Internal mud removing construction process for offshore wind power booster station steel pipe pile

An offshore wind power and construction technology technology, applied in sheet pile wall, foundation structure engineering, earth mover/shovel, etc. mud efficiency, expanding the water flow area, and ensuring the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

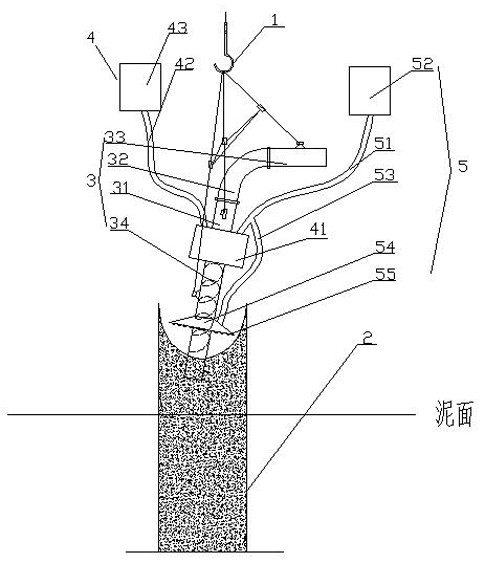

[0035] In this embodiment, a construction process for clearing mud inside steel pipe piles in offshore wind power step-up stations, including

[0036] S1. Measuring the depth of the soil in the steel pipe pile 2: measure the depth h1 of the steel pipe pile 2 inserted into the mud surface of the seabed, which is the depth of the soil in the steel pipe pile 2, and the length of the steel pipe pile 2 is h2. The distance from the inner mud surface of pile 2 to the top of steel pipe pile 2 is h, h=h2-h1;

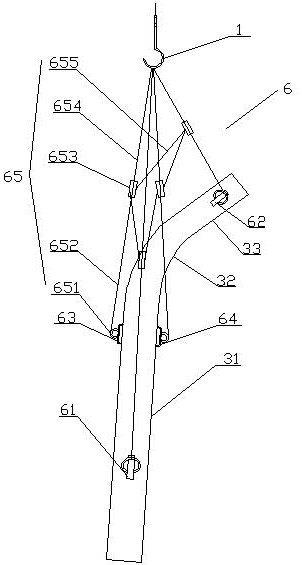

[0037] S2. Positioning the air-lift mud pump: the air-lift mud pump includes a mud pump assembly 3, an air delivery assembly 4, a water delivery as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com