Patents

Literature

97results about How to "Not easy to seepage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

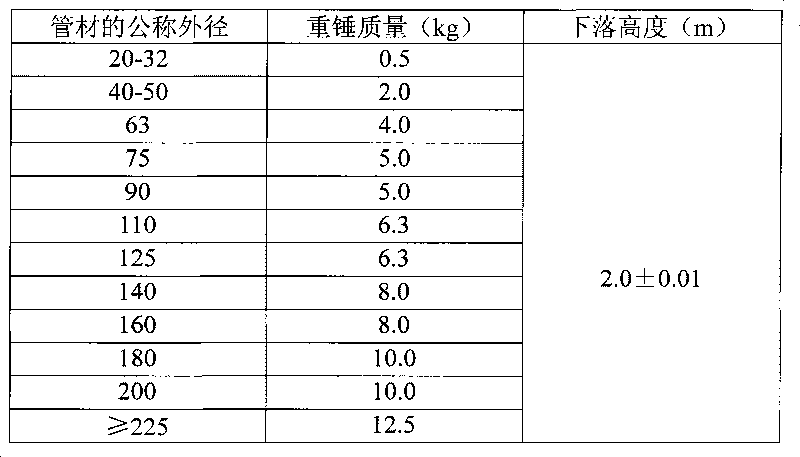

Hard polyethylene pipe with high impact resistance

The invention relates to a hard polyethylene pipe with high impact resistance, which solves the problem that the hard PVC pipe has low impact strength, has brittleness, and is easy to leak, permeate and crack. The technical scheme to solve the problem is that: the hard polyethylene pipe is prepared from the following components in part by weight: 220 to 280 parts of PVC, 6 to 10 parts of heat stabilizer, 0.7 to 1.3 parts of lubricant, 2.1 to 2.9 parts of titanium pigment, 10 to 20 parts of impact modifier, 2 to 4 parts of processing aid and 3.5 to 6.5 parts of calcium carbonate; and the hard polyethylene pipe is prepared by the following steps: firstly, evenly mixing the components to prepare a mixture; secondly, heating the mixture to between 105 and 145DEG C, and cooling the mixture to between 30 and 55DEG C; standing the cooled mixture at a normal temperature of between 18 and 25DEG C for 8 to 12h; extruding the mixture at a temperature of between 130 and 220DEG C with an extruder; and cooling at a temperature of between 10 and 22DEG C. The hard polyethylene pipe has good toughness and impact resistance, chemical resistance, and difficult leakage, seepage and crack, and is innovation on pipes.

Owner:康泰塑胶科技集团(郑州)有限公司

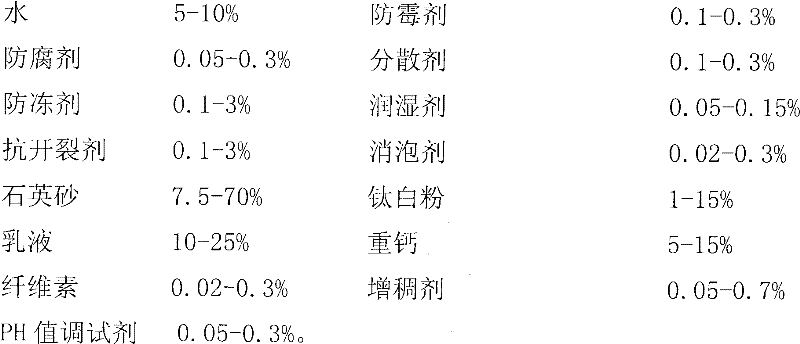

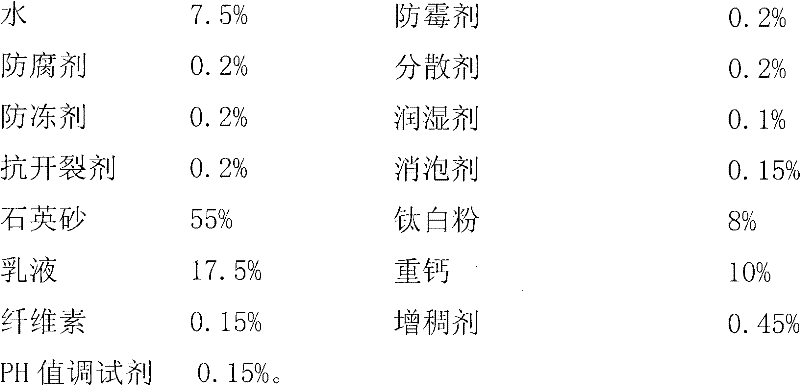

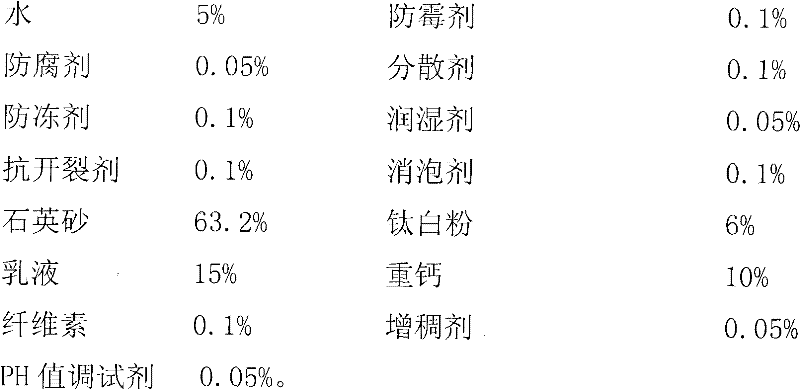

Special flexible texture coating for external heat insulating wall, and preparation method thereof

The invention discloses a special flexible texture coating for an external heat insulating wall. The coating is characterized by: 1) mixing water, an antimildew agent, a preservative, a dispersing agent, a wetting agent, a antifoaming agent, titanium pigment and calcium carbonate according to a mass ratio, followed by carrying out high speed dispersion to provide a spare use; 2) then mixing an emulsion, quartz sand and the antifoaming agent according to a mass ratio, followed by being added to the prepared mixed solution from the step 1), then carrying out medium-speed stirring; 3) mixing cellulose and the water according to a mass ratio, and carrying out stirring to prepare a mixed material of the cellulose to provide a spare use; 4) adding the mixture prepared through medium-speed stirring to the mixed material of the cellulose to carry out stirring, such that the mixed material of the cellulose can provide uniform thickening effect; 5) carrying out a color treatment for the finished product from the step 4). The coating provided by the present invention has characteristics of free of crack, high cohesional strength, effective prevention from coating deterioration, good water resistance, excellent penetration resistance, excellent flexibility. With the coating provided by the present invention, the fine cracks can be filled so as to prolong a service life of the external heat insulating wall and effectively protect buildings.

Owner:SHANDONG QINHENG TECH

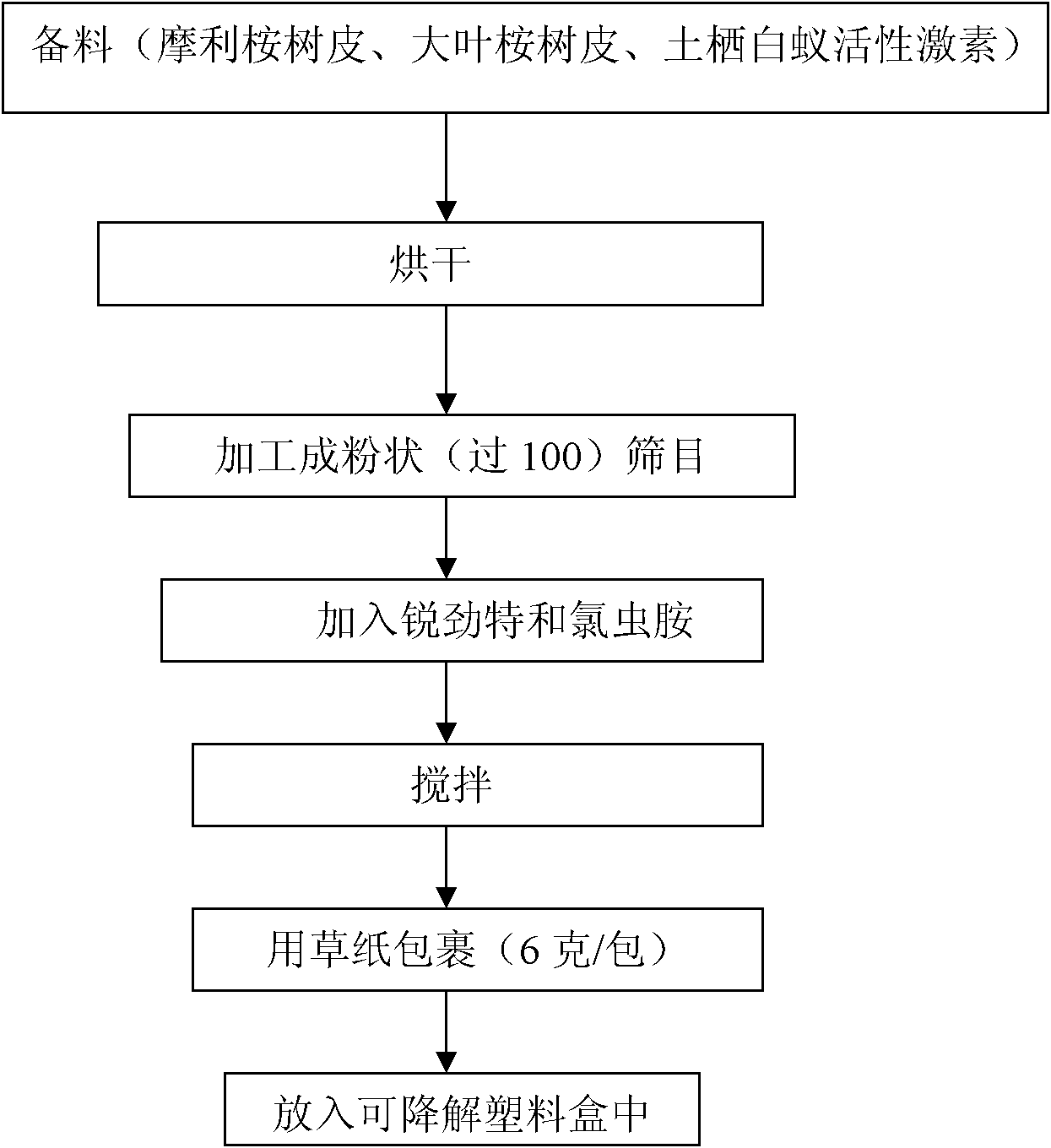

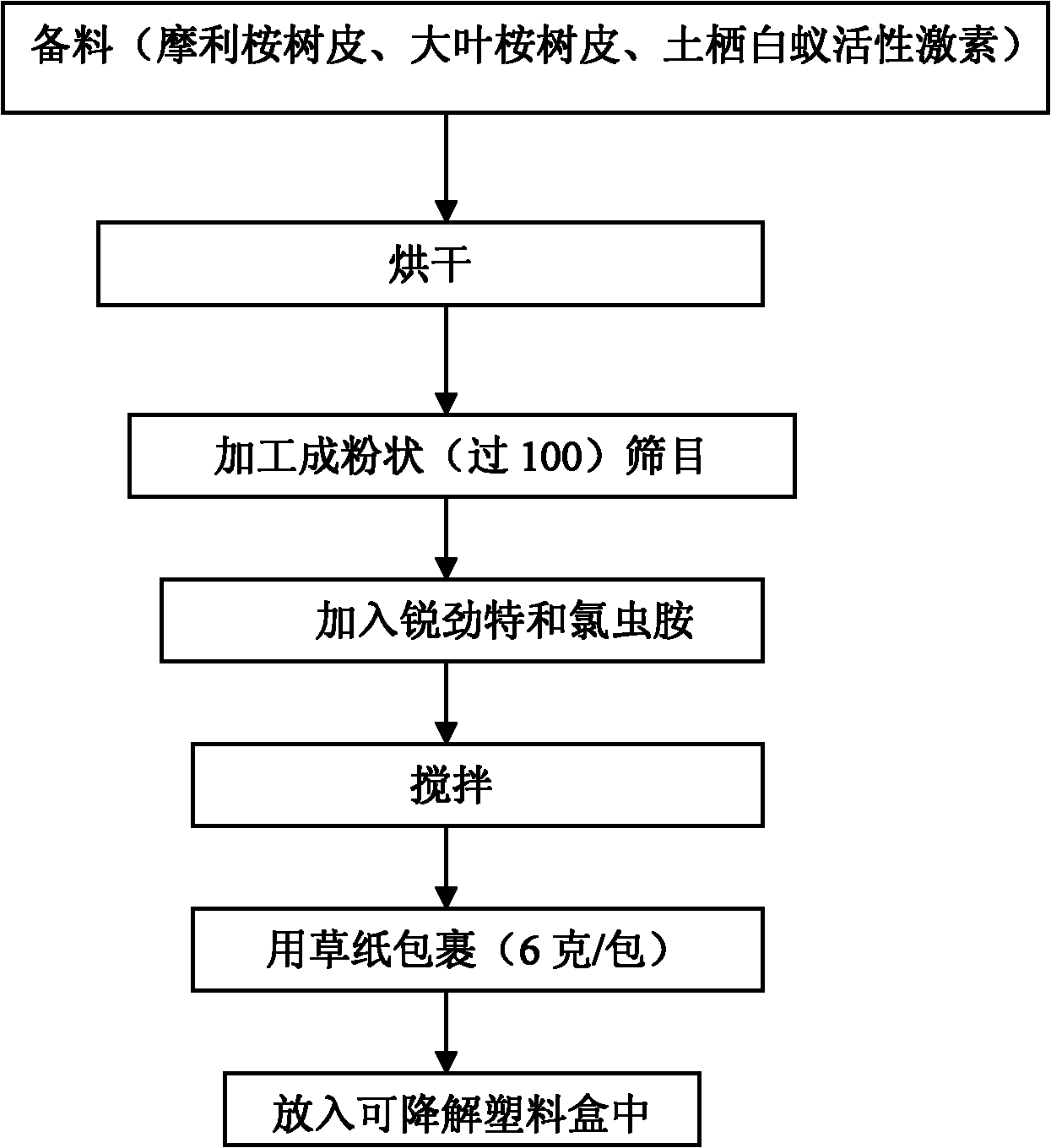

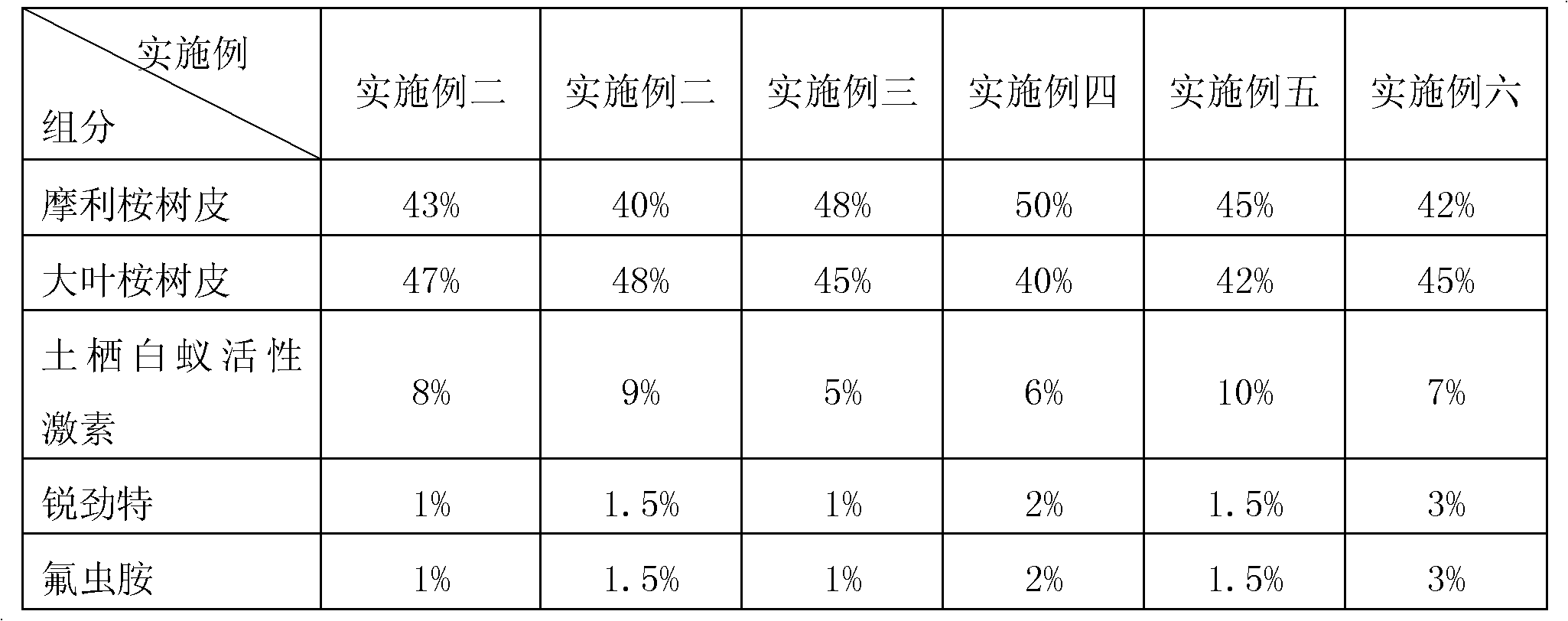

Soil termite trapping medicine and soil termite trapping method by using the same

InactiveCN101861876AStrong phagocytosisNot easy to mildewBiocidePest attractantsFipronilWater leakage

The invention relates to a trapping medicine of termites and a termites trapping method thereof. The soil termites trapping medicine comprises the following components by weight percent: 40 to 50 percent of moli eucalyptus bark, 40 to 50 percent of macrophyll eucalyptus bark, 5 to 10 percent of soil termites active hormone, 1 to 3 percent of fipronil, and 1 to 3 percent of sulfluramid. The invention can avoid the drug resistance of the termites and enhance the trapping effect action obviously and has the advantages of strong trapping capability for the soil termites, uneasy mouldness, extensive source, low cost, no damage risk on crops and easy generalization. The soil termites trapping method comprises the following steps that: the medicine powder manufactured through the prescription is packed with coarse paper and is placed in a degradable plastic box to manufacture a soil termites trapping box. The trapping box is buried at the place the soil termites move frequently and the middle of the dense grouping holes when the grouping holes are formed and before the grouping is carried out. The invention has the effects of uneasy water leakage, low labor cost and ideal prevention and treatment effect.

Owner:柳州市白蚁防治所 +2

PVC (Polyvinyl Chloride)-M (Modified) shock-resistant tubular product

InactiveCN102827439AGood toughness and impact resistanceChemical resistanceRigid pipesWaxStearic acid

The invention relates to a PVC (Polyvinyl Chloride) tubular product, and in particular relates to a PVC (Polyvinyl Chloride)-M (Modified) shock-resistant tubular product. The tubular product is made of the following raw materials in parts by weight: 100 parts of a PVC resin, 6 parts of calcium powder, 3 parts of titanium dioxide powder, 6 parts of a stabilizer, 2 parts of stearic acid, 13 parts of a shock-resistant modifier, 1 part of PE (Polyethylene) wax, 0.5 part of an MBS (Methyl-methacrylate-Butadiene-Styrene) resin, and 4 parts of ACR (Acrylic Resin)-530. The PVC (Polyvinyl Chloride)-M (Modified) shock-resistant tubular product by the invention has good toughness and good shock resistance, can resist chemical corrosion, is improved in tension strength and elongation at break, and has difficulty in leaking or penetrating water, and cracking; and the MBS resin is added into the PVC tubular product for improving plasticization, so that the dispersion of inorganic matters and the processing fluidity of PVC melts are enhanced, and the low-temperature shock strength of the tubular product is improved.

Owner:ANHUI KANGJIA PLASTIC BUILDING MATERIAL

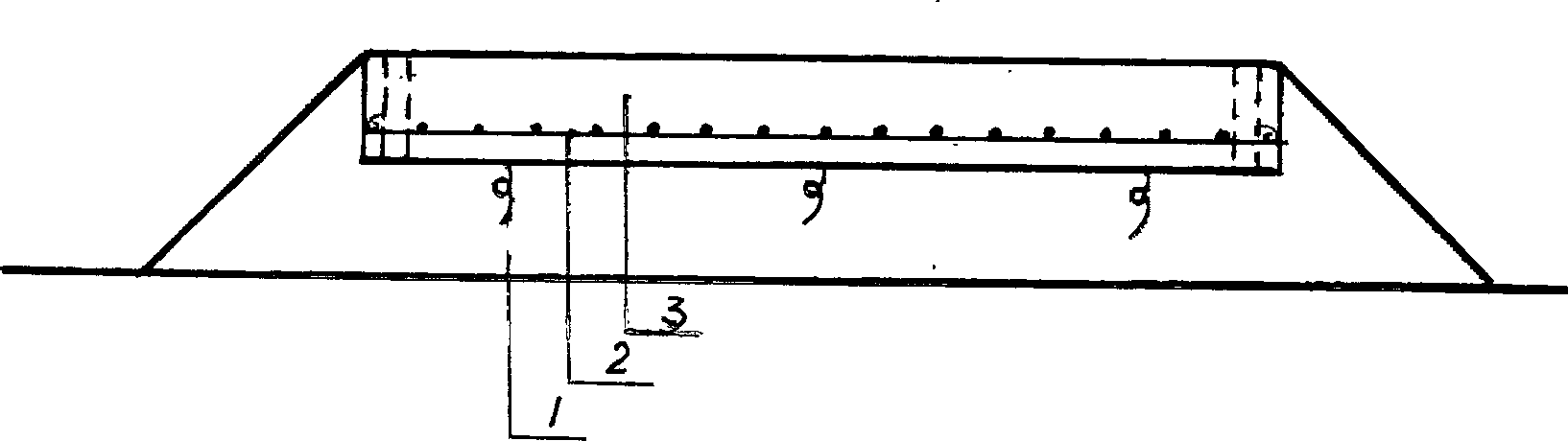

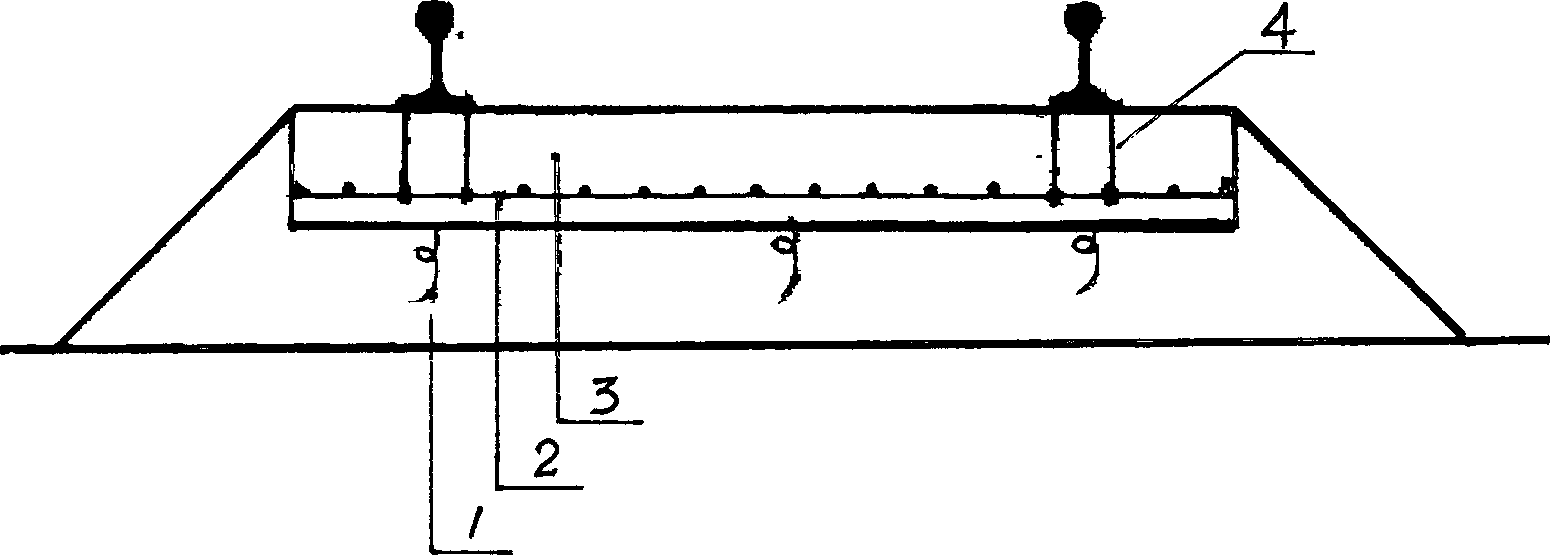

Roadbed structrue for highway and railway and its construction method

InactiveCN1460748ASimple structureImprove waterproof performanceIn situ pavingsReinforced concreteRoad engineering

The roadbed for highroad and railroad only is formed from compacted soil layer and reinforced concrete road surface layer fixedly connected on it, in which the compacted soil layer is the layer-to-layer compacted primary soil layer and the reinforced concrete road surface layer. In the concrete the grilled net reinforcing bars are set, so that said roadbed has good water-proofing property.

Owner:路福昌

Waterproofing roof engineering construction method

InactiveCN110528789AIncreased durabilityEasy accessRoof covering using flexible materialsBuild-up roofsArchitectural engineeringProtection layer

The invention relates to a waterproofing roof engineering construction method. The method comprises the following steps: S1. repairing a leveling layer; S2. brushing a first waterproof layer, whereinthe first waterproof layer is formed by brushing a base layer by polyurethane cement-based waterproof paint; S3. paving a second waterproof layer, wherein the second waterproof layer is formed by paving a waterproof coil on the first waterproof layer after the paint is dried to form a film; S4. brushing a third waterproof layer, wherein the third waterproof layer is formed by brushing the upper surface of the second waterproof layer by the polyurethane cement-based waterproof paint; and S5. paving a protective layer. The method has the advantages that three layers of waterproof measures are adopted for the roof, the tolerance for paving defects is strong, the durability of the waterproof layers is increased, rainwater can hardly enter the roof surface from the gap at special parts of the roof, which have good waterproof effect, and the risk of rainwater infiltration is reduced.

Owner:广东中南建设有限公司

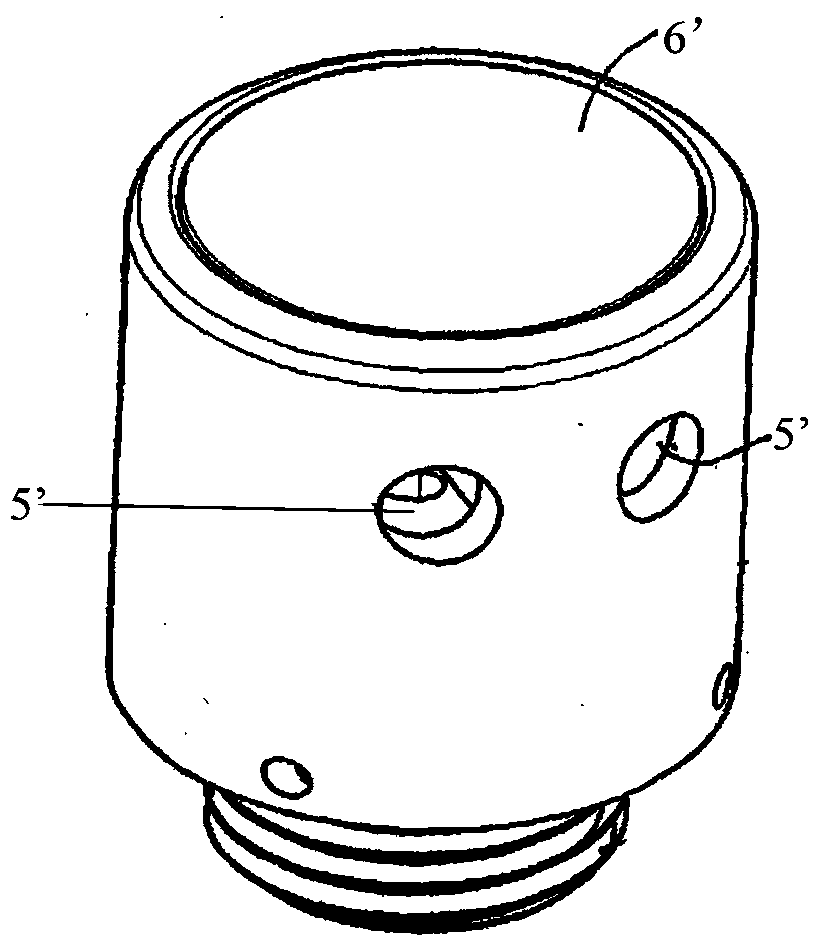

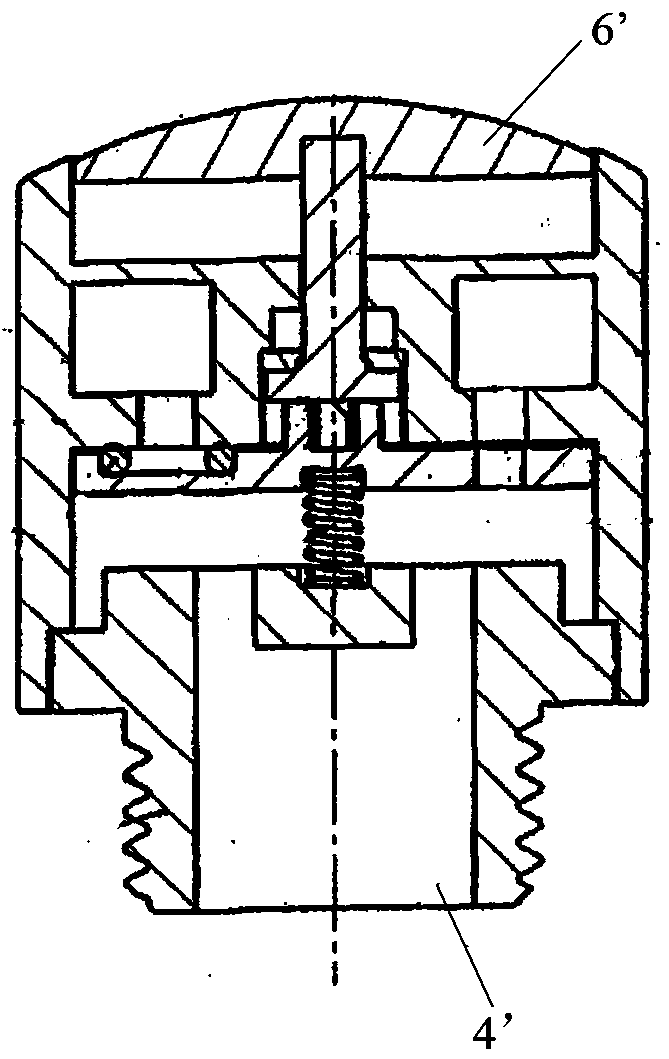

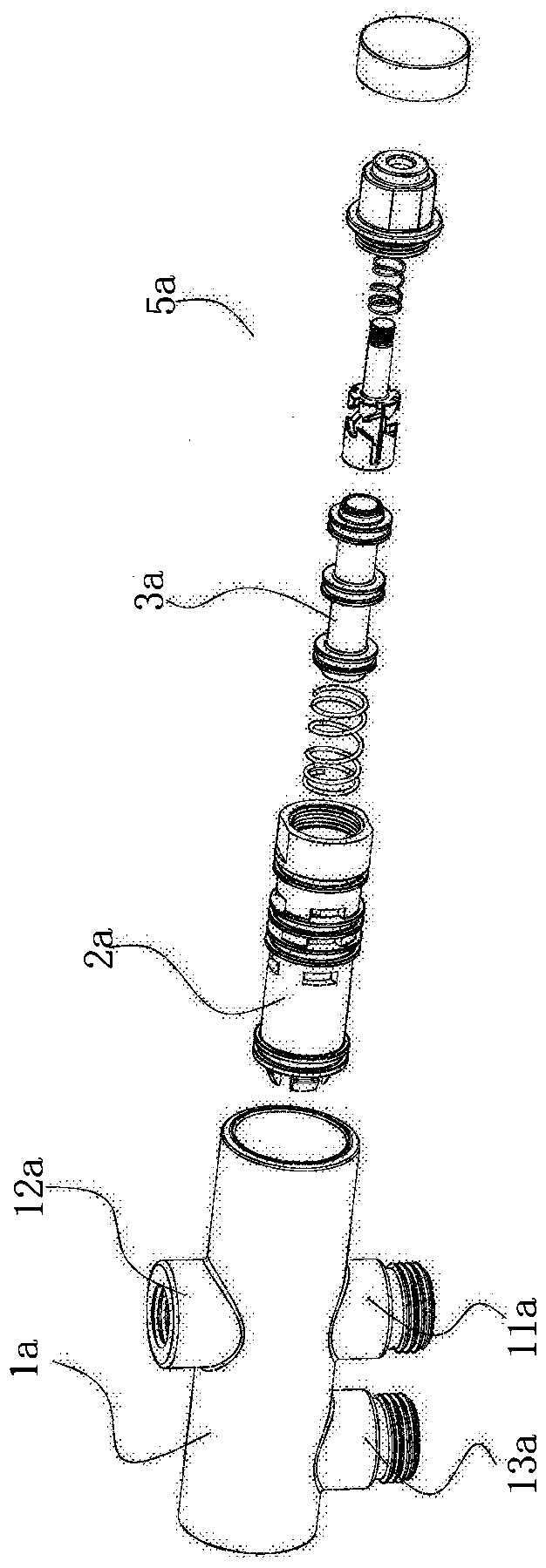

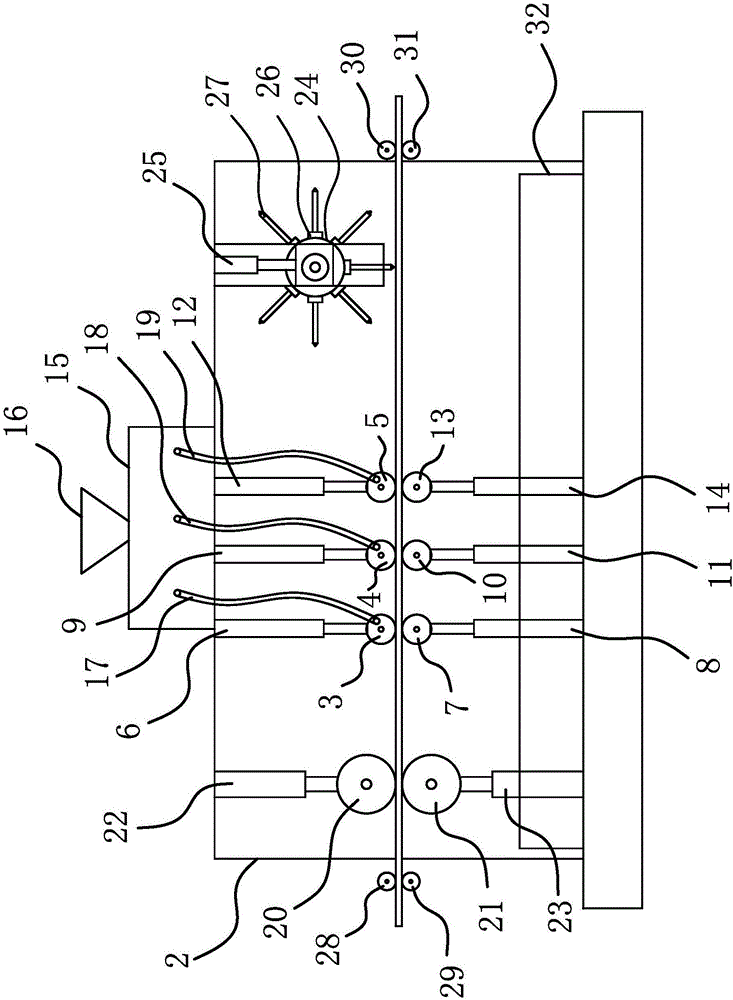

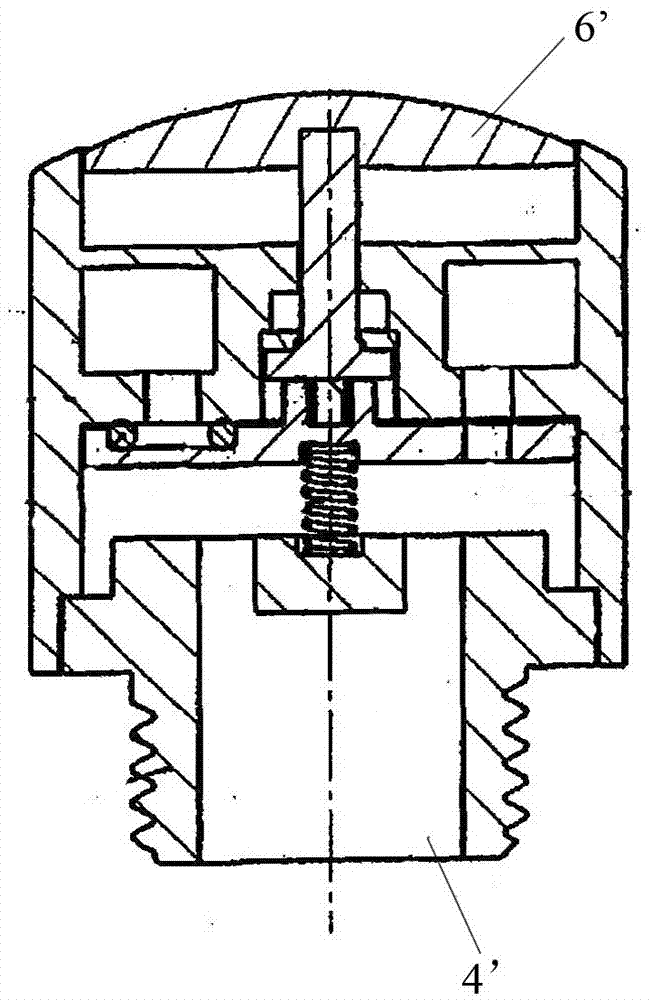

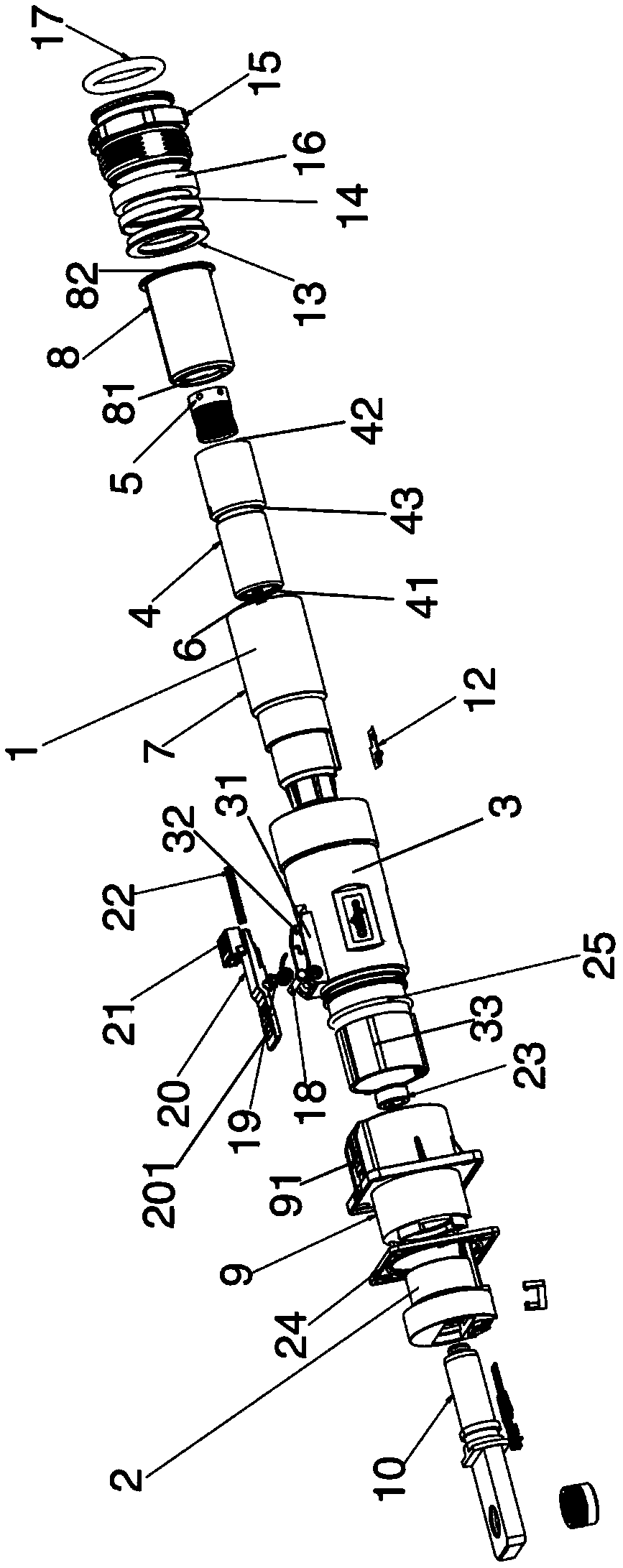

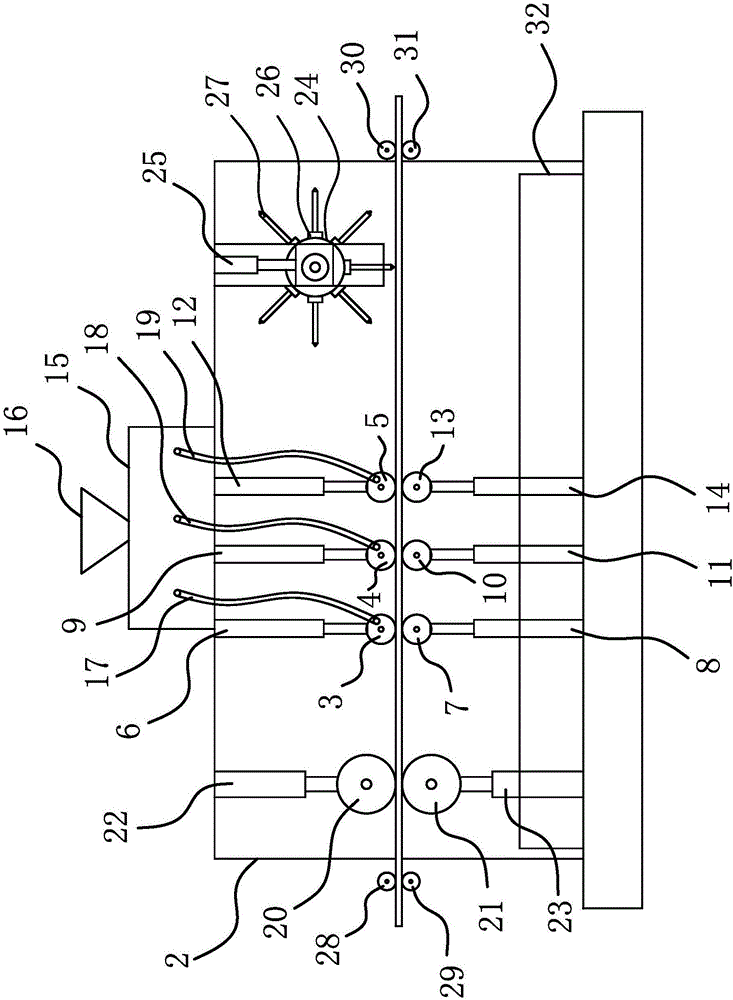

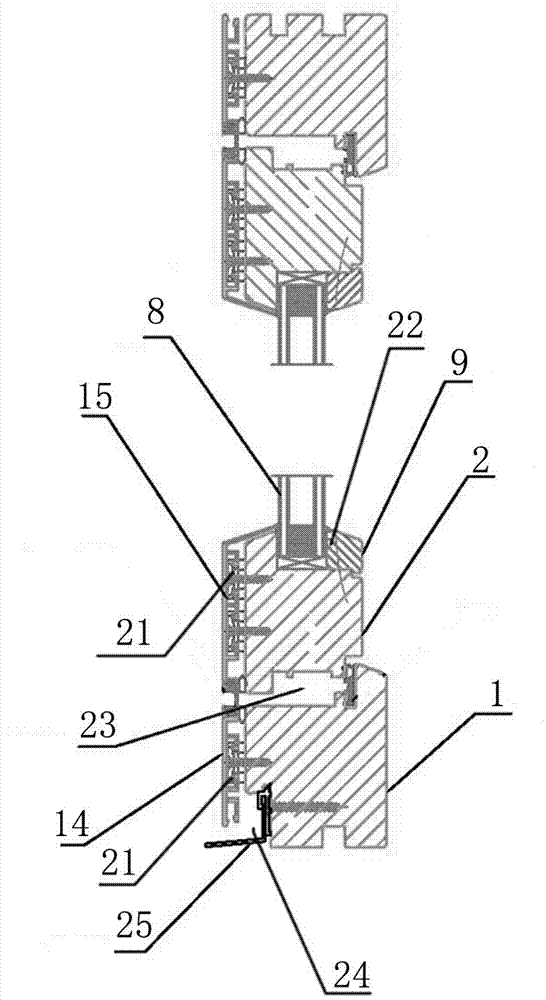

Multifunctional switching valve and water outlet device thereof

PendingCN107606231AReduce frictional resistanceFast switching responseOperating means/releasing devices for valvesMultiple way valvesReciprocating motionEngineering

A multifunctional switching valve comprises an automatic ball pen type pressing mechanism, a sealing guide rod, a first spring and a valve element body. Through triggering of the automatic ball pen type pressing mechanism, the first spring can exert resilience opposite to pressing force to the sealing guide rod, the sealing guide rod constantly abuts against the pressing mechanism, the sealing guide rod reciprocates up and down in the axial position of the valve element body through the high-position and low-position stroke of the pressing mechanism, accordingly, a plug on the sealing guide rod can selectively block a first flow guiding hole or a second flow guiding hole, and opening / closing of a water inlet and a first water outlet or a second water outlet is finally achieved. meanwhile,through rotation of the included angle between the valve element body and a valve element base, the overflow area of a flow adjusting hole is changed, and accordingly the purposes of flow switchover and water temperature adjustment are achieved.

Owner:XIAMEN PSSIN TECH CO LTD

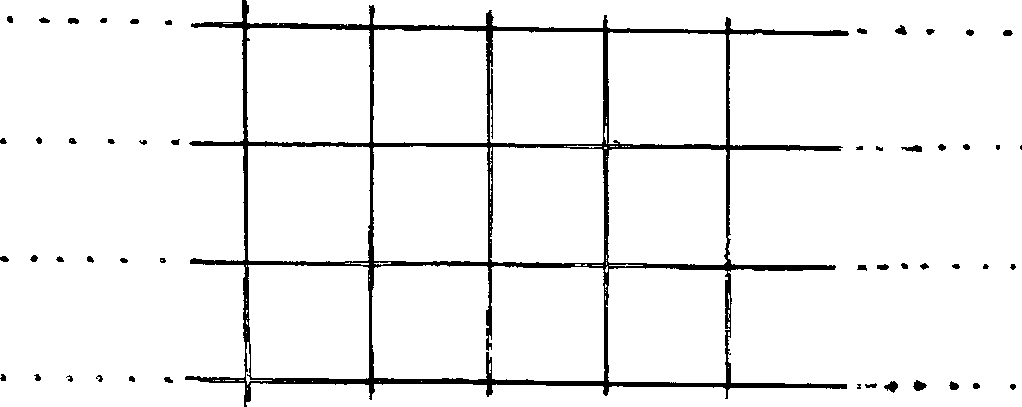

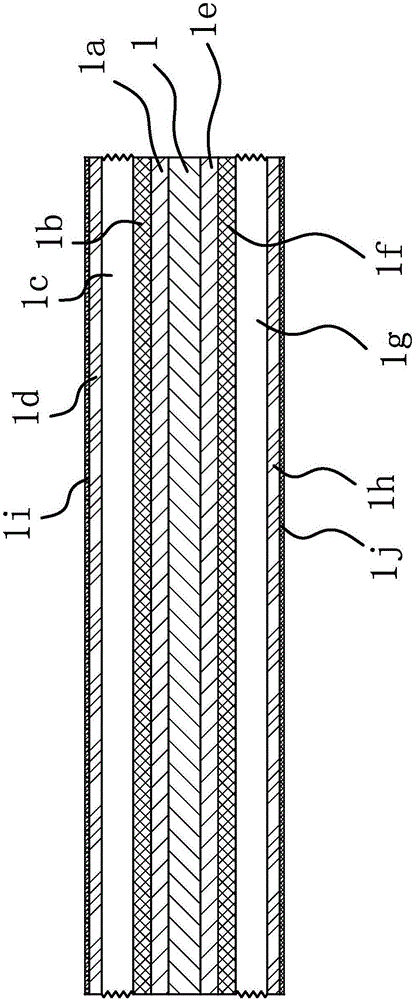

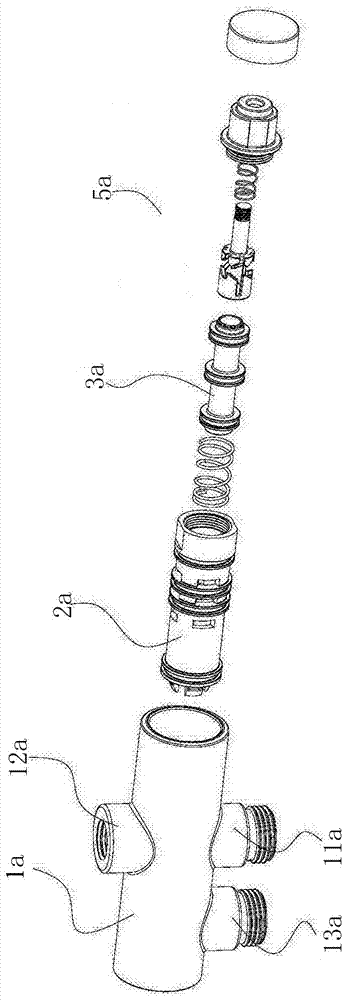

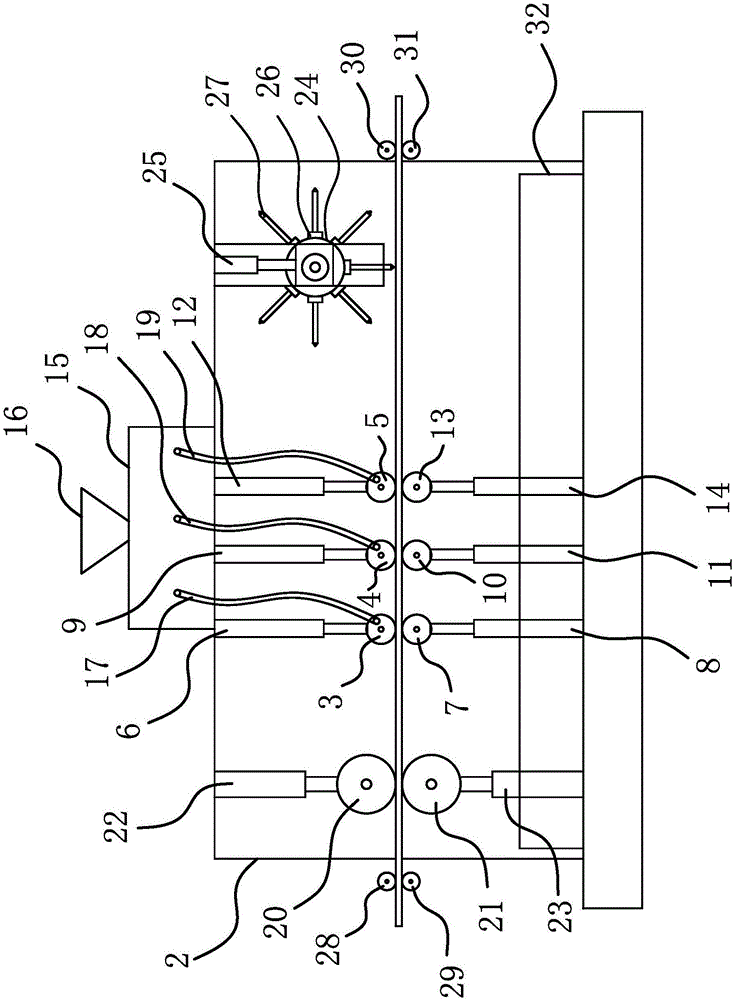

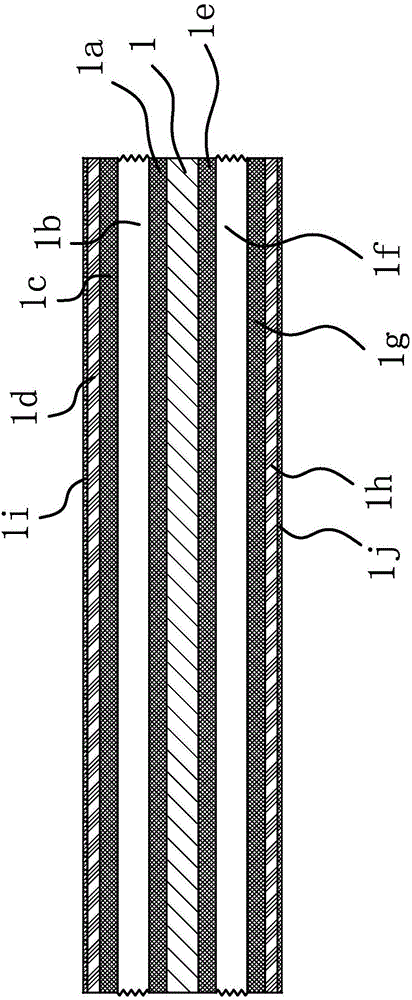

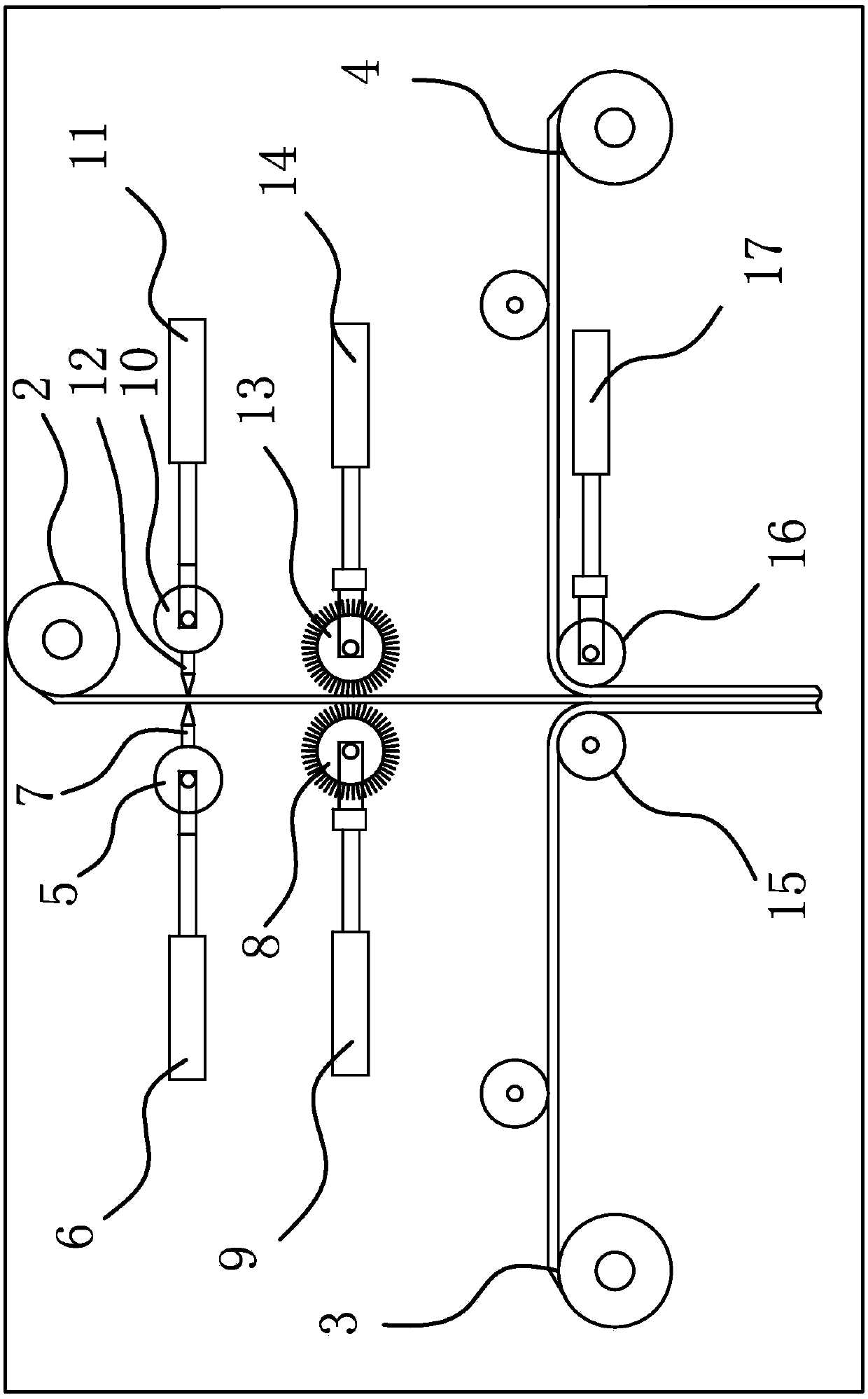

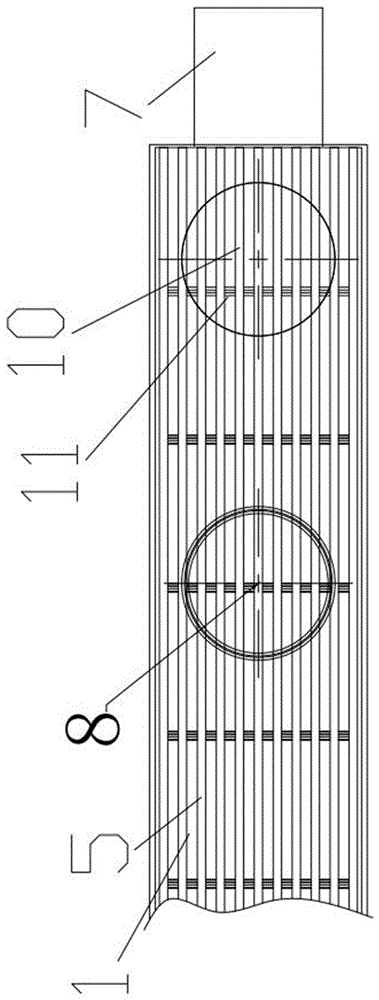

High-strength woven base cloth coating air-inflation shell fabric and spraying device thereof

ActiveCN106544877ANot easy to moldNot easy to seepageLiquid surface applicatorsCoatingsFiberBiochemical engineering

The invention provides a high-strength woven base cloth coating air-inflation shell fabric, belonging to the technical field of shell fabrics. The high-strength woven base cloth coating air-inflation shell fabric comprises base cloth and is characterized in that the base cloth is woven cloth with a warp-weft density of 50*50 units per inch and is made of bamboo carbon fiber materials; a first flame-retardant layer, a first metal net layer, a first air bag layer and a first waterproof layer are sequentially arranged on one side of the base cloth from inside to outside; a second flame-retardant layer, a second metal net layer, a second air bag layer and a second waterproof layer are sequentially arranged on the other side of the base cloth from inside to outside; a plurality of anti-slide grains are uniformly formed in the outer surfaces of the first waterproof layer and the second waterproof layer; and the outer surfaces of the first waterproof layer and the second waterproof layer are respectively covered with a first nylon layer and a second nylon layer. The high-strength woven base cloth coating air-inflation shell fabric has the advantages of being high in strength and inflatable.

Owner:ZHEJIANG FEIHU NEW MATERIAL CO LTD

Multifunctional changeover valve and water distributing device thereof

InactiveCN107246486AReduce frictional resistanceFast switching responseOperating means/releasing devices for valvesMultiple way valvesReciprocating motionEngineering

The invention discloses a multifunctional changeover valve. The multifunctional changeover valve comprises an automatic ball-point pen type pressing mechanism, a sealing guide rod, a first spring and a valve element body, wherein the automatic ball-point pen type pressing mechanism is triggered, and the first spring applies return force opposite to pressing force to the sealing guide rod, so that the sealing guide rod abuts against the pressing mechanism all the time; the pressing mechanism has high stroke and low stroke, so that the sealing guide rod performs up and down reciprocating motion along the axial position of the valve element body, and therefore, the first flow-guide hole or a second flow-guide hole is selectively plugged by a plug on the sealing guide rod, and a water inlet and a first water outlet or a second water outlet are opened / closed; and an included angle between the valve element body and a valve element seat body is rotated, so that an over-flow area of a flow regulating hole is changed, and therefore, the flow switching purpose is realized.

Owner:江烨

Improved automobile lampshade

InactiveCN104373892AEasy to disassembleEasy maintenanceLighting elementsGas-tight/water-tight arrangementsVisual field lossWater leakage

The invention relates to an improved automobile lampshade. The improved automobile lampshade comprises a lampshade body. The inner side and the outer side of the edge of the lampshade body are each provided with a sealing pressing strip. A polished mirror surface is adopted for the middle of the lampshade body, and polygon prism surfaces are adopted for the two sides of the lampshade body. A protection cover is arranged outside the lampshade body, and a soft lamp cleaning brush capable of stretching and contracting automatically in the vertical direction is arranged in a containing groove in the side, close to the lampshade body, of the protection cover. By the improvement, the improved automobile lampshade is good in leakproofness and not prone to water leakage; water spots or dust on the surface of the lampshade can be cleaned away at any time as needed through the soft lamp cleaning brush, and the soft lamp cleaning brush is convenient to detach and maintain and can be put down when not in use; the lampshade can be protected through a protection plate and the protection cover arranged outside the soft lamp cleaning brush and will not be damaged by external shock; the polished mirror surface and the polygon prism surfaces are adopted for the surface of the lampshade, so that the improved automobile lampshade has the advantages of providing good lighting and expanding the irradiation range and the visual field of a driver.

Owner:张玉庆

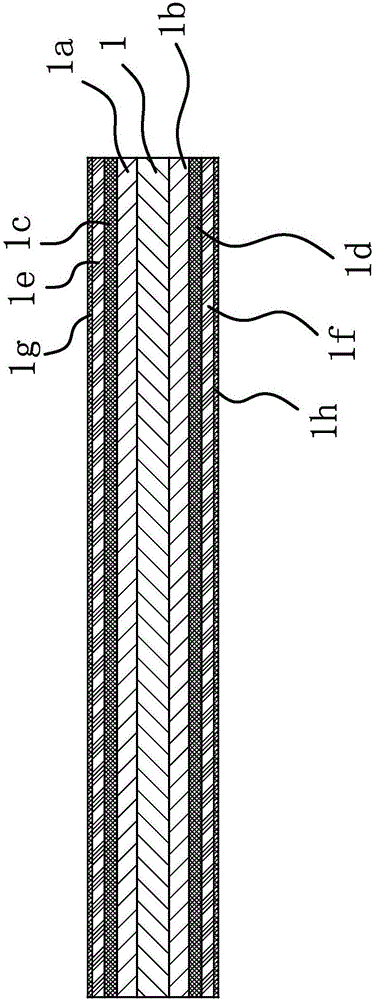

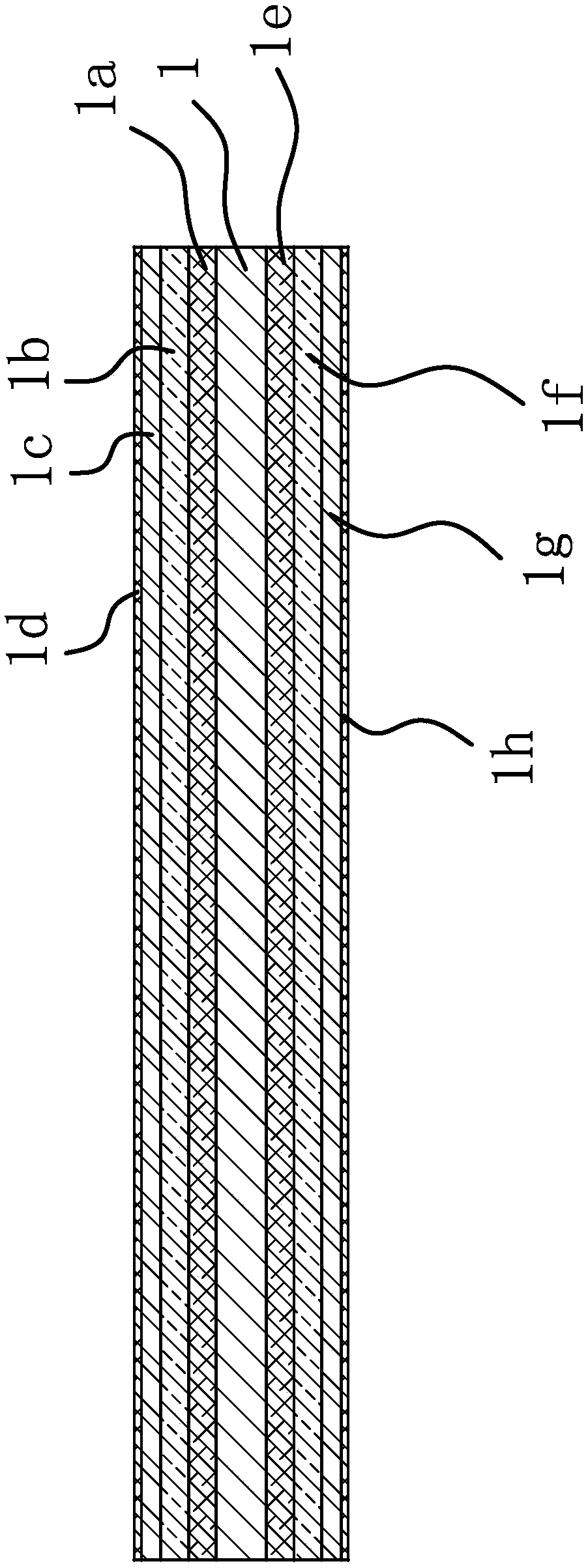

Mildew resistant and cold resistant PVC coating fabric and spraying apparatus thereof

ActiveCN106592260ANot easy to moldNot easy to seepageTextiles and paperPolyesterBiochemical engineering

The invention provides a mildew resistant and cold resistant PVC coating fabric, and belongs to the technical field of fabrics. The mildew resistant and cold resistant PVC coating fabric comprises a base cloth, wherein the base cloth uses a woven fabric having a warp and weft density of 30*30 / inch, and the warp and the weft of the woven fabric use 1000D polyester filament. The mildew resistant and cold resistant PVC coating fabric is characterized in that one side of the base cloth is sequentially provided with a first mildew resistant agent layer, a first flame retardant layer and a first waterproof layer from inside to outside, the other side of the base cloth is sequentially provided with a second mildew resistant agent layer, a second flame retardant layer and a second waterproof layer from inside to outside, the outer surfaces of the first waterproof layer and the second waterproof layer are uniformly provided with a plurality of anti-skid patterns, and the outer surfaces of the first waterproof layer and the second waterproof layer are respectively covered with a first nylon layer and a second nylon layer. The mildew resistant and cold resistant PVC coating fabric of the present invention has good anti-mildew effect.

Owner:ZHEJIANG FEIHU NEW MATERIAL CO LTD

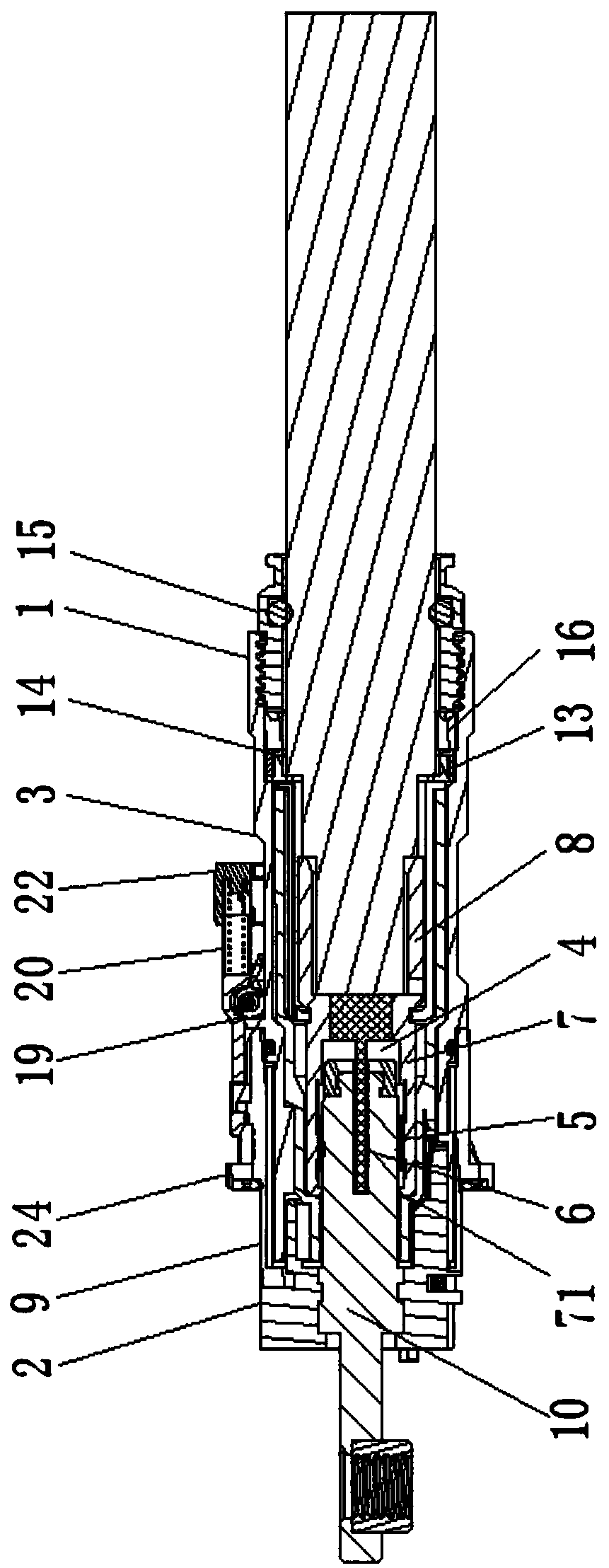

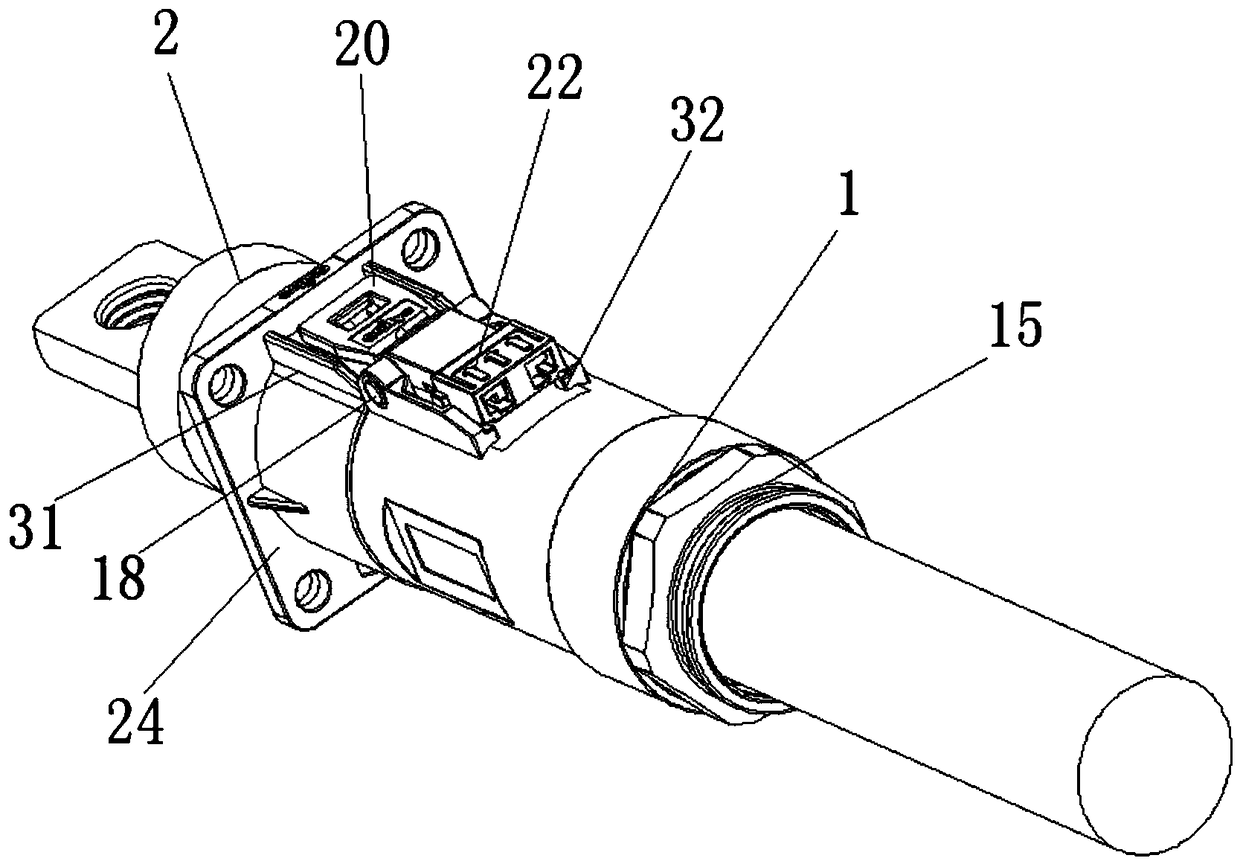

Single-core metal connector

PendingCN109038030AIncrease the lengthExtended service lifeCoupling contact membersCouplings bases/casesMetal fabricationSingle-core

The invention discloses a single-core metal connector, comprising a plug and a socket. The plug consists of a metal plug housing and a tubular power female terminal fixed inside the plug housing, Theinner part of the first end part of the power female terminal is coaxially fixed with a tubular elastic contact finger and a plug rod, the outer part of the power female terminal is provided with an insulating shell with both ends open and a cylindrical insulating sleeve matched with the insulating shell, and the second end part of the power female terminal is tightly matched with the insulating sleeve; the tail end of the plug rod is flush with the opening of the insulating housing; and the socket is composed of a metal socket housing and a tubular power male terminal fixedly arranged coaxially inside the socket housing, the power male terminal is internally provided with a socket matched with the plug rod, the socket housing and the plug housing are connected, and the power male terminaland the spring finger are tightly matched. The invention is made of all metal, and has better shielding performance, better electric conductivity, better internal sealing performance, less water permeability and higher safety.

Owner:SUZHOU CHILYE GREEN TECH

Environment-friendly waterproof coating inflatable fabric and spraying device thereof

ActiveCN106758277ASpray evenlyGood adhesionLiquid surface applicatorsCoatingsAirbag deploymentWoven fabric

The invention provides an environment-friendly waterproof coating inflatable fabric, belonging to the technical field of fabrics. The environment-friendly waterproof coating inflatable fabric comprises a base fabric. The invention is characterized in that the base fabric adopts a woven fabric of which the thread count is 50*50 yarn / inch; the woven fabric is prepared from a bamboo charcoal fiber material; one side of the base fabric is sequentially provided with a first waterproof layer, a first airbag layer, a second waterproof layer and a first flame-retardant layer from inside to outside; the other side of the base fabric is sequentially provided with a third waterproof layer, a second airbag layer, a fourth waterproof layer and a second flame-retardant layer from inside to outside; the external surfaces of the first flame-retardant layer and second flame-retardant layer are uniformly provided with a plurality of antiskid grains; and a first nylon layer and a second nylon layer are respectively coated on the external surfaces of the first flame-retardant layer and second flame-retardant layer. The inflatable fabric is environment-friendly and inflatable.

Owner:ZHEJIANG FEIHU NEW MATERIAL CO LTD

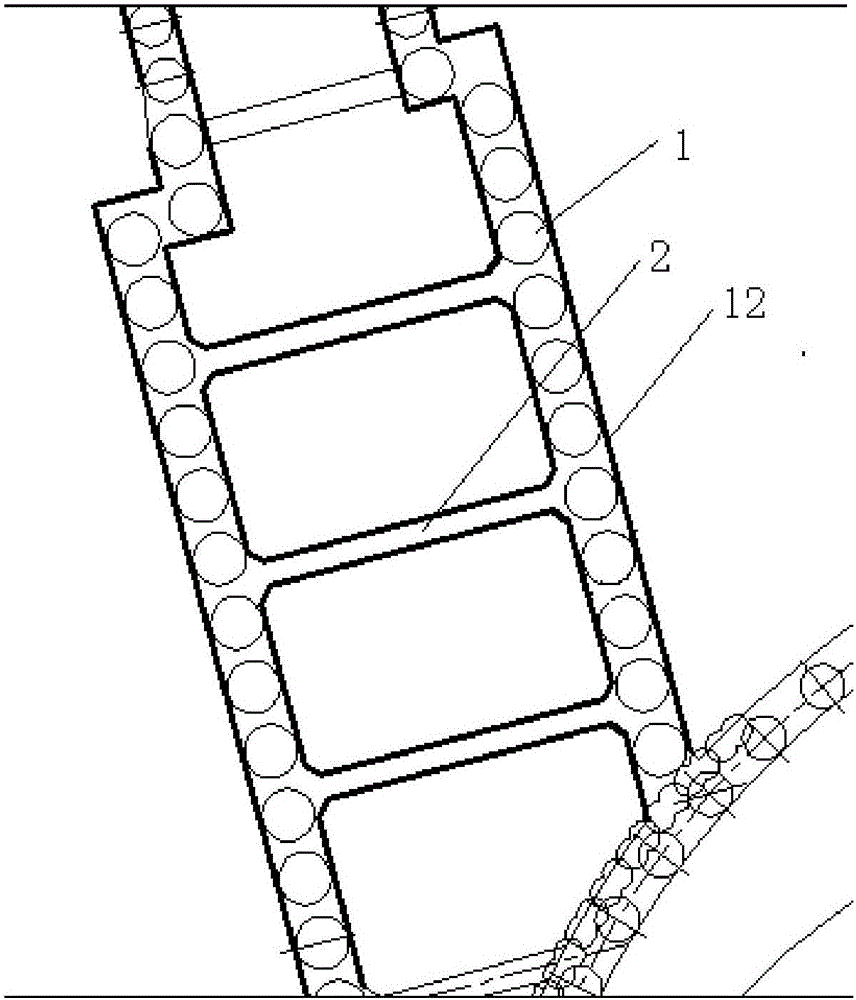

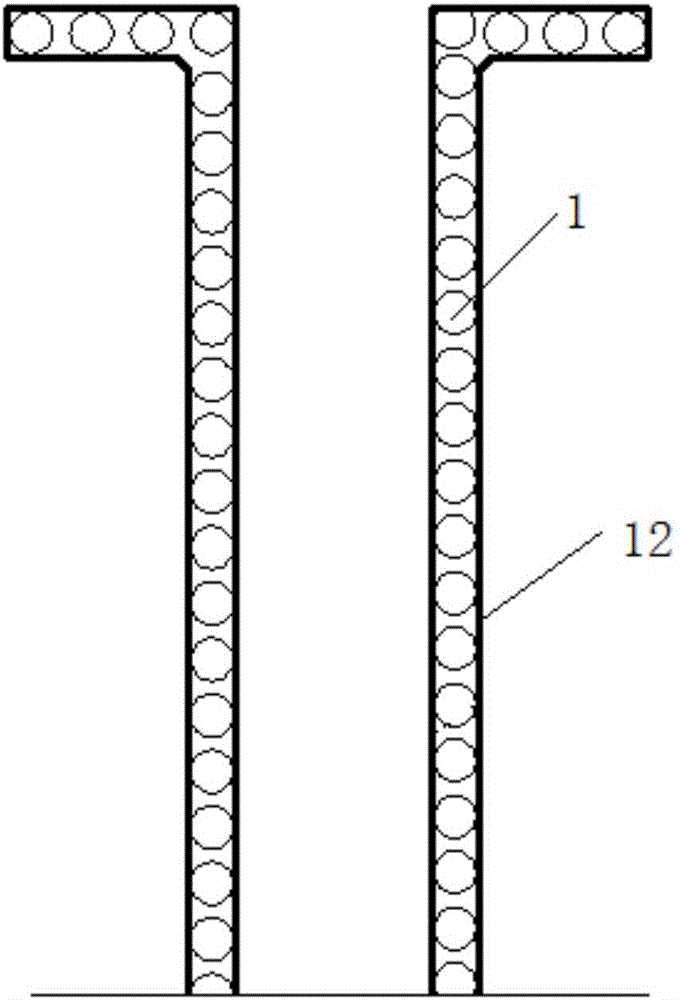

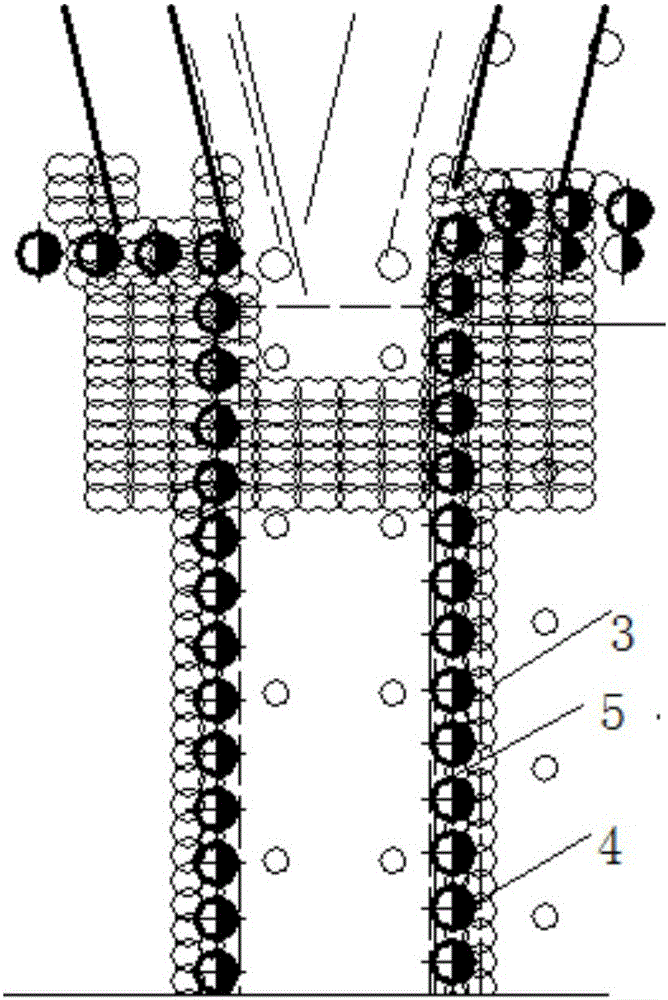

Slag trough structure and construction method for same

The invention discloses a slag ditch structure and a construction method thereof, belonging to the field of foundation pit construction. It includes support beams and slag ditch walls. Support piles are arranged outside the slag ditch walls, and support beams are arranged between the support piles. The supporting piles include water-stop piles and water-stop curtain piles, and the water-stop curtain piles are arranged between two adjacent water-stop piles. The supporting piles are bored cast-in-place piles, which are drilled with a drilling rig, then the steel cage is lowered into the hole, and concrete is poured. During the construction of the supporting piles, the pile position, the elevation of the top and bottom of the pile, the specific gravity of the mud, and the quality of the underwater concrete are strictly controlled. The number of water-stop piles is set to more than two rows, which is to strengthen the water-stop effect, and the water-stop piles can also play a role in resisting the lateral pressure of the soil. It can prevent water from entering the slag ditch, and can also bear the side pressure of the soil. The high-pressure rotating nozzle sprays the cement slurry into the soil layer and mixes with the soil to form a continuous lapped cement reinforcement. The construction occupies less land, has less vibration and less noise. Low.

Owner:马钢集团设计研究院有限责任公司

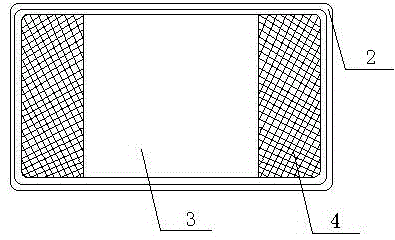

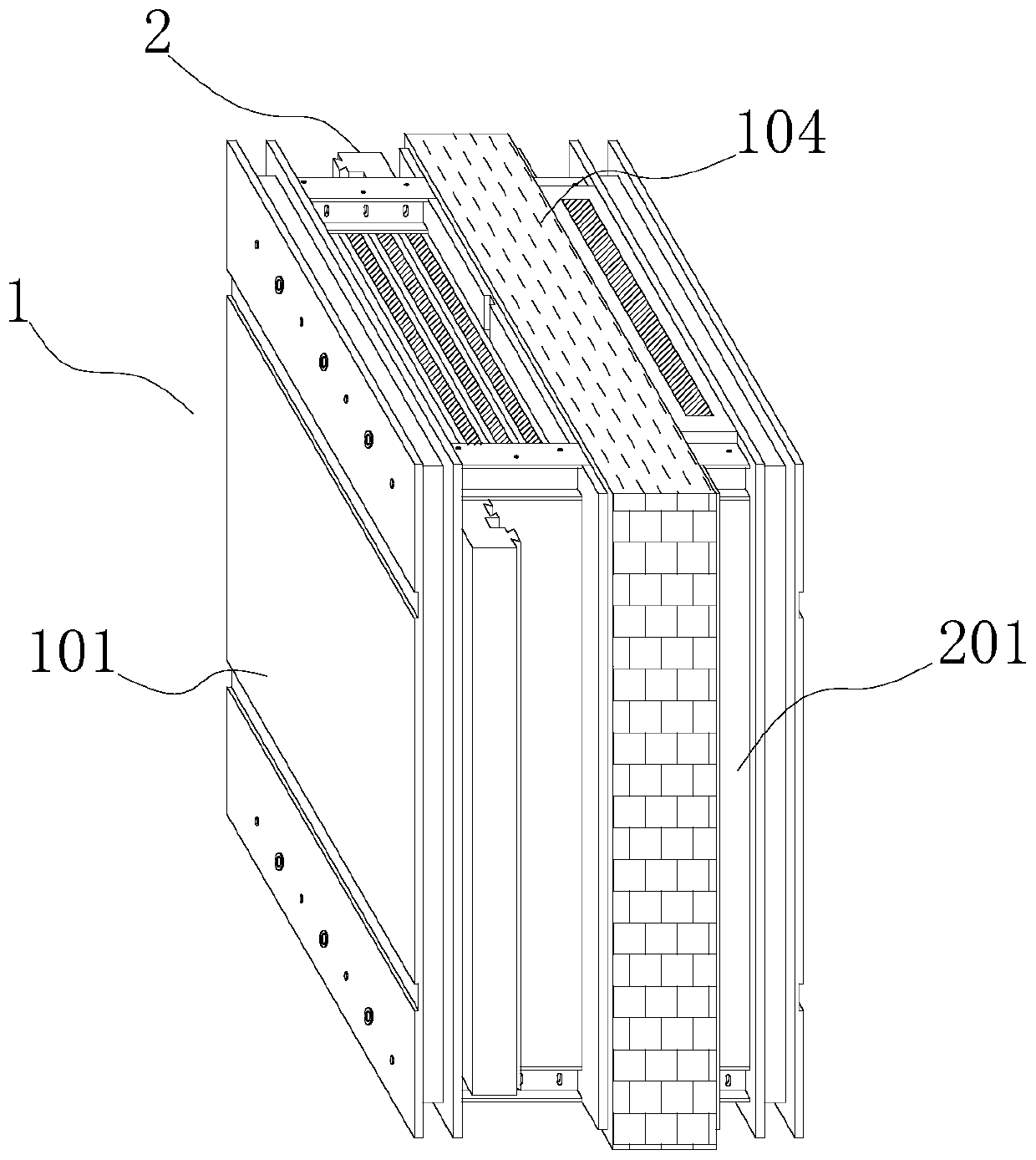

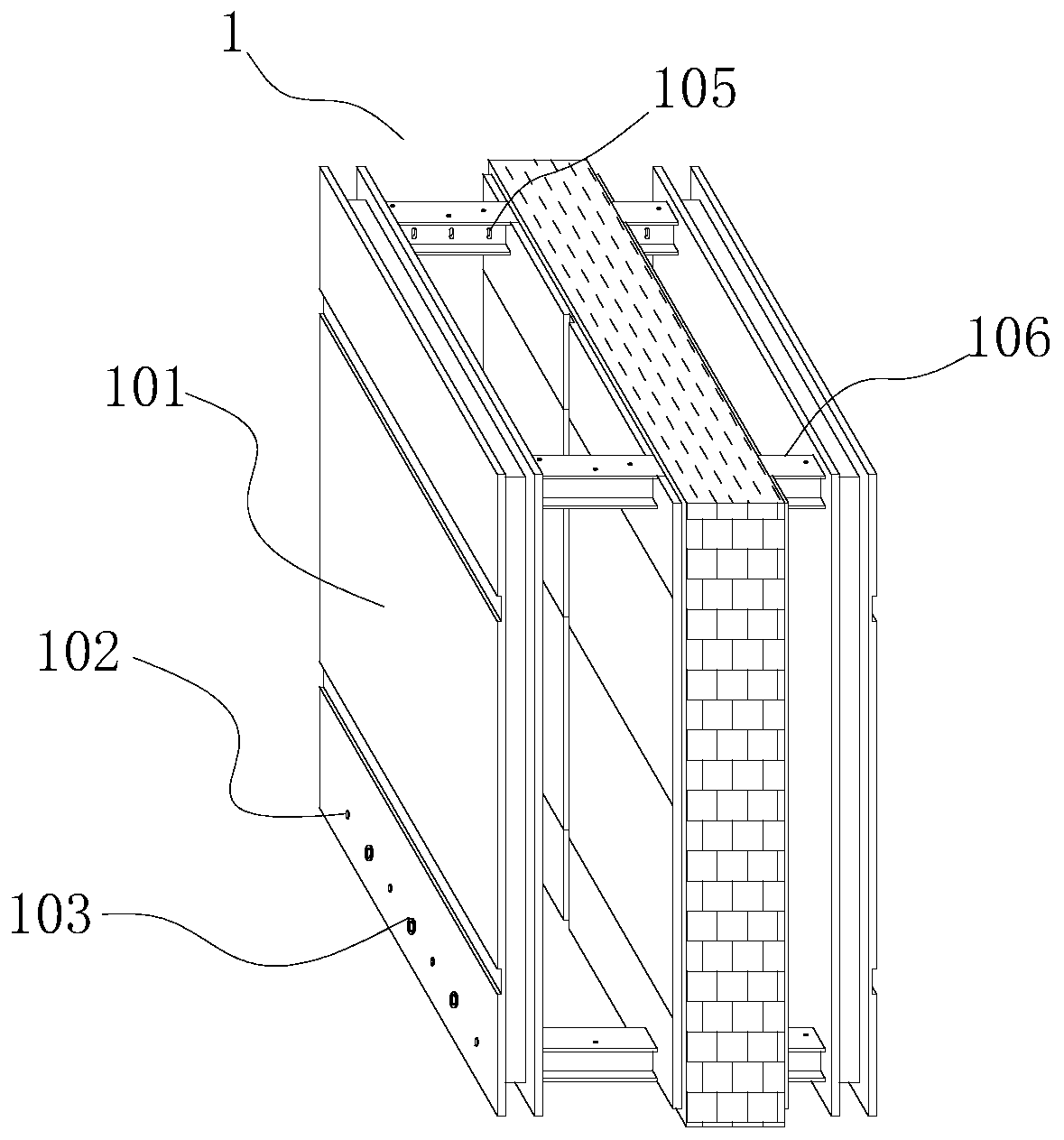

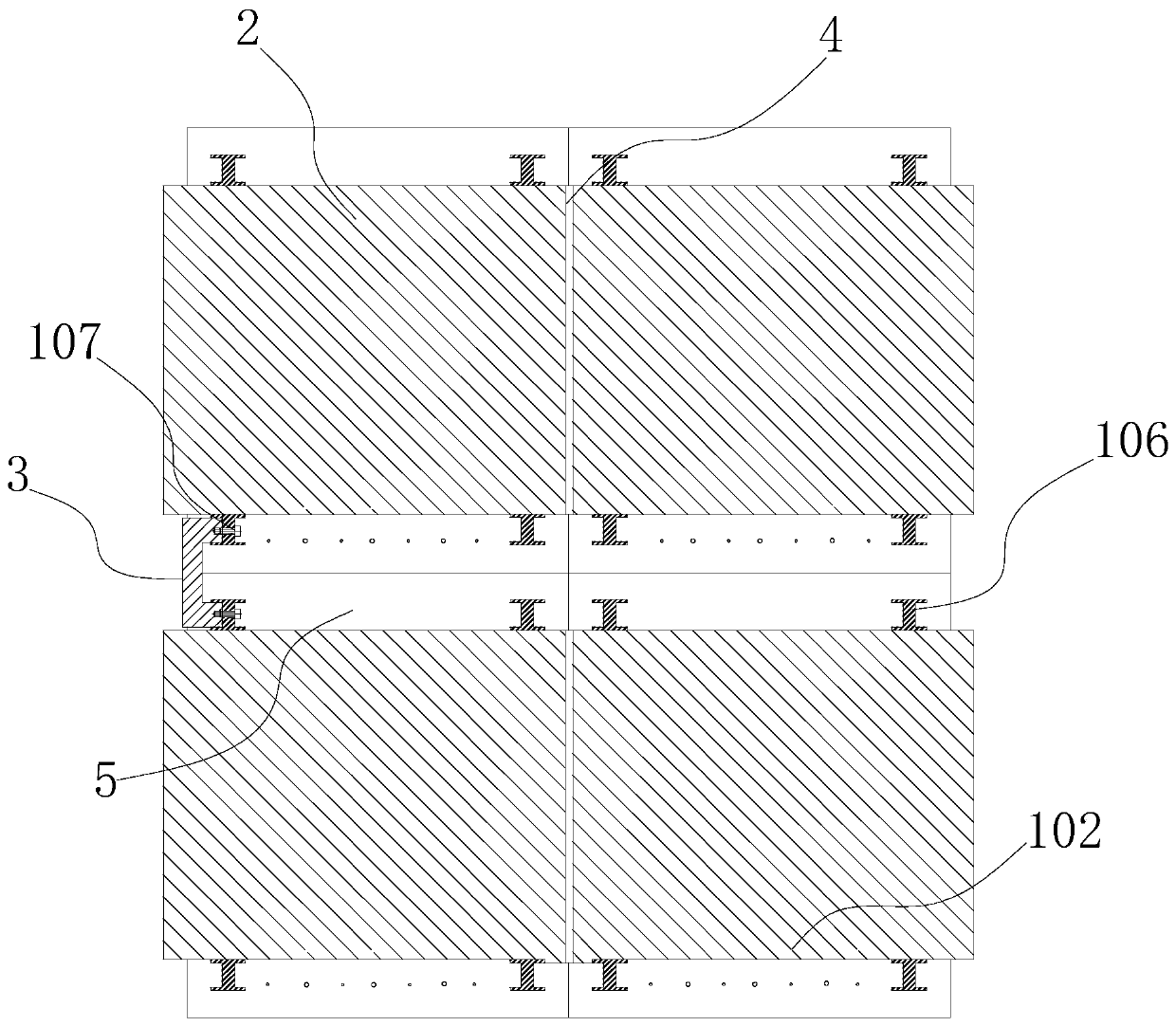

Composite fireproof thermal insulation wall body

ActiveCN111485642ARealize the structureNot easy to seepageWallsHeat proofingVapor barrierInsulation layer

The invention discloses a composite fireproof thermal insulation wall body. The composite fireproof thermal insulation wall body is formed by splicing a plurality of orderly and evenly arranged fabricated composite wall bodiess, each fabricated composite wall body comprises an outer frame and an inner function distribution layer, wherein the each inner function distribution layer is arranged in the corresponding outer frame and closely attached to the corresponding outer frame; each inner function distribution layer sequentially comprises a heat insulation layer, a protective layer, an anti-corrosion damp-proof layer and a fireproof layer, each outer frame comprises two outer wall panels and a bearing wall body, the two outer wall panels are fixed to two sides of the bearing wall body respectively, the left side of the bearing wall body is the inner side of the building wall body, and the right side of the bearing wall body is the outer side of the building wall body; and connecting steel pieces are symmetrically fixed to the four corners of the bearing wall body, the connecting steel pieces penetrate through the bearing wall body and connect and fix the outer side of the buildingwall body and an outer wall panel on the inner side of the building wall body, and the outer wall panel is a decorative layer of the composite fireproof heat preservation wall body.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Glass fiber cloth and processing technology thereof

PendingCN107757063AAvoid breakingNon-flammableSynthetic resin layered productsLaminationPolyesterGlass fiber

The invention provides glass fiber cloth and a processing technology thereof and belongs to the technical field of cloth. The glass fiber cloth comprises a glass fiber layer which is a woven fabric, the thread count of which is 30*30 / inch; the warps and wefts of the woven fabric are polyester silks of 1000D; the glass fiber cloth is characterized in that a PVC coating I and a PVC coating II separately coat two sides of the glass fiber layer; a waterproof layer I, a flame retardant layer I and a PVC coating III are successively on one side of the PVC coating I from inside to outside; a waterproof layer II, a flame retardant layer II and a PVC coating IV are successively arranged on one side of the PVC coating II from inside to outside. The glass fiber cloth provided by the invention has theadvantages of being flame retardant, waterproof and crack-folding-resistant.

Owner:ZHEJIANG FEIHU NEW MATERIAL CO LTD

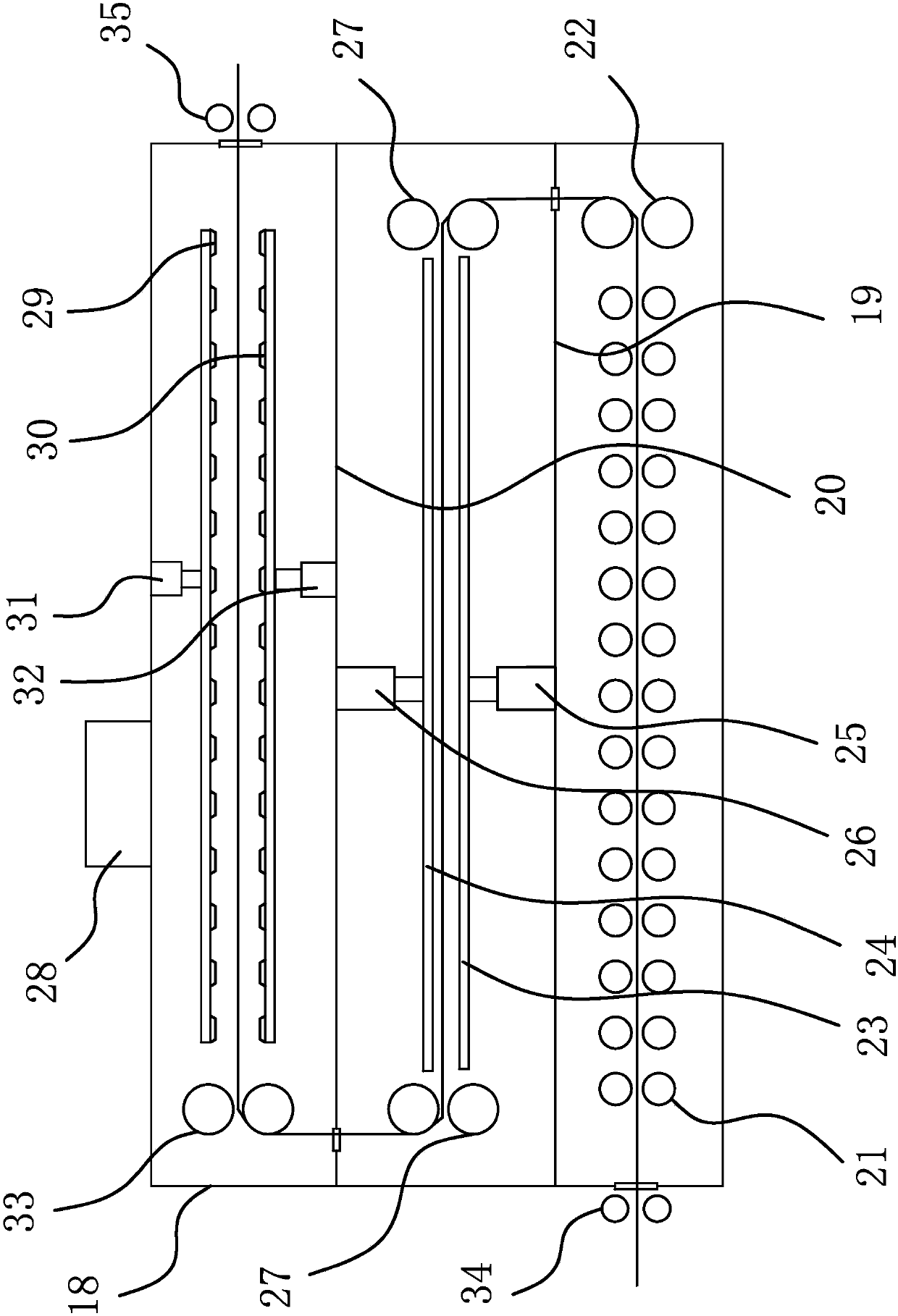

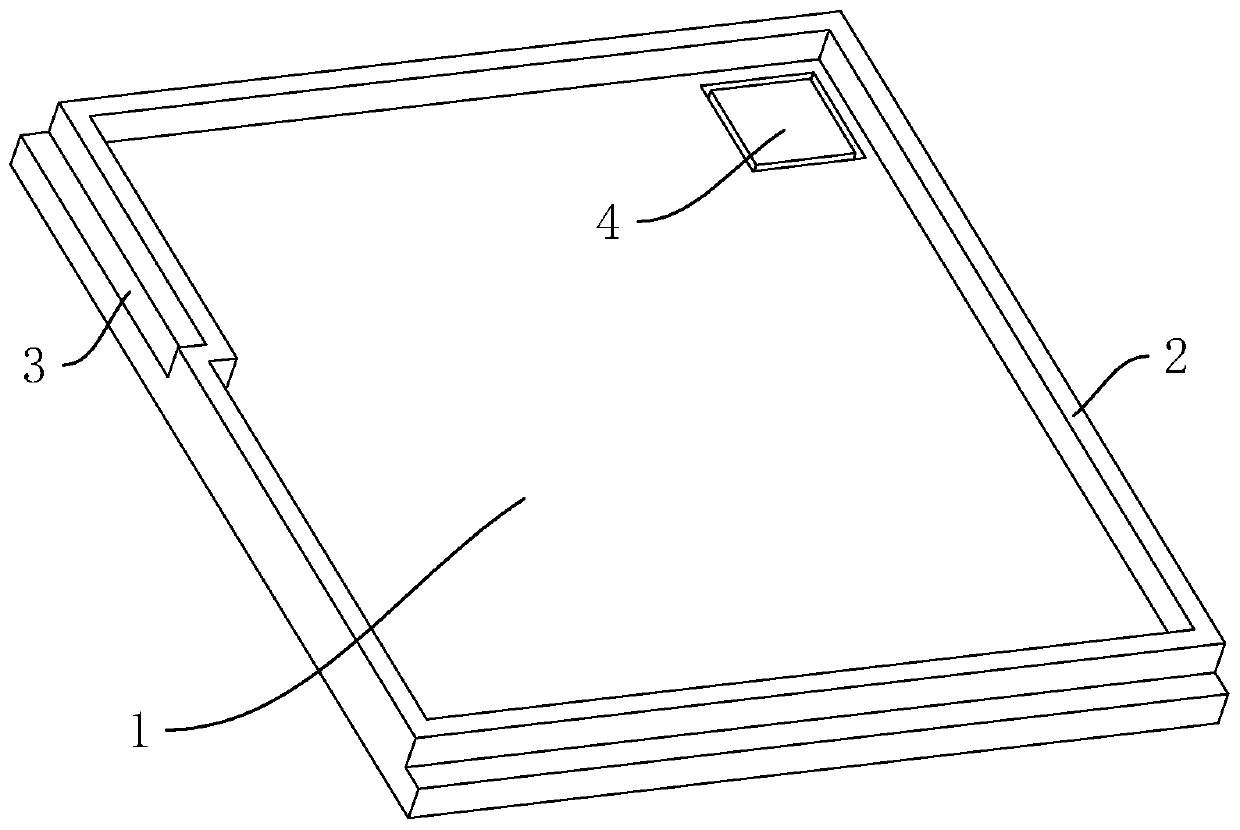

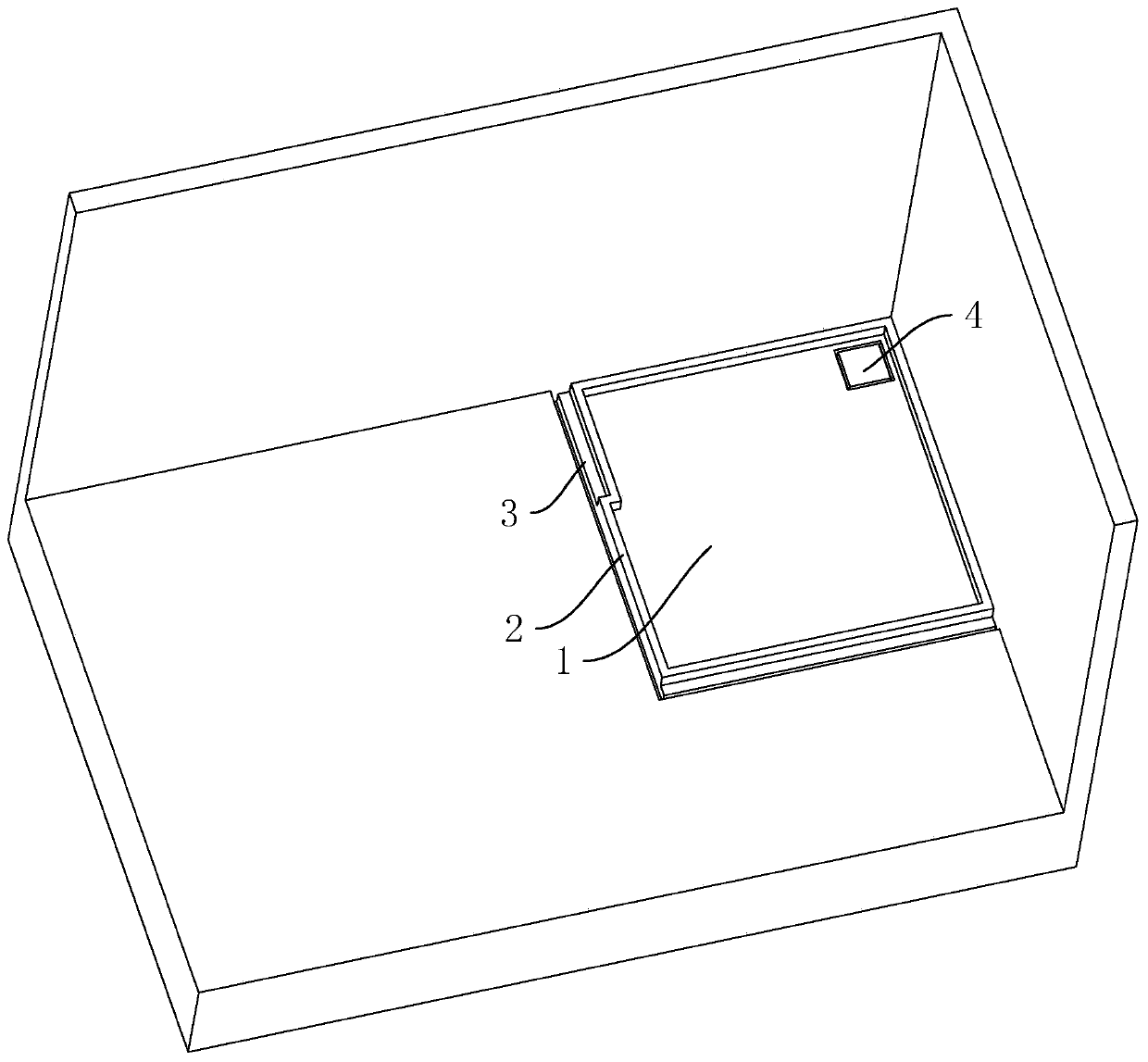

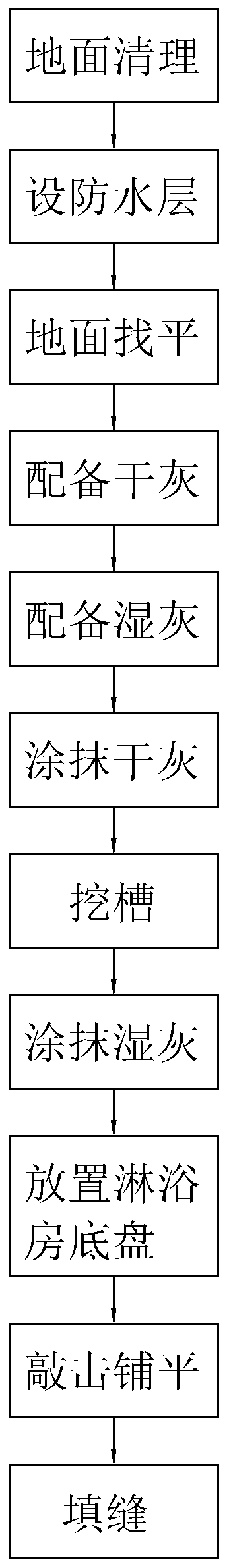

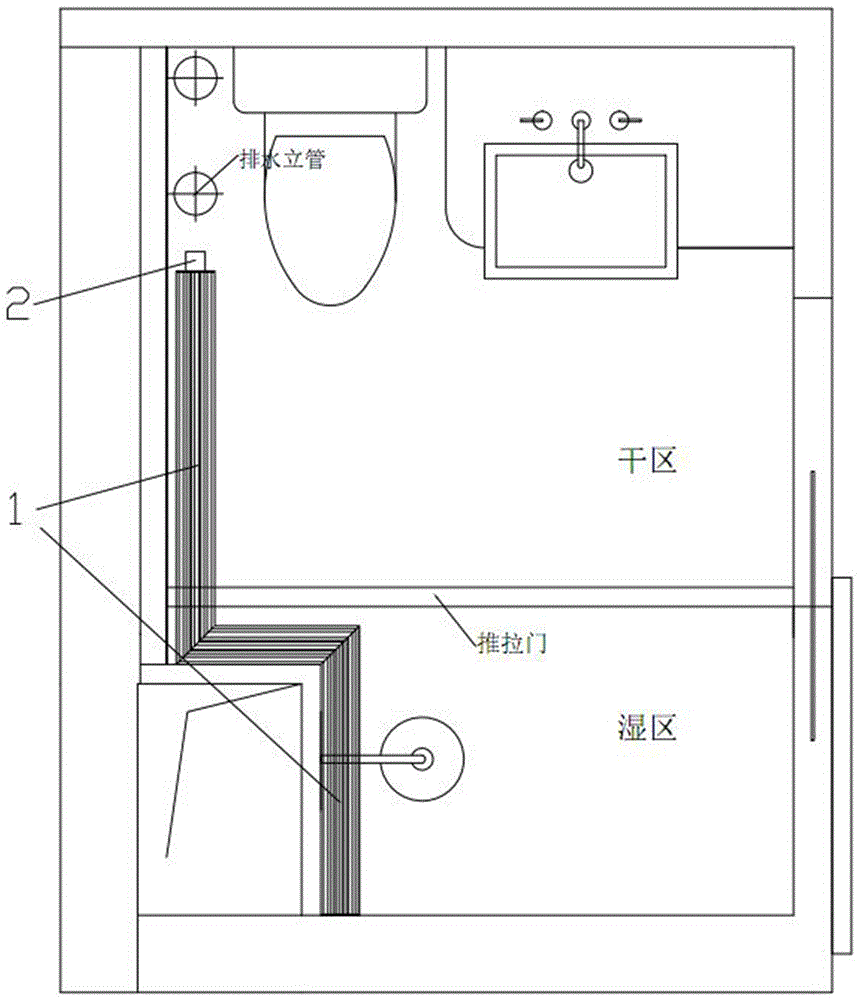

Bathroom shower room chassis and construction method thereof

ActiveCN109864644AWon't leakImprove waterproof performanceSewerage structuresBathsArchitectural engineeringBacteria

The invention discloses a bathroom shower room chassis, and relates to the field of interior decoration. According to the technical scheme, the chassis comprisesan integrally arranged marble bottom plate, the marble bottom plate is provided with a floor drain, the marble bottom plate is further integrally provided with a waterproof ring, the waterproof ring is formed by cutting the marble bottom plate, the outer side wall of the waterproof ring is flush with the outer side wall of the marble bottom plate, and the waterproof ring has a thin wall thickness of 5-20 mm. Afilling seam between a tile and a base and a beautiful seam are not soaked in the water for a long time,the time and water required for the water to penetrate are reduced, so that the water does not easily seep the seam between the tile and the base, the shower room base has good waterproof performance, and the effect thata wallbody does not easily get mildewed or breed bacteria is achieved.

Owner:台州铭星装饰工程股份有限公司

LED (Light Emitting Diode) module

ActiveCN104180192AReduce the numberNarrow design is beneficialPoint-like light sourceElectric circuit arrangementsWater leakageEngineering

The invention discloses an LED (Light Emitting Diode) module. The LED module comprises a lens group, LED beads, a circuit board and a radiator, wherein the LED beads are arranged on the circuit board in a welding way, the circuit board and the radiator are fixedly connected, the lens group is arranged above the LED beads in a covering way and is connected with the radiator, a wire penetrating hole is formed in the radiator, and a wire which is connected with a power supply penetrates through the wire penetrating hole and is arranged on the circuit board in the welding way so as to supply electricity to the LED beads; following double sealing structures of a double-layer silicone ring sealing structure and a wire double-layer sealing structure are adopted by the LED module. According to the LED module disclosed by the invention, a double protection mode of the double-layer silicone ring sealing structure and the wire double-layer sealing structure is adopted, the protection level of the LED module is effectively increased, the sealing performance of the LED module can be better, and water leakage is not easily caused; in addition, the structure of the lens group is redesigned, the surface of the lens group is additionally provided with reinforcing ribs, and the defect that the middle part of the lens group easily protrudes and deforms after the lens group is used for a long time is effectively solved; narrowing design is also carried out on the lens group, the raw materials are saved, and the cost is reduced.

Owner:HANGZHOU HPWINNER OPTO CORP

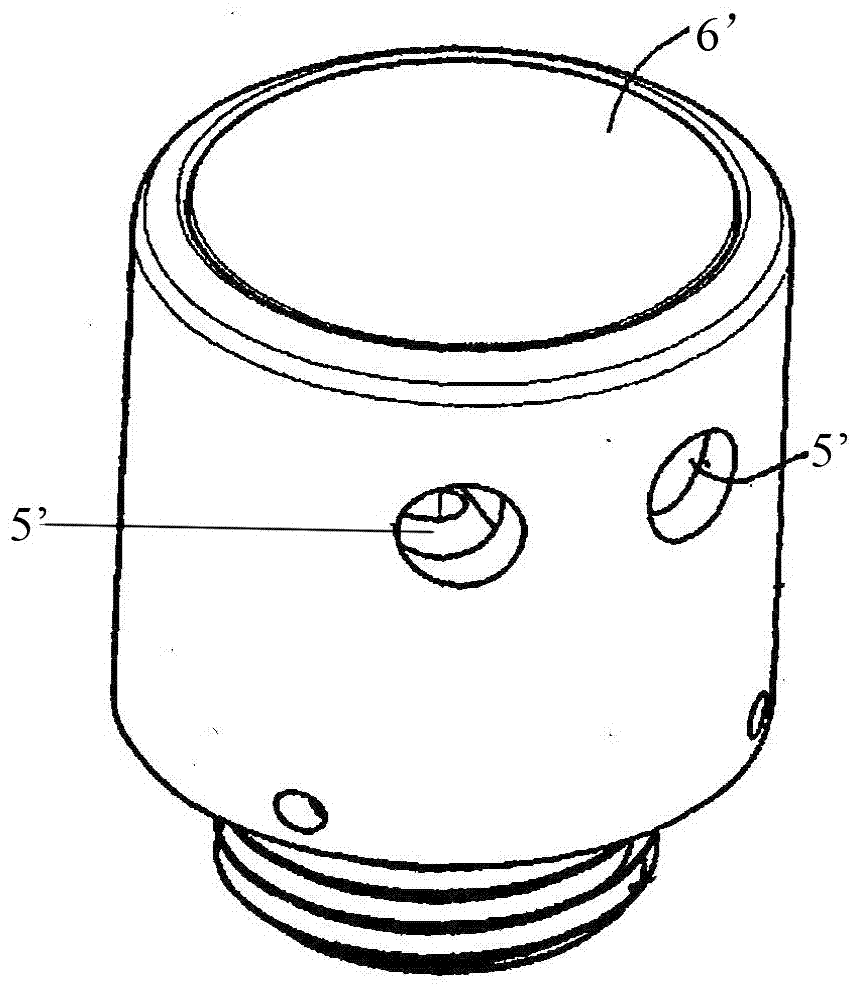

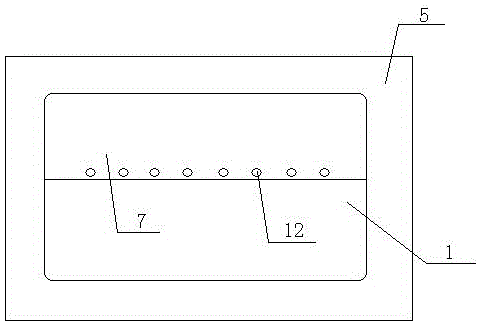

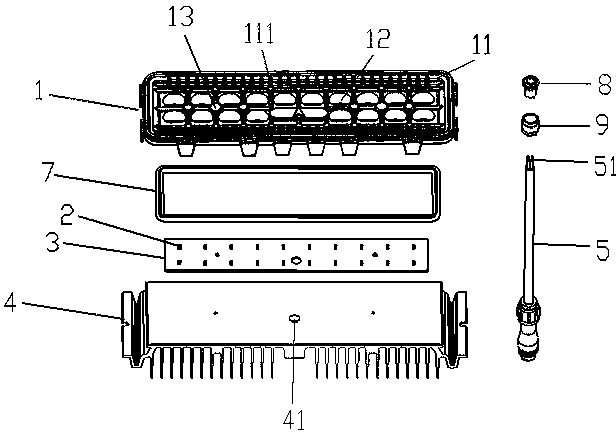

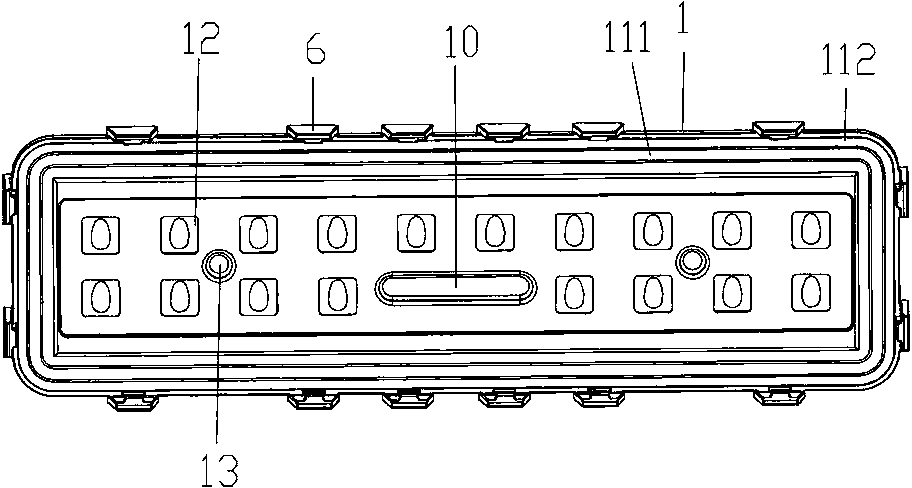

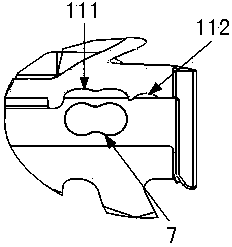

Spliced ultra-thin same-floor drainage facility provided with access port

InactiveCN105839764AIncrease water flow areaSatisfy deodorant effectSewerage structuresSewer pipelinesFloor slabEngineering

The invention provides a spliced ultra-thin same-floor drainage facility provided with an access port. The same-floor drainage facility comprises a drainage channel and a side drainage structure, wherein the drainage channel is formed by mutually splicing a plurality of strip-shaped converge bottom grooves, and a grate covers the upper parts of the converge bottom grooves; the drainage channel is arranged on a mounting surface by a gradient; the tail end of the drainage channel is the lowest point of the gradient, and the tail end of the drainage channel communicates with the side drainage structure; a water tank and a side drainage pipe are arranged in the side drainage structure; the water tank is matched with the converge bottom grooves of the drainage channel, so that a water seal is formed and the water seal communicates with an external drainage vertical pipe; a cleaning opening is formed in the upper part of the water outlet end of the water tank and the cleaning opening communicates with the converge bottom grooves; an opening cover is arranged on the cleaning opening; and the grate on the converge bottom grooves extends to the side drainage structure and covers the water inlet end and the cleaning opening of the water tank. According to the same-floor drainage facility disclosed by the invention, drainage and converge structures are optimized in a mode of splicing strips; moreover, through the coordination with the side drainage structure, a water passing area is increased, and by virtue of the structure, a cleaning operation is optimized; therefore, the same-floor drainage facility can meet an internal water seal standard, and meanwhile, the same-floor drainage facility can achieve same-floor drainage from a low-level floor slab to a floor drain finished surface.

Owner:FUZHOU KEME ENERGY SAVING TECH

Waterproof and sun-proof plastic woven bag

The invention relates to a waterproof and sun-proof plastic woven bag. The plastic woven bag comprises the following raw material components in parts by weight: 60-70 parts of polypropylene; 40-60 parts of linear low density polyethylene; 15-20 parts of polystyrene; 8-12 parts of titanium dioxide; 10-15 parts of nano calcium carbonate; 5-10 parts of octabromo ether; 15-20 parts of an ultraviolet light absorber; 8-16 parts of a tackifier; 10-14 parts of a toughening agent; 6-12 parts of an antioxidant; 5-10 parts of a flame retardant; and 4-10 parts of a filler. The plastic woven bag produced by using the formula materials is excellent in ultraviolet resistance and good in sunscreen and waterproof effects, and the service life of the plastic woven bag is prolonged.

Owner:TIANJIN JIUDA PLASTIC PRODS

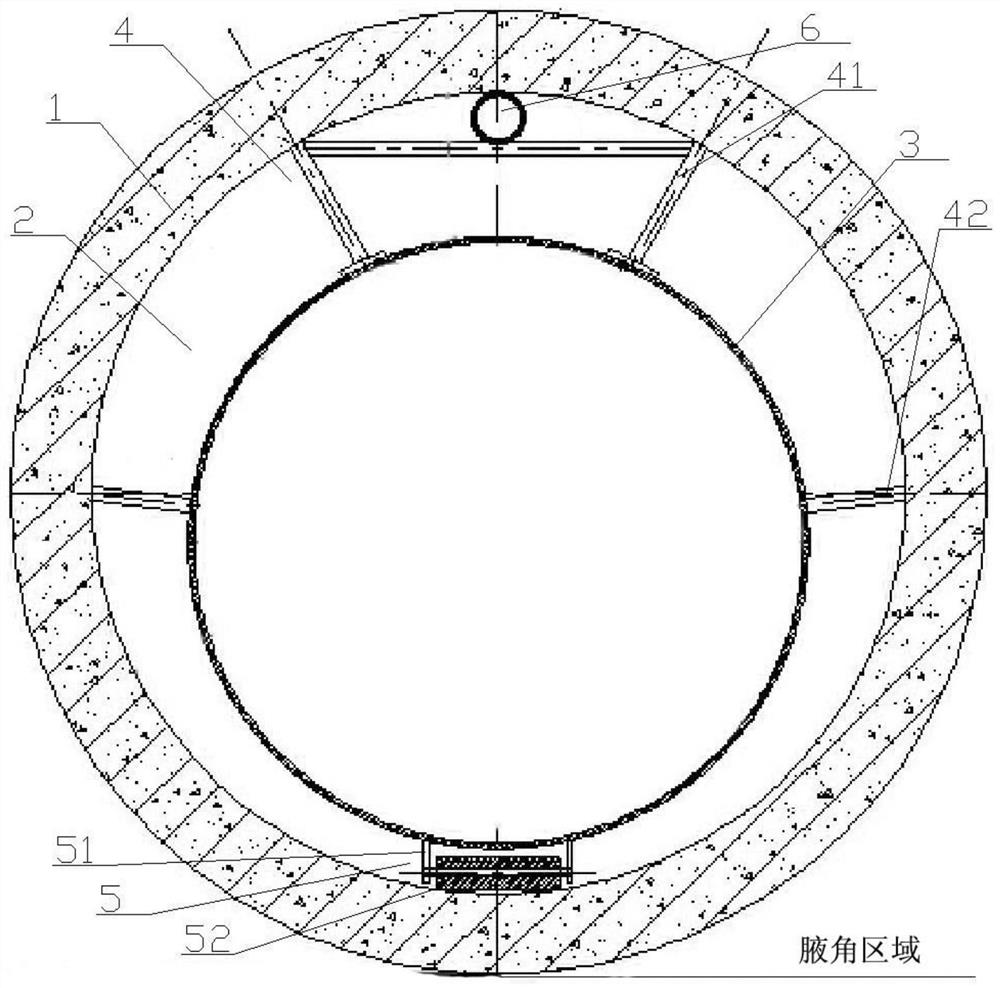

Casing type water delivery pipeline applied to crossing bridges and its installation and construction method

ActiveCN109323049BGuaranteed stabilityNot easy to seepagePipe supportsPipe laying and repairPenstockCross bridge

The invention discloses a casing pipe type water conveying pipeline applied to a crossing bridge and an installation and construction method thereof. The construction method comprises the following steps of: step 1. excavating a water conveying pipeline trench; step 2. installing a concrete casing pipe; step 3. backfilling the water conveying pipeline trench; step 4. installing a pressure steel pipe; step 5. filling concrete. A casing pipe type water conveying pipeline comprises the concrete casing pipe, a concrete pouring layer and the pressure steel pipe, wherein the concrete pouring layer is arranged at the outer side of the pressure steel pipe in a sleeving manner; the concrete casing pipe is arranged at the outer side of the concrete pouring layer in a sleeving manner; a supporting device is also connected between the concrete casing pipe and the pressure steel pipe; and steel idler wheels are also fixedly at the bottom of the pressure steel pipe. The construction method has closeworking procedure connection and effectively improves the construction efficiency. The stability of the pressure steel pipe is effectively ensured through the matching of the casing pipe layer structure and the supporting device, so that water is unlikely to seep from the pressure steel pipe.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

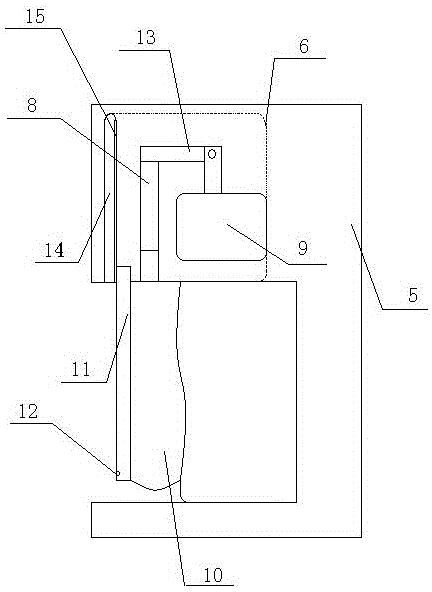

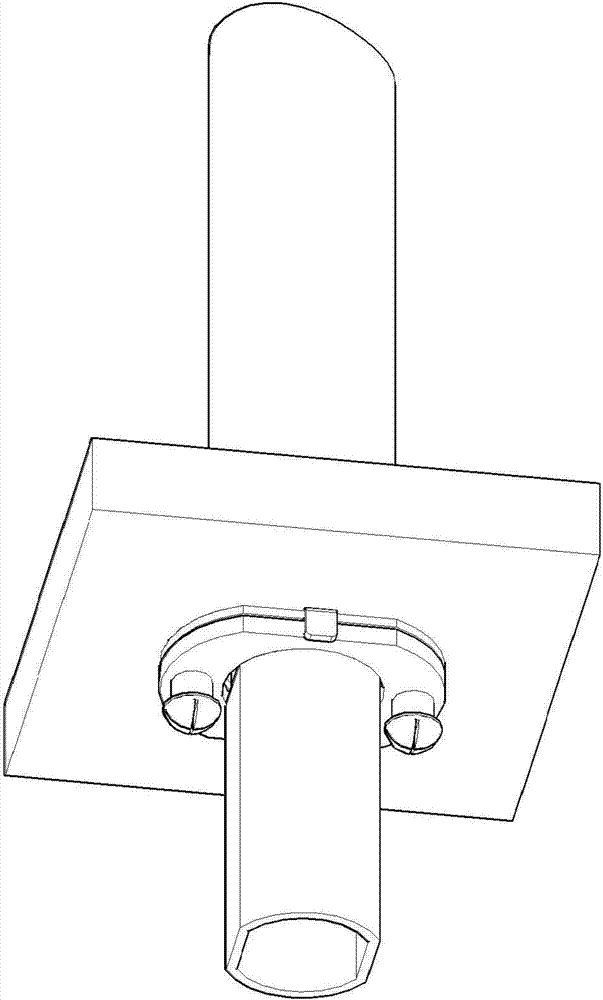

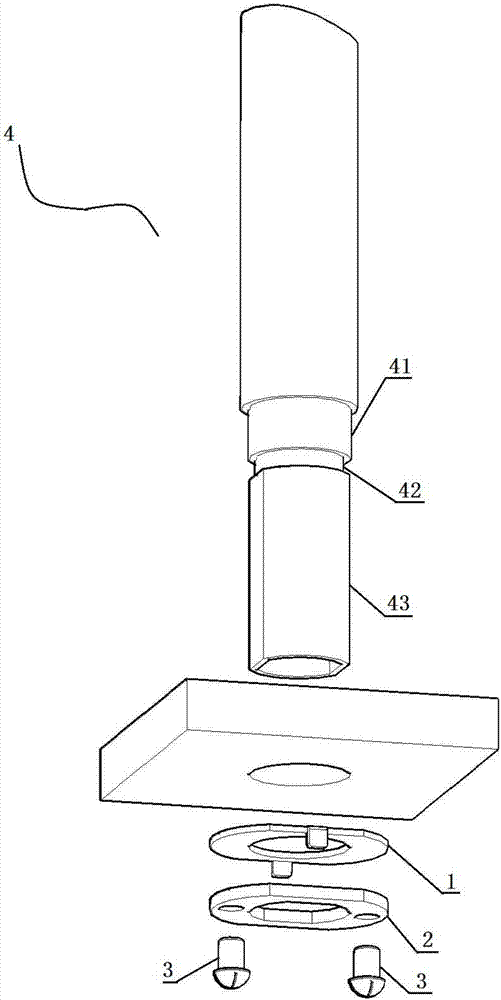

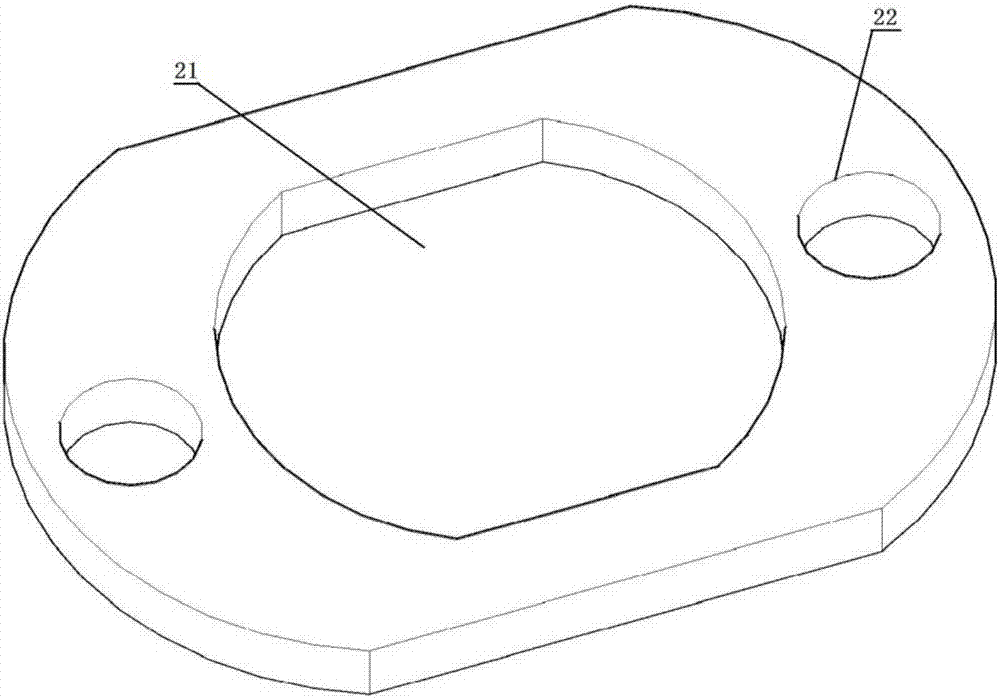

Faucet mounting fixer

InactiveCN107130665ARapid positioningNot easy to rotateValve arrangementsDomestic plumbingEngineeringMechanical engineering

A faucet installation fixture mainly includes a cover, a pressing piece and more than two locking screws; Rotate the sheet at a certain angle, so that the cover and the pressing sheet cannot slide out from the fixing column below the locking column, and then use the locking screw to press the pressing sheet on the cover from bottom to top, and the cover transfers the force to the table, so that The pressing piece and the gland are tightly pressed on the wall of the platform from bottom to top, so that the faucet cannot be pulled out, so as to realize the rapid positioning of the faucet, and then connect the water inlet pipe with the faucet installation guide post under the pressing piece, Complete the installation of the faucet; use the pressing piece to tighten the locking column, so that the position of the installation guide post of the faucet is fixed and difficult to rotate, so that the connection between the faucet and the water inlet pipe is not easy to loose and cause water seepage.

Owner:ZHONGSHAN YAXI ENVIRONMENTAL PROTECTION TECH

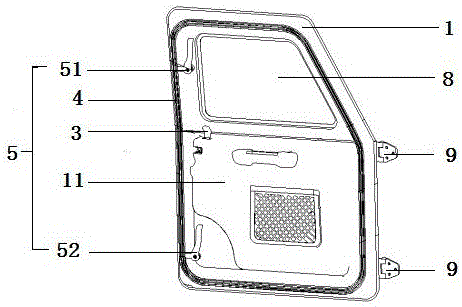

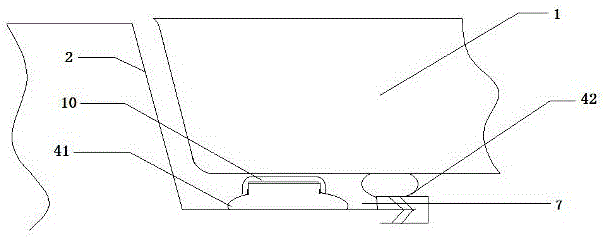

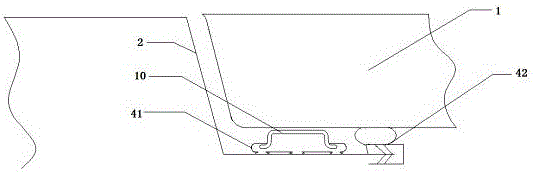

All-terrain vehicle and vehicle door thereof

ActiveCN106080137AImprove sealingReduce volumeEngine sealsVehicle sealing arrangementsCar doorAll terrain vehicles

The invention relates to the technical field of vehicle doors of amphibious vehicles and particularly discloses a vehicle door of an all-terrain vehicle. The vehicle door of the all-terrain vehicle comprises a door body, a door frame and a door lock. The first edge of the door body is hinged to the door frame. The vehicle door of the all-terrain vehicle further comprises two or more elastic sealing strips. The elastic sealing strips are arranged on the periphery of an inner plate of the door body and / or the door frame and used for sealing a gap between the door body and the door frame. When the vehicle door is in a closed state, the elastic sealing strips are in pressure contact with the door body or the door frame, and an airtight space is formed between every two adjacent elastic sealing strips. The sealing performance of the vehicle door can be greatly improved, and the vehicle door can meet the working requirement in water areas or similar environments.

Owner:GUIZHOU JONYANG KINETICS

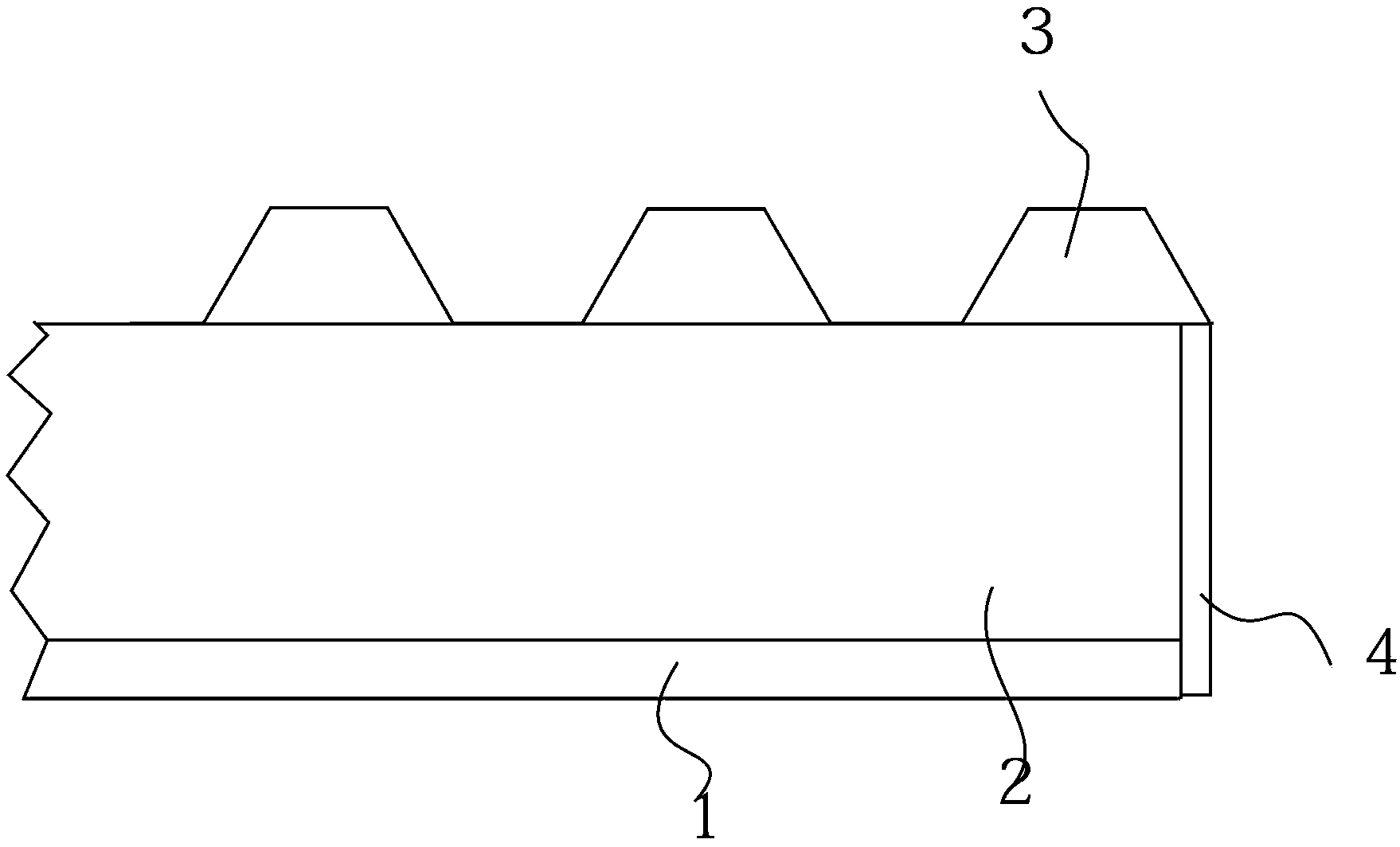

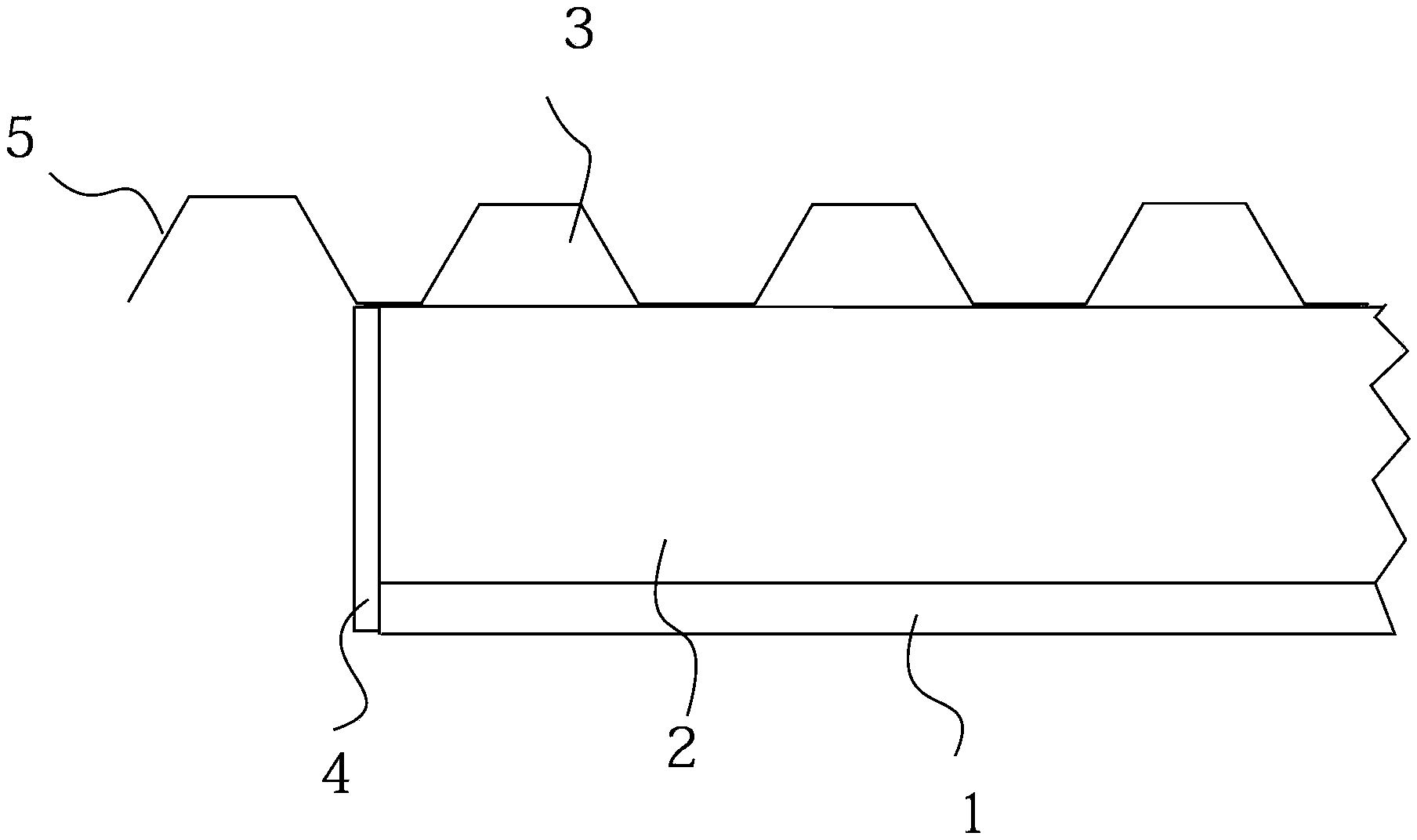

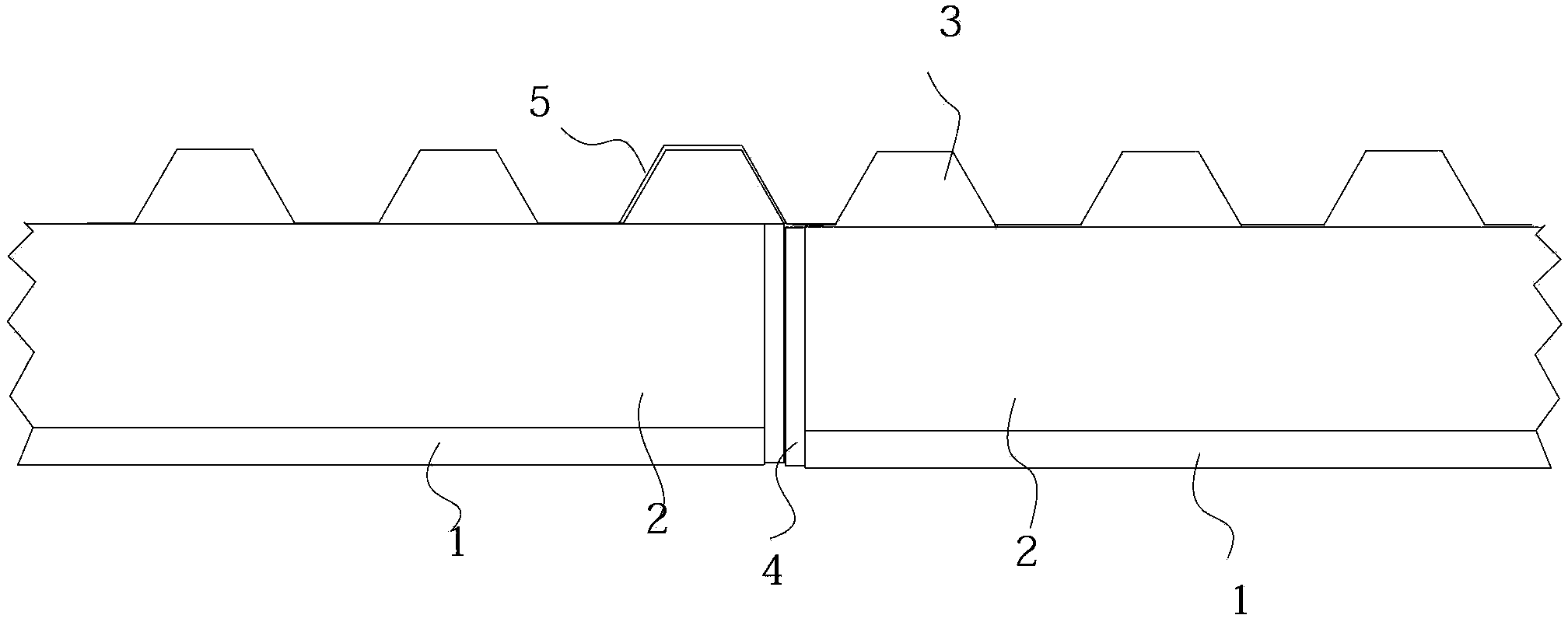

Metal profiled plate

InactiveCN104060772ASimple structureNice appearanceRoof covering using slabs/sheetsThermal insulationMaterials science

The invention discloses a metal profiled plate comprising antirust coatings, metal plate layers, thermal insulation layers, terrace shaped pieces and a connecting piece, wherein the metal plate layer is arranged at the bottom of the thermal insulation layer; the surface of each metal plate layer is coated with the corresponding antirust coating; the terrace shaped pieces are mounted at the tops of the thermal insulation layers; the connecting piece is arranged on the extended area of the thermal insulation layers; the connecting piece is in pressing fit and connected with one terrace shaped piece. The metal profiled plate has the benefits of simple structure, attractive appearance, tight connection, water seepage resistance and high simplicity in installation.

Owner:TIANJIN TIANFENG METAL PRESSURE PLATE

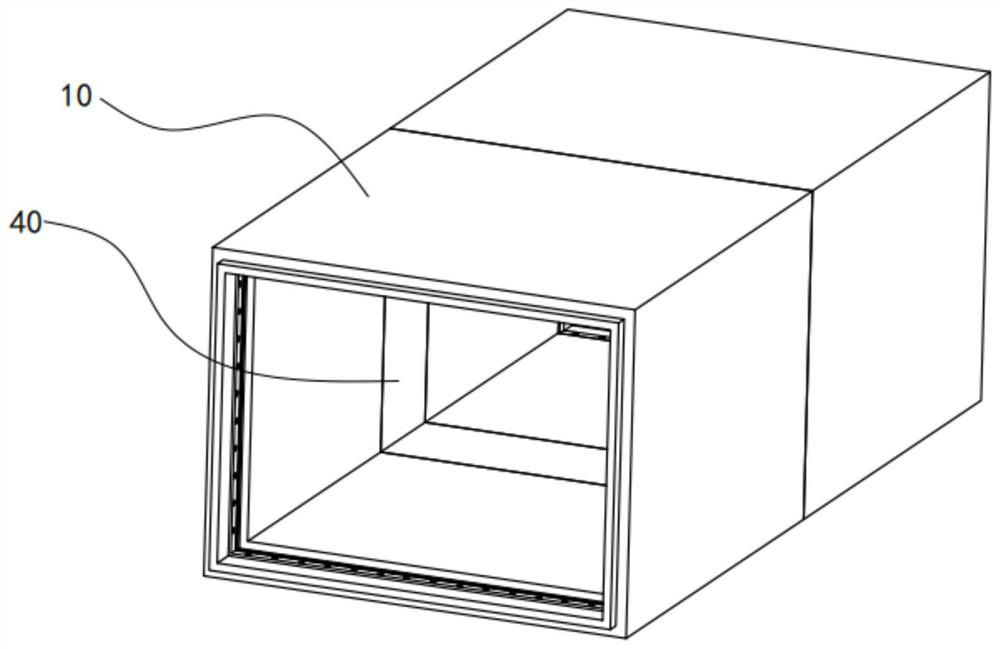

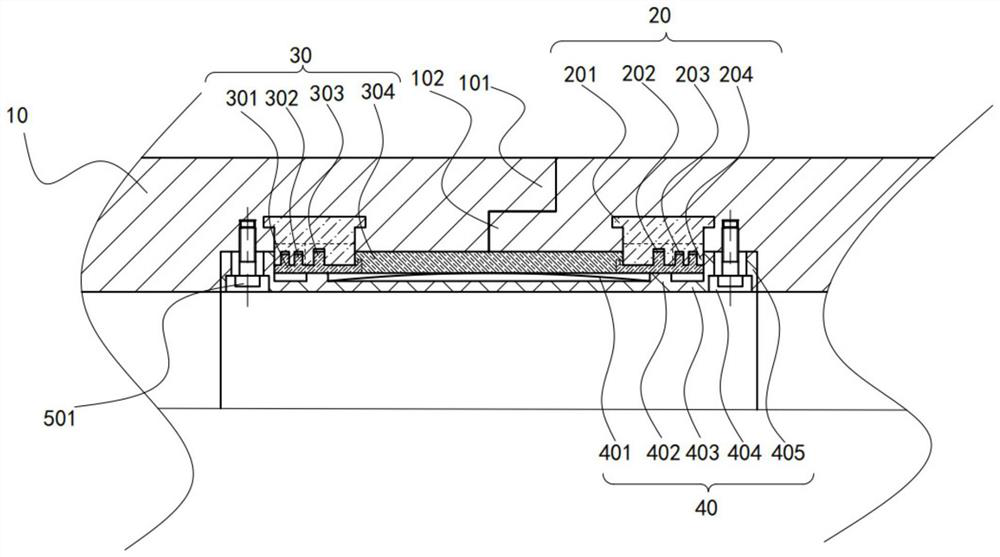

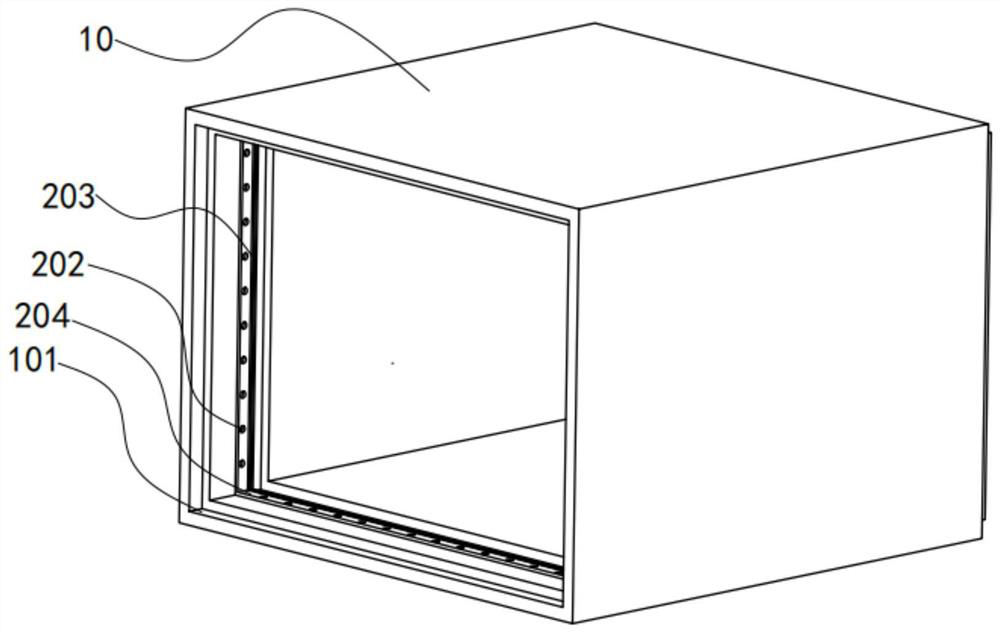

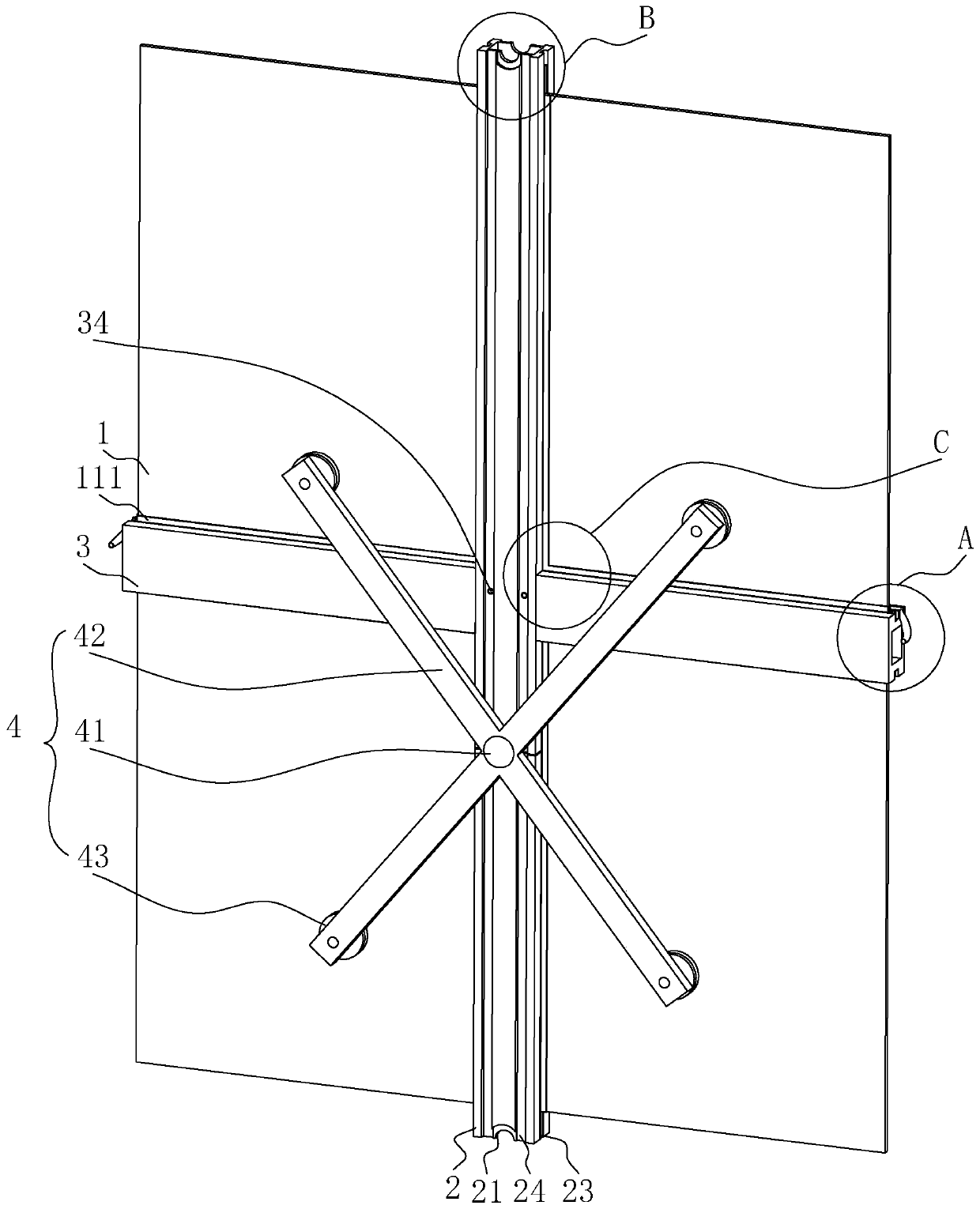

Waterproof pipe gallery with good sealing performance

ActiveCN113463686AAvoid damageReduce forceArtificial islandsProtective foundationStructural engineeringPipe

Owner:JINAN YELLOW RIVER CONSTR GRP CO LTD +1

Glass curtain wall with drainage structure and mounting method thereof

The invention relates to the technical field of glass curtain walls, in particular to a glass curtain wall with a drainage structure and a mounting method thereof. The glass curtain wall with the drainage structure comprises glass plates, stand columns and cross beams, the stand columns are connected through longitudinal insertion cores, and the stand columns and the cross beams are connected through transverse insertion cores; transverse limiting grooves are formed in the cross beams, longitudinal limiting grooves are formed in the stand columns, and the peripheral edges of the glass plates are clamped and fixed to the transverse limiting grooves and the longitudinal limiting grooves in a connected mode; waterproof sealing rubber strips are filled into the positions between the glass plates and the cross beams and between the glass plates and the stand columns, and the waterproof sealing rubber strips are bonded and fixed to the glass plates through silicone adhesives; transverse drainage grooves are formed in one sides of the cross beams, and openings of the transverse drainage grooves of the cross beams are connected with water guide nozzles; leading-in openings of the water guide nozzles are connected with the openings of the transverse drainage grooves, and leading-out openings of the water guide nozzles penetrate through the stand columns and are led out to the other sides of the glass plates; and the stand columns are provided with longitudinal drainage grooves used for draining water drained by the water guide nozzles. The glass curtain wall has the effects that theconstruction steps of extra pipeline drainage can be reduced, and rapid installation of the glass curtain wall is facilitated.

Owner:广东汇赢模块化房屋科技有限公司

Moisture-proof plastic woven bag

The invention relates to the technical field of woven bags, and especially relates to a moisture-proof plastic woven bag. The moisture-proof plastic woven bag comprises, by mass, 10-20 parts of an ethylene-vinyl acetate copolymer, 10-15 parts of nano-sulfobetaine, 5-10 parts of bentonite, 5-10 parts of dimethylaminoethyl acrylate, 3-8 parts of tetraethoxysilane, 3-8 parts of nanometer calcium carbonate, 10-20 parts of low-density polyethylene and 10-15 parts of polypropylene particles. The moisture-proof plastic woven bag adopting the above components is not prone to aging, peeling, breaking and crushing, and is not prone to be seeped in a humid environment, so that the service life of the plastic woven bag is prolonged; and the moisture-proof plastic woven bag also has the advantages of no environment pollution, low component cost, and easiness in production.

Owner:徐州华邦塑业有限公司

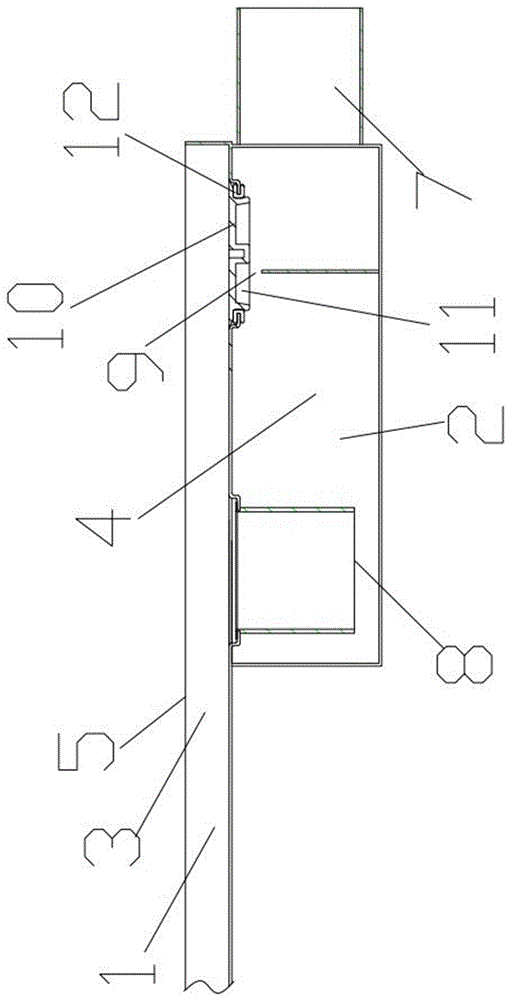

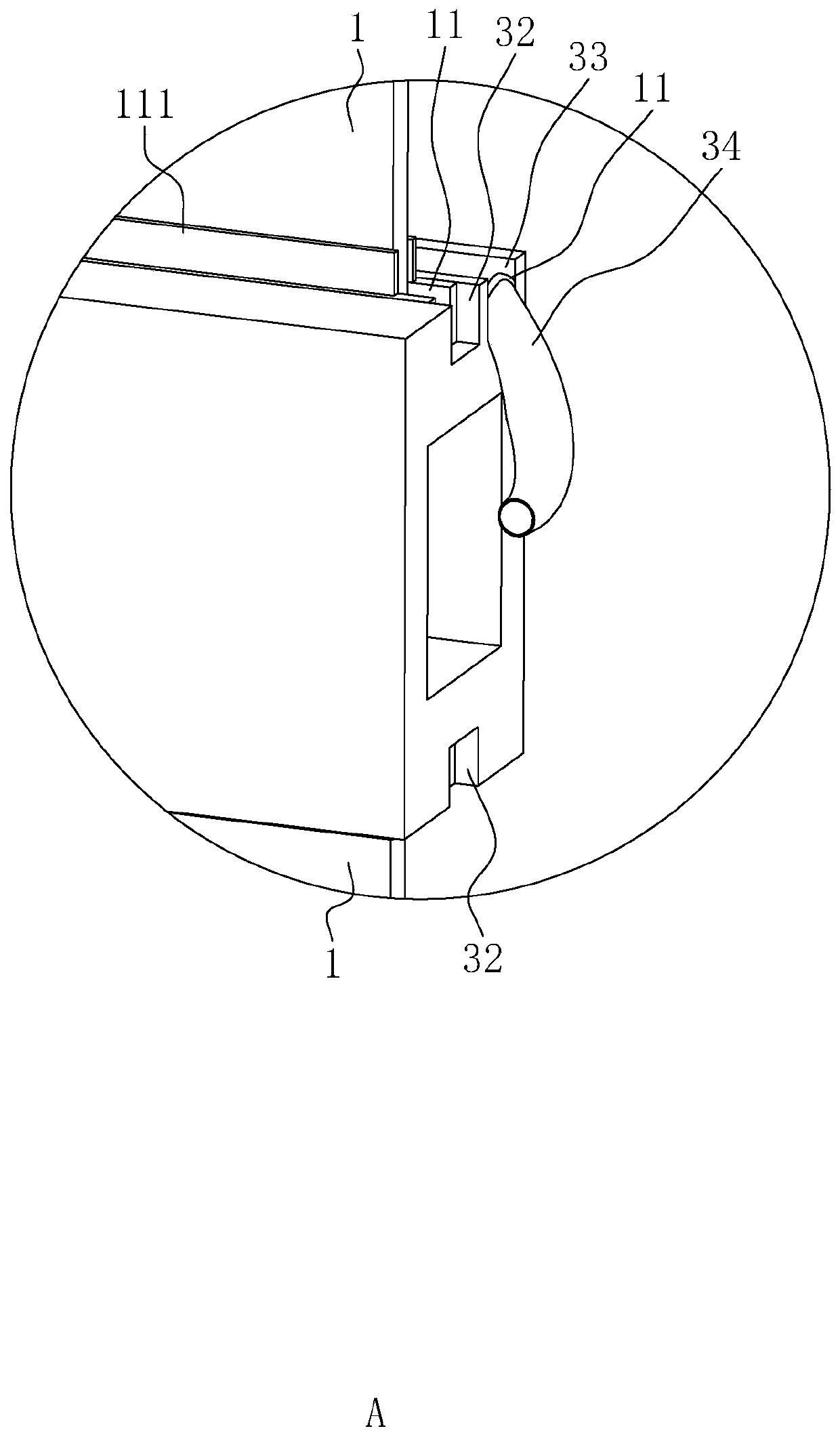

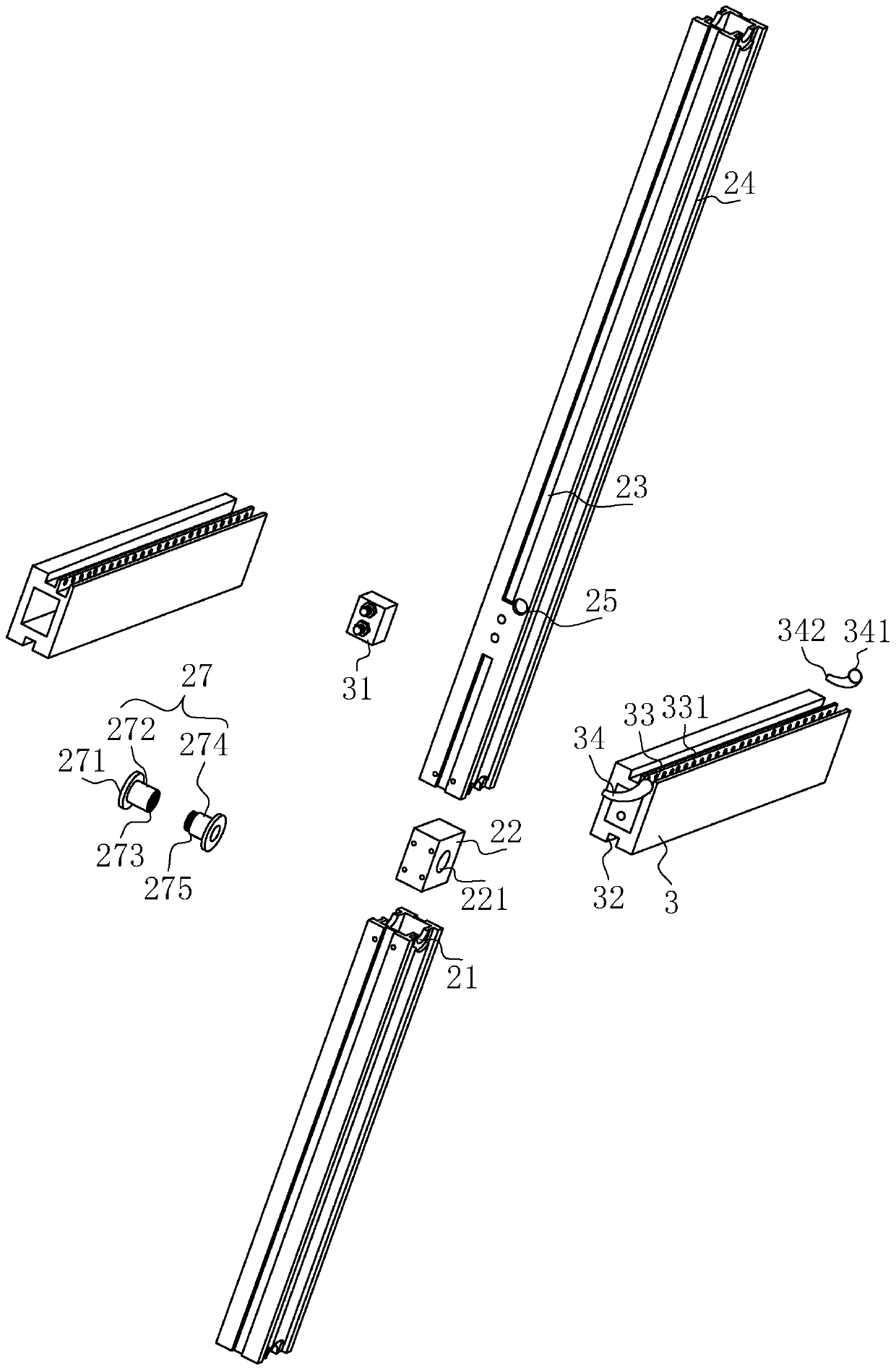

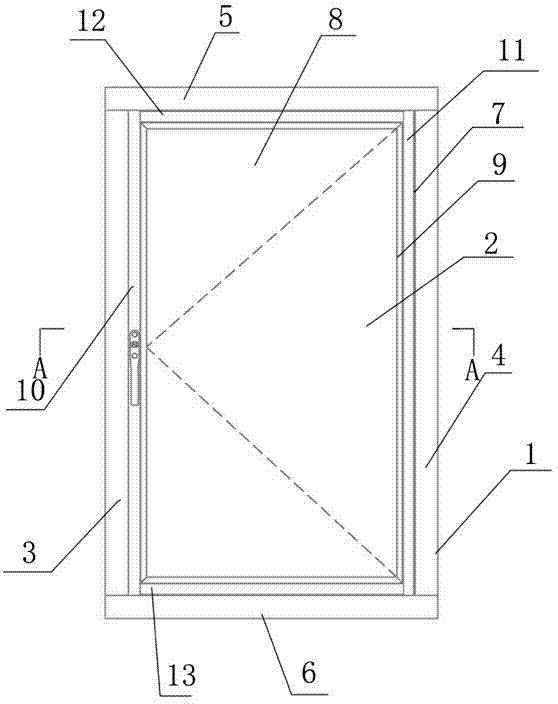

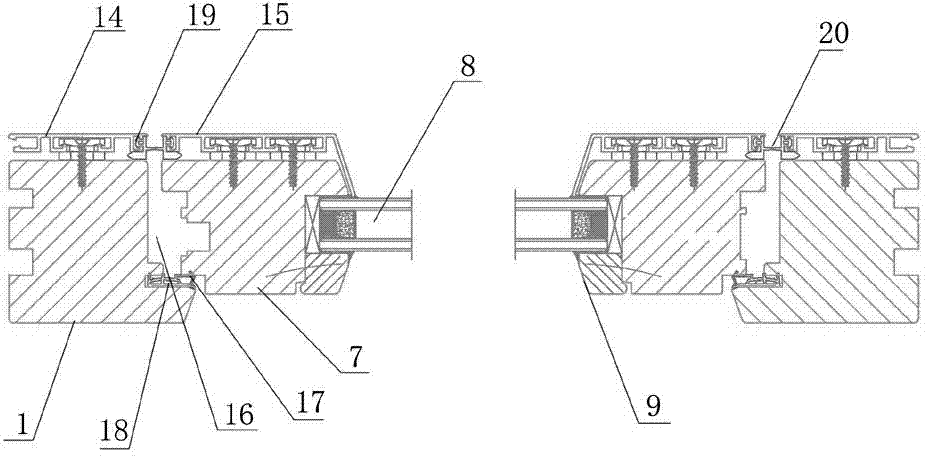

Aluminium-clad wood outward-opening door or window system

InactiveCN104775711AReasonable structureCompact structureWindow/door framesSealing arrangementsSash windowEngineering

The invention relates to an aluminium-clad wood outward-opening door or window system, which mainly comprises a door or window frame and a door leaf or window sash; the door or window frame mainly comprises a left wooden border, a right wooden border, an upper wooden border and a lower wooden border; the door leaf or window sash comprises a wooden leaf or sash frame, hollow glass and press line bar, wherein the wooden leaf or sash frame mainly comprises a left leaf or sash border, a right leaf or sash border, an upper leaf or sash border and a lower leaf or sash border; an aluminium door or window frame is fixed on the outdoor sidewall of the door or window frame, and an aluminium leaf or sash frame is correspondingly fixed on the outdoor sidewall of the wooden leaf or sash frame; the left wooden border, the right wooden border, the upper wooden border and the lower wooden border of the door or window frame are respectively provided with at least one stepped rabbet which faces outdoors, a joint is formed between the indoor side edge of the door leaf or window sash and the side edge of the stepped rabbet when the door leaf or window sash is closed into the door or window frame from outdoors, a rubber seal strip forming a second seal is arranged at the joint, and when the door leaf or window sash is closed into the door or window frame from outdoors, the outdoor surfaces of the aluminium door or window frame on the outdoor sidewall of the door or window frame and the aluminium leaf or sash frame on the outdoor sidewall of the wooden leaf or sash frame are flush on the same plane.

Owner:ZHEJIANG ROOMEYE ENERGY SAVING TECH CO LTD

One-time pouring moulding method for pipe rack segment

InactiveCN109853615AShort construction periodLow costArtificial islandsUnderwater structuresEngineeringWater seepage

The invention discloses a one-time pouring moulding method for a pipe rack segment. The method comprises the following steps: (1) positioning a pay-off line; (2) binding reinforcing steel bars of a bottom plate and a side wall; (3) installing a template of the side wall; (4) installing a load-bearing bracket; (5) installing the template of a top plate; (6) installing the reinforcing steel bars ofthe top plate, and further comprise the following steps: (7) pouring concrete. Pipe rack concrete adopts one-time integral pouring, a cross section is adopted to symmetrically pour longitudinal stratification to achieve pouring moulding in order, and compared with pouring in stages, the method has the advantages of short construction period, difficult water seepage at construction joints, and lowoverall cost.

Owner:中铁四局集团市政工程有限公司 +1

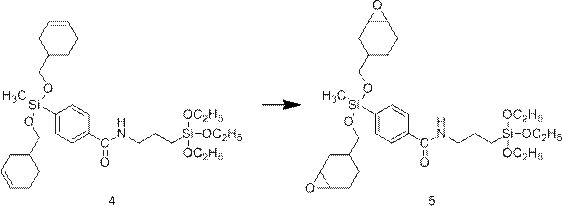

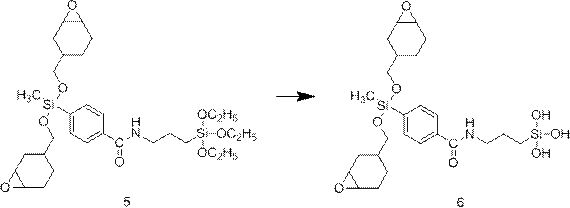

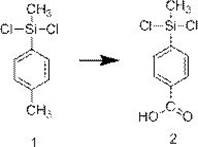

High-impermeability anti-crack concrete and preparation process thereof

The invention discloses high-impermeability anti-crack concrete and a preparation process thereof. The high-impermeability concrete is composed of the following raw materials in parts by weight: 100-120 parts of cement, 30-40 parts of fly ash, 35-50 parts of sand, 5-8 parts of a water reducing agent, 20-30 parts of a reinforced emulsion and 10-15 parts of ethylenediamine. The reinforced emulsion is prepared in the process of preparing the high-impermeability concrete; long-chain alkyl is grafted on the surface of a pre-modified carbon nanotube, and the long-chain alkyl has a good hydrophobic effect, so that the concrete is not prone to water seepage; meanwhile, the reinforced emulsion and ethylenediamine are added, and modified fibers in the reinforced emulsion are dispersed in the concrete, and under the action of ethylenediamine, the epoxy group on the surface of the modified fibers is subjected to ring opening and is fixed with the concrete, so that the concrete is not easy to crack, the service life of the concrete is prolonged, and the impermeability effect is better.

Owner:浙江华滋奔腾建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com