Spliced ultra-thin same-floor drainage facility provided with access port

A technology for same-layer drainage and inspection openings, which is applied to drainage structures, waterway systems, water supply devices, etc., can solve the problems of designing and cleaning structures without traps, failure to achieve same-layer drainage, and no confluence structure, etc., to meet the requirements of Anti-odor effect, optimized water seal position, effect of lowering height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

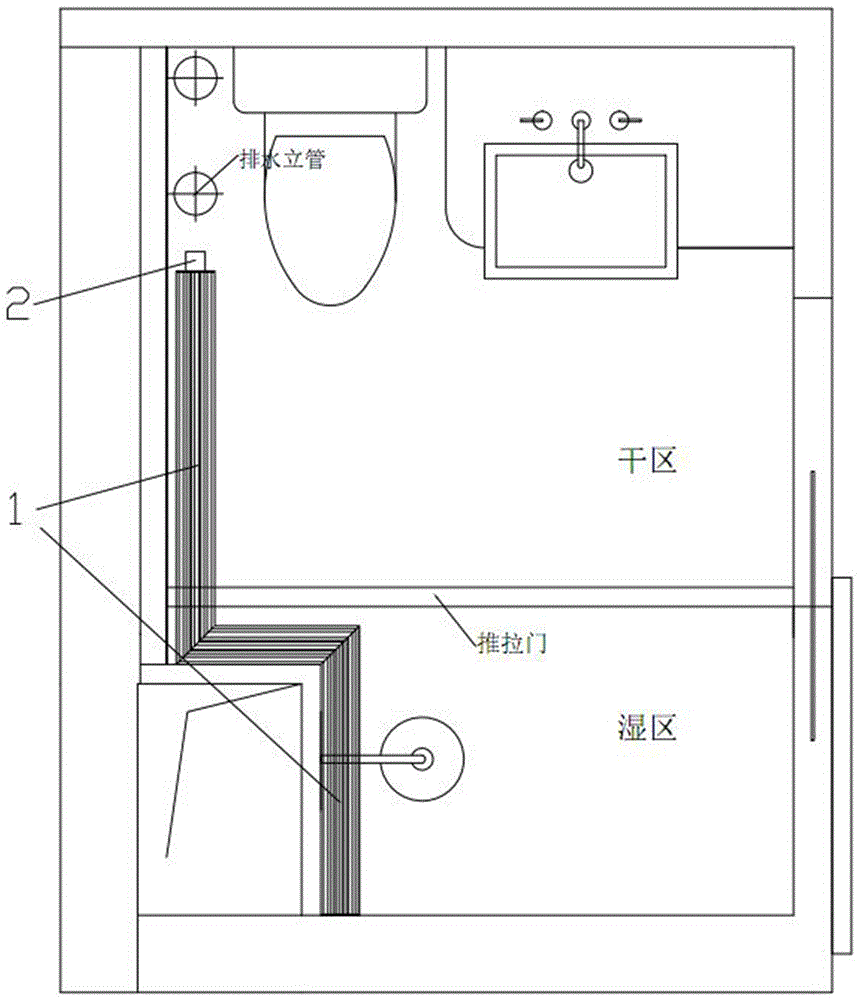

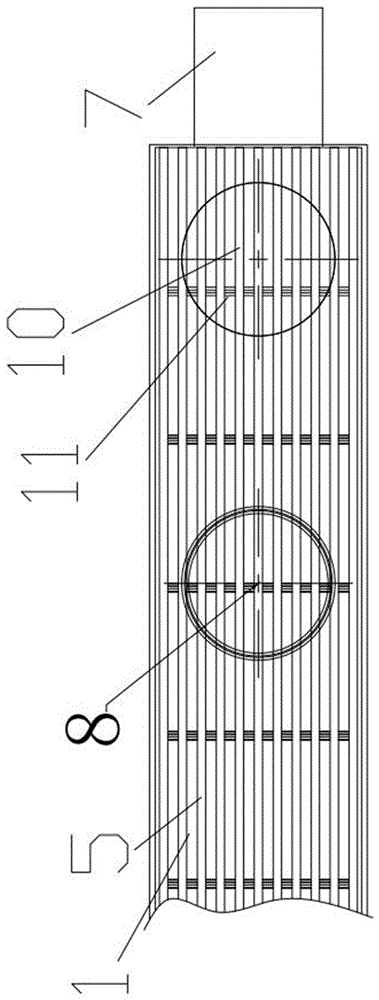

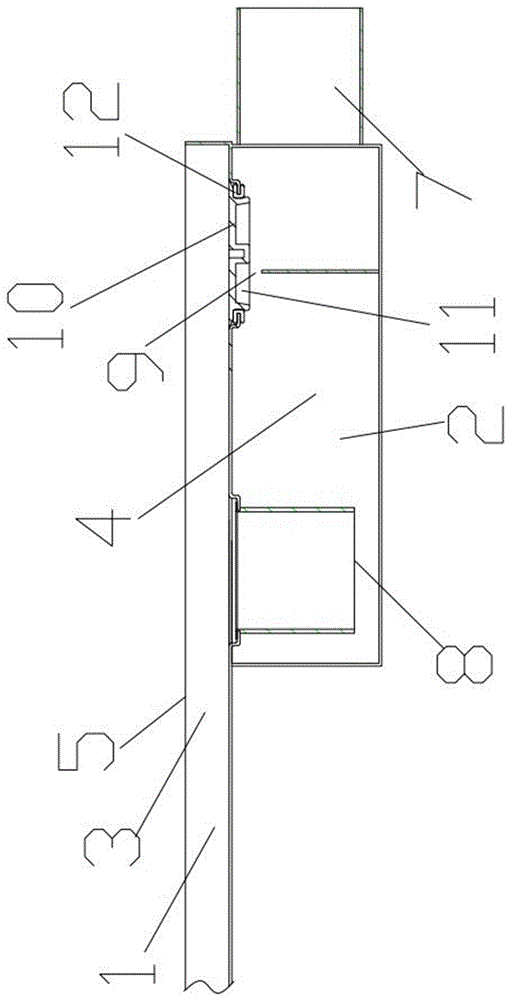

[0039] When constructing a bathroom with a large space, the brick-paved ground is sloped on one side, and several confluence bottom grooves 3 are spliced with each other through the flange 6 at the end to form a drainage channel, and the drainage channel is arranged on a slope. In the drainage installation area of the brick floor, the lowest end is installed with a side row structure 2 links leading to the main vertical drainage pipe of the building. After the bottom groove of the confluence is covered with grates, the installation of the product is completed.

Embodiment 2

[0041]When the bathroom space is narrow and it is impossible to lay a long drainage channel, the product adopts the long-strip floor drain form of the same floor drain in which the drainage channel 1 and the water inlet end of the side drain structure 2 are integrally formed, and the side drain structure of the long strip floor drain is directly connected to the building. The main vertical drainage pipe of the building, and slope the ground on the four sides of the floor drain, so that the floor drain is at the lowest point, that is, the installation of the product is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com