LED (Light Emitting Diode) module

A technology of LED module and lens group, applied in the field of lighting, can solve the problems of damage, middle bulge, and high raw material cost, and achieve the effects of reducing raw material cost, solving bulge deformation, and improving protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

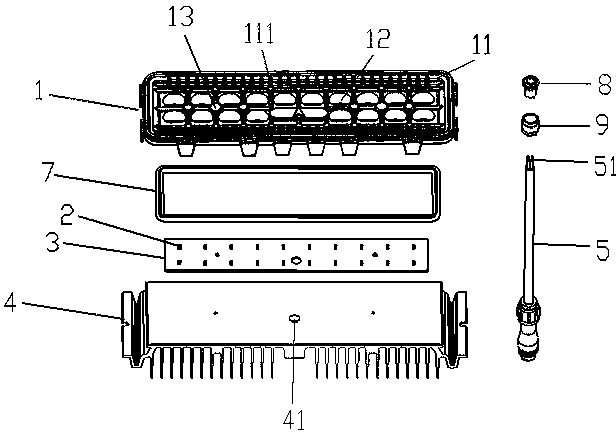

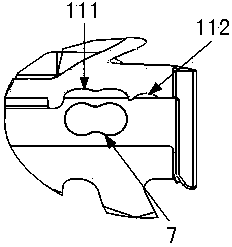

[0038] see figure 1 and figure 2 , this embodiment provides an LED module, including a lens group 1, LED particles 2, a circuit board 3, and a heat sink 4. The LED particles 2 are welded on the circuit board 3, and the circuit board 3 is fixedly connected to the heat sink 4. The lens group 1. The cover is set above the LED particle 2 and connected to the radiator 4. The radiator 4 is provided with a wire hole 41, and the wire 5 passes through the wire hole 41 to supply power to the LED particle 2. In this embodiment, the lens group 1 includes The lens base 11 and a plurality of lenses 12 arranged on the lens base 11 in a certain way, and the lens base 11 is rectangular, the LED module adopts double-layer silicone ring sealing structure and double-layer sealing structure of electric wire for double sealing protection structure, where:

[0039] The sealing structure of the double-layer silicone ring is: the connection between the lens group 1 and the radiator 4 is sealed with...

Embodiment 2

[0047] see Figure 7 and Figure 8 , compared with the lens in the first embodiment, the lens in this embodiment has the following differences:

[0048] The distance between the lens in the lens group 1' and the edge of the lens base 11' is narrower, which facilitates the narrowing of the lens group and the LED module, and saves raw materials; to match;

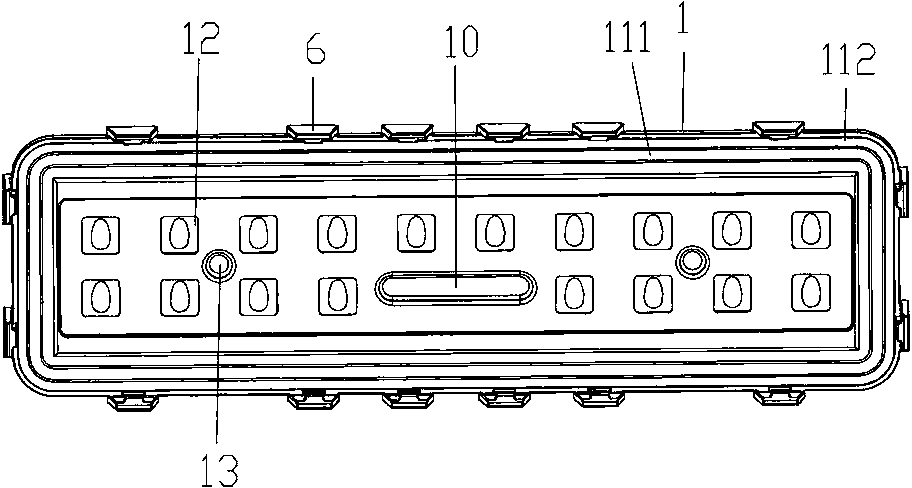

[0049] The arrangement of lenses on the lens group 1' is different: the lens 12 is divided into two rows, and a lens is respectively arranged at the two ends of the two rows of lenses, and the wire-avoiding groove 10 is arranged in the middle of one row of lenses. For example in Figure 7 Among them, the number of lenses is 16, of which 8 lenses form a row, and the other 6 lenses form another row, and the remaining two lenses are arranged at both ends of the upper two rows of lenses, and the one containing 6 lenses The position of the two lenses in the middle of the row is used for setting the wire-avoiding groove 10, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com