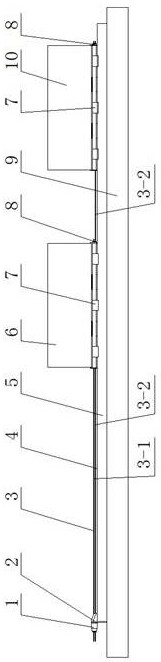

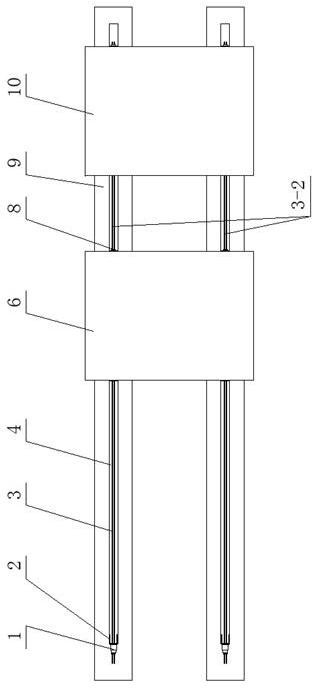

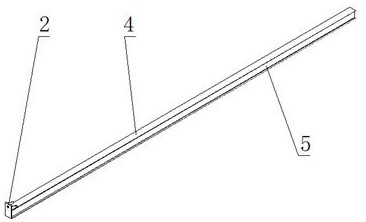

Translation device for synchronously replacing new and old components and construction method thereof

A technology for translational devices and components, which is applied in bridge erection/assembly, bridge maintenance, bridge reinforcement, etc., which can solve problems such as waste, long construction period, and high labor intensity, and achieve low cost, shortened construction period, and less land occupation for construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail with an embodiment below:

[0034] Assuming that there is an existing railway bridge, the original bridge is a one-way traffic road, and now the traffic road under the bridge is widened to two-lane or three-lane or more lanes according to the needs. If the traditional construction method is used, the original The bridge and original piers were demolished, and a new bridge was rebuilt. However, because the original railway bridge needs trains to pass through, the construction of the broken bridge will inevitably cause long-term train suspension. Therefore, the traditional construction method will cause huge losses to the railway department.

[0035] If the traditional technology of building an independent reaction seat for traction is adopted, since the surrounding area of the railway bridge is a residential area, there is not enough space to build a reaction seat, so the replacement of old and new bridge components cannot b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com