Glass curtain wall with drainage structure and mounting method thereof

A glass curtain wall and drainage structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of time-consuming, complicated, unfavorable fast installation of glass curtain walls, etc., and achieve the effect of avoiding inconvenience and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

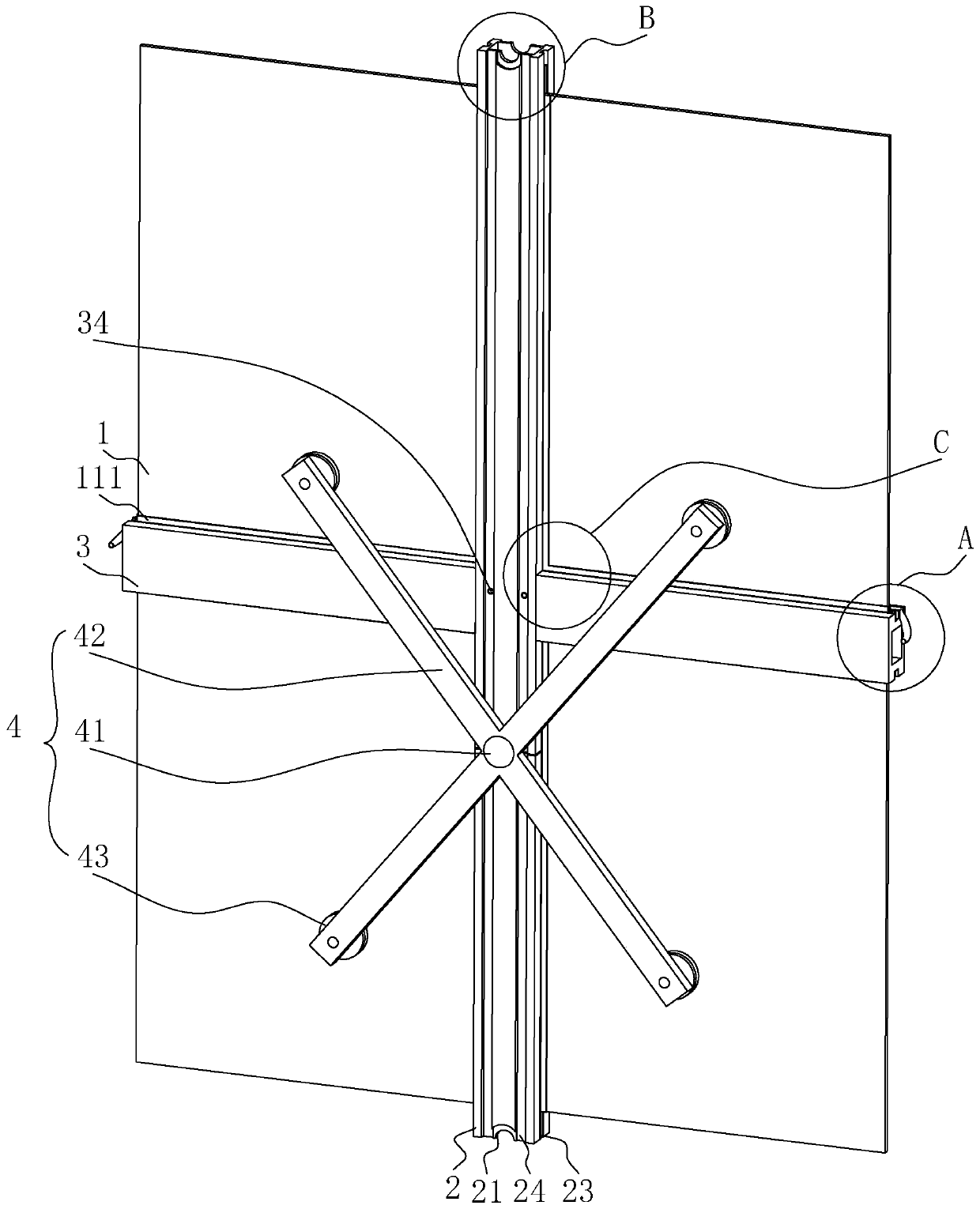

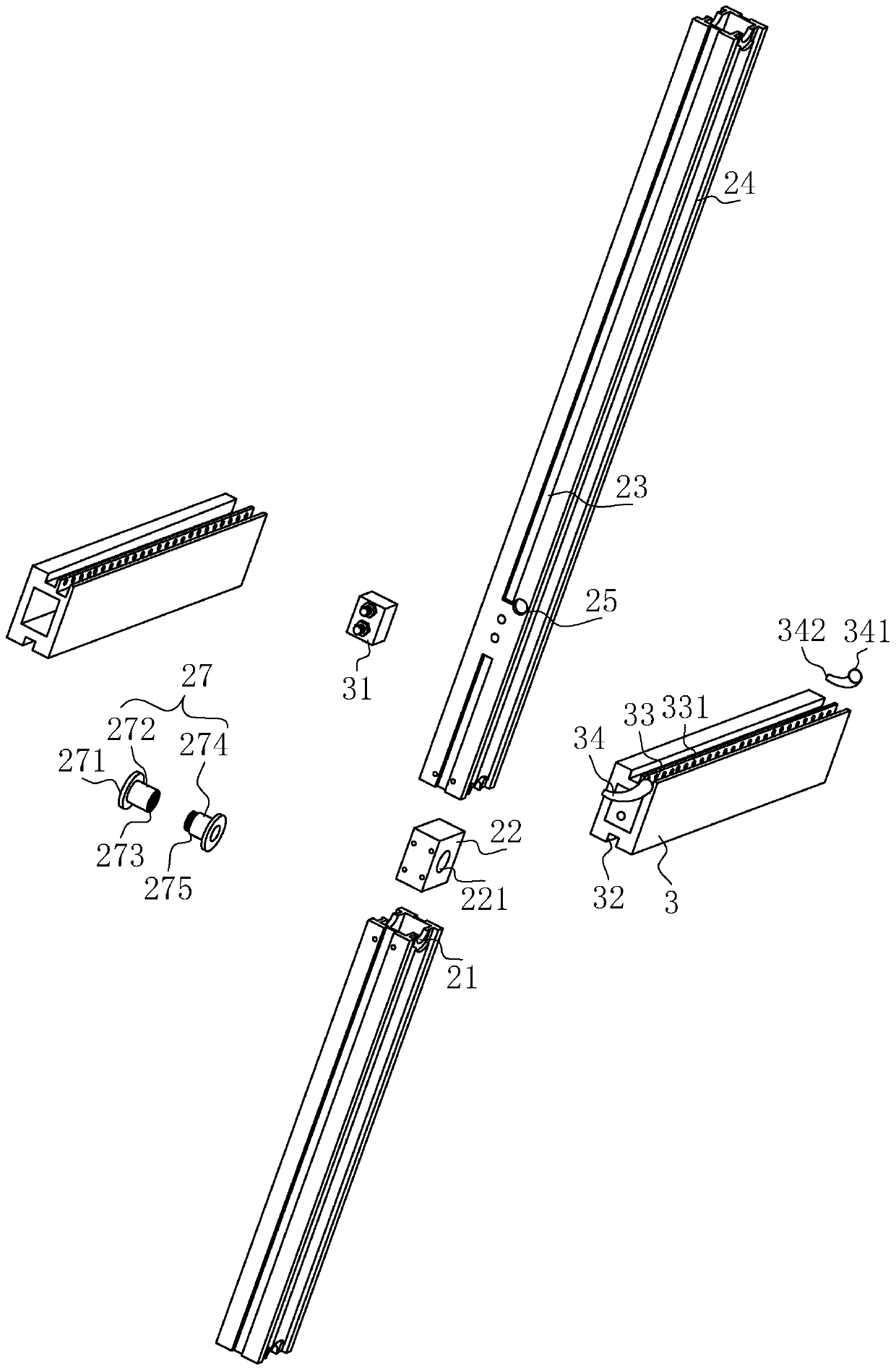

[0052] refer to figure 1 , is a glass curtain wall with a drainage structure and its installation method disclosed in the present invention, including a glass plate 1, a column 2 and a beam 3, wherein the end of the column 2 is plugged with another column 2 to realize the connection between the columns 2 , The column 2 and the beam 3 are fixedly connected by bolts; the glass plate 1 is embedded in the sides of the column 2 and the beam 3 . The installed glass plate 1 is clamped and fixed by the glass claws 4 and the fastening claws 5 .

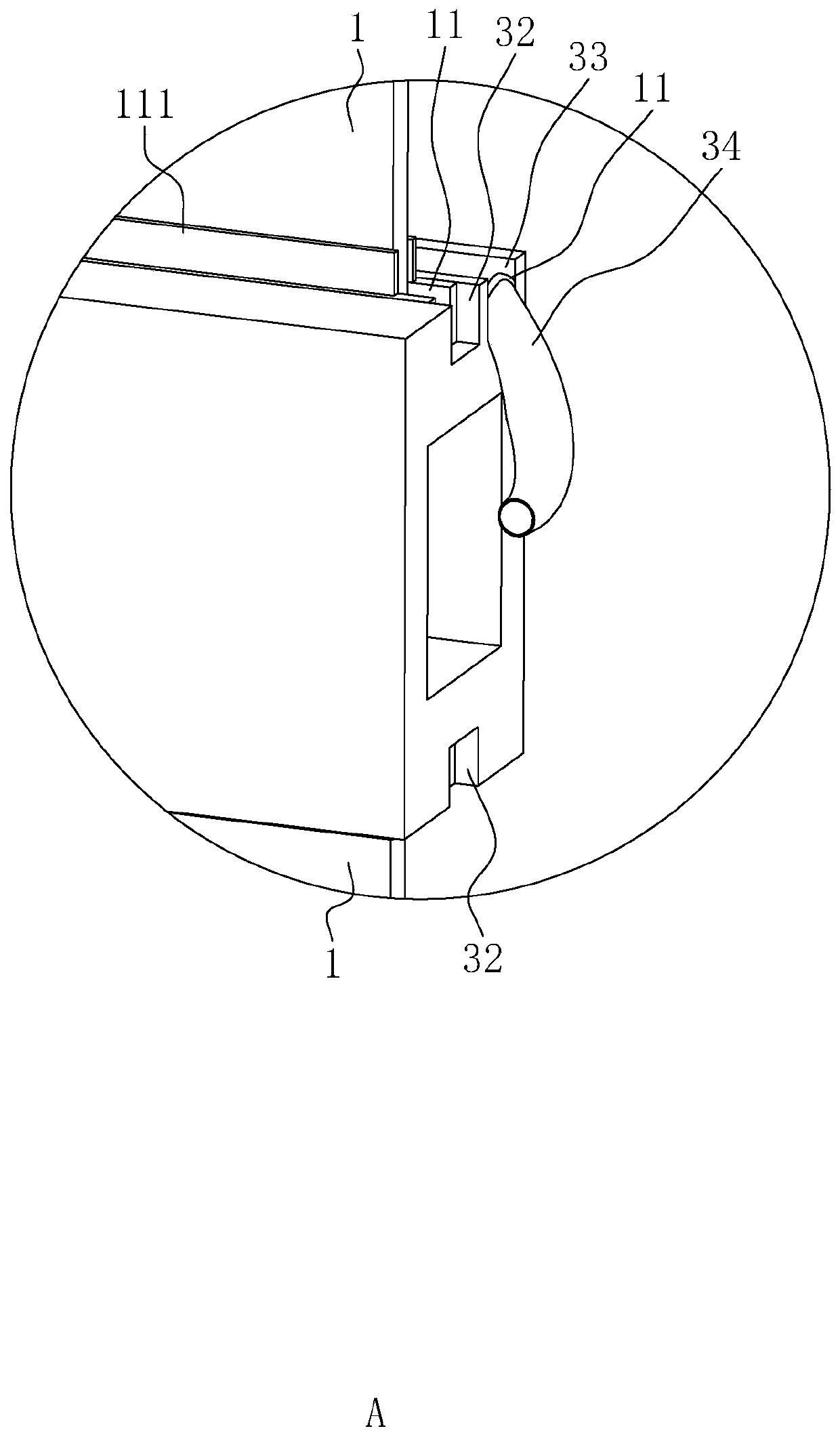

[0053] refer to figure 1 , figure 2 , the above beam 3 can be made of aluminum alloy, and the inside of the beam 3 is hollow. The opposite sides of the crossbeam 3 are provided with transverse limit grooves 32, the length direction of the transverse limit grooves 32 is parallel to the length direction of the crossbeam 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com