Roadbed structrue for highway and railway and its construction method

A technology of road, railway and construction method, which is applied to the cohesive pavement paved on site, roads, roads and other directions, which can solve the problems affecting the speed of the railway, breaking the traffic, and breaking the roadbed, so as to reduce the loss of disasters, reduce maintenance, Effect of waterproof performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

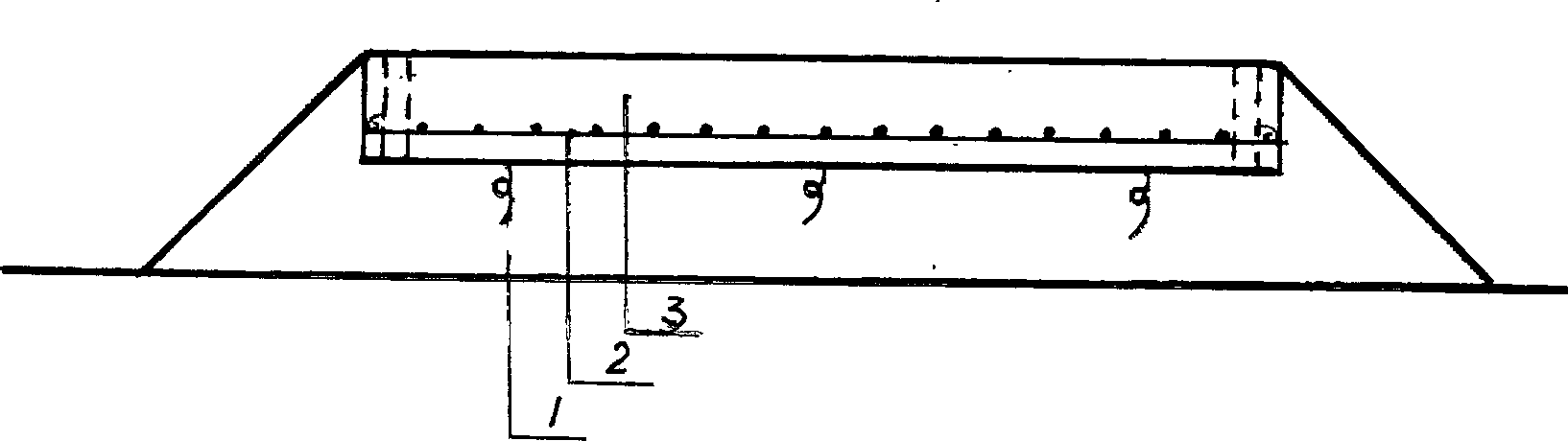

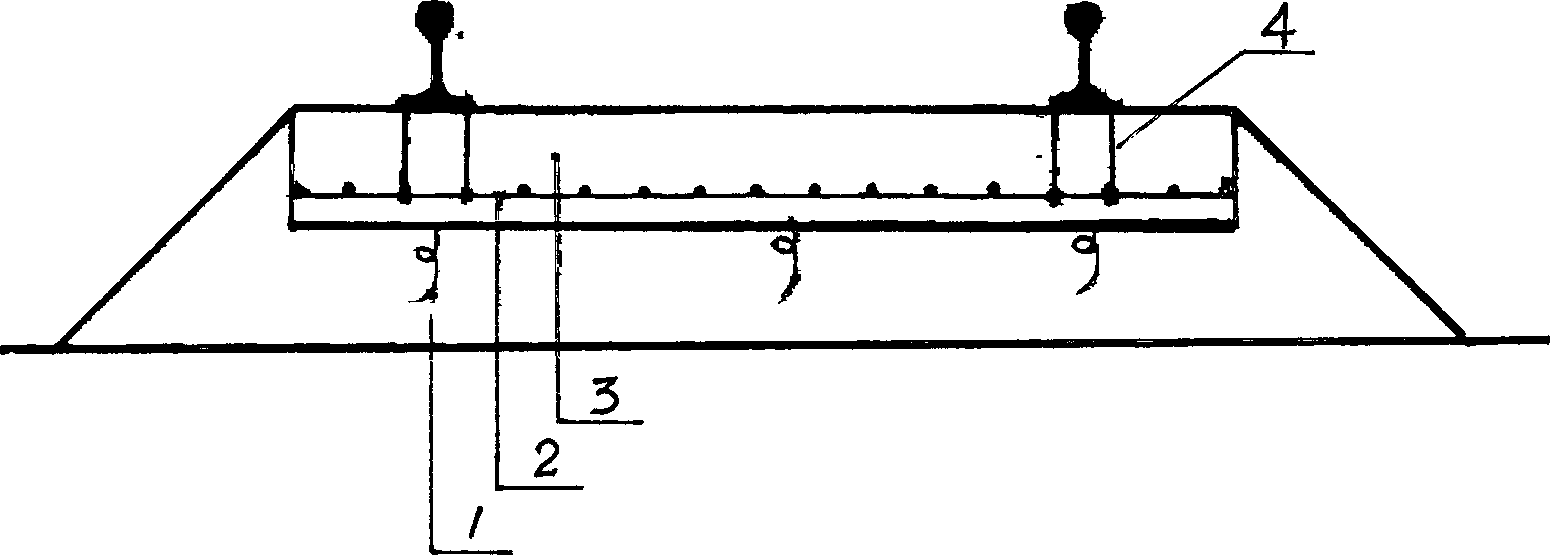

[0022] The thickness of the plain soil compaction layer is 300-500mm, and its elevation, slope, flatness and vertical load all meet the design requirements; the vertical load of the plain soil compaction layer is 8T / m 2 Above, the longitudinal slope of earthwork is less than 1 / 100, and the transverse slope is less than 1 / 100.

[0023] The thickness of the reinforced concrete pavement layer is 250-300mm, and its elevation, slope, flatness and load all meet the design requirements; the collective load of the pavement reaches 100T / m 2 .

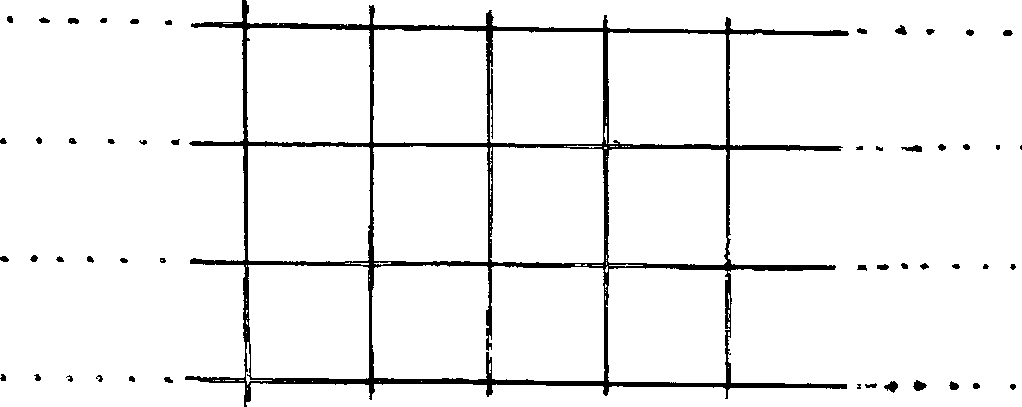

[0024] The length of the full-length steel bar that is arranged in the concrete layer to form a grid network is equivalent to the length and width of the road surface in the longitudinal direction and the transverse direction;

[0025] The grid net can be 300-600mm per grid 2 Composed of squares or rectangles, the steel grid is laid in the concrete layer at a height of 1 / 3 from the top surface of the plain soil compaction layer and 2 / 3 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com