Slag trough structure and construction method for same

A construction method and slag ditch technology, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as drainage without specific implementation plans, and achieve the effects of saving manpower, preventing water seepage, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

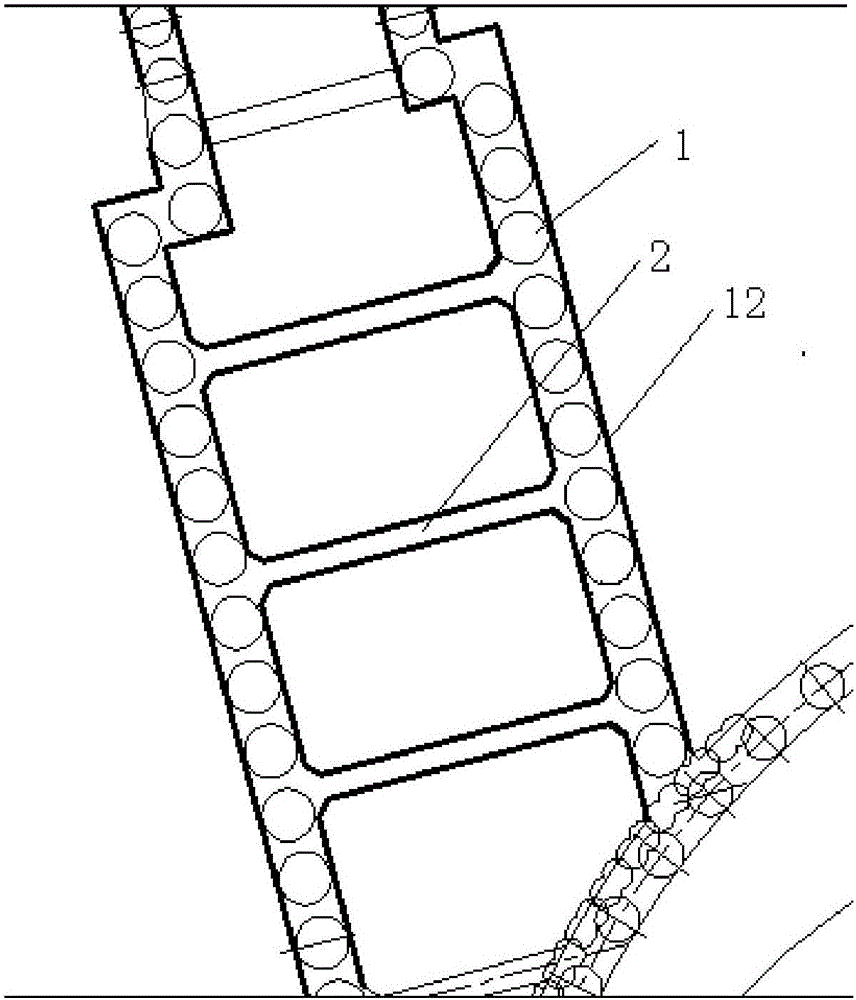

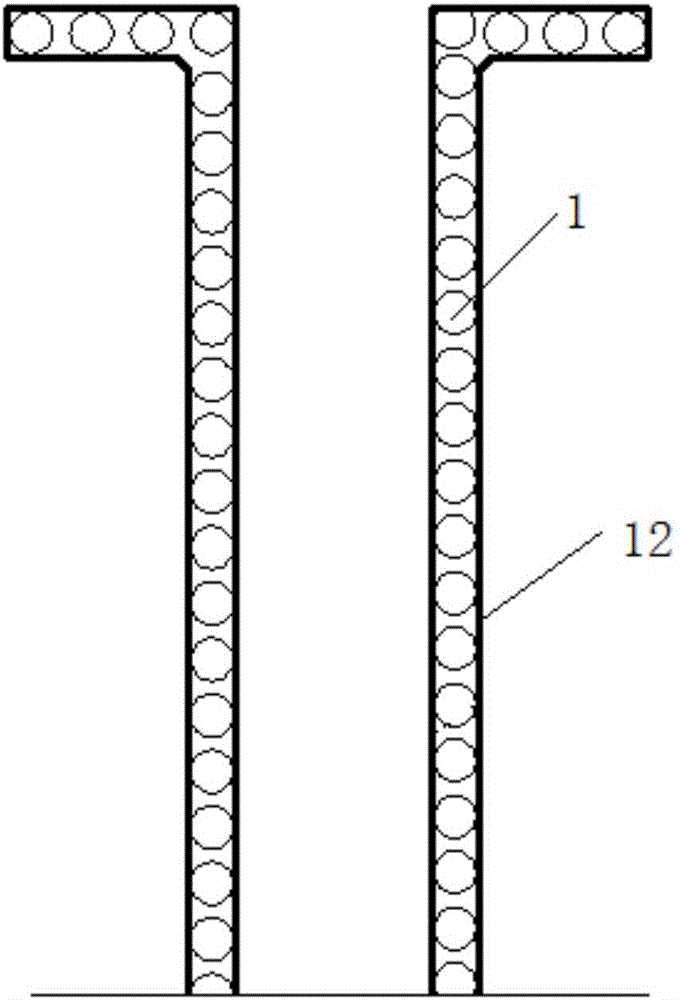

[0049] Combine Figure 1-7 , A slag ditch structure includes a supporting beam 2 and a slag ditch wall 12. A supporting pile 1 is provided on the outside of the slag ditch wall 12, and a supporting beam 2 is arranged between the supporting piles 1; the supporting pile 1 includes a water stop Pile and water-stop curtain pile 5, the water-stop curtain pile 5 is set between two adjacent water-stop piles; supporting pile 1 is a bored pile, use a drill to drill the hole, put the steel cage down into the hole, and cast cement. During the construction of supporting pile 1, strictly control the pile position, pile top and bottom elevation, mud specific gravity, and underwater concrete quality to ensure the construction quality of supporting pile 1.

[0050] The number of water-stopping piles is more than two rows, which is to strengthen the water-stopping effect, and the water-stopping piles can also play a role in resisting the lateral pressure of the soil; the water-stopping piles are...

Embodiment 2

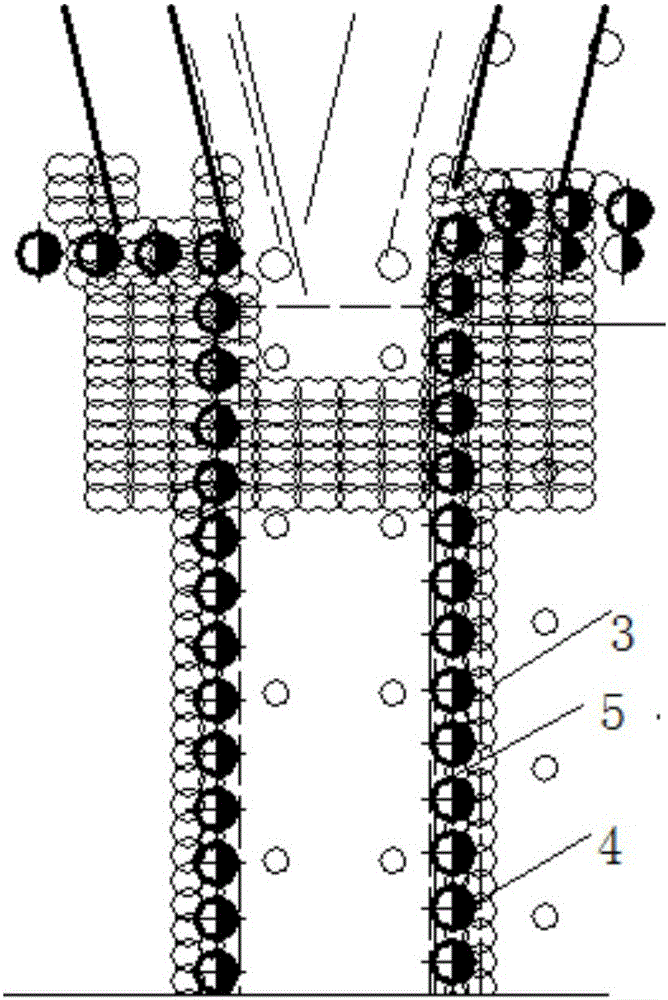

[0063] Similar to Example 1, combined Figure 1-7 In this embodiment, two rows of water stop piles are used, and the construction sequence is to pour the second row of water stop piles 4 first, then pour the first row of water stop piles 3, and the second row of water stop piles 4 using bored pile construction , The bored pile uses a rotary drilling machine to form the hole, the underwater concrete is poured in the construction process, and the hole jumps to form the hole; the thickness of the steel protection layer of the bored pile is 50mm, and the vertical deviation of the bored pile is less than or equal to 1 / 200; the thickness of the pile tip sediment is less than or equal to 50mm.

[0064] In the production of water-stop curtain piles, the diameter of the high-pressure jet-grouting pile is 700mm. The high-pressure jet-grouting pile needs to penetrate the sand and silt soil layer. The length of overlap between each water-stop pile and each row of water-stop piles Both are 1...

Embodiment 3

[0067] Similar to Example 2, Image 6 The steel cage 11 in the steel includes welded reinforcement hoop 15, spiral stirrup 14 and main reinforcement 13, such as Figure 7 Shown. Reinforcing steel cage 11 is required to be integrally manufactured and hoisted; the steel joints shall be flash butt welding or mechanical connection joints, and lap joints shall not be used; the thickness of the protective layer of the steel reinforcement of the supporting pile 1 is 50mm, and the second row of water-stop pile 4 is poured cement Use C30 grade; C15 grade for cushion.

[0068] Real-time example 4

[0069] A construction method of slag trench structure, the steps are:

[0070] A. Design the overall plan, and calculate the number and size of water stop piles according to the size of the slag trench;

[0071] B. Excavate the foundation pit in the selected area; the depth of the foundation pit is 3m; it can reduce the length of the second row of water stop piles and reduce the construction cost; s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com