Patents

Literature

60results about How to "Construction occupies less land" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for reinforcement construction of soft soil foundation by exchange-filling with foam lightweight soil

ActiveCN102505598ASuppression uniformityInhibition of lateral movementRoadwaysLateral displacementUnderground pipeline

The invention discloses a method for reinforcement construction of soft soil foundation by exchange-filling with foam lightweight soil. The method adopts high-strength foam lightweight soil as filler for foundation pits. Due to pumping construction, the construction of a construction road is omitted, the construction floor occupation is small, the construction difficulty is reduced greatly while the construction period is shortened, the post-construction settlement of the filler is eliminated effectively, the additional pressure of foundation to underground pipelines is decreased, the nonuniform settlement and lateral displacement of foundation are suppressed, and the stability of roadbed is improved. Therefore, the method can ensure safety of underground pipelines, but also meet the bearing capacity requirement of foundation.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

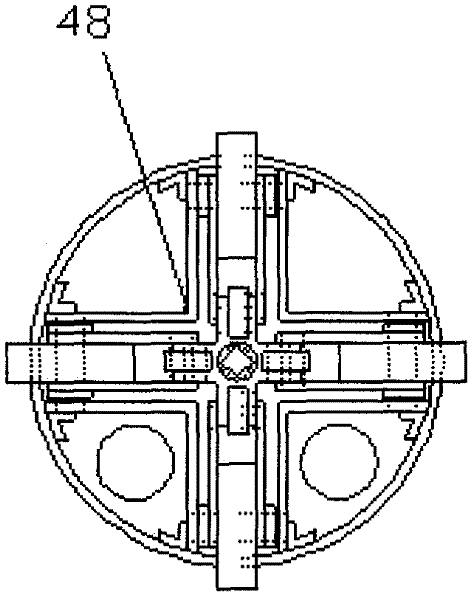

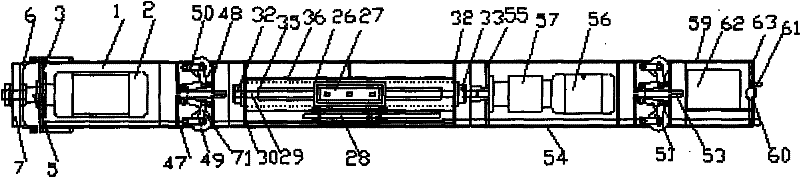

Integrated working machine for non-excavation pipeline

ActiveCN102200212AChange usage specificationsEasy to operatePigs/molesLow noiseIndustrial engineering

The invention relates to an integrated working machine for a non-excavation pipeline, belonging to the field of engineering machinery. A rigid working head, a supporting machine, a pipe wall tensioning machine, a spiral pusher, a supporting machine and a control box are spliced to form the integrated working machine for the non-excavation pipeline. The working machine provided by the invention isspecial machinery specially used in cleaning silt, cleaning and checking the dragging and pushing operation in a pipe for a pipeline at the state of non-excavation, and can maintain the partial defects of the inner part of the pipe. The working machine has the advantages of small flooring area, low noise, rapid speed, high concealment, good enginnering safety and civilized construction, does not damage to the ground environment, does not influence traffic, the normal life and working order for people, is environmentally-friendly construction machinery, and is good helper for management pesonnel and maintaining personnel for city management; and the machine has the advantages of working efficiency, low construction cost, energy conservation, time and labor conservation, and high automoticity and is simple in operation, is convenient to maintain the pipeline, the service life of a pipe body is prolonged, the operation cost of the pipeline is reduced, and the econimoc benefit is improved.

Owner:高为人

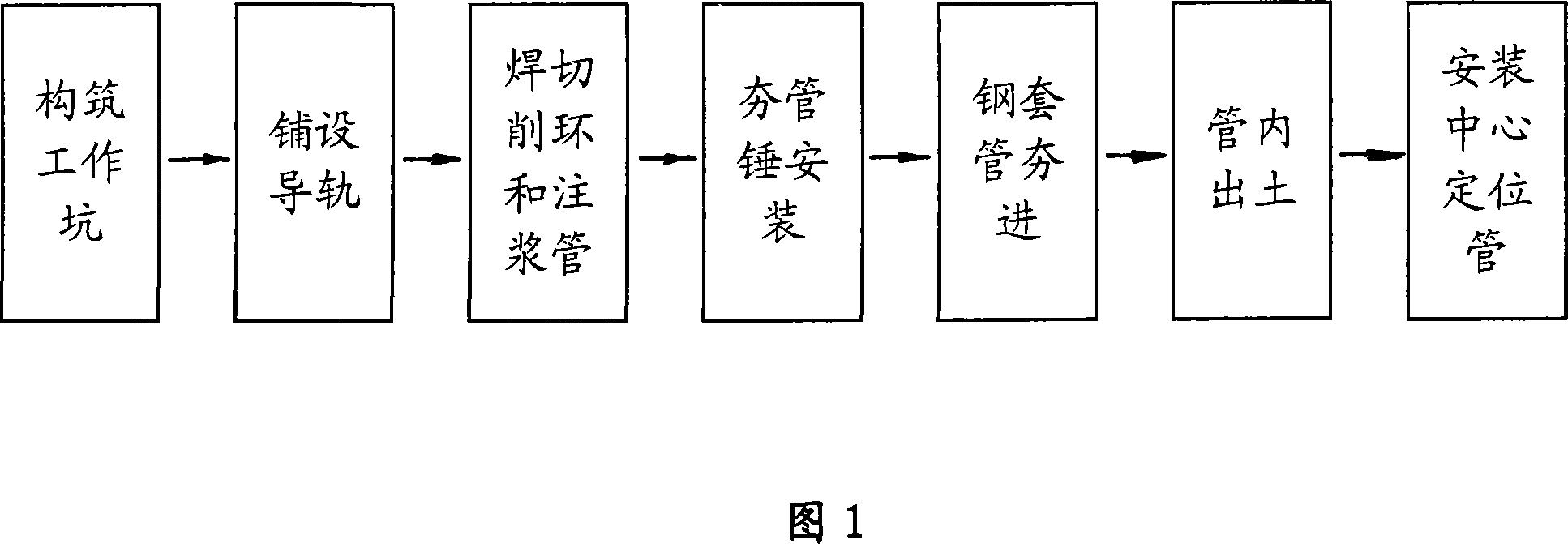

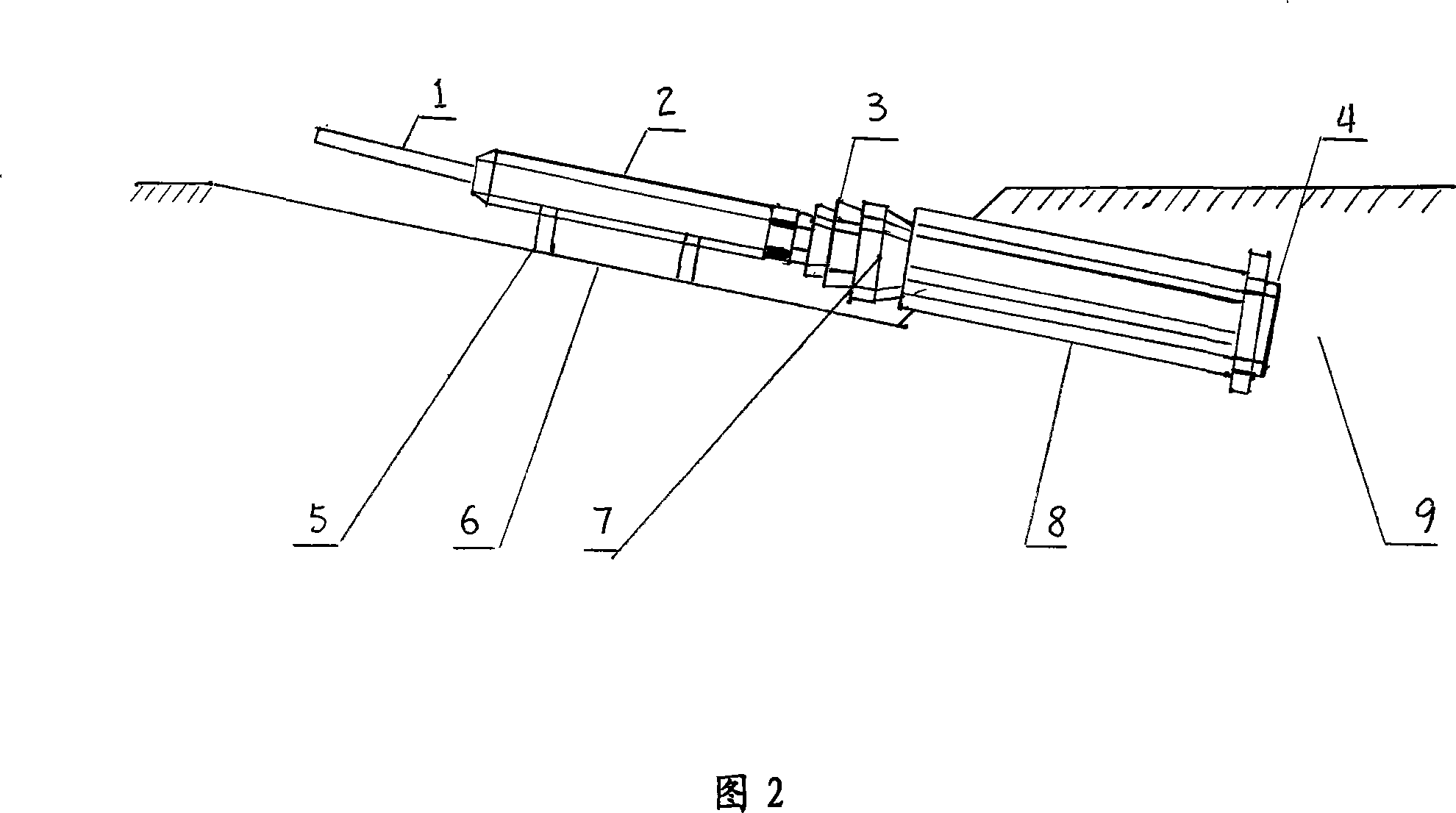

A process for horizontal directional drill passing through and tampering casing for separating gravel

The present invention relates to piping no dig construction technique. The level orienting drill pass through tamping bushing separation egg gravel technique first need to build a work pit, its improvement is that: it has the following steps: (1) laying rail; (2) mounting tamping pipe hammer; (3) tamping steel bushing; (4) digging out earth from the bushing; (5) mounting a central position pipe. The technique combines the tamping bushing construction technique with the level orienting drill construction technique, solves the problem that the construction can not be proceeded caused by the unsteady of the ground at two ends of earth in and out points in the level orienting drill construction, and has the following characteristics: (1) adapting to piping for multiple earth layers, backfill layers, running sand layers and various gravel containing ground layers. (2) The ground will not generate apophysis or sedimentation phenomenon, the ground layer adaptability is strong, piping speed is fast and can be to 25m / h. (3) the construction occupies small ground. The tamping bushing construction work surface is in the orienting drill pass through drill ground, occupies small ground, has small earth cubic, and convenient in operation.

Owner:CHINA PETROLEUM PIPELINE BUREAU

Soil pressure balancing method

ActiveCN106122589AImprove corrosion resistanceImprove hydraulic performancePipe laying and repairSoil scienceUnderground pipeline

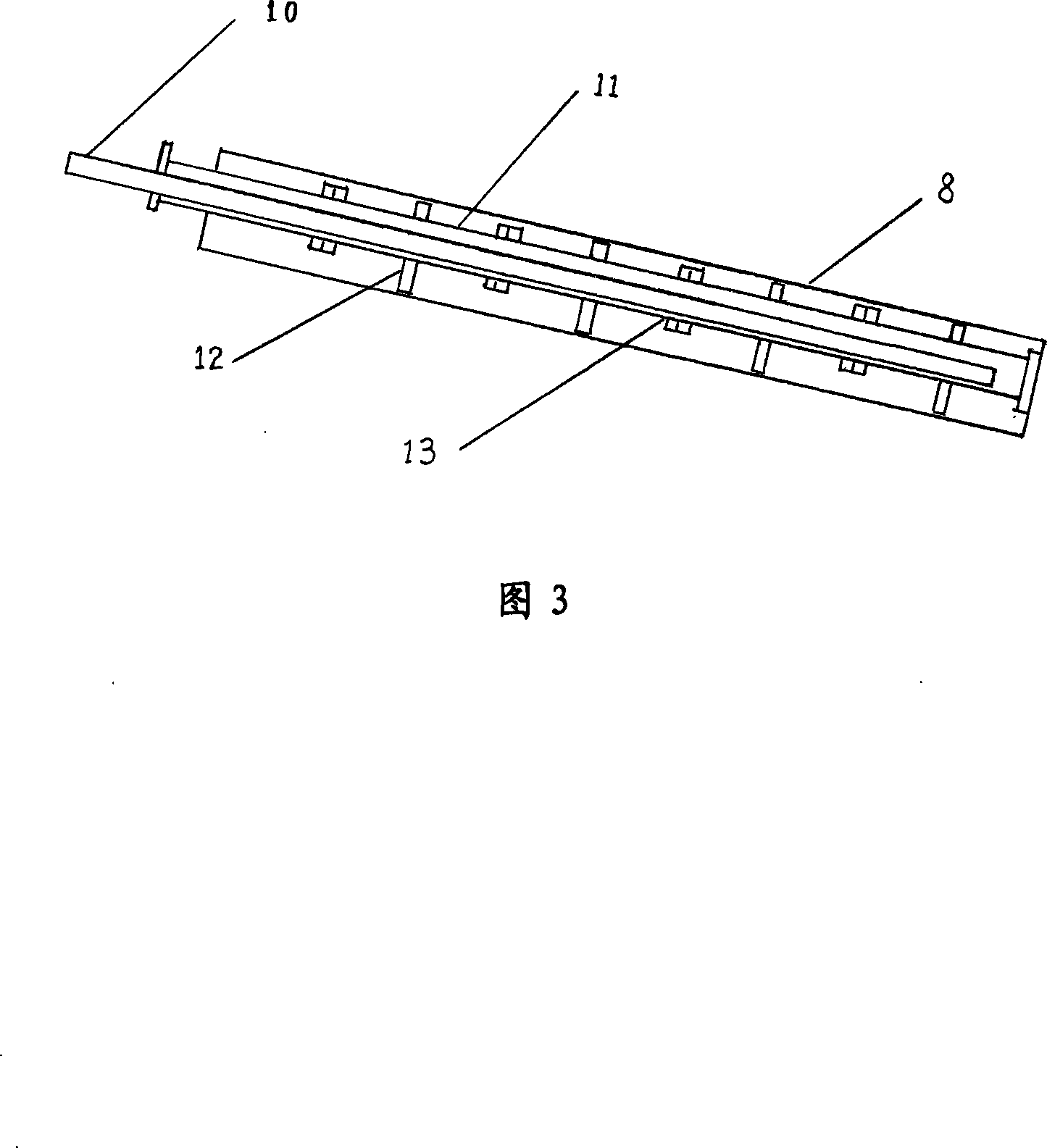

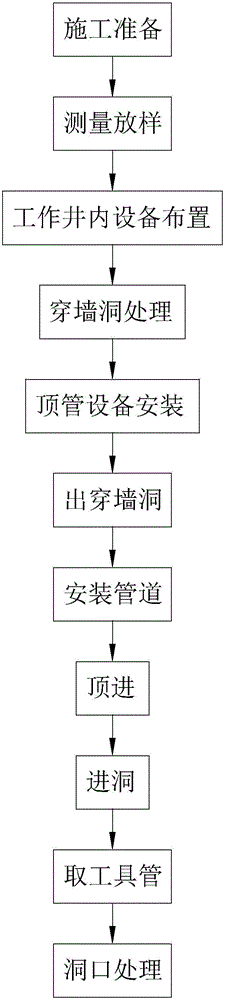

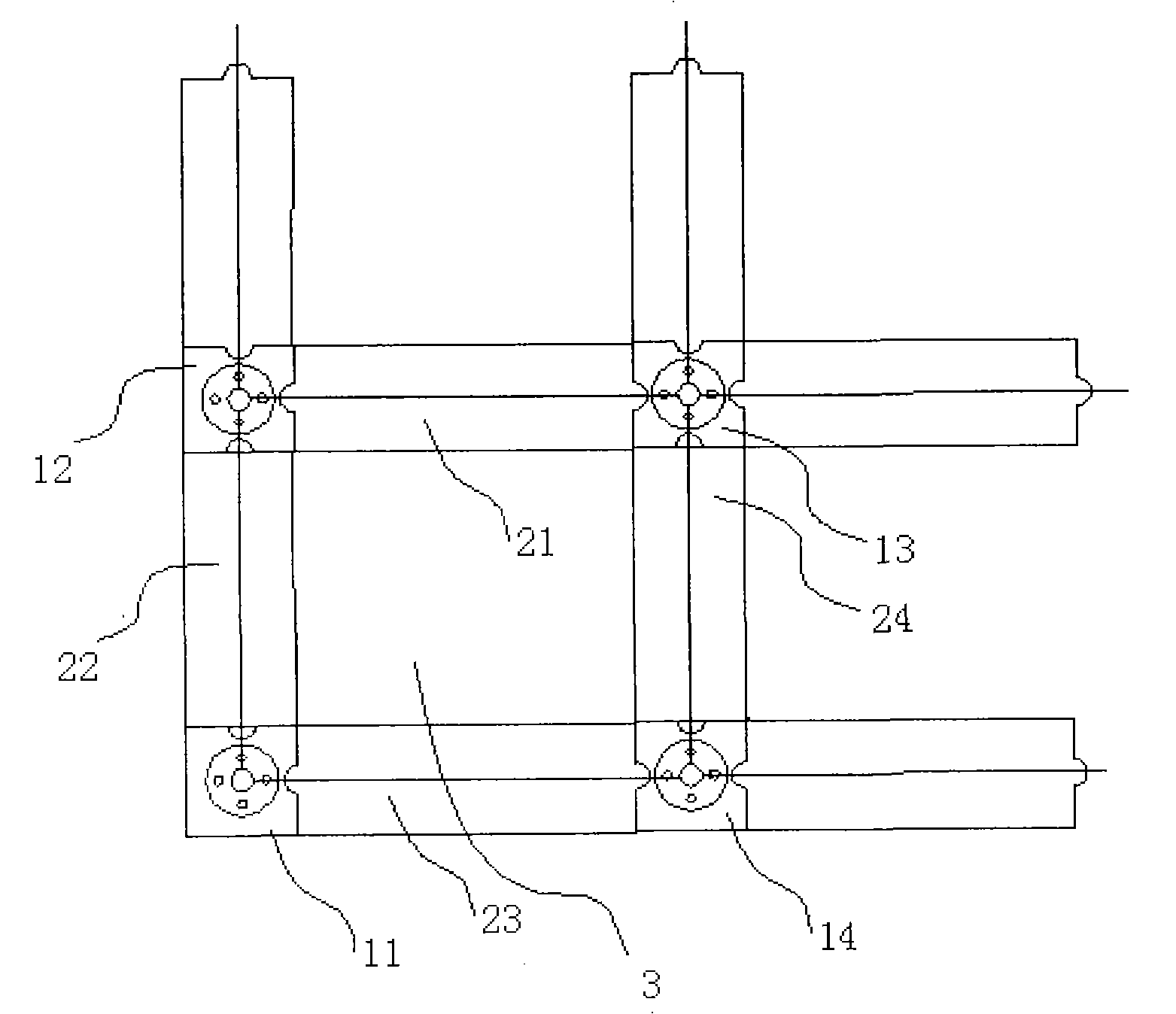

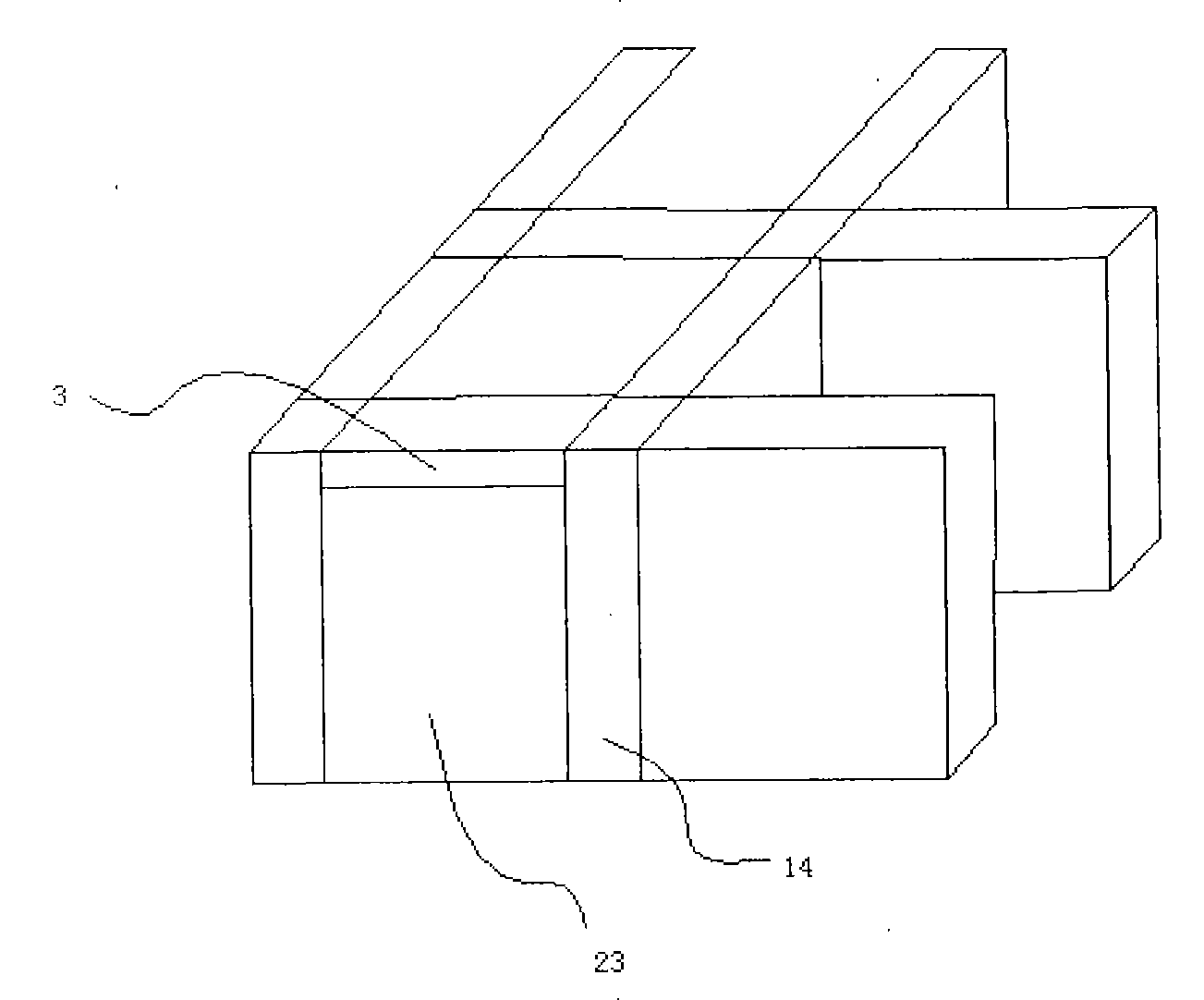

The invention discloses a soil pressure balancing method. The problems that in the jacking pipe operation process, over-excavation and under-excavation may happen when a face earthwork is excavated, a surrounding soil body is likely to be disturbed, the road on the ground is damaged, a building sinks and deforms, and an underground pipeline is broken are solved. According to the technical scheme, the soil pressure balancing method is characterized by comprising the following steps that firstly, construction preparation is made; measuring and setting-out are conducted; thirdly, equipment is arranged in a work well; fourthly, wall penetrating hole treatment is conducted; fifthly, jacking pipe equipment is installed; sixthly, a jacking pipe penetrates out of a wall penetrating hole; seventhly, pipeline installation is conducted; eighthly, jacking is conducted; ninthly, the jacking pipe enters the hole; tenthly, a tool pipe is taken out; and eleventhly, hole treatment is conducted. By means of the soil pressure balancing method, over-excavation and under-excavation generated when the face earthwork is excavated are reduced, the disturbance to the surrounding soil body is reduced, the damage to the road on the ground is reduced, and meanwhile the phenomena that the building sinks and deforms and the underground pipeline is broken are reduced.

Owner:天鸿建设集团有限公司

Fully-fabricated building system with grid steel structure

InactiveCN102174858AMeet different energy saving requirementsMeet energy saving requirementsWallsFloorsSteel frameWall plate

The invention discloses a fully-fabricated building system with a grid steel structure. The system comprises wall plates, a floor plate and load bearing combination columns, wherein each wall plate comprises a grid steel frame and gelatine powder granular layers pressed on the two side faces of the grid steel frame in a casting way; both ends of the wall plate are provided with a bulged clamping head; a door opening is formed on the wall plate on one side; each load bearing combination column comprises a connecting column and a gelatine powder granular layer; the gelatine powder granular layer is arranged adjacent to the outer side at the periphery of the connecting column through press casting to make the cross section of the load bearing combination column rectangular; slots matched with clamping heads at the two ends of the wall plate are formed on two, three or four side faces of the load bearing combination column; the wall plates are clamped together through the load bearing combination columns to form a building; and the floor plate is arranged on the top surfaces of the wall plates. The fully-fabricated building system with the grid steel structure has an environment-friendly building structure which has light weight and is heat-preserving, sound-proof, fire-resistant, rust-proof, load-bearing and quake-proof, has high construction efficiency, saves labor hours, has small construction floor area, does not have dust in a site environment and contributes to civilized construction.

Owner:黄志元

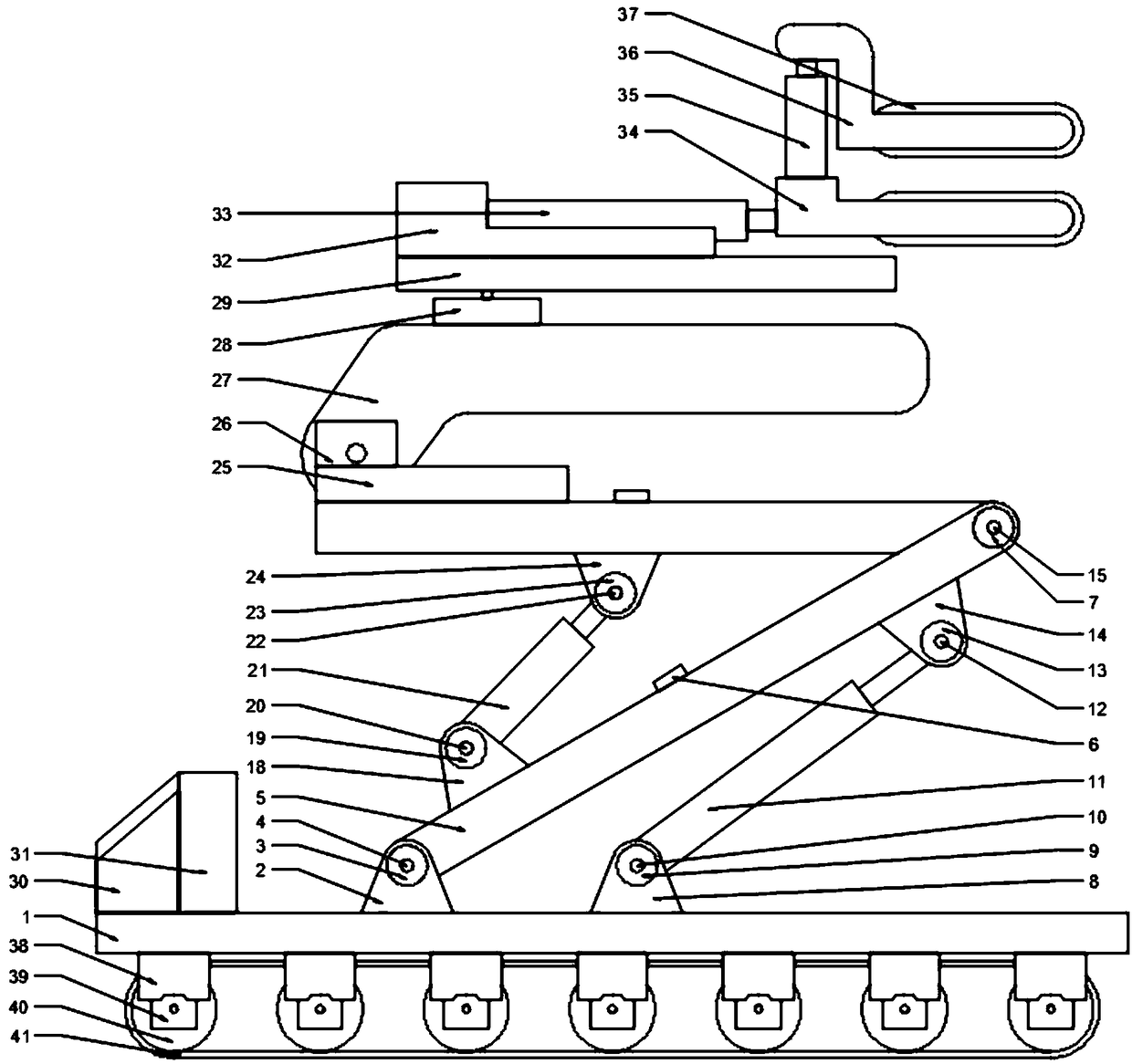

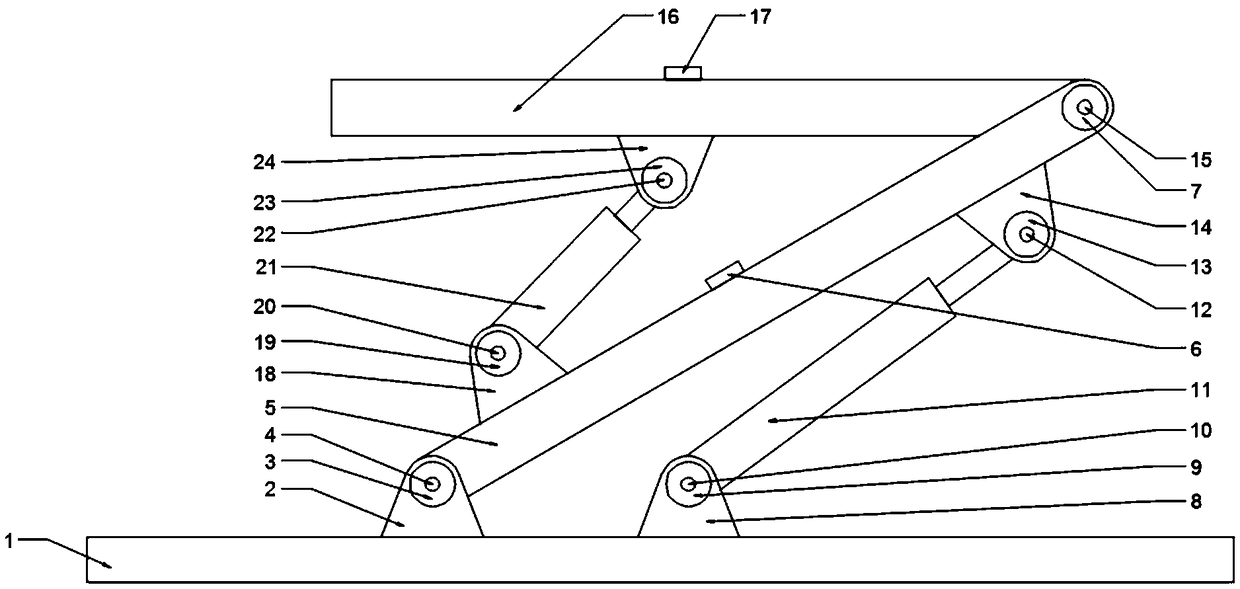

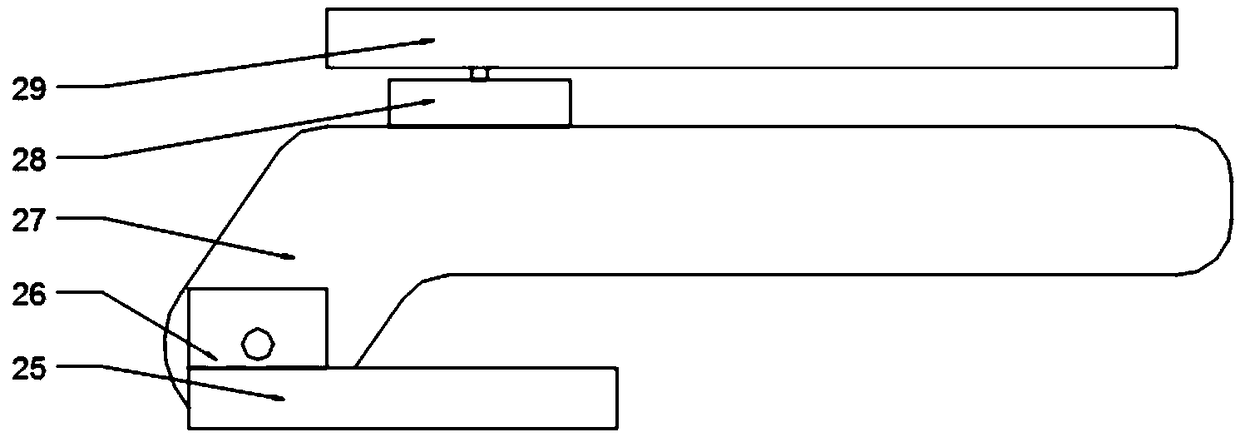

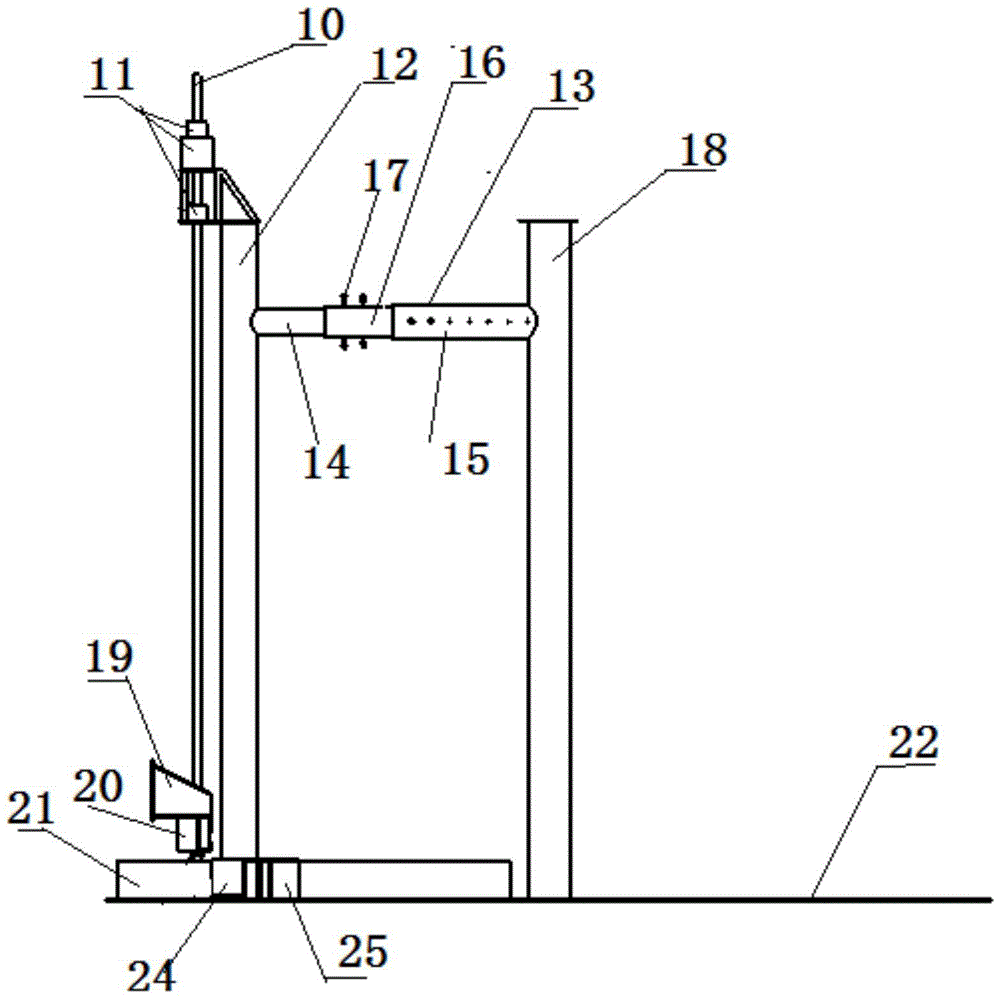

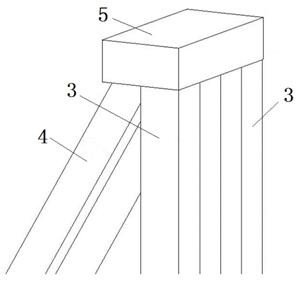

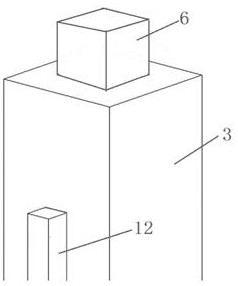

Steel structure cutting demolition vehicle

ActiveCN108756293AConstruction occupies less landBuilding repairsElectric machineryElectrical battery

The invention discloses a steel structure cutting demolition vehicle comprising a base located on the ground. A mechanical arm mechanism is arranged on the base; a cutting platform mechanism is arranged on the mechanical arm mechanism, and a cutting feeding mechanism is arranged on the cutting platform mechanism; a traveling mechanism is arranged on the lower portion of the base, a controller anda battery box are arranged on the base; the power source input end of the controller is electrically connected with the power source output end of the battery box, and the power source output end of the controller is electrically connected with a first mechanical arm linear motor, a second mechanical arm linear motor, a longitudinal cutting angle stepping motor, a transverse cutting motor, the cutting feeding mechanism and the traveling mechanism; and the signal output end of the controller is electrically connected with the first mechanical arm linear motor, the second mechanical arm linear motor, the longitudinal cutting angle stepping motor, the transverse cutting motor, the cutting feeding mechanism and the traveling mechanism. The steel structure cutting demolition vehicle has the beneficial effects of being simple in structure and high in practicability.

Owner:义乌市圣涛装饰有限公司

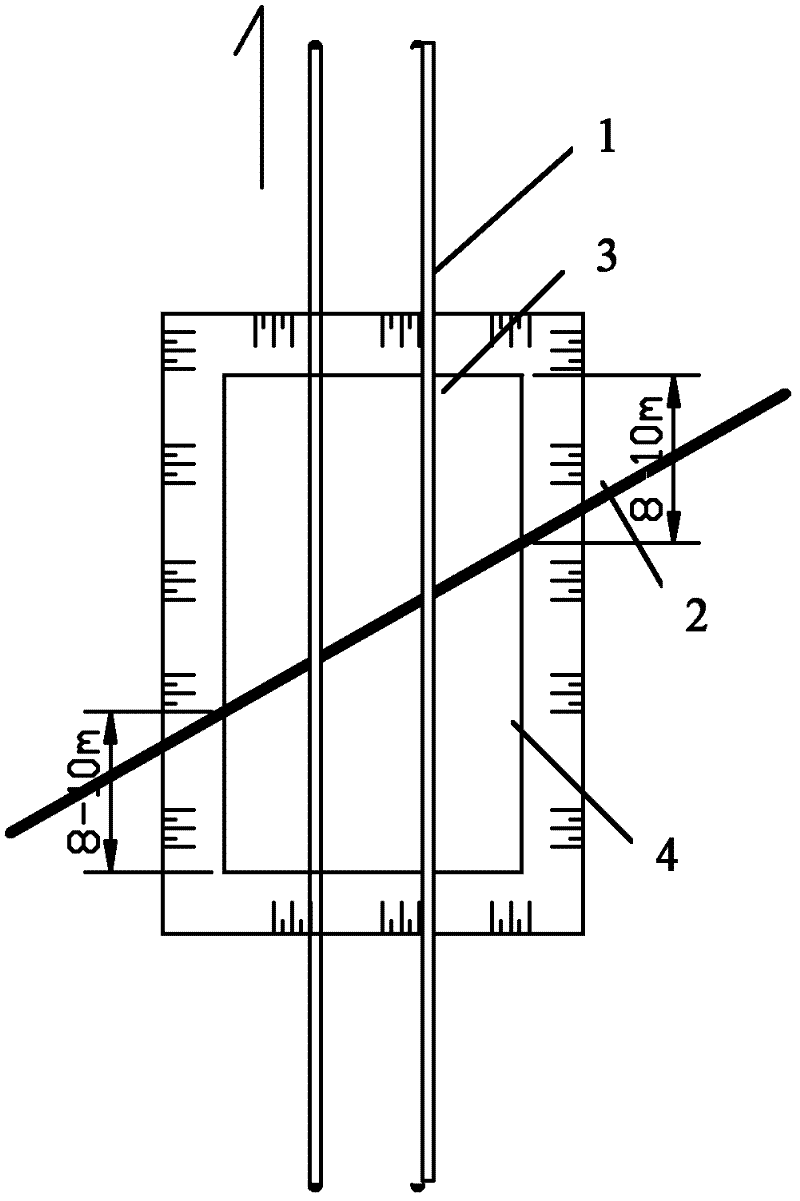

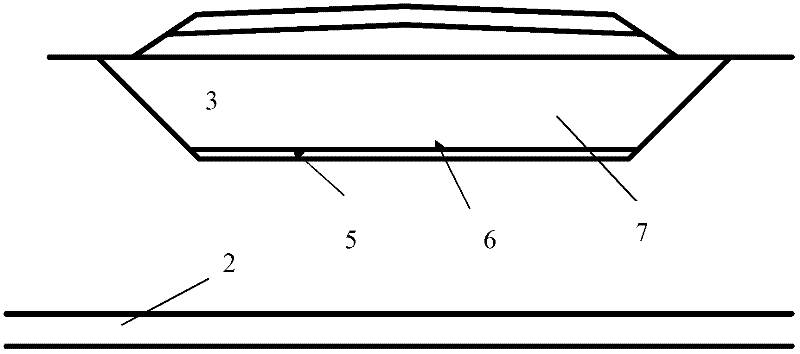

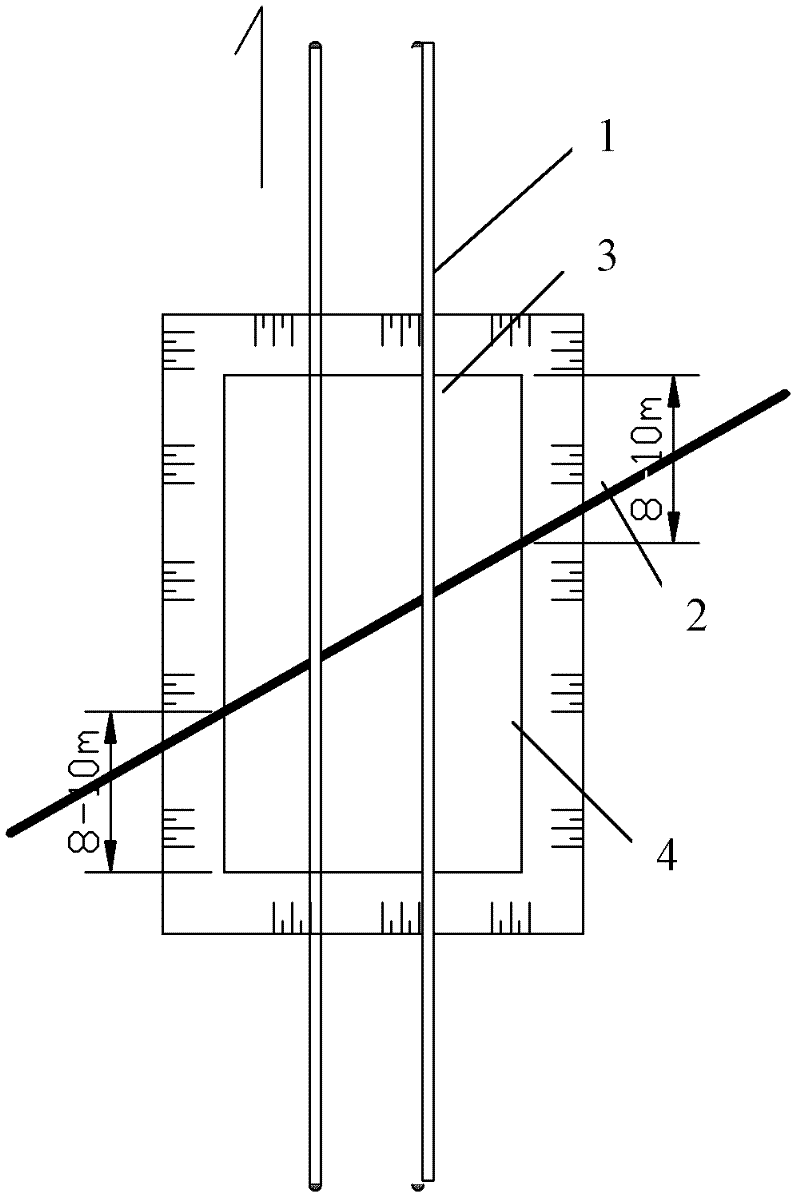

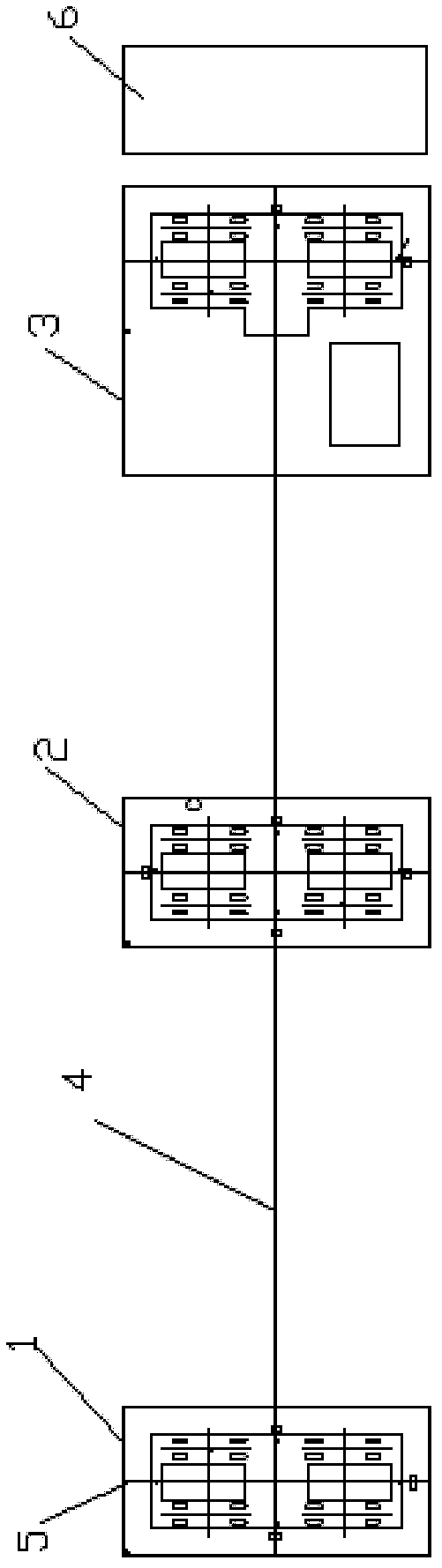

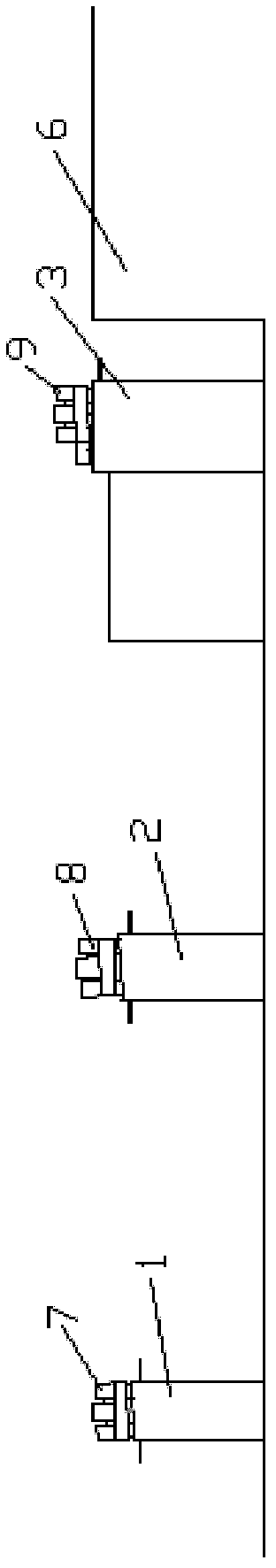

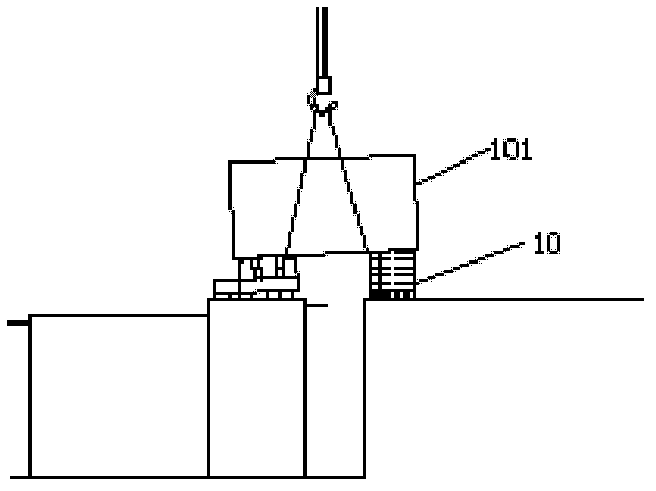

Installation method for rotary kiln for large-sized cement production line

InactiveCN103206852ASave installation timeConstruction occupies less landRotary drum furnacesProduction lineEconomic benefits

The invention discloses an installation method for a rotary kiln for a large-sized cement production line. The installation method comprises the following steps of 1, performing basic preparations and marking off; 2, hoisting riding wheel sets; 3, hoisting a first barrel; 4, hoisting a second barrel; 5, hoisting a third wheel belt; 6, sheathing a gearwheel; 7, hoisting a third barrel; 8, hoisting a fourth barrel; 9, hoisting a fifth barrel; and 10, hoisting a second wheel belt; hoisting a first wheel belt; hoisting a sixth barrel and a seventh barrel; hoisting an eighth barrel; enabling the first wheel belt to be in position; and installing a transmission device of the rotary kiln, an oil tube, a water tube and an air tube and performing test run. The installation method not only is simple but also is time-saving, and construction economic benefits can be directly provided.

Owner:SINOMA SUZHOU CONSTR

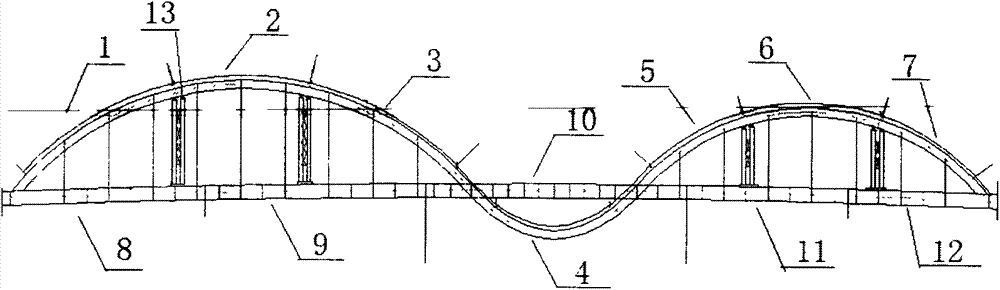

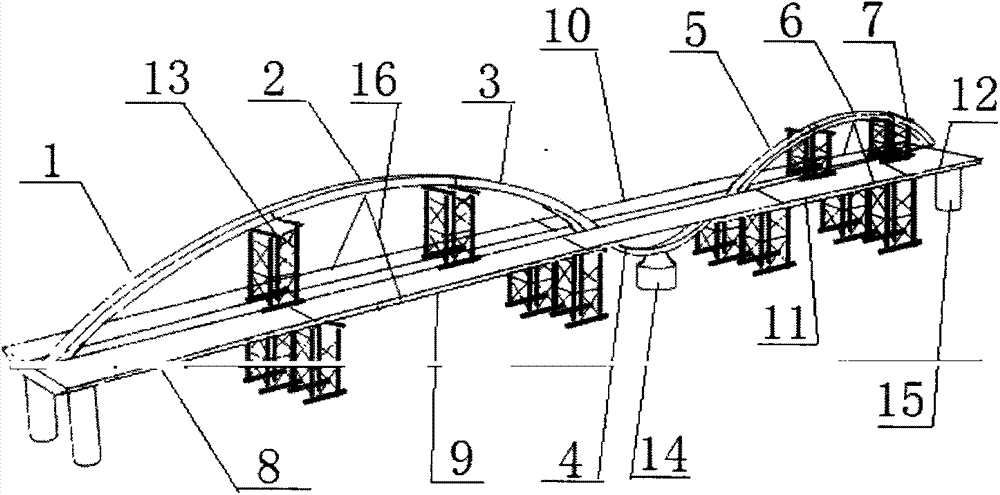

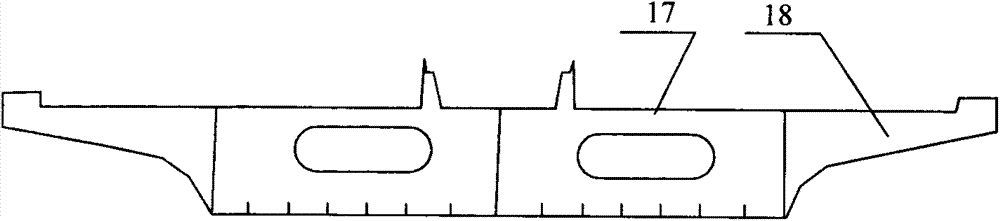

Arched beam combination bridge lifting construction method

Owner:YONGSHENG CONSTR GRP

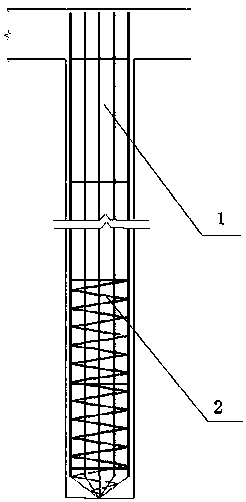

High pressure rotary jet grouting pile construction method for power transmission line iron tower pile foundation construction

The invention discloses a high pressure rotary jet grouting pile construction method for power transmission line iron tower pile foundation construction. The high pressure rotary jet grouting pile construction method is specifically performed according to the following steps of: (1) measuring a pile placement position; (2) mounting a drill; (3) drilling; (4) arranging a pile driver in place; (5) performing jet testing on the ground; (6) preparing slurry; (7) performing rotary jet grouting; (8) performing backfill grouting; and (9) washing grouting pipe machine equipment by using clear water. According to the high pressure rotary jet grouting pile construction method for the power transmission line iron tower pile foundation construction, a continuously lap-jointed cement reinforcing body can be formed; and the method has the prominent advantages of small occupation of land for construction, small vibration, low noise and the like. Meanwhile, attention is required to be paid to environmental pollution, the construction cost is controlled, and the method is prevented from being used under the special soil condition that the jetted slurry cannot be solidified as much as possible.

Owner:STATE GRID CORP OF CHINA +1

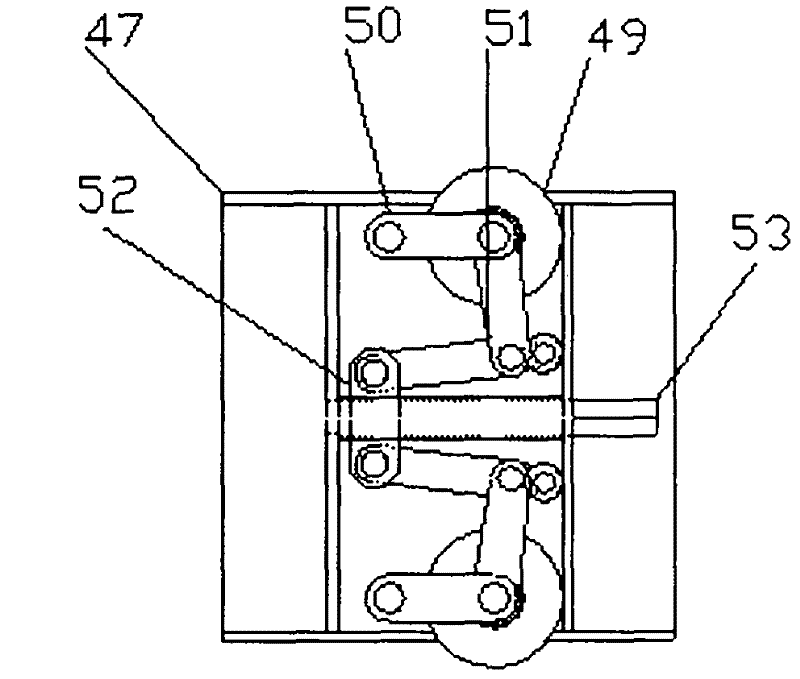

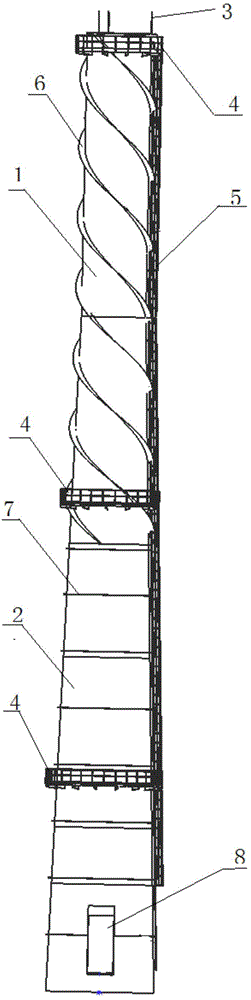

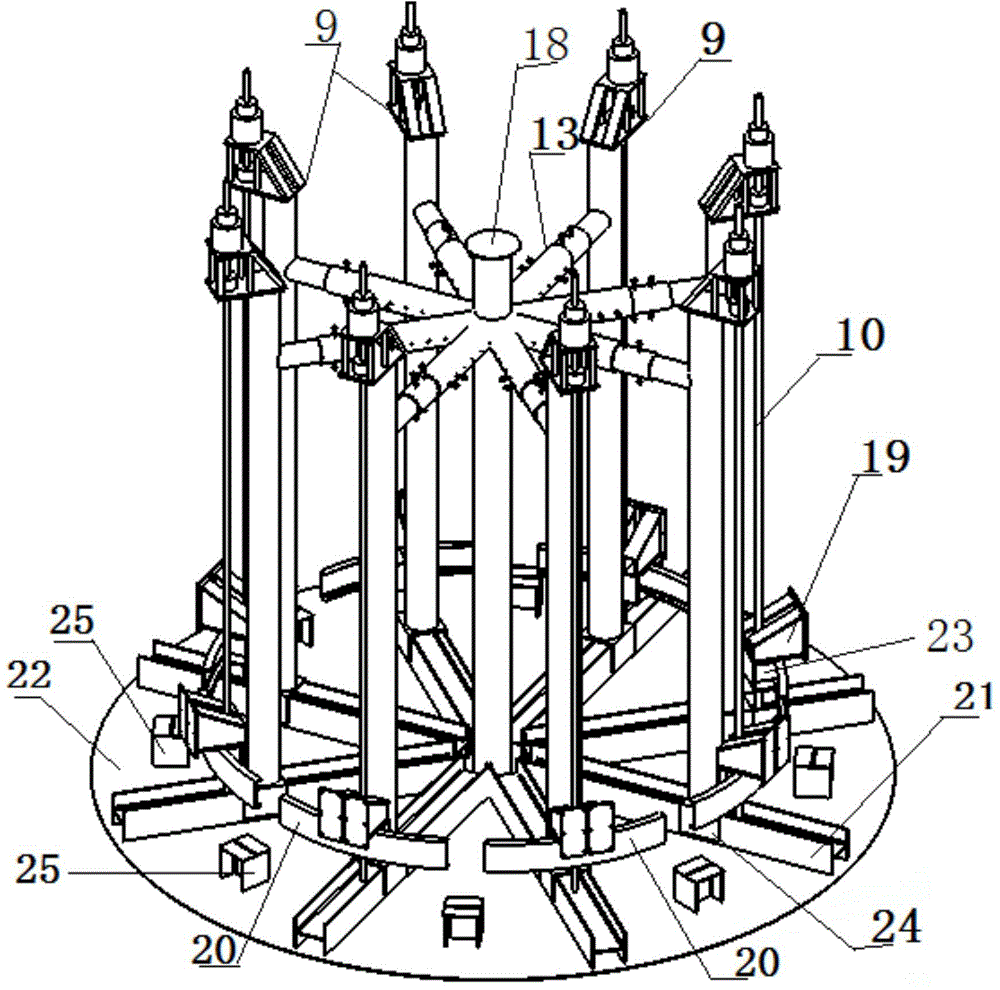

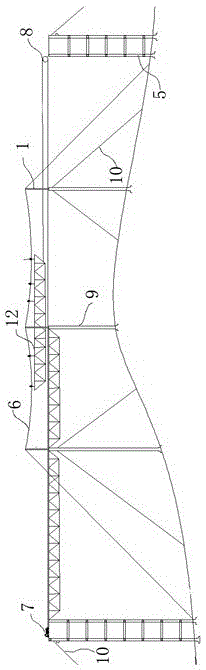

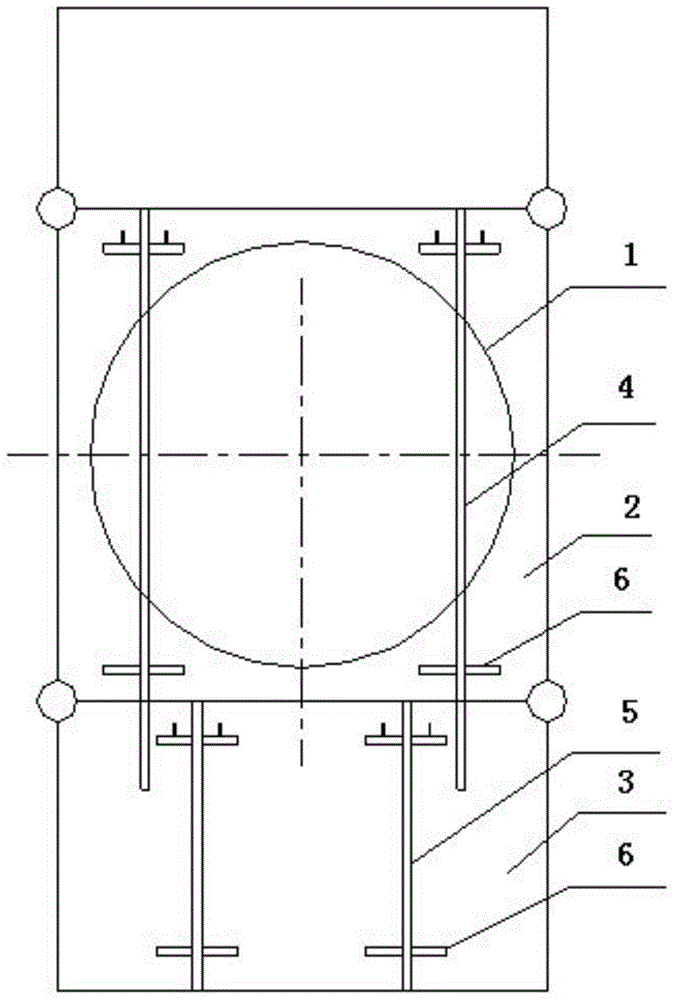

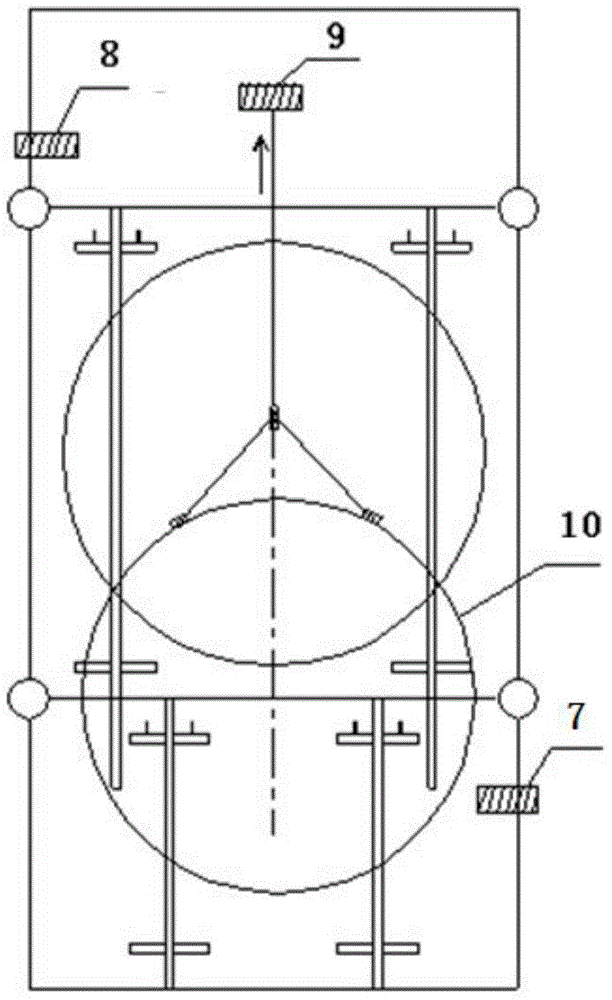

Reversed assembling method of upright cylindrical equipment

The invention discloses a reversed assembling method of upright cylindrical equipment; the upright cylindrical equipment consists of a pillar section and a tapered section; the reversed assembling method employs a hydraulic hoisting device for assembling; the hydraulic hoisting device comprises a horizontally arranged base plate, a central pillar, a plurality of cylindrical section wall plate buttresses and a plurality of hoisting mechanisms; in the process of assembling the tapered section of the equipment, the distance from the hoisting mechanisms to the central pillar needs to be adjusted based on the diameter changes of the tapered section of the upright cylindrical equipment. All assembling works of the equipment are implemented in a range of 2 meters above the ground without building up an overhead butt joint welding platform; therefore the danger of dismantling the temporary overhead platform and the potential safety hazard of work staff climbing up and down the overhead platform do not exist, thus greatly increasing the safety; the construction quality is easy to be ensured; land occupied by construction can be reduced; heavy hoisting equipment is not necessary; the construction cost is reduced; and the construction period is saved; the reversed assembling method has a wide application range.

Owner:TIANJIN 20 CONSTR

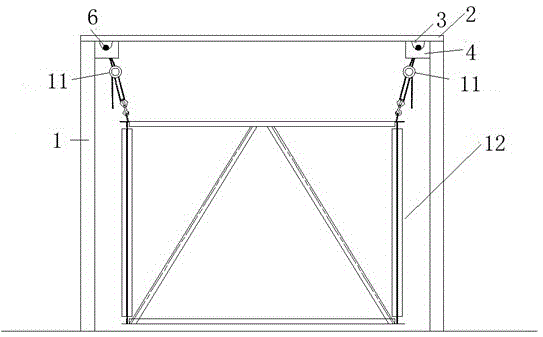

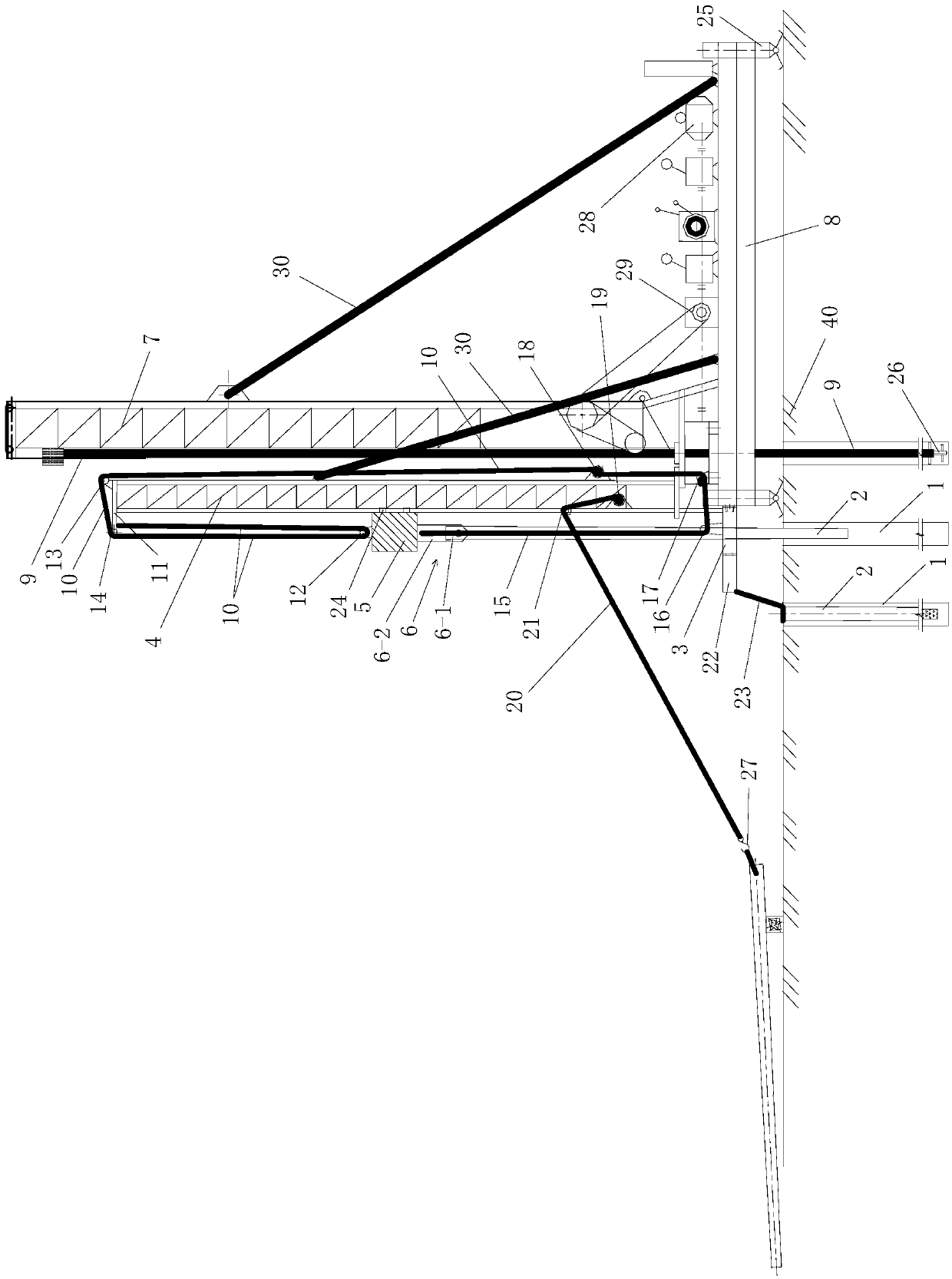

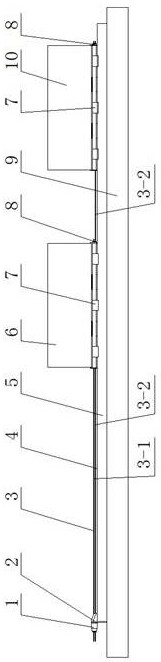

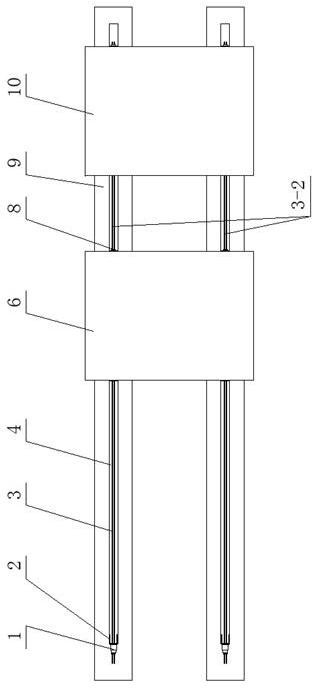

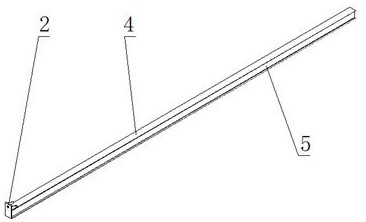

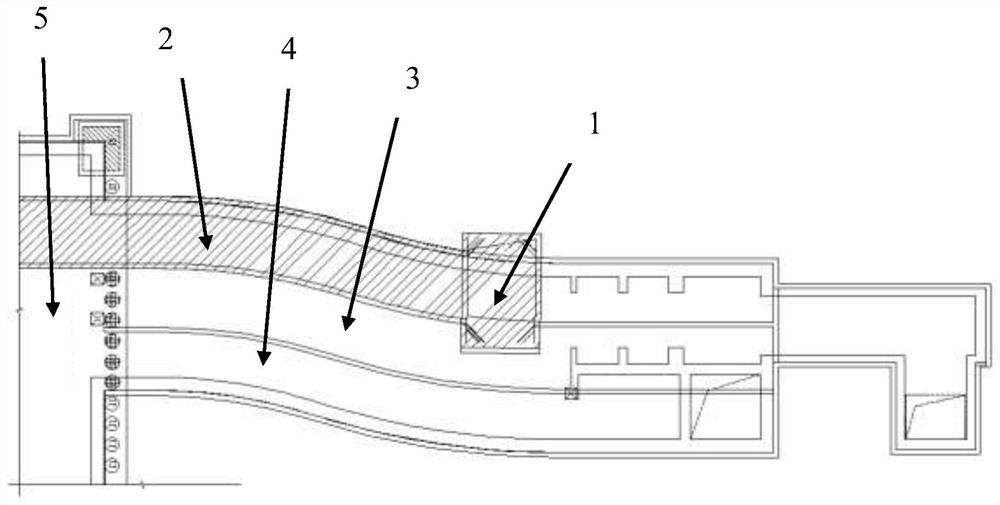

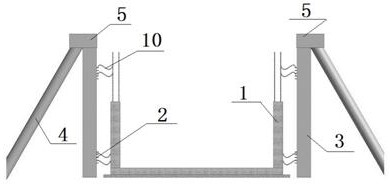

High-altitude sliding hoisting device of corridor truss of mountain and implementing method of high-altitude sliding hoisting device

ActiveCN105113803AConstruction occupies less landSave on transportation costsBuilding material handlingEngineeringPulley

The invention discloses a high-altitude sliding hoisting device of a corridor truss of a mountain and an implementing method of the high-altitude sliding hoisting device. The problem that a crane hoisting mode or a climbing pole hoisting mode cannot be used in a cliffy mountain in the prior art is solved. The high-altitude sliding hoisting device of the corridor truss of the mountain comprises supports, a sliding frame, a sliding rope and a traction mechanism; the supports are arranged at two ends of a mounting platform; the sliding frame is arranged on the top of the mounting platform and consists of upright columns; the sliding rope and the traction mechanism are used with the sliding frame; a crossbeam is arranged on tops of each two upright columns at the same end; rib plates with through holes are arranged on each crossbeam and are close to positions where the crossbeam is connected with the corresponding upright columns; the sliding rope penetrates in the rib plates on the tops of two ends of the sliding frame; two tips of the sliding rope are anchored to the support; and the corridor truss is positioned in the sliding frame, is dragged by the traction mechanism, and moves on the sliding rope through a movable pulley mounted on the sliding rope. By the high-altitude sliding hoisting device, technology quality of manufacturing assembly and hoisting of the corridor truss is ensured, construction safety and precision are ensured, construction cost is reduced greatly, and construction period is shortened.

Owner:CHINA MCC5 GROUP CORP

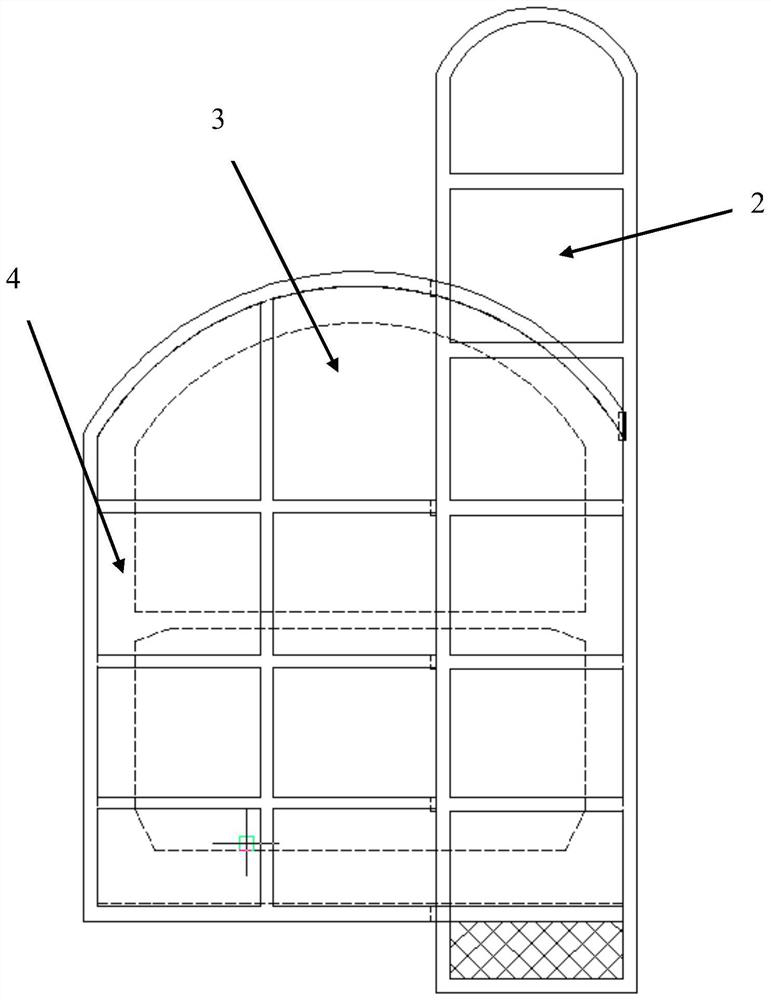

Construction method of lightweight concrete batten partition door opening

ActiveCN109339632AEasy to transportLight weightFrame fasteningWindow/door framesLintelEnergy analysis

The invention discloses a construction method of a lightweight concrete batten partition door opening. Galvanization square steel pipes are adopted to replace concrete structural columns / jamb on dooror window and concrete lintels. The construction method has the advantages that construction is convenient, the construction quality is high, the construction period is short, energy is saved, and environment protection is achieved.

Owner:CSCEC CITY CONSTR DEV +1

Slag trough structure and construction method for same

The invention discloses a slag ditch structure and a construction method thereof, belonging to the field of foundation pit construction. It includes support beams and slag ditch walls. Support piles are arranged outside the slag ditch walls, and support beams are arranged between the support piles. The supporting piles include water-stop piles and water-stop curtain piles, and the water-stop curtain piles are arranged between two adjacent water-stop piles. The supporting piles are bored cast-in-place piles, which are drilled with a drilling rig, then the steel cage is lowered into the hole, and concrete is poured. During the construction of the supporting piles, the pile position, the elevation of the top and bottom of the pile, the specific gravity of the mud, and the quality of the underwater concrete are strictly controlled. The number of water-stop piles is set to more than two rows, which is to strengthen the water-stop effect, and the water-stop piles can also play a role in resisting the lateral pressure of the soil. It can prevent water from entering the slag ditch, and can also bear the side pressure of the soil. The high-pressure rotating nozzle sprays the cement slurry into the soil layer and mixes with the soil to form a continuous lapped cement reinforcement. The construction occupies less land, has less vibration and less noise. Low.

Owner:马钢集团设计研究院有限责任公司

High-pressure grouting device for deepwater karst fissure development geology and construction method

PendingCN111005361AEasy constructionConstruction occupies less landSoil preservationDrill holeGeotechnical engineering

Owner:SHANGHAI CIVIL ENG GRP FIFTH

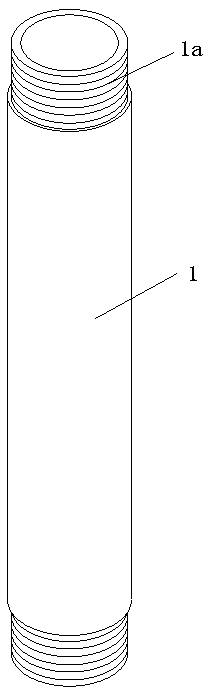

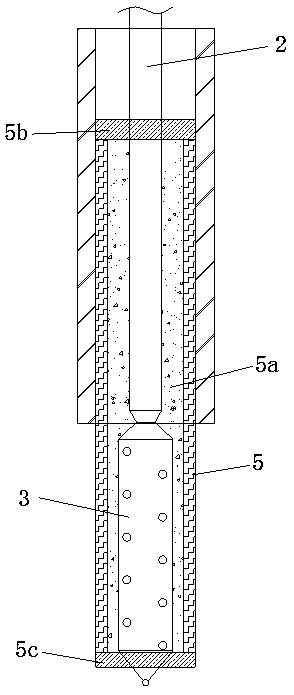

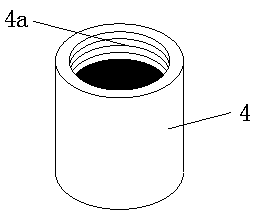

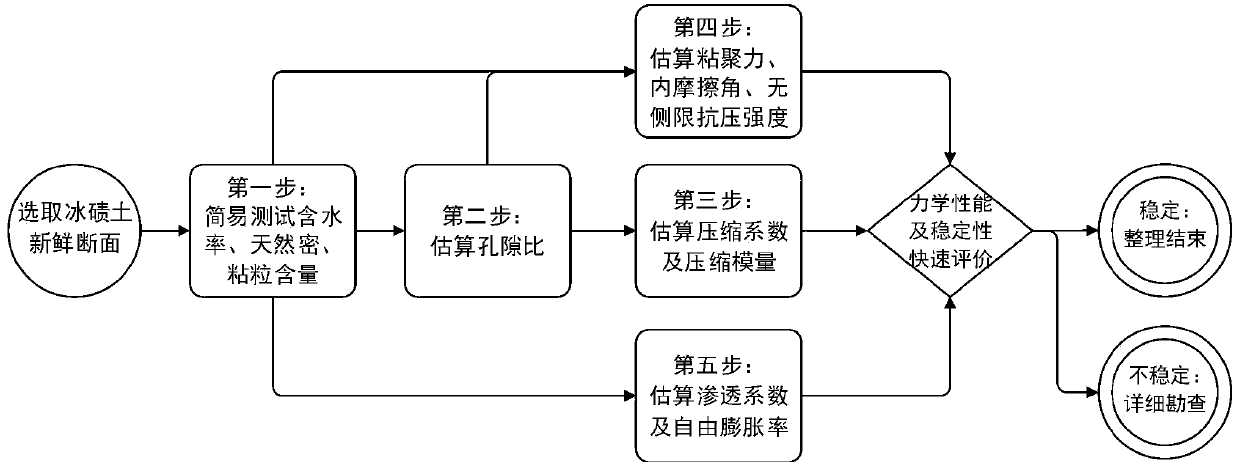

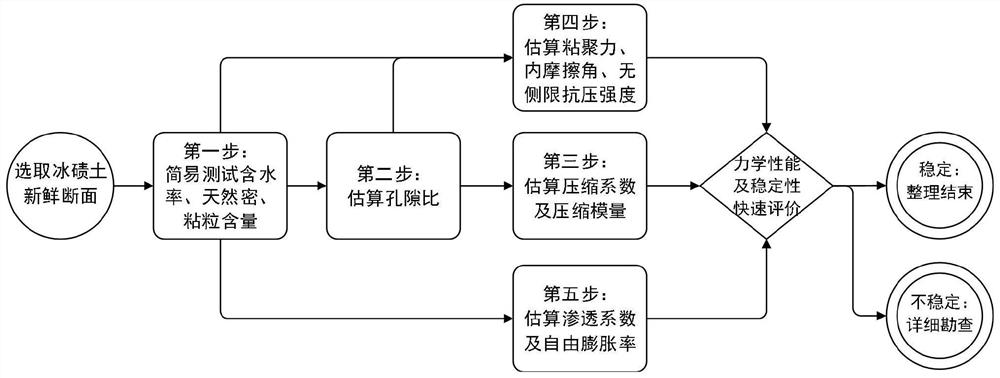

Rapid estimation method for physical and mechanical parameters of tillite soil

ActiveCN110210173AQuick estimateShorten the construction periodGeometric CADDesign optimisation/simulationWater contentCost (economic)

The invention provides a rapid estimation method for physical and mechanical parameters of tillite soil, which summarizes the statistical relationship between the moisture content, the porosity ratio,the clay content and other physical and mechanical parameters through a large amount of field tests in the early stage and data analysis of indoor tests. The method comprises the following steps: firstly, simply testing the water content, the natural density and the clay content of a fresh section of a tillite soil accumulation body; estimating other relatively complex engineering mechanical indexes such as the porosity ratio, the compression index, the shear strength, the compressive strength, the permeability and the expansibility according to the test data statistical relational expressionamong the parameters, so as to quickly and preliminarily evaluate the field stability; and then according to an evaluation result, selecting a dangerous site in a targeted manner for detailed exploration. Compared with the prior art, the method has the advantages that the working period of exploration and evaluation can be shortened, the types and processes of parameter testing are reduced, the economic cost is reduced, and the method has remarkable applicability advantage for exploration and evaluation of tillite soil in marine glacier areas with high alpine regions, high altitudes and severe topographic conditions in the southeast of Tibetan Province.

Owner:INST OF EXPLORATION TECH OF CHINESE ACAD OF GEOLOGICAL SCI +1

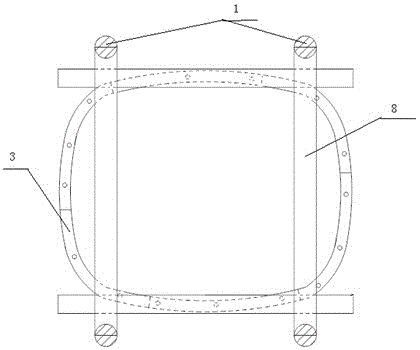

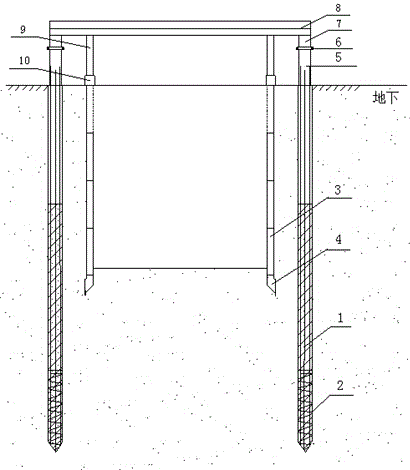

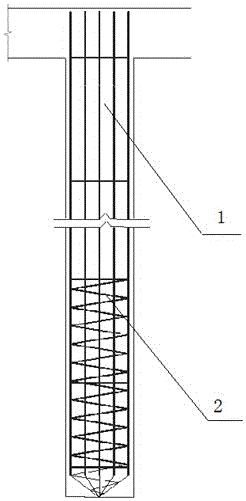

Construction device of active assembling type open caisson and construction method using same

ActiveCN105951863AImprove mechanical performanceImprove structural stabilityCaissonsRebarStructural stability

The invention provides a construction device of an active assembling type open caisson and a construction method using same. The construction device comprises pouring piles, first steel pipes, second steel pipes, flange plates, upper pressing rods and oil pickaxe jacks, wherein a plurality of pouring piles are mounted around a mounting position of the active assembling type open caisson; first reinforcing steel bars are welded to the first steel pipes; two I-steels are overlapped and welded at the upper parts of the pouring piles to be used as the upper pressing rods, and the upper pressing rods are welded to the second steel pipes; the first steel pipes and the second steel pipes are connected through the corresponding flange plates; one or a plurality of oil pickaxe jacks are mounted below the upper pressing rods. The construction device has a plurality of advantages, such as that the overall stressing performance is outstanding, the structure stability is high, the construction area can be effectively reduced, the construction process is simple, the energy can be saved, the environment is protected, the construction safety coefficients are high, the construction time can be greatly decreased, the construction workload can be reduced, the applicable scope is wide, the stability in a special geological condition is outstanding, and the quality, the safety and the environment can be ensured.

Owner:BEIJING NO 4 MUNICIPAL CONSTR ENG +1

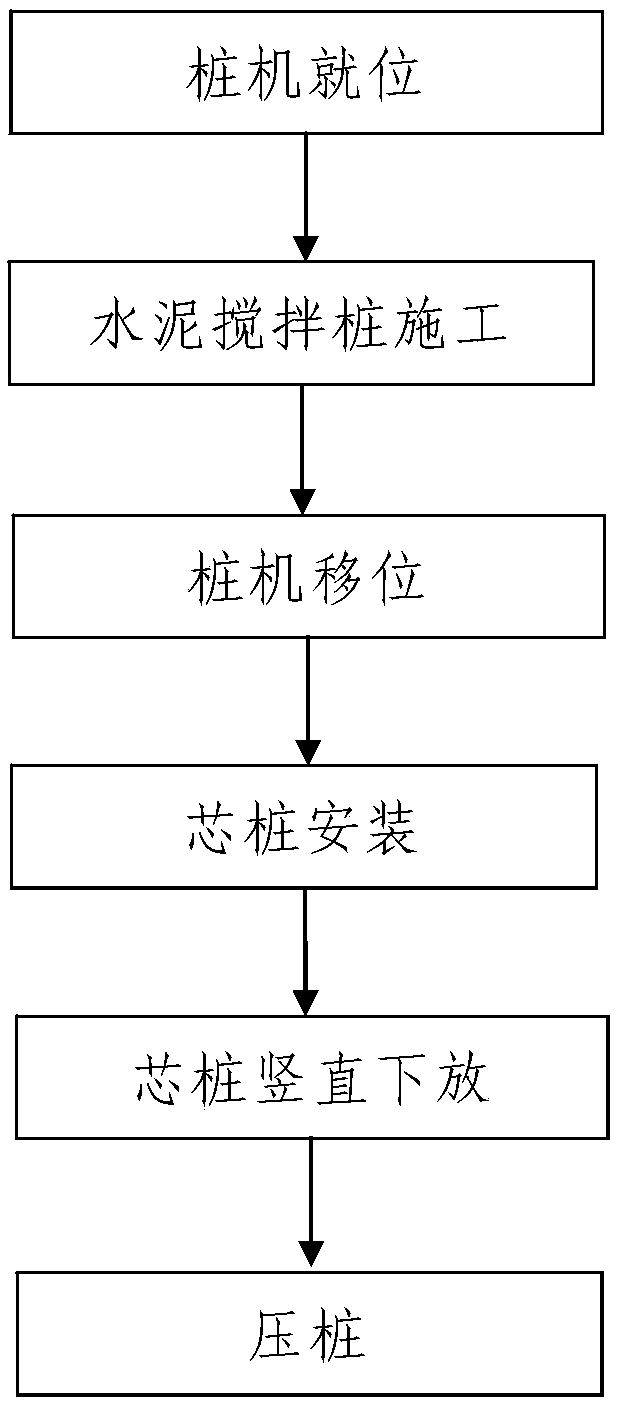

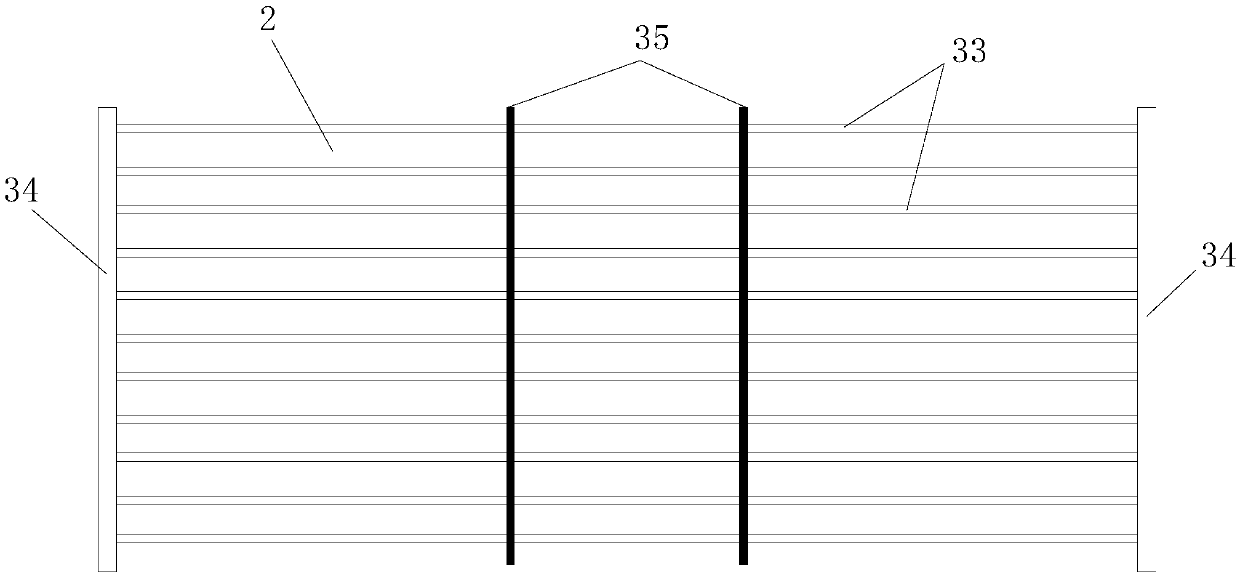

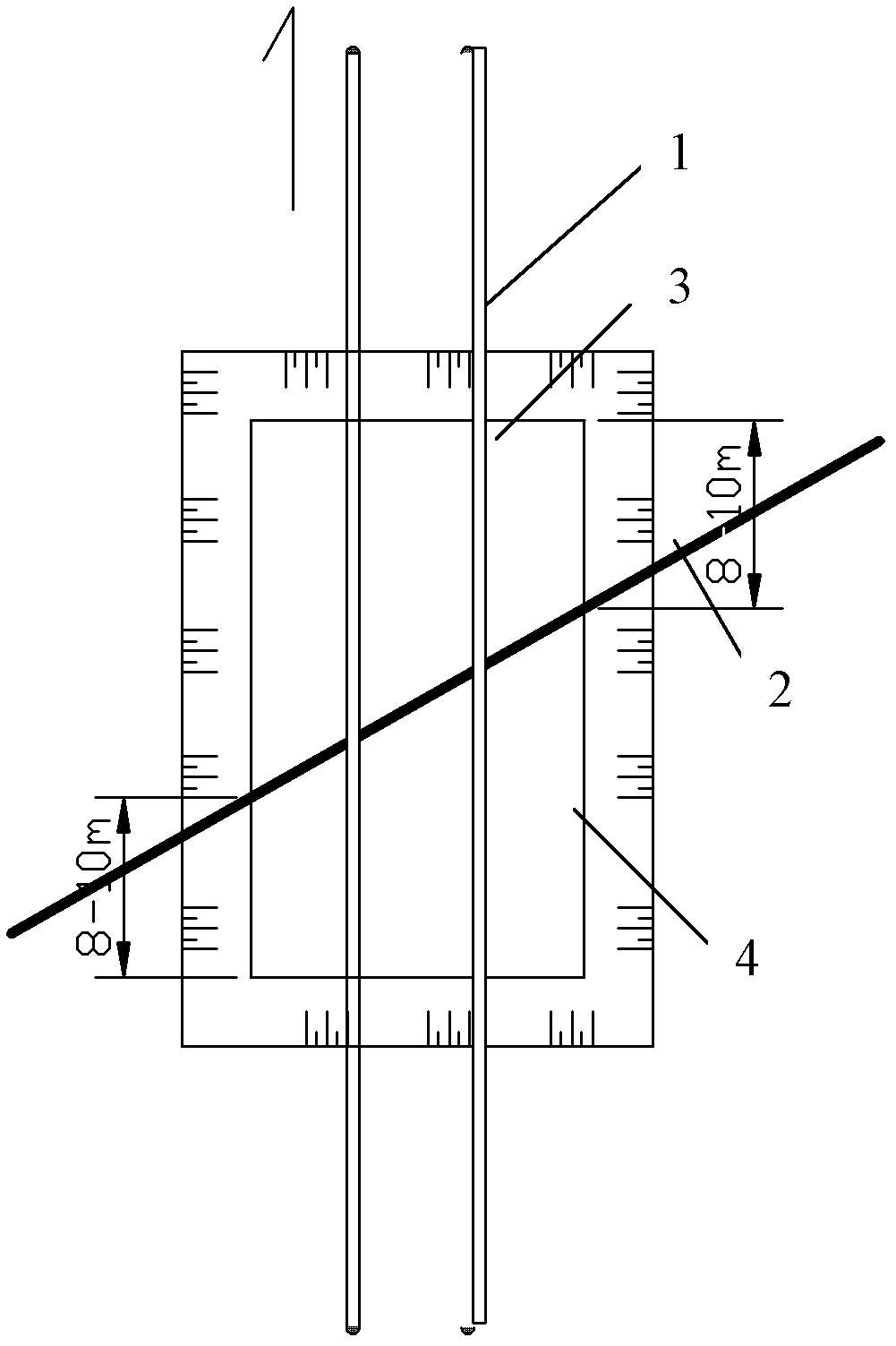

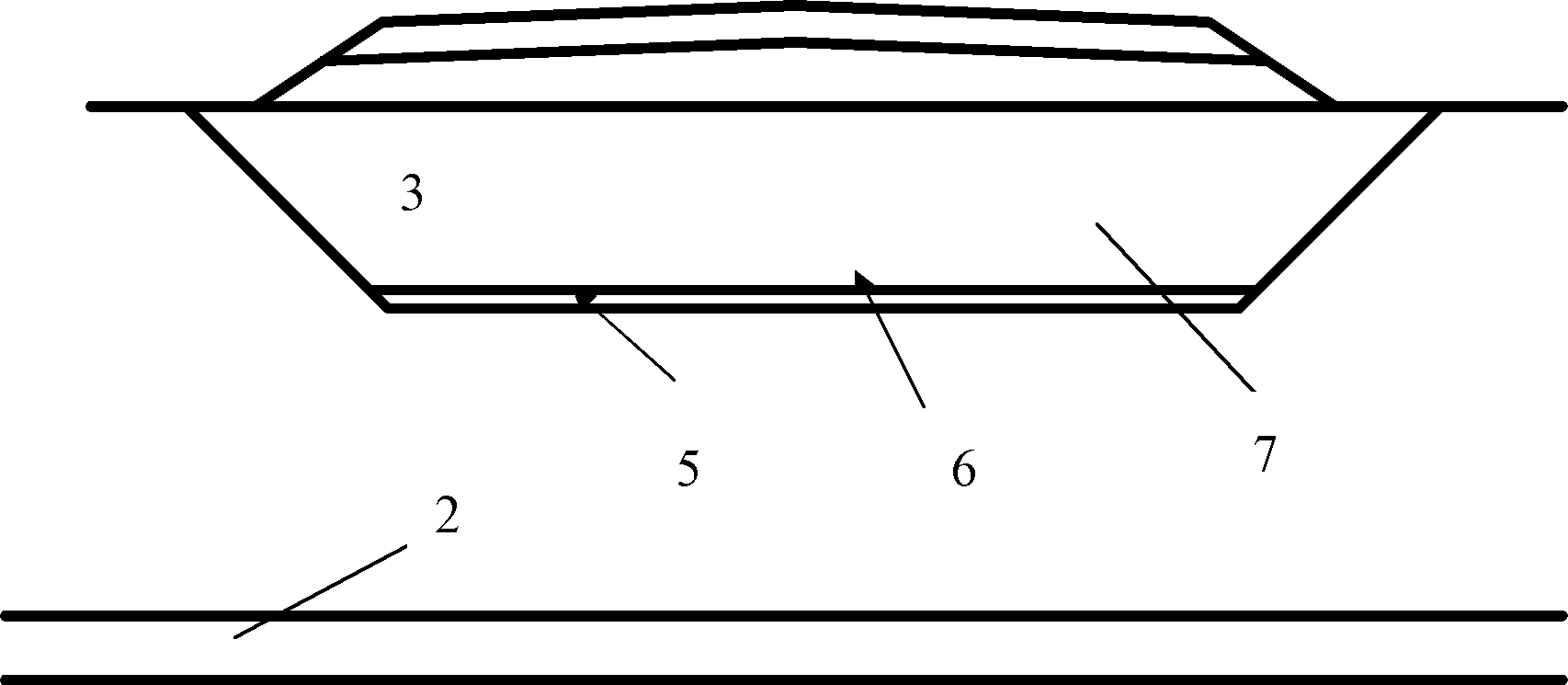

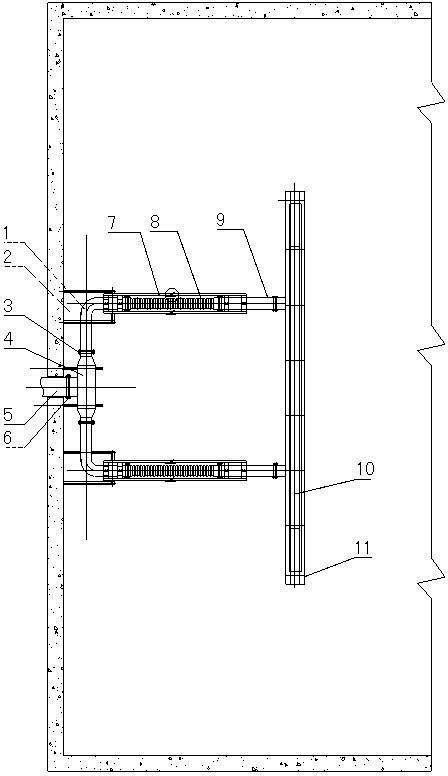

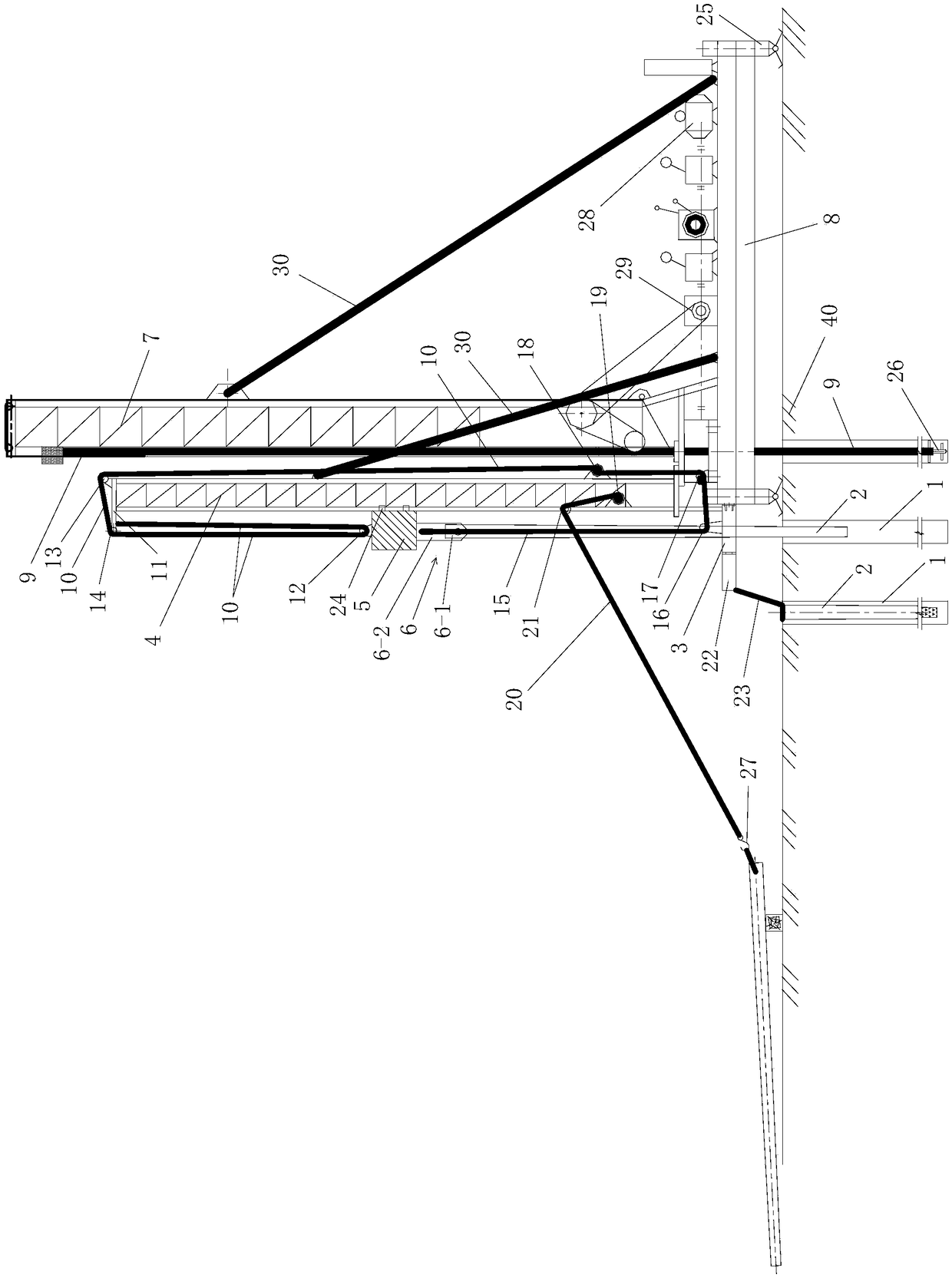

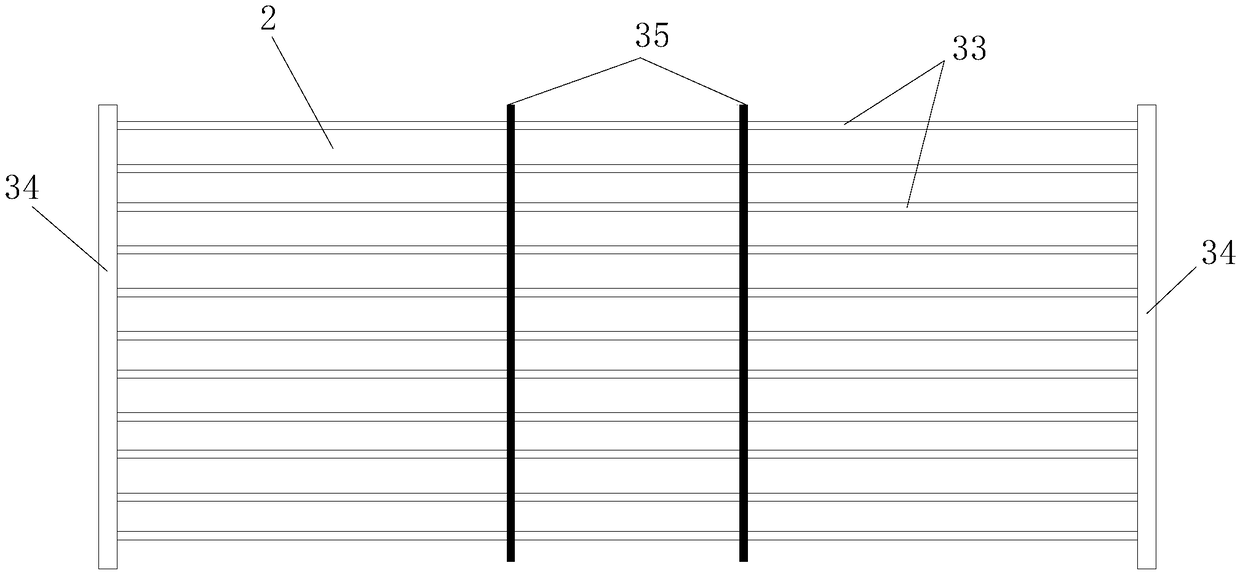

Cement concrete cored pile construction integrated type cored pile driver and construction method thereof

PendingCN109098176AReasonable structural designEasy to useBulkheads/pilesSoil preservationTreatment effectCement

The invention discloses a cement concrete cored pile construction integrated type cored pile driver. The cement concrete cored pile construction integrated type cored pile driver comprises a mixed pile machine for implementing construction of cement mixed piles, and a pile driving device for pressing core piles into cement-mixed piles, wherein the pile driving device is mounted onto the mixed pilemachine and comprises a pile driving platform, a vibrating hammer, a guiding rack for guiding the vibrating hammer, and a pile conveyer arranged at the bottom of the vibrating hammer. Meanwhile, theinvention also discloses a cement concrete cored pile construction method. The cement concrete cored pile construction method comprises the steps of setting of the mixed pile machine, construction ofthe cement-mixed piles, displacement of the mixed pile machine, installation of the core piles, vertical driving of the core piles and pile pressing. The cement concrete cored pile construction integrated type cored pile driver is reasonable in design, simple in construction, high in construction efficiency and good in use effects, capable of completing construction of the cement-mixed piles and pressing of the core piles during construction of cement concrete cored piles, and high in construction speed; meanwhile, during the pile pressing process, the perpendicularity of the core piles is easy to control to effectively ensure the quality of the constructed cement concrete cored piles and guarantees the treatment effects of land foundation reinforcement.

Owner:NO 1 ENG LIMITED OF CR20G

Method for reinforcement construction of soft soil foundation by exchange-filling with foam lightweight soil

ActiveCN102505598BMeet the bearing capacity requirementsReduce additional stressRoadwaysLateral displacementUnderground pipeline

The invention discloses a method for reinforcement construction of soft soil foundation by exchange-filling with foam lightweight soil. The method adopts high-strength foam lightweight soil as filler for foundation pits. Due to pumping construction, the construction of a construction road is omitted, the construction floor occupation is small, the construction difficulty is reduced greatly while the construction period is shortened, the post-construction settlement of the filler is eliminated effectively, the additional pressure of foundation to underground pipelines is decreased, the nonuniform settlement and lateral displacement of foundation are suppressed, and the stability of roadbed is improved. Therefore, the method can ensure safety of underground pipelines, but also meet the bearing capacity requirement of foundation.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

Translation device for synchronously replacing new and old components and construction method thereof

PendingCN112796230AShort construction periodThe direction of movement is accurateBridge erection/assemblyBridge strengtheningEngineeringFriction force

The invention discloses a translation device for synchronously replacing new and old components and a construction method thereof. The translation device comprises a slide way and a sliding structure formed by connecting two sliding shoe assemblies, one sliding shoe assembly supports the old component, and the other sliding shoe assembly supports the new component; a counter-force seat is fixed at one end of the slide way and is connected with a traction end, so that the slide way, the counter-force seat and the traction end are connected into a whole; when a traction driving component pulls or pushes a traction component, the old component and the new component are moved together. During construction, the new component is prefabricated beside the old component, after the new component is prefabricated, the prefabricated new component and the old component are placed on the corresponding sliding shoe assemblies respectively, and the new component and the old component are horizontally moved in place through a traction device. The device has the advantages that the counter-force device and the sliding device are connected into a whole, so that sliding friction force (or rolling friction force) between the counter-force device and the sliding device belongs to internal force between the devices, the old component is moved out and the new component is translated in place at the same time through one-time traction, the overall manufacturing cost is low, the construction occupied area is small, and the bridge construction period is short.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

Joint soil nail-reinforcing construction method for foundation micropiles of slope top tower cranes for deep foundation pits

InactiveCN103015449ASafety managementShort construction periodFoundation engineeringElectricityWhole body

The invention discloses a joint soil nail-reinforcing construction method for foundation micropiles of slope top tower cranes for deep foundation pits, which includes the following steps: the site is leveled up, positions where holes need to be drilled are clearly marked, a manual Luoyang shovel or a small drilling machine is adopted to drill the holes, the diameter and depth of each hole need to meet design requirement, and steel pipes need to be inserted into the holes as soon as the holes are drilled, and are centered in the holes; in the injection of cement paste, a plastic pipe is adopted as a conduit, a stop plug is arranged in the orifice of the plastic pipe, and the mixed cement paste is injected to the bottoms of the drilled holes and from the bottoms of the holes to the outside under normal pressure; a tower crane foundation is excavated to a designed elevation, and soil nail hole construction and cement injection are carried out around the foundation pit; exposed soil nail reinforcements and the steel pipes are bound together, and concrete is poured, so that the ends of the soil nails, the steel pipes and the tower crane foundation are formed into a whole body. Since the joint soil nail-reinforcing construction method adopts the Luoyang shovel or the small drilling machine to drill the holes, the safety management of the construction site is benefitted. The steel pipes are directly inserted into the holes. The construction period is short, the consumption of electricity is less, the land occupied by construction is small, and the affection on the surrounding environment is less.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

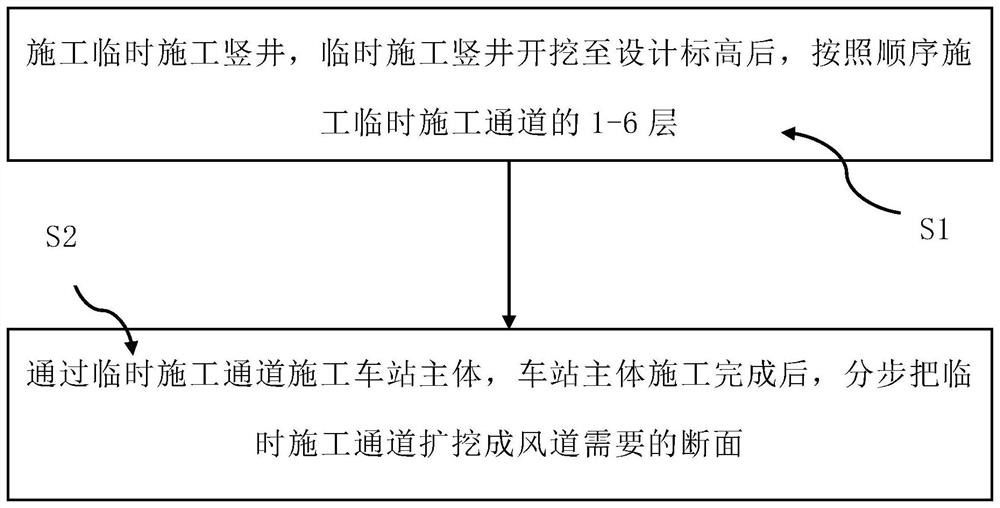

Air duct formed by expanding excavation of multiple layers of temporary construction channels and construction method

InactiveCN111911184AAvoid wastingSolve the problem of occupying space separatelyTunnel/mines ventillationTunnelsArchitectural engineeringStructural engineering

The invention discloses an air duct formed by expanding excavation of multiple layers of temporary construction channels and a construction method, the air duct comprises a temporary construction vertical shaft, one side of the temporary construction vertical shaft is provided with the temporary construction channels, and six layers of temporary construction channels are mounted. Air duct middle pilot tunnels are arranged at the left sides of the temporary construction channels, and four layers of air duct middle pilot tunnels are mounted. Air duct left pilot tunnels are arranged at the left sides of the air duct middle pilot tunnels, and four layers of air duct left pilot tunnels are mounted. A station body is arranged at one sides of the temporary construction channels, the air duct middle pilot tunnels and the air duct left pilot tunnels. By means of the air duct construction method, the problems that in a traditional method, station body construction and air duct construction occupy places correspondingly, construction supporting facilities are arranged correspondingly, economy is poor, and underground space is wasted are solved; and the temporary construction channels for underground excavation of the station body construction is combined with the station air duct, one piece of construction land is saved, a set of construction supporting facilities is saved, the temporaryconstruction channels needing to be abandoned are reasonably utilized, investment is saved, and waste of underground space is avoided.

Owner:SUBWAY ENG CO LTD OF CHINA RAILWAY 16TH CONSTR BUREAU +2

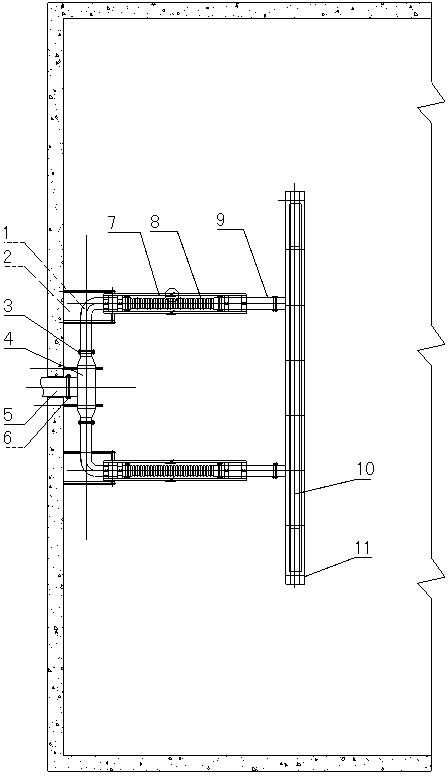

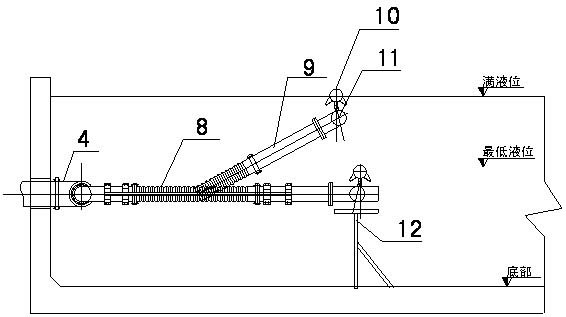

Method for constructing large pontoon-type decanter

ActiveCN102616872AEasy to remove directlyEasy to removeWater/sewage treatmentEngineeringSewage treatment

The invention discloses a method for constructing a large pontoon-type decanter. The method comprises the following steps of: distributing parts to each sewage treatment tank, and transporting to a site; fixedly arranging a decanter bracket at the bottom of the sewage treatment tank, erecting a bracket close to a tank wall provided with a through-wall pipe, arranging the decanter on the decanter bracket, and arranging a bent pipe on the bracket; connecting the through-wall pipe and one end of a water inlet pipe through a flange, connecting the other end of the water inlet pipe and one end of the bent pipe through a connecting bolt, connecting one end of a rubber hose and the other end of the bent pipe, and fixedly connecting the other end of the rubber hose and one end of a decanter steelpipe; connecting the other end of the decanter steel pipe to the decanter, and arranging a decanter pontoon on the top of the decanter; removing the bracket; and performing a full water test. The method has the advantages that by constructing a temporary bracket, the decanter is conveniently and reliably installed; the bracket can be recycled, so that material waste is avoided, cost is low, and construction time is short; the safety factor of each joint is high; and a small area is occupied during construction.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

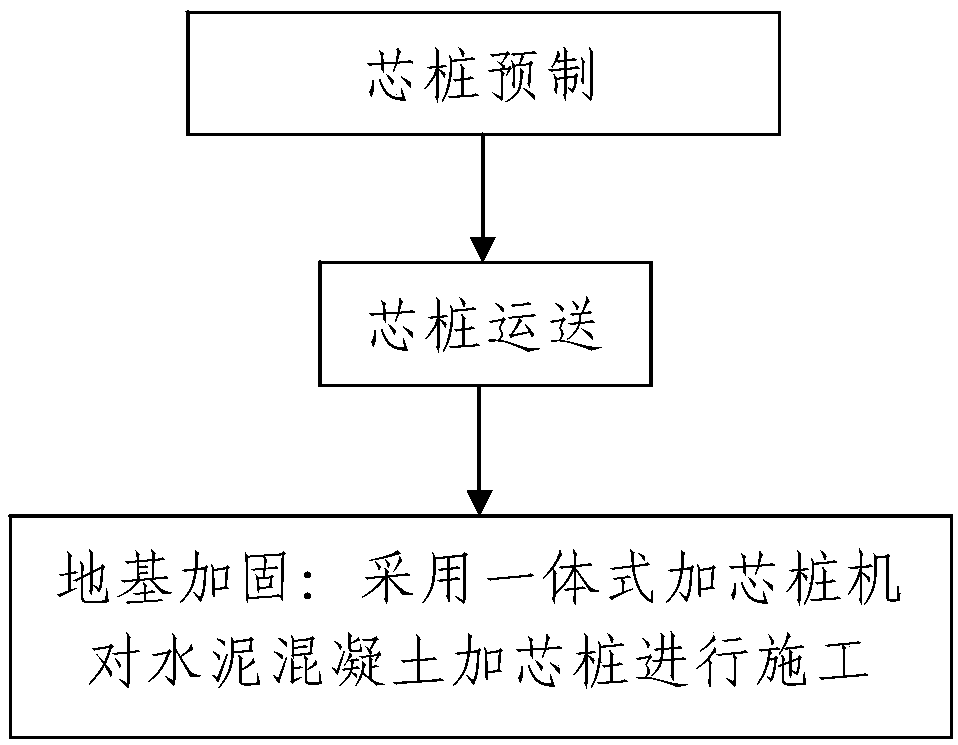

Soft soil foundation reinforcing method based on cement concrete cored piles

InactiveCN109162270ASimple construction methodReasonable designSoil preservationMaterials sciencePrefabrication

The invention discloses a soft soil foundation reinforcing method based on cement concrete cored piles. Multiple cement concrete cored piles, vertically distributed, are adopted to reinforce a soft soil foundation; and the method comprises the steps of: (1) prefabrication of the cored piles; (2) conveying of the cored piles; and (3) reinforcement of the foundation: the cement concrete cored pilesare constructed by adopting an integrated cored pile machine; and when any one cement concrete cored pile is constructed, six steps of placement of the pile machine in place, construction of cement stirring piles, shifting of the pile machine, installation of the cored piles, vertical placement of the cored piles and pressing of the piles are carried out. The method is simple in step, reasonable in design, convenient for construction, high in construction efficiency and excellent in use effect; after prefabrication of all the cored piles, the integrated cored pile machine finishes the construction of the cement stirring piles in the cement concrete cored piles and the pressing process of the cored piles, so that the construction speed is high; and the verticality of the cored piles in thepile pressing process is easily controlled, so that the quality of the formed cement concrete cored piles can be effectively guaranteed, and the reinforcing effect of the soft soil foundation is guaranteed.

Owner:NO 1 ENG LIMITED OF CR20G

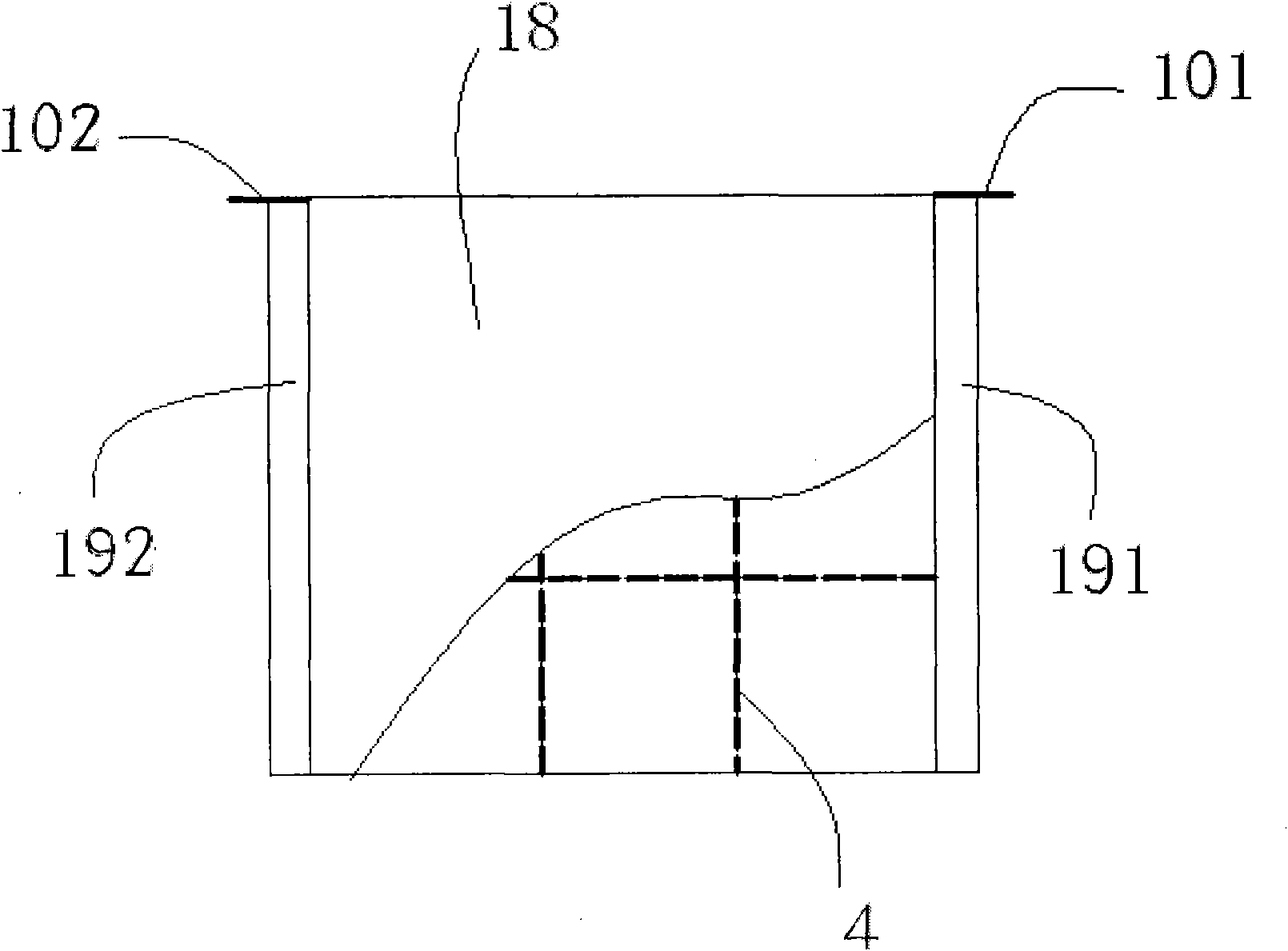

Cable and plate dam

InactiveCN1680663ASuperiorLess material consumption for dam constructionBarrages/weirsWater flowEngineering

The invention consists of back guy and board. The back guy and board both are made of high tensile strength material. Both ends of back guy are anchored at the mountain body beside the river. The board is fixed on the back guy, and its bottom and broadside is building in riverbed and rock mass beside river by using cement concrete or mortar. With the invention, the dam can be built from top to bottom, and construction can not be influenced by water flow of river.

Owner:CHINA THREE GORGES UNIV +2

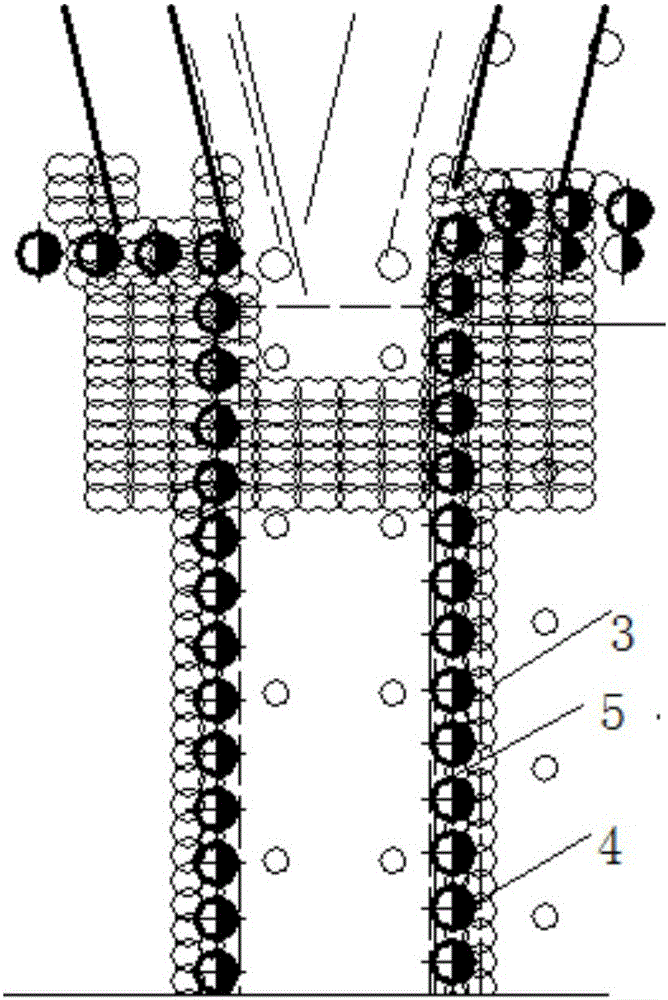

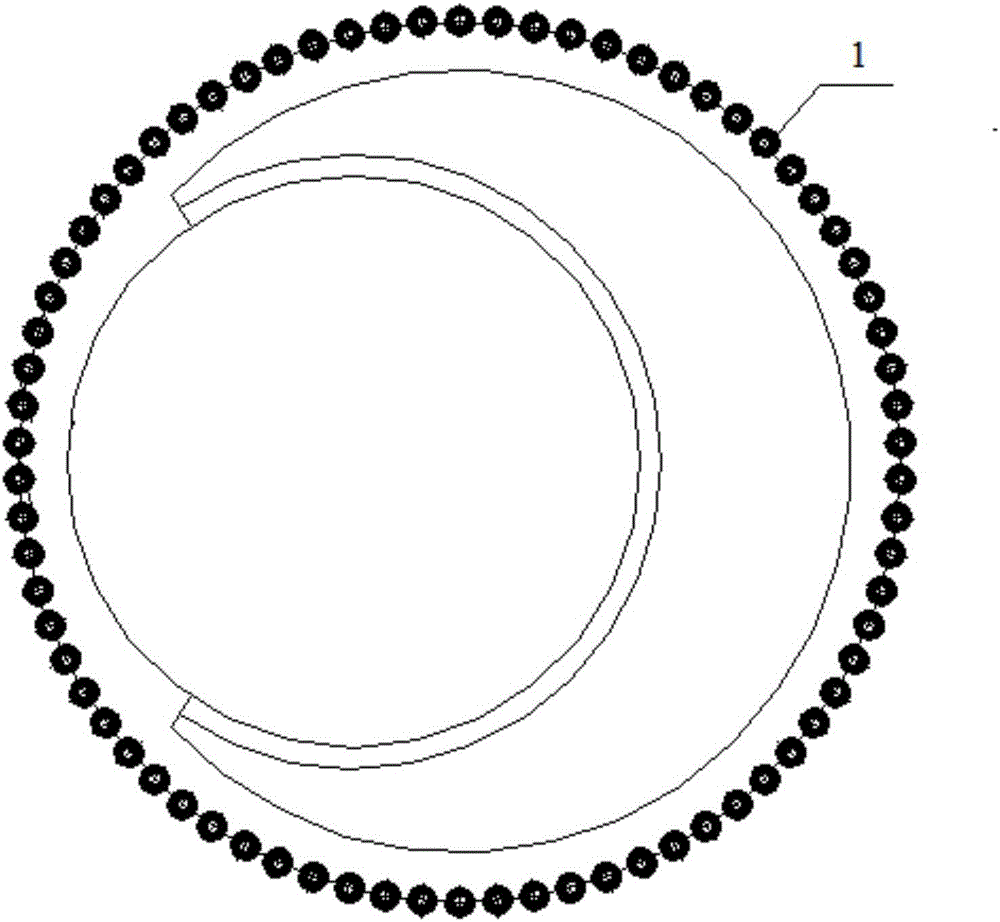

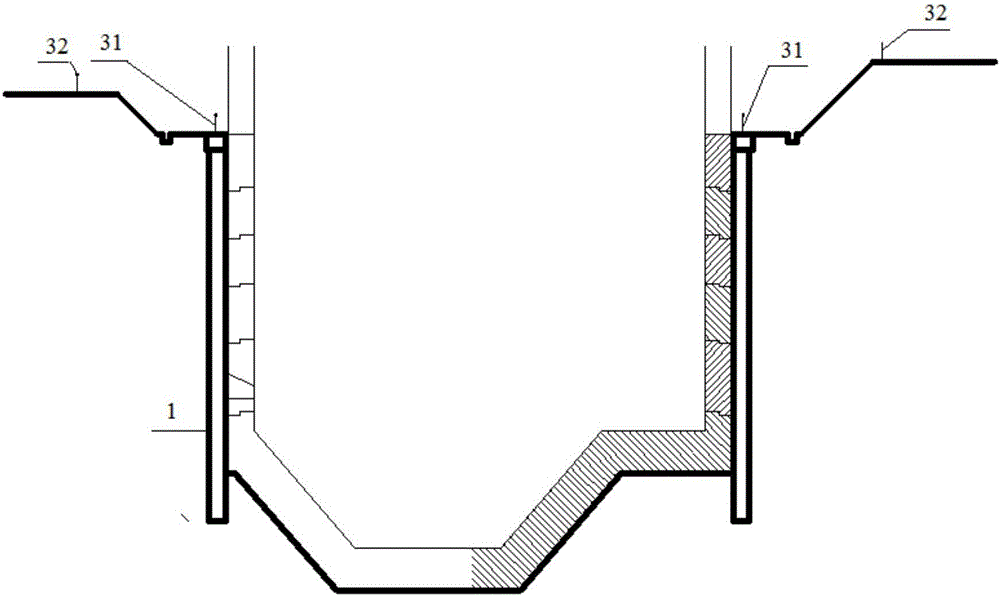

Swirl pool water stop curtain and construction method thereof

InactiveCN105970984AShorten pile lengthReduce construction costsExcavationsBulkheads/pilesHigh pressureRebar

The invention discloses a water-stop curtain for a swirl pool and a construction method thereof, belonging to the construction field of an underground circular swirl pool. It includes the outer cylinder of the swirling pool, supporting piles and water-stop piles. A row of supporting piles is set outside the outer cylinder of the swirling pool, and water-stopping piles are set outside the supporting piles. Water-stop piles are overlapped between two contacted water-stop piles. The support piles are bored cast-in-situ piles. Drill holes with a drilling rig, lower the steel cage into the hole, pour cement, and weld a section inside the support piles. The steel bars are used to form a whole with the outer cylinder wall of the whirlpool, and the supporting piles are used as part of the wall thickness of the outer cylinder of the whirlpool, which saves cost, increases the self-weight of the whirlpool, and increases the buoyancy resistance. The number of water-stop piles is more than two rows. The water-stop piles adopt the construction technology of high-pressure jet spray piles, and the support piles are set at equal intervals to prevent water from entering the whirlpool. At the same time, they can also bear the lateral pressure of the soil, and the construction is convenient.

Owner:马钢集团设计研究院有限责任公司

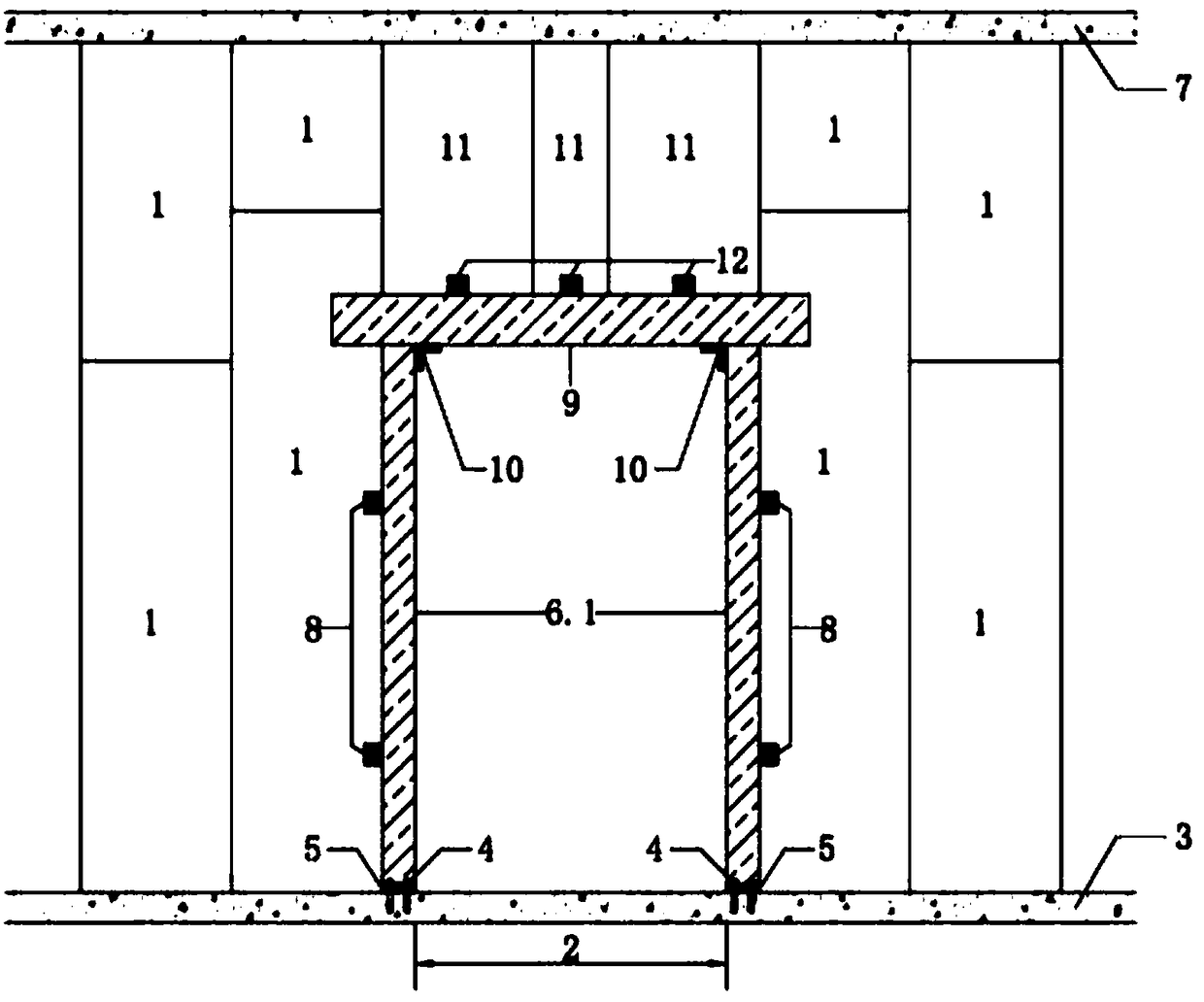

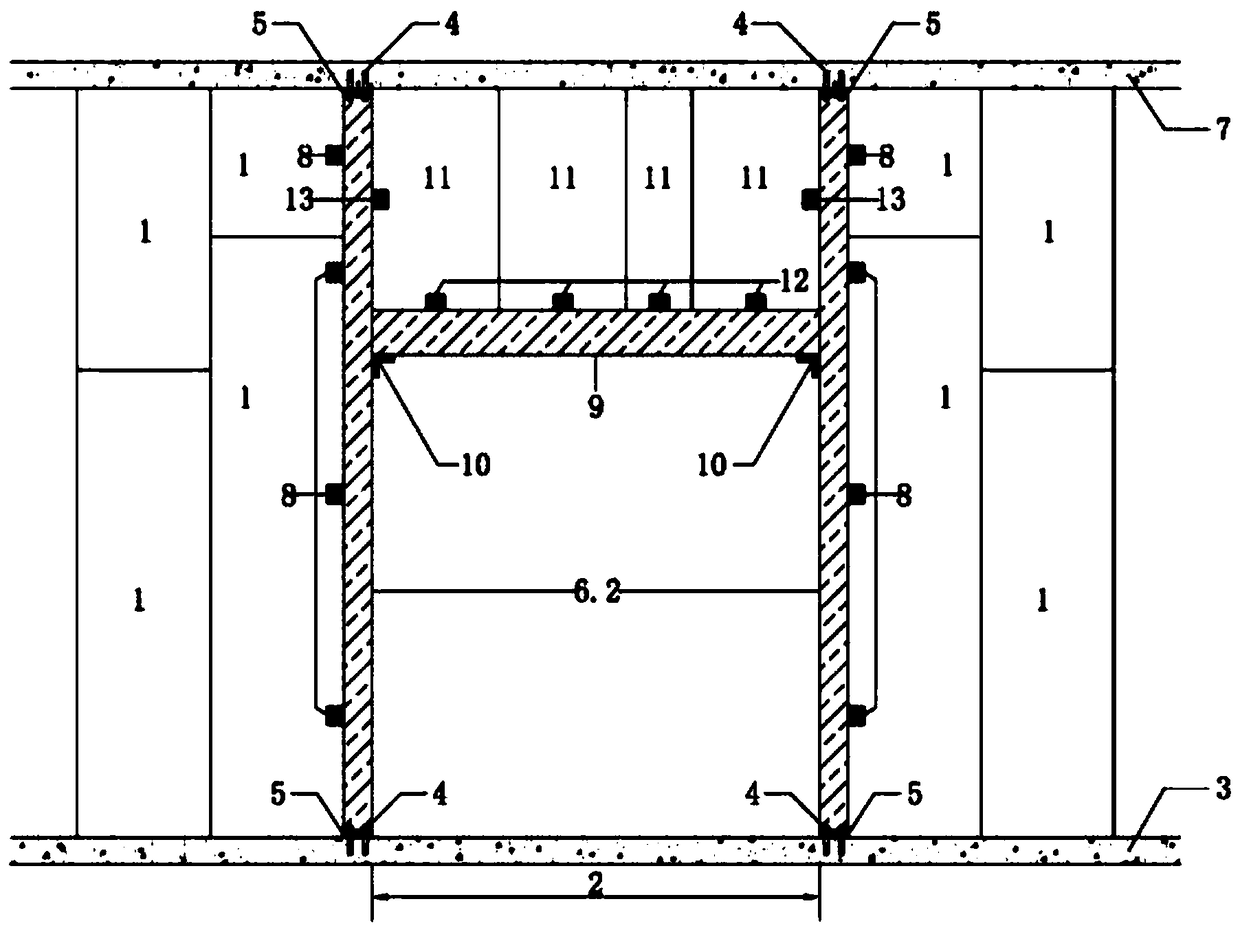

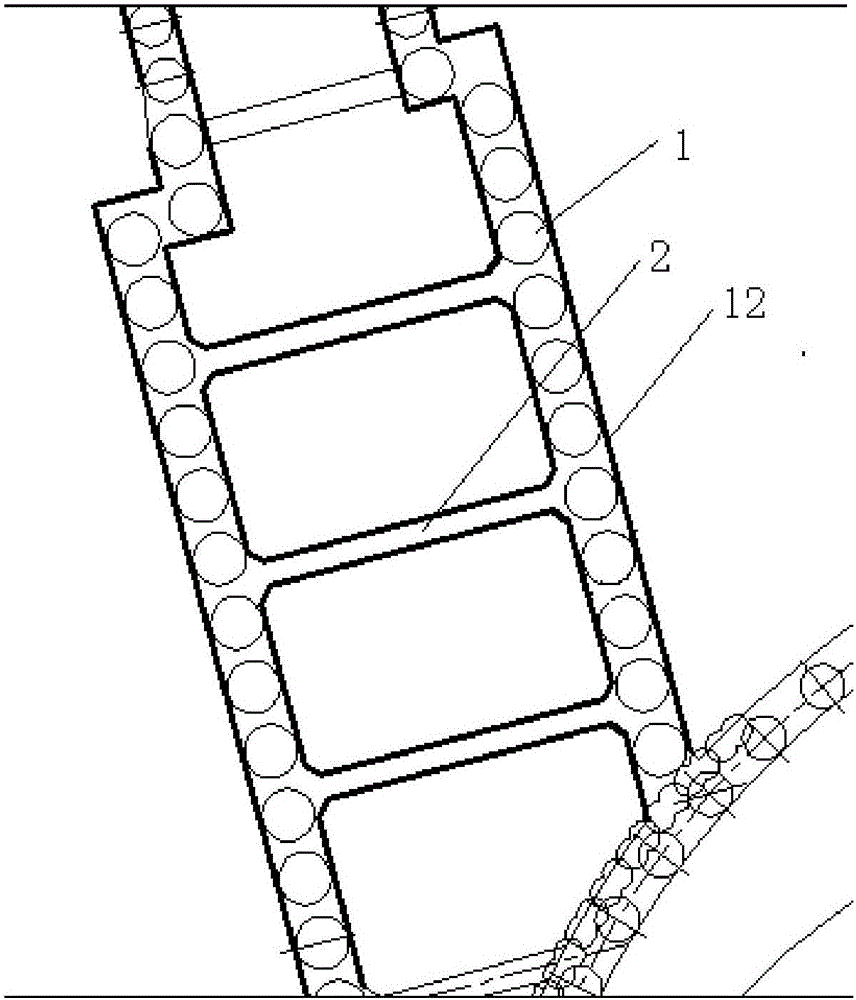

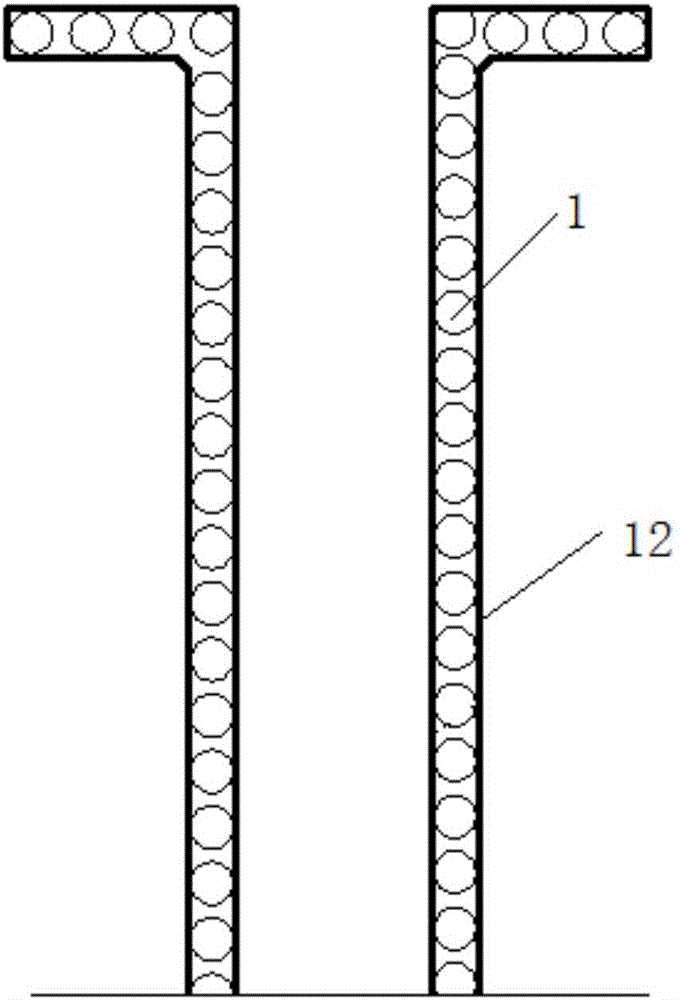

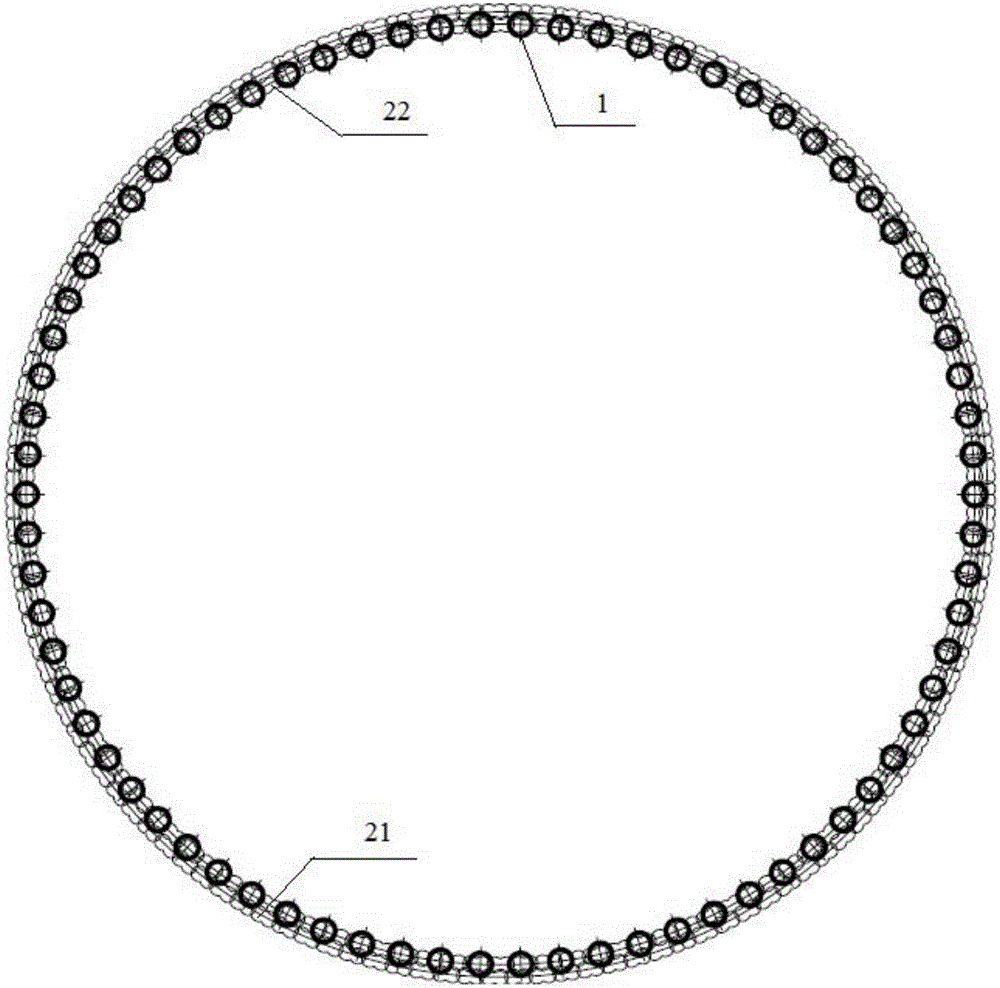

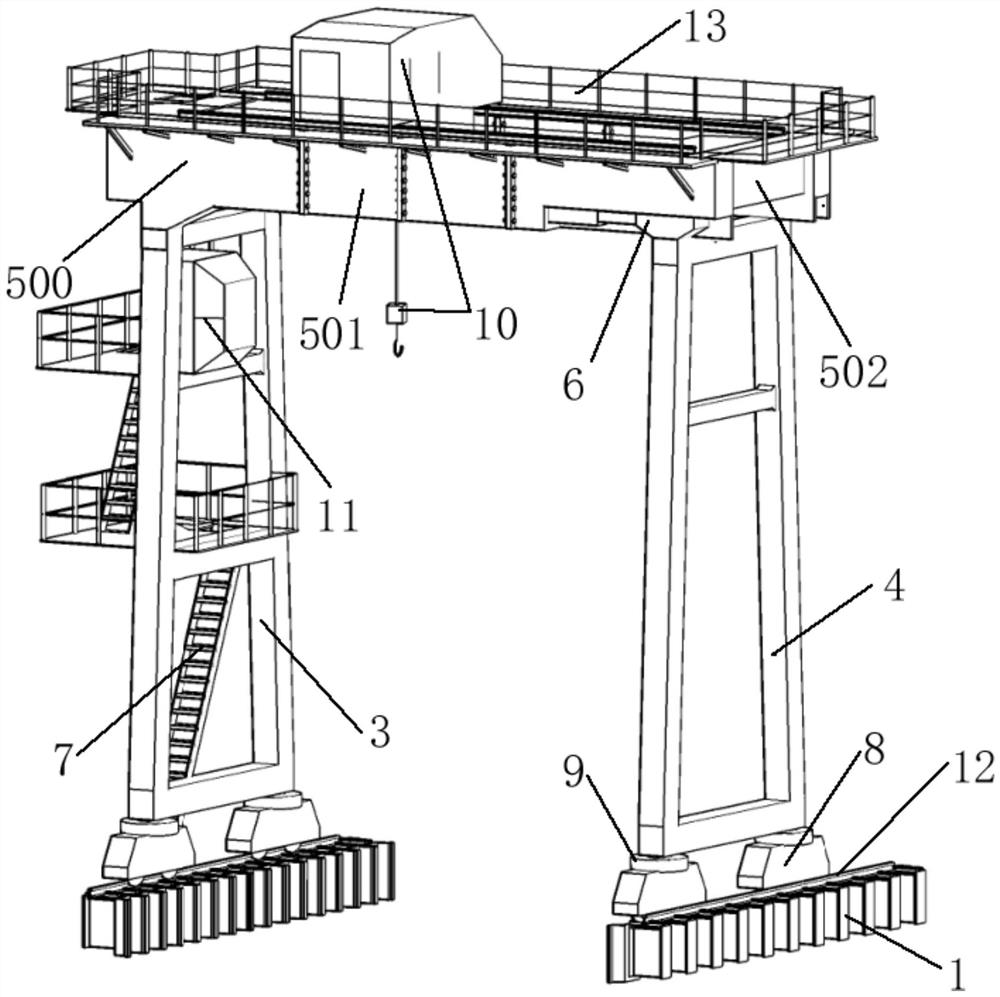

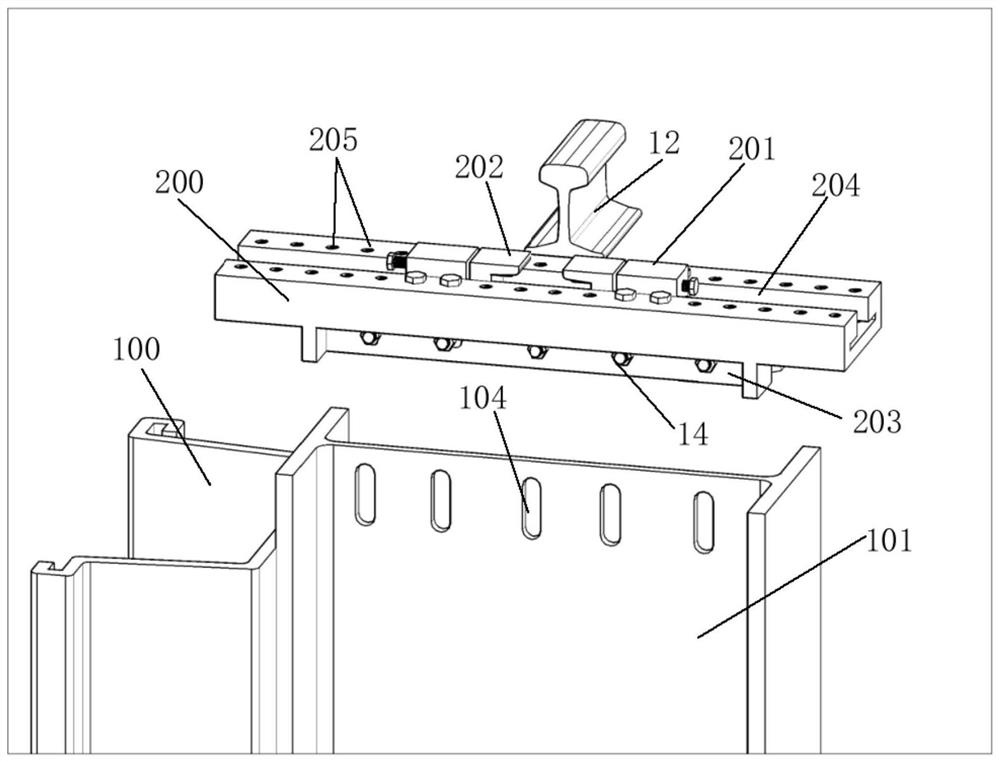

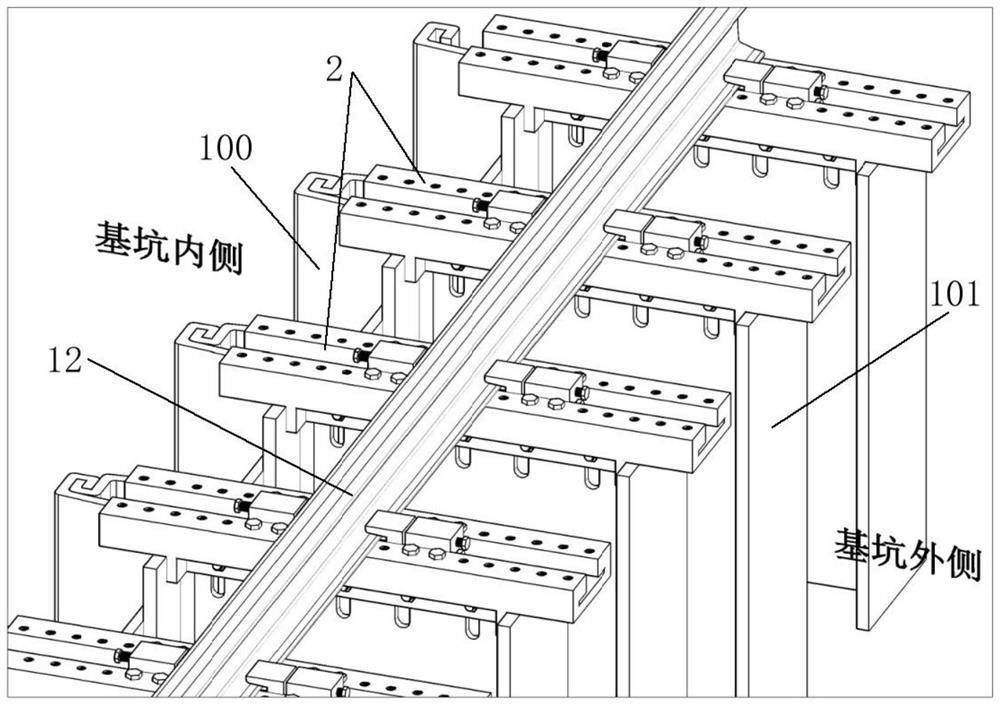

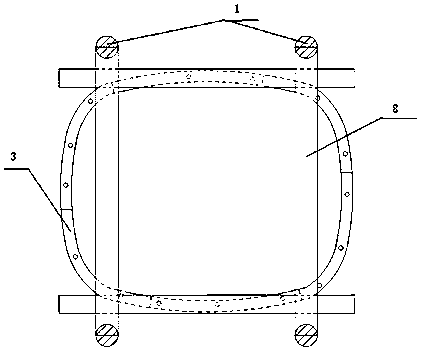

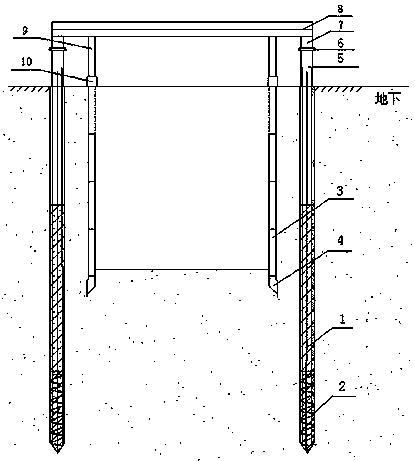

Construction equipment and method for an underground comprehensive pipe gallery

ActiveCN112627234BIncreased load-bearing capacityGood water stop effectArtificial islandsUnderwater structuresSupporting systemTrackway

The invention provides construction equipment and a construction method for an underground comprehensive pipe gallery. The construction equipment includes a foundation pit enclosure structure, track connectors, walking rails and gantry lifting devices; the foundation pit enclosure structure includes a plurality of composite piles composed of U-shaped steel sheet piles and H-shaped steel pillars interlocked side by side , the track connector includes a base and two sets of track positioning adjustment members symmetrically installed on the base, the bottom of the track connector is connected with the H-shaped steel pillar web of the composite pile, and rails are installed on the track connector; The device includes a fixed outrigger, a span adjustment outrigger, a bridge frame connecting the two outriggers and a traveling mechanism, and the gantry lifting device is slidingly connected with the traveling rail through the traveling mechanism. The invention combines foundation pit support and hoisting equipment into one body, and makes full use of each other, which not only enhances the integrity of the support system, but also reduces the occupied area of rail laying, reduces environmental pollution, and after the construction is completed, All equipment is recyclable.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Construction method of construction equipment for actively assembled caisson

ActiveCN105951863BImprove mechanical performanceImprove structural stabilityCaissonsArchitectural engineeringRebar

The invention provides a construction device of an active assembling type open caisson and a construction method using same. The construction device comprises pouring piles, first steel pipes, second steel pipes, flange plates, upper pressing rods and oil pickaxe jacks, wherein a plurality of pouring piles are mounted around a mounting position of the active assembling type open caisson; first reinforcing steel bars are welded to the first steel pipes; two I-steels are overlapped and welded at the upper parts of the pouring piles to be used as the upper pressing rods, and the upper pressing rods are welded to the second steel pipes; the first steel pipes and the second steel pipes are connected through the corresponding flange plates; one or a plurality of oil pickaxe jacks are mounted below the upper pressing rods. The construction device has a plurality of advantages, such as that the overall stressing performance is outstanding, the structure stability is high, the construction area can be effectively reduced, the construction process is simple, the energy can be saved, the environment is protected, the construction safety coefficients are high, the construction time can be greatly decreased, the construction workload can be reduced, the applicable scope is wide, the stability in a special geological condition is outstanding, and the quality, the safety and the environment can be ensured.

Owner:BEIJING NO 4 MUNICIPAL CONSTR ENG +1

Platform for sliding furnace shell in high furnace limited space and erecting method of platform

ActiveCN104531926AWork lessGuaranteed to workBlast furnace componentsBlast furnace detailsEngineeringBlast furnace

Owner:TIANJIN 20 CONSTR

Support construction structure and process of fully prefabricated, spliced and superposed comprehensive pipe gallery

PendingCN111733878AReduce thicknessReduce steel usageArtificial islandsExcavationsArchitectural engineeringPipe

The invention belongs to the technical field of comprehensive pipe gallery construction, and in particular relates to a support construction structure and process of a fully prefabricated, spliced andsuperposed comprehensive pipe gallery. The support construction structure comprises a prefabricated comprehensive pipe gallery and further comprises prefabricated support piles, a prefabricated external anchor pile and a prefabricated crown beam. Adjacent prefabricated support piles are in bell-and-spigot joint together, the prefabricated support piles and the prefabricated external anchor pile are in bell-and-spigot joint to the prefabricated crown beam, and the prefabricated comprehensive pipe gallery and the prefabricated support pile are connected by a wet process. Construction of prefabricated and spliced structural parts is carried out fully from a foundation pit support in construction of the comprehensive pipe gallery to later main body structure, and the support structure and themain body structure are superposed fully to reduce the thickness of the main body structure, so that the steel amount and the concrete amount of the structural parts are alleviated, the cost is saved, the occupied area for construction is reduced, and the construction period is shortened.

Owner:JINAN URBAN CONSTR GRP

A Rapid Estimation Method of Physical and Mechanical Parameters of Moraine Soil

ActiveCN110210173BQuick estimateShorten the construction periodGeometric CADDesign optimisation/simulationEvaluation resultSoil science

The invention provides a method for quickly estimating the physical and mechanical parameters of moraine soil. Through the data analysis of a large number of field tests and indoor tests in the early stage, the statistical relationship between water content, void ratio, clay content and other physical and mechanical parameters is summarized. First, a simple test of moisture content, natural density and clay content is carried out on a fresh section of the moraine soil accumulation body, and then the void ratio, compression index, shear strength, compressive strength, Permeability and expansibility and other relatively complex engineering mechanics indicators, so that the preliminary evaluation of site stability can be quickly carried out; and then according to the evaluation results, targeted selection of dangerous sites for detailed investigation. Compared with the previous technology, the present invention can save the construction period of exploration and evaluation, reduce the types and procedures of parameter testing, and reduce economic costs. Significant applicability advantages.

Owner:INST OF EXPLORATION TECH OF CHINESE ACAD OF GEOLOGICAL SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com