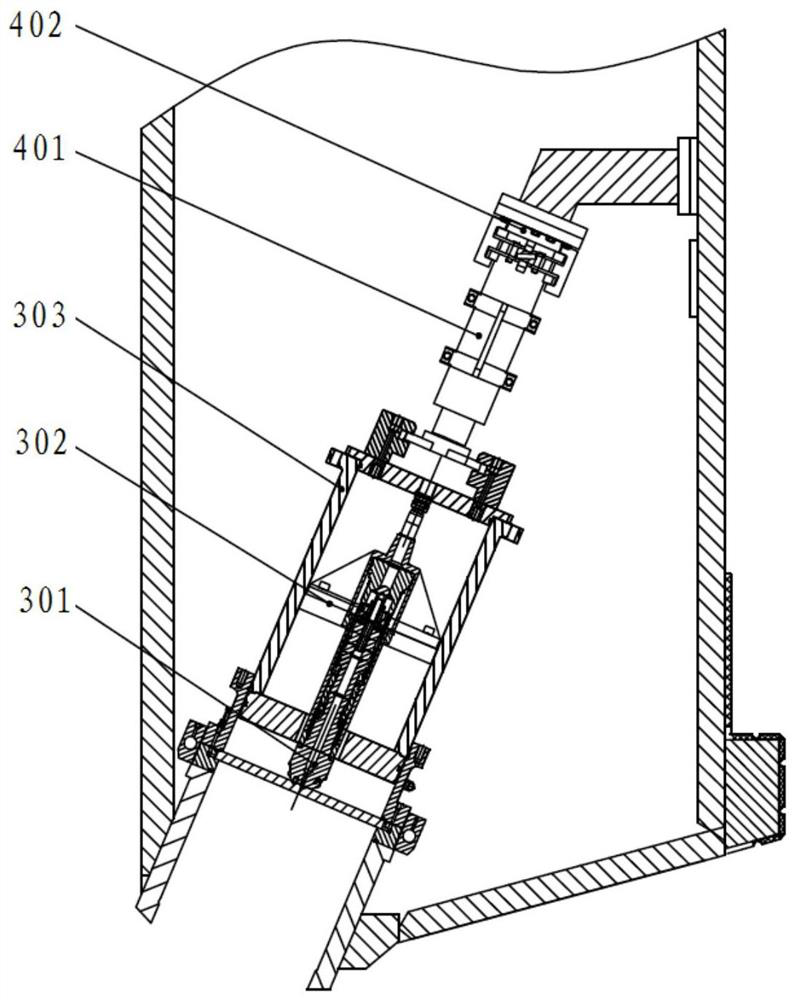

The invention discloses a waste removal equipment and technology of an aerated concrete green body, and belongs to the field of concrete processing. The waste removal equipment comprises a steam-curing vehicle, a green body transferring machine, a conveying vehicle, a separating and breaking machine, a billet clamping machine and a turnover device; the steam-curing vehicle is arranged below any one end of the green body transferring machine, and the conveying vehicle is arranged below the other end of the green body transferring machine; the green body transferring machine is used for transferring steam-curing bottom plates on the steam-curing vehicle to the conveying vehicle; and the separating and breaking machine and the billet clamping machine are sequentially arranged on any one sideof the green body transferring machine, and the turnover device is arranged on the other side of the green body transferring machine. Waste removal operation can be conveniently carried out on the green body after steam-curing, the damage to the green body especially for panels is reduced, removed waste can be well collected for recycling, and the working efficiency of the whole set of device is extremely high. By adopting the waste removal equipment, the waste removal and recycling efficiency is extremely high, and the problem of low efficiency of removing and recycling the waste by labor issolved.

Owner:ANHUI KEDA IND CO LTD

Machining locating method of glass guide rail

InactiveCN105382589AAvoid vibrationThe direction of movement is accuratePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a machining locating method of a glass guide rail. The machining locating method comprises the steps that a clamping unit capable of changing a clamping clearance according to the appearance and size of the glass guide rail is firstly composed of a movable baffle and a fixed baffle on a rack of a machining locating device, the arranged fixed baffle can achieve the function of limiting the glass guide rail, and the movable baffle can be pushed by a hydraulic mechanism to quickly advance and retreat so as to clamp or loosen the glass guide rail; when the material cutting procedure is carried out, the glass guide rail is closely attached to the inner wall of the fixed baffle, the movable baffle is pushed by the hydraulic mechanism to move close to the fixed baffle till the glass guide rail is clamped, and finally the glass guide rail is cut by a cutting mechanism; and the machined glass guide rail directly and quickly slides towards dedicated glass guide rail collecting equipment through a discharging opening.

Owner:SICHUAN JINFENG CONSTR

Orthopedic nursing traction bracket

InactiveCN111803877AThe direction of movement is accurateSimple structureResilient force resistorsFractureEngineeringOrthopedic department

The invention belongs to the technical field of medical supplies, and discloses an orthopedic nursing traction bracket, which comprises a base, a sliding seat mechanism and a footstep traction mechanism, wherein a first sliding groove and a second sliding groove are formed in the upper end of the base, the sliding seat mechanism is slidably connected into the first sliding groove in a height-adjustable mode, a first elastic piece is arranged in the first sliding groove so as to conveniently adjust the distance between the sliding seat mechanism and the footstep traction mechanism through the first elastic piece, the footstep traction mechanism is slidably connected to the second sliding groove, and a second elastic piece is arranged in the second sliding groove so as to conveniently adjustthe distance between the footstep traction mechanism and the sliding seat mechanism through the second elastic piece. Through cooperation of multiple aspects, it is guaranteed that the purpose of exercising is easily achieved through force exertion of the feet and the legs, traction of the legs is effectively achieved, use is convenient, flexibility is high, and the experience effect is good.

Owner:南充市中心医院

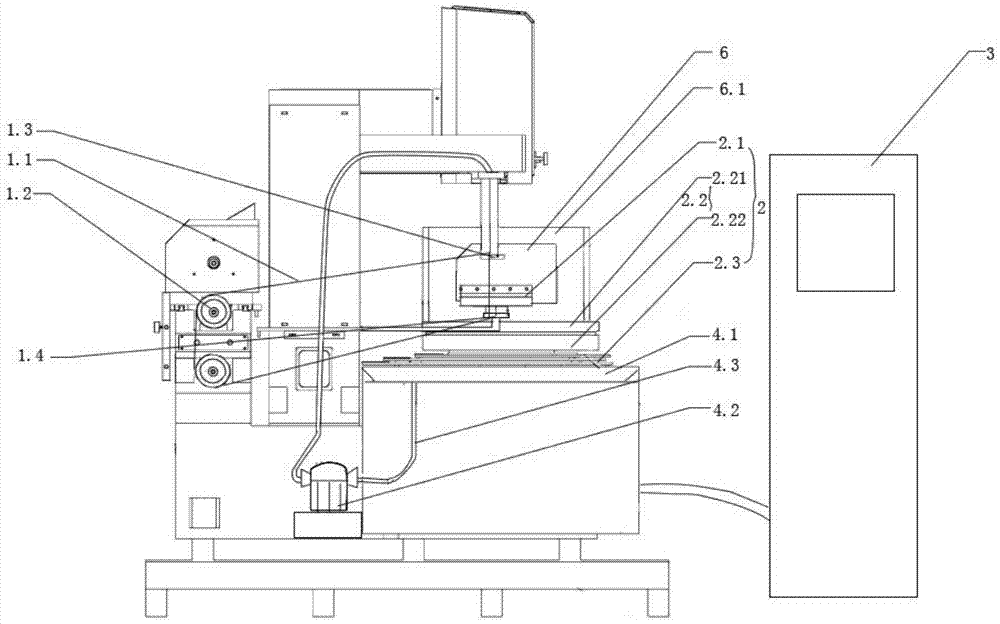

Numerical control wire saw processing machine

InactiveCN104493982AAchieve one-way movementReduce pauseMetal sawing devicesMetal sawing accessoriesNumerical controlControl system

The invention provides a numerical control wire saw processing machine. The numerical control wire saw processing machine comprises a wire storage system, a workbench, a control system and a cutting fluid lubricating system, wherein the control system is connected with the cutting fluid lubricating system; the workbench comprises a revolving platform, a linear moving platform and a base; the linear moving platform is connected with the base in a sliding way; the revolving platform is arranged above the linear moving platform; the wire storage system comprises a cutting wire, a wire storage guide-wheel group, an upper wire rack and a lower wire rack; the upper wire rack and the lower wire rack are arranged above and below the outer side of the revolving platform respectively; the cutting wire is connected end to end, passes through the upper wire rack and the lower wire rack, and is wound on the outer side of the wire storage guide-wheel group; the control system is connected with the wire storage guide-wheel group, the revolving platform and the linear moving platform. An enclosed annular cutting wire is formed through end-to-end connection, so that one-way motion of the cutting wire is realized, and pause of the cutting wire is reduced; 360-degree rotation of a processed part can be realized through the revolving platform, and the motion direction of the workbench is consistent with the profile cutting direction of a workpiece, so that the smoothness of a processing face is ensured.

Owner:NANTONG HENGLONG MACHINERY MFG

household cabinet door handle

The invention discloses a door knob of a household kitchen cabinet door. The door knob comprises a kitchen cabinet box and a kitchen cabinet door body, wherein the kitchen cabinet door body comprises a door plate of the kitchen cabinet door and a movement mechanism, which are symmetrically arranged; the door plate of the kitchen cabinet door is in sliding connection with a hidden door knob; the hidden door knob is provided with a first magnet; a plurality of elastic bulges and through holes are formed in an outer wall of the door plate of the kitchen cabinet door; each elastic bulge is provided with an inclined wedged block; a machining room is arranged in the door plate of the kitchen cabinet door; the movement mechanism comprises a supporting column and a movable block; the supporting column is fixedly connected with an inner wall of the machining room; a sliding groove is formed in one end of the movable block and a second magnet with magnetism which is the same as that of the first magnet is arranged at the other end of the movable block; the supporting column is in sliding connection with the sliding groove; a compressed spring is arranged between the supporting column and the sliding groove; a starting switch is further arranged on the sliding groove; the starting switch is electrically connected with a sounder; a plurality of grooves are formed in the middle of the movable block. According to the door knob of the household kitchen cabinet door, the problems that blind people cannot conveniently find the hidden door knob and blind people are easily injured when touching or beating the rough kitchen cabinet door are mainly solved.

Owner:重庆金华兴门业有限公司

Seedling grafting device

PendingCN113711791AThe direction of movement is accurateStructural location is reasonableGraftingRootstockEngineering

The invention discloses a seedling grafting device. A rootstock seedling preparation mechanism and a scion seedling preparation mechanism are arranged on a machine frame in the X-axis direction at intervals, the rootstock seedling preparation mechanism comprises a rootstock maintaining part and a rootstock cutting part, and the scion seedling preparation mechanism comprises a scion maintaining part and a scion cutting part; the rootstock maintaining part is used for maintaining the posture of a rootstock transversely arranged on the rootstock maintaining part, and the scion maintaining part maintains the posture of a scion transversely arranged on the scion maintaining part; the rootstock maintaining part and the scion maintaining part can get close to and get away from each other in the X-axis direction, and a displacement interval is formed between the rootstock maintaining part and the scion maintaining part; and a seedling clamping mechanism is arranged between the rootstock seedling preparation mechanism and the scion seedling preparation mechanism and comprises a standby clamping part and a clamping part, the standby clamping part is arranged in the Y-axis direction, and the clamping part is arranged at the front end of the standby clamping part and located below the displacement interval. The seedling clamping mechanism, the rootstock seedling preparation mechanism and the scion seedling preparation mechanism are reasonable in position relation, can realize automatic seedling cutting, automatic grafting and automatic clamping through mutual cooperation, and are efficient in cooperation and high in grafting efficiency.

Owner:JINHUA ACAD OF AGRI SCI +1

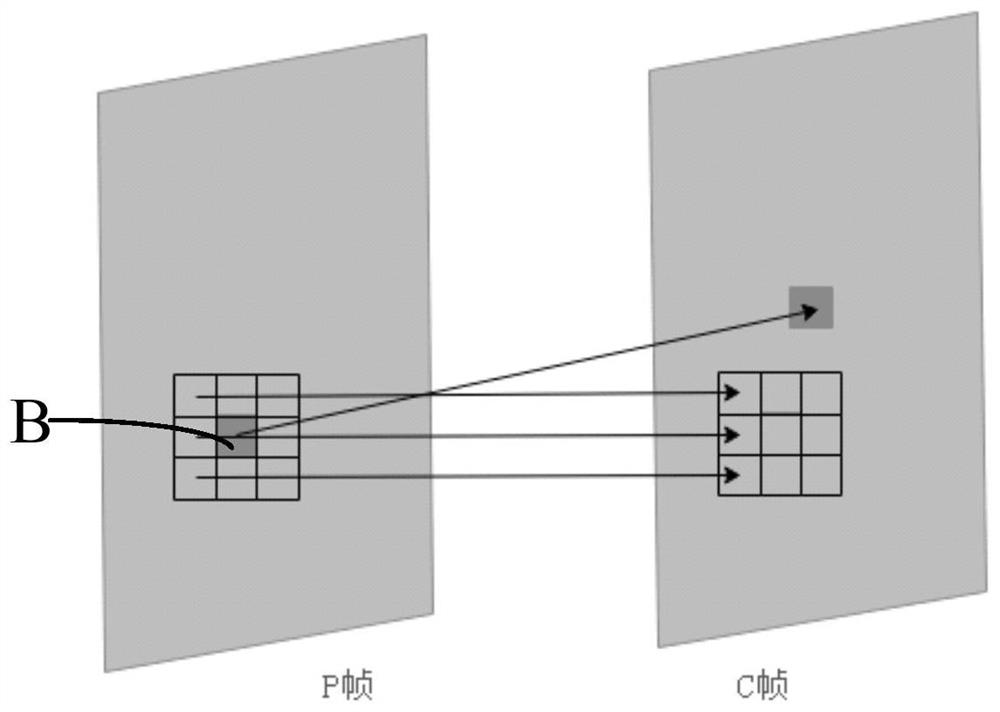

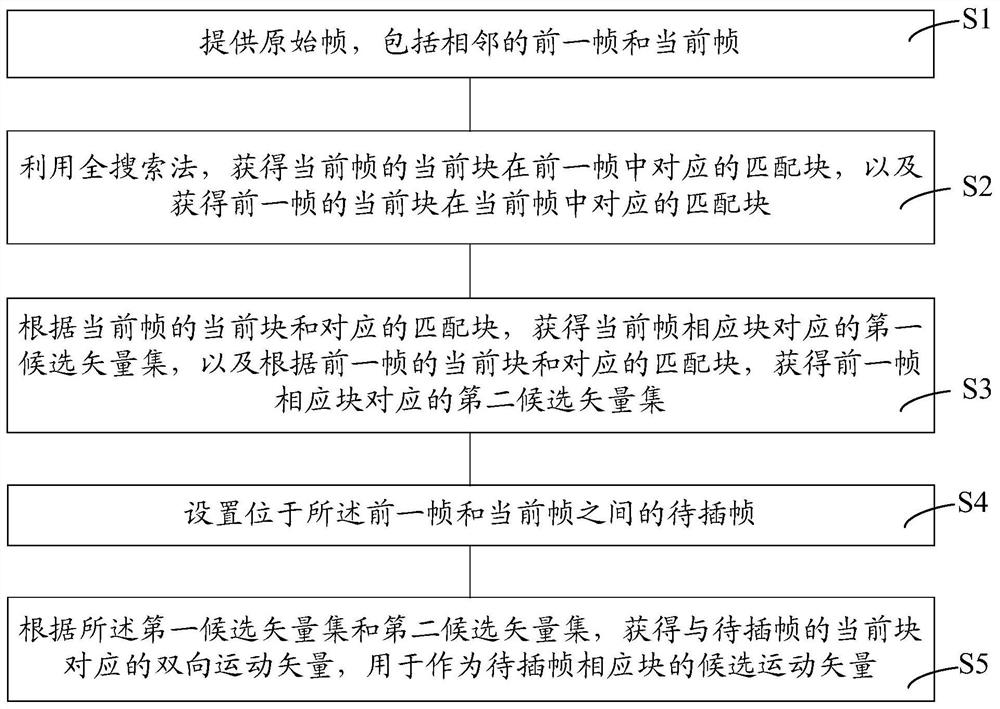

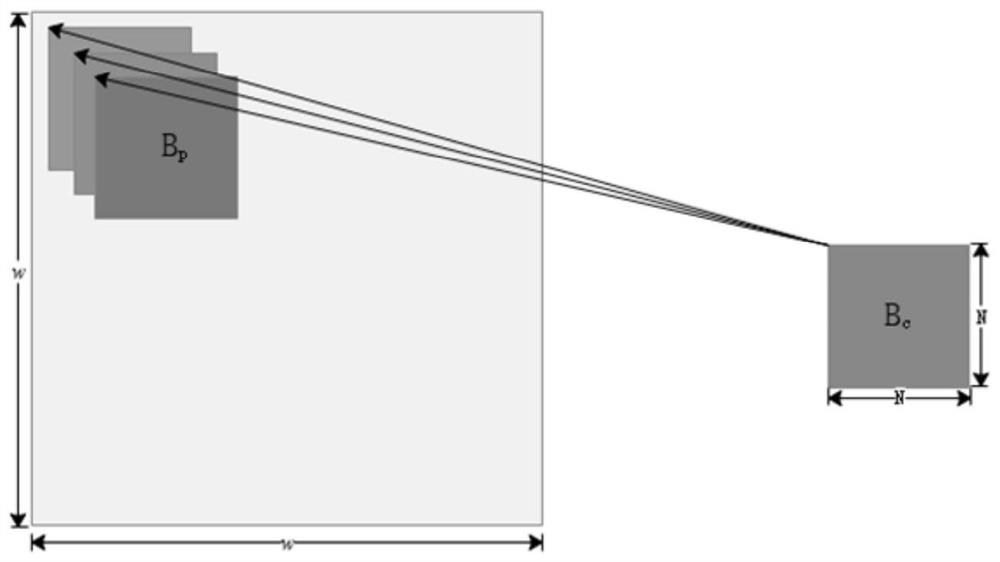

Motion estimation method, chip, electronic equipment and storage medium

PendingCN113870302AThe direction of movement is accurateImprove accuracyImage enhancementImage analysisMotion vectorControl theory

The invention discloses a motion estimation method, a chip, electronic equipment and a storage medium. The motion estimation method comprises the following steps: providing an original frame; obtaining a matching block corresponding to the current block of the current frame in the previous frame by using a full search method, and obtaining a matching block corresponding to the current block of the previous frame in the current frame; obtaining a first candidate vector set corresponding to the corresponding block of the current frame according to the current block of the current frame and the corresponding matching block, and obtaining a second candidate vector set corresponding to the corresponding block of the previous frame according to the current block of the previous frame and the corresponding matching block; setting a frame to be inserted between the previous frame and the current frame; and according to the first candidate vector set and the second candidate vector set, obtaining a bidirectional motion vector corresponding to the current block of the to-be-interpolated frame, and using the bidirectional motion vector as a candidate motion vector of the corresponding block of the to-be-interpolated frame. The embodiment of the invention is beneficial to improving the accuracy of motion estimation.

Owner:AMOLOGIC (SHANGHAI) CO LTD

Circular knife machining and stripping all-in-one machine

PendingCN112478891AExcellent peelabilityGuaranteed uptimeArticle unpackingArticle deliveryMachine partsElectric machinery

The invention discloses a circular knife machining and stripping all-in-one machine. The circular knife machining and stripping all-in-one machine comprises a rack, a circular knife machining part, anauxiliary discharging part, a stripping part and a detection assembly, wherein the circular knife machining part is installed in the middle of the rack; the auxiliary discharging part is installed atthe upper end of the discharging side face of the rack; the stripping part is installed in the middle; a feeding shaft of the auxiliary discharging part is rotatably connected to a lateral frame through a first bearing; a central shaft hole direct coupling shaft sleeve of the side end face of the feeding shaft is connected with an output shaft of a feeding motor; the upper inclined surface of a stripping knife of the stripping part is tangent to the feeding shaft and located below the left end of the feeding shaft; the two sides of the left end of the stripping knife are in threaded connection with a horizontal base plane of an inner base shaft; and an optical fiber sensor of the detection assembly is located over the stripping knife. The circular knife machining and stripping all-in-onemachine provided by the invention has the effects that circular knife machining, stripping and directional material moving are integrated, the equipment is compact, the production efficiency is high,and the product yield is high.

Owner:LINGSHENGCHENG TECH JIANGSU CO LTD

Three-color mold structure

The invention discloses a three-color mold structure. The three-color mold structure comprises a mold base and is characterized in that the mold base comprises an upper base body and a lower base bodywhich are arranged in an up-down spaced mode and connected with each other, a first station and a second station which are used for simultaneous injection molding and a third station which is used for independent injection molding are transversely arranged on the upper base body side by side, the first station is fixed to the upper base body, the second station and the third station are fixed toa lifting rotating body capable of ascending, descending and rotating up and down, a manipulator is arranged beside the mold base and used for transferring products formed on the stations in an injection molding mode, the lifting rotating body comprises a square rotating disc embedded in the upper base body and a rotating shaft arranged under the square rotating disc, one end of the rotating shaftis fixedly connected with the axis of the square rotating disc, the other end of the rotating shaft is rotationally connected with a supporting plate movably arranged above the lower base body, a lifting assembly is arranged between the supporting plate and the lower base body, and a rotating assembly is further arranged between the mold base and the rotating shaft. The three-color mold structureis small and compact in structure, simplified in procedure and high in automation degree.

Owner:NINGBO FANGZHENG TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com