Prefabricated assembled integral framework column bottom grouting structure

A prefabricated assembly and frame column technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problem of the inability to exhaust the air in the shear groove, and achieve the purpose of improving the connection performance, ensuring the bearing capacity and ensuring the compactness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

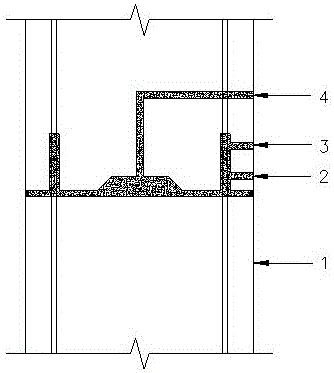

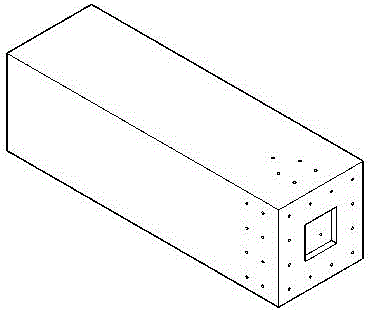

[0014] The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0015] like Figure 1-Figure 2 As shown in the figure, a prefabricated and assembled integral frame column bottom grouting structure of the present invention includes a prefabricated frame column and a shear groove arranged at the bottom of the prefabricated frame column. The bottom of the prefabricated frame column is also preset with a grouting sleeve, so The grouting sleeve is arranged around the prefabricated frame column and is used to connect the stressed steel bars of the prefabricated frame column. The lower part of the barrel wall of the grouting sleeve is provided with a grouting hole, and the upper part of the barrel wall of the grouting sleeve is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com