Method for repairing and reinforcing wood beam by carbon fibre bar

A carbon fiber reinforced and carbon fiber technology is applied in the field of maintenance and reinforcement of decayed and damaged wooden beams, which can solve problems such as affecting the safe use of structures, decaying ends of wooden beams, and easy decay of wood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

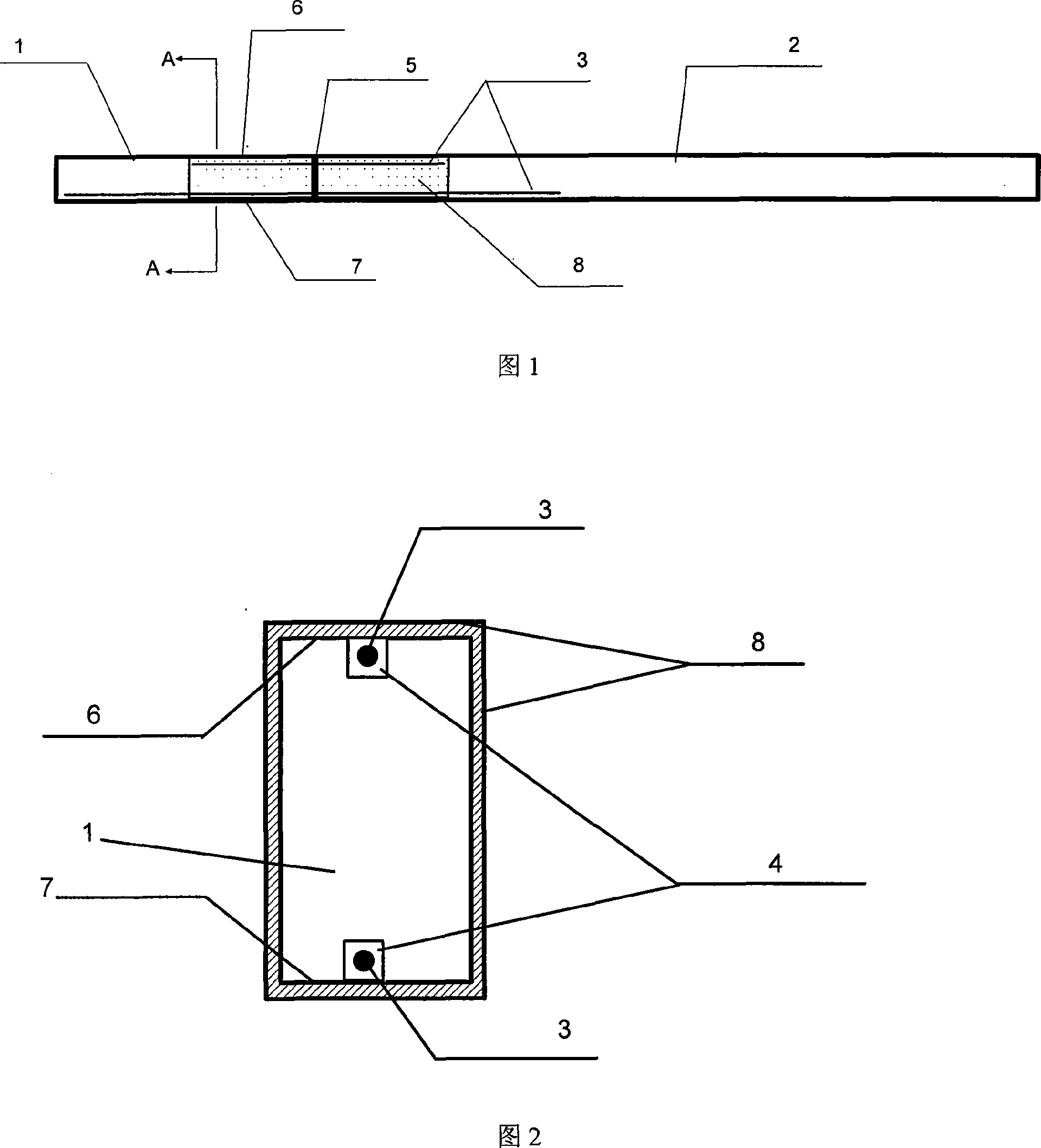

[0020] Repair a decayed and damaged wooden beam at the left end, and the height of the wooden beam is 150mm.

[0021] Set up the support first, and cut off the damaged part on the left side of the wooden beam.

[0022] Select an undamaged wood block with the same or similar material properties as the wooden beam, and cut it into a replacement wood block with the same size as the cut part, and the wood grain direction of the replacement wood block is the same.

[0023] Open a wooden groove 4 at the center position of the compression edge 6 and the tension edge 7 of the replaced wooden block 1 and wooden beam 2 respectively. The width of the wooden groove is 12mm and the height is 16mm. Seam 5 starts; the lengths of the wood slots for the replacement blocks and the compression edges of the beams are 500 mm; the lengths of the wood slots for the replacement blocks and the tension edges of the beams are 1000 mm. If the length of the replacement block is less than 500mm, the lengt...

Embodiment 2

[0028] Repair a decayed and damaged wooden beam at the left end, and the height of the wooden beam is 300mm.

[0029] Set up the support first, and cut off the damaged part on the left side of the wooden beam.

[0030] Select an undamaged wood block with the same or similar material properties as the wooden beam, and cut it into a replacement wood block with the same shape, size and grain direction as the cut part.

[0031] Open a wooden groove 4 at the center of the compression edge 6 and the tension edge 7 of the replaced wooden block 1 and wooden beam 2 respectively. The cross-sectional width of the wooden groove is 18mm and the height is 24mm. Starting from the joint 5 of the joint, the length of the wooden slots of the replacement wooden blocks and the compression edges of the wooden beams is not less than 750mm; the length of the wooden slots of the replacement wooden blocks and the tensile edges of the wooden beams is not less than 1500mm. If the length of the replaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com