Multifunctional switching valve and water outlet device thereof

A multi-functional switching and switching valve technology, applied in the bathroom field, which can solve the problems of low service life, narrow application area, and inability to pass through identification and conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

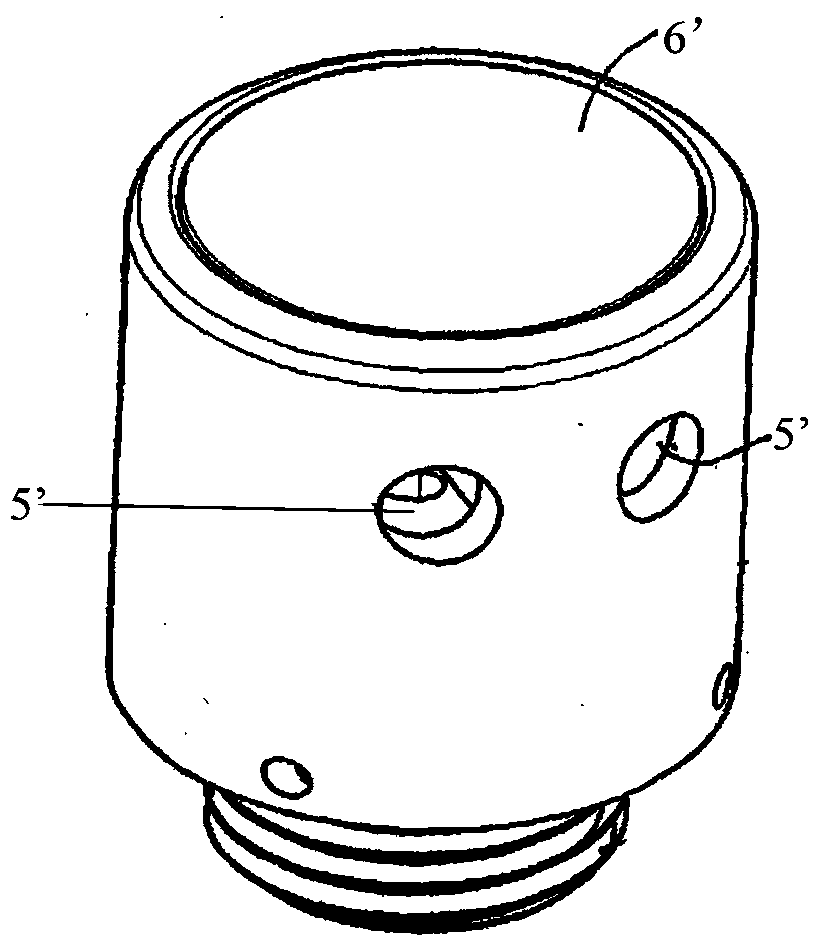

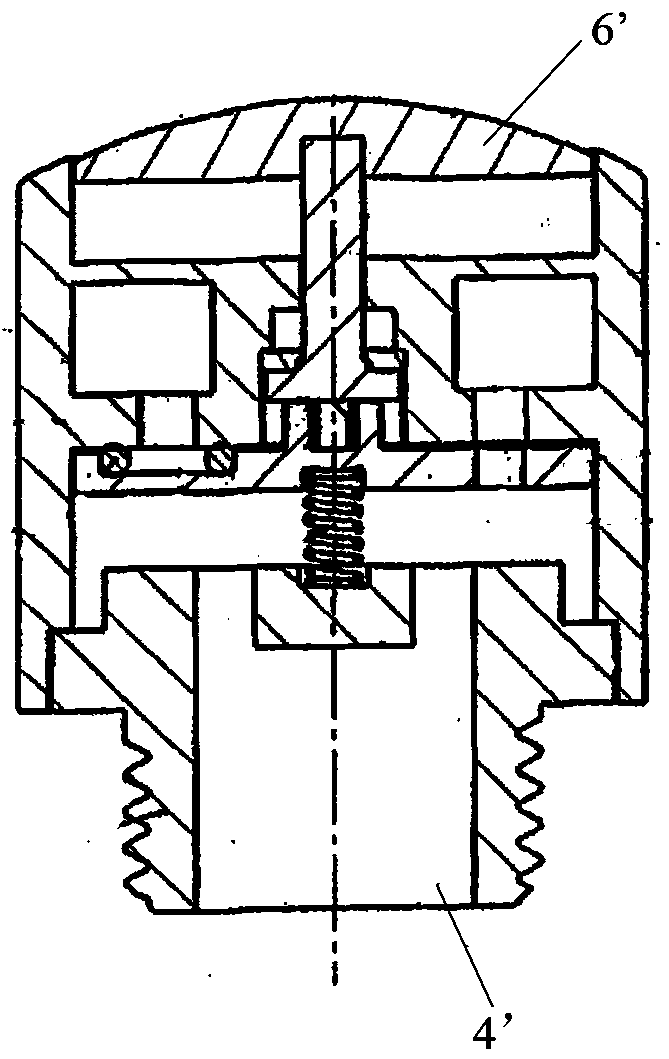

[0066] Such as Figure 3-1 —— Figure 3-6 As shown, a multifunctional switching valve includes an automatic ballpoint pen type pressing mechanism 1 , a sealing guide rod 2 , a valve core body 3 , a first spring 5 and a flow regulating device 6 .

[0067] The automatic ballpoint pen pressing mechanism 1 is consistent with the principle of the ordinary ballpoint pen pressing mechanism, but the specific connection and matching methods have certain characteristics. Specifically, the automatic ballpoint pen pressing mechanism 1 includes a static ratchet 11, a dynamic ratchet 12, and a ratchet seat. 13 and the second spring 14; the static ratchet 11 has an open end 111, and its bottom has a saw-toothed ratchet 112, and several positioning projections 113 are evenly distributed on the outer circumference of the ratchet 112; The movable ratchet 12 has an open end 121, and its bottom has a movable ratchet 122 that cooperates with the static ratchet ratchet 112, and the movable ratchet...

no. 2 example

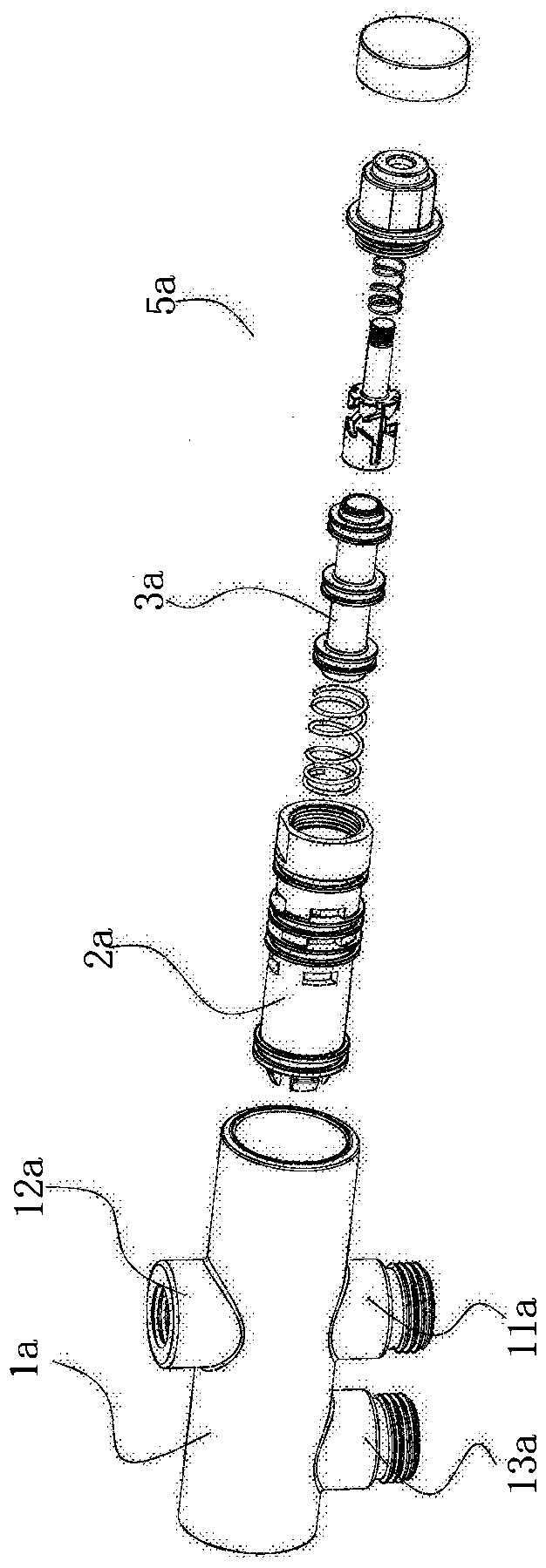

[0084] Such as Figure 10 As shown, the upper structure of the switching valve 1000A including the pressing mechanism 1A, the sealing guide rod 2A, the valve core 3A, etc. is basically the same as that of the first embodiment of the switching valve, but the valve core seat 301A is additionally provided with Two mutually independent water inlets 37A, 37B, and at the same time, the peripheral portion of the ceramic stator 61A is provided with two water inlet through holes 611A, 611B, the aforementioned two water inlet through holes 611A, 611B are respectively connected to the valve core seat body 301A The two water inlets 37A, 37B are connected to each other; the peripheral portion of the ceramic moving piece 62A is provided with at least one flow regulating hole 621A and a sealing surface 622A, and the flow regulating hole 621A is rotatably connected to the two ceramic stationary pieces 62A. The water inlet holes 611A and 611B are interconnected, and at the same time, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com