Pillow beam type precast concrete structure layer and assembling method thereof

A technology of concrete structure and precast concrete, which is applied to pavements, roads, and special pavements paved with prefabricated blocks, etc., can solve the problems of poor pavement flatness, many functional holes on the surface of the pavement, affecting the integrity of the pavement surface, etc. Guarantee the bearing capacity and the effect of supporting the foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

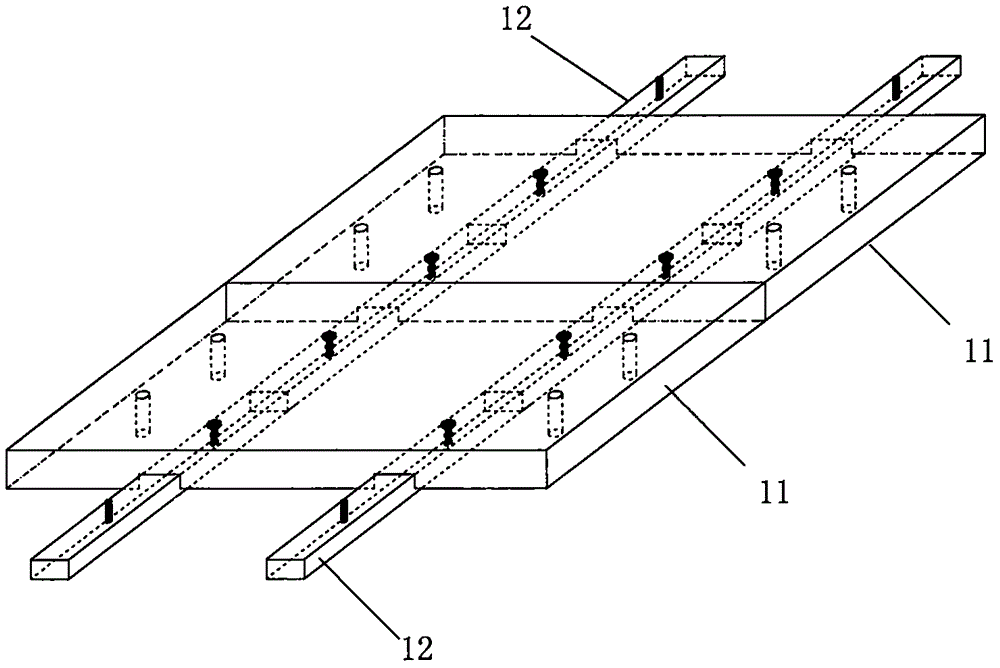

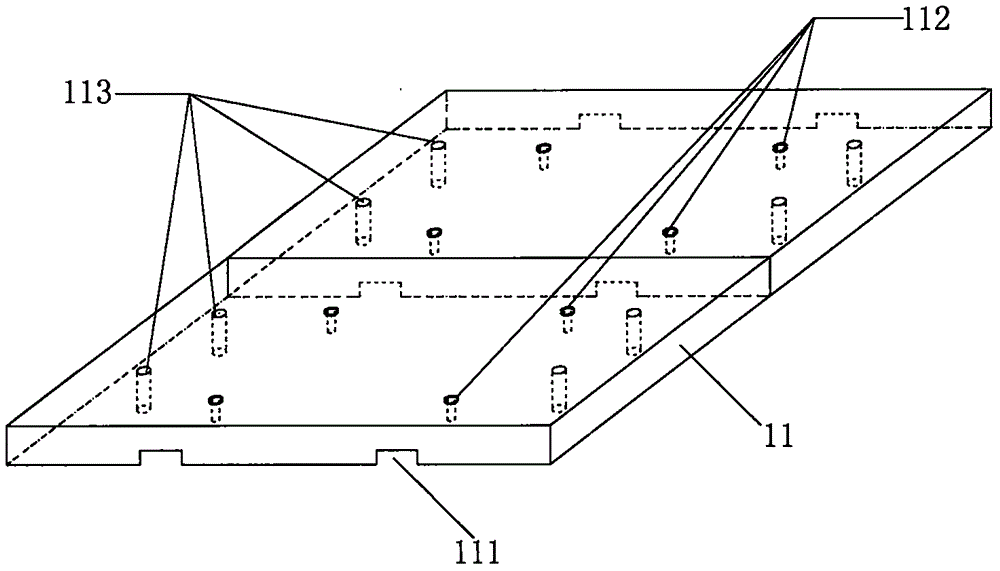

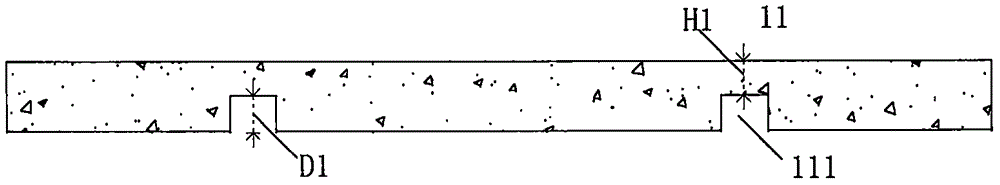

[0036] figure 1 It is a schematic diagram of the installation state of the corbel-type prefabricated concrete structure layer of Embodiment 1 of the present invention, Figure 2a It is a perspective view of an exemplary structure of a precast concrete slab in a corbel-type prefabricated concrete structure layer according to Embodiment 1 of the present invention, Figure 2b It is a side view of an example structure of a prefabricated concrete slab in a corbel-type prefabricated concrete structure layer according to Embodiment 1 of the present invention, image 3 It is a bottom view of an exemplary structure of a precast concrete slab in a corbel-type prefabricated concrete structure layer in Embodiment 1 of the present invention. Figure 4a It is a three-dimensional view of an exemplary structure of a precast concrete beam in a corbel-type prefabricated concrete structure layer according to Embodiment 1 of the present invention. Figure 4b It is a side view of an example stru...

Embodiment 2

[0044] Figure 7 It is a schematic diagram of the fixing method of the corbel-type prefabricated concrete structure layer according to the second embodiment of the present invention. On the basis of Example 1, as Figure 7 and figure 1 As shown, in the corbel-type prefabricated concrete structure layer of this embodiment, a through hole 122 corresponding to the position of the fixing rod 121 is provided from the top surface of the installation groove 111 of the precast concrete slab 11 to the upper surface of the precast concrete slab 11 , the fixing rods 121 pass through the corresponding through holes 122 to fix the precast concrete slab 11 and the precast concrete beam 12 .

[0045] preferred, such as Figure 7 As shown, there is a fixing groove 123 on the upper part of the through hole 122 in the precast concrete slab 11, and a gasket 124 is installed in the fixing groove 123, and the nut 31 and the gasket 124 are used to connect the The precast concrete slab 11 is fix...

Embodiment 3

[0047] Figure 8 It is a schematic diagram of the fixing method of the corbel-type prefabricated concrete structure layer according to the third embodiment of the present invention. On the basis of Example 1, as Figure 8 and figure 1 As shown, in the corbel-type prefabricated concrete structure layer of this embodiment, a blind hole 125 corresponding to the position of the fixing rod 121 is provided from the top surface of the installation groove 111 to the upper surface of the precast concrete slab 11, The fixing rods 121 are inserted into the corresponding blind holes 125 to fix the precast concrete slab 11 and the precast concrete beam 12 .

[0048] preferred, such as Figure 8 As shown, a mounting hole 126 corresponding to the position of the fixing rod 121 is provided on the side of the precast concrete slab 11, and a fixing pin 33 is inserted in the mounting hole 126, and one end of the fixing pin 33 is inserted into the The fixing rod 121 is used to fix the precast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com