Special flexible texture coating for external heat insulating wall, and preparation method thereof

A texture coating and external thermal insulation technology, which is applied in the field of architectural coatings, can solve the problems of affecting the service life of external thermal insulation walls, affecting thermal insulation performance, and increasing thermal conductivity, so as to add three-dimensional artistic appeal, prolong service life, and high bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

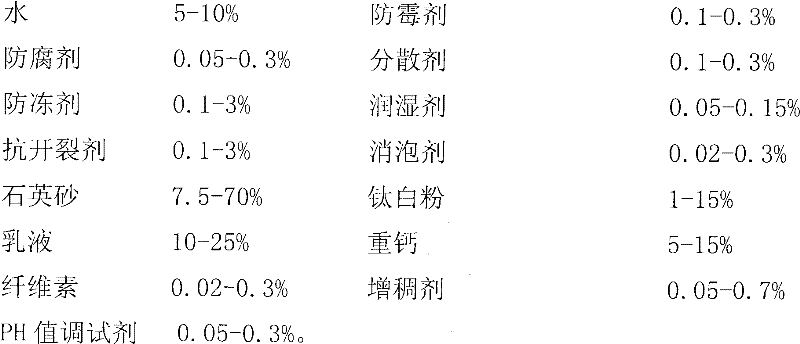

[0027] Special flexible texture coating for external thermal insulation wall, it is composed of the following raw materials in weight ratio:

[0028]

[0029] The method for preparing the above-mentioned coating is as follows: step 1, mix water, anti-fungal agent, preservative, dispersant, wetting agent, defoamer, titanium dioxide and heavy calcium together according to the above-mentioned mass percentage and perform high-speed dispersion. ;

[0030] Step 2, mixing the emulsion, quartz sand and defoamer together according to the above mass percentage, and adding them to the mixed solution prepared in the above step 1, and stirring at a medium speed;

[0031] Step 3, mix cellulose and water according to the above mass percentage, stir for 10-20 minutes, and stir to make a cellulose mixture, set aside;

[0032] Step 4, then add the mixture obtained in the above step 2 to the cellulose mixture prepared in the step 3 for stirring at a medium speed, so that the cellulose mixtur...

Embodiment 2

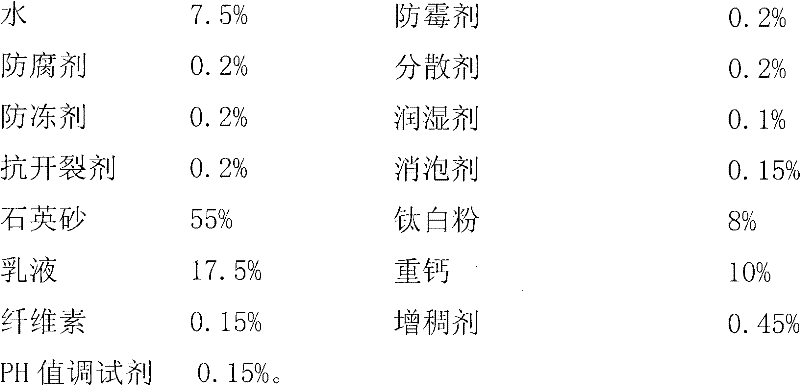

[0048] Wherein the weight proportion of each raw material is:

[0049]

[0050] Others are basically the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

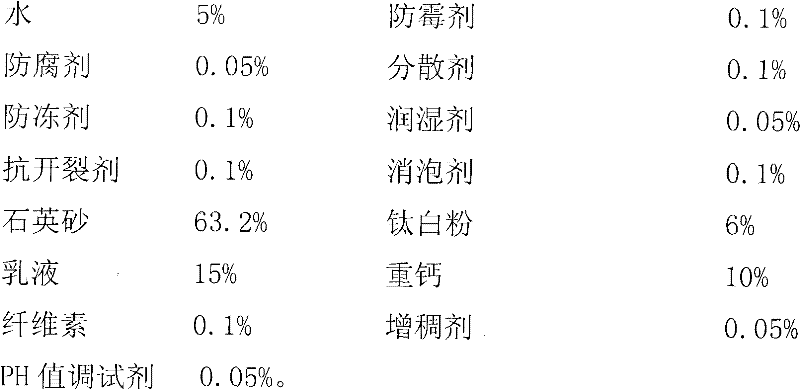

[0052]

[0053] Others are basically the same as those in Embodiment 1, and will not be repeated here.

[0054] The present invention is an organic combination of perfect external thermal insulation and art paint for buildings. When using, first add a cationic sealing primer to the external thermal insulation system, a primer of the same color as the exterior wall, a second layer of flexible texture paint, and finally a water-based fluorocarbon finish wall paint. Since the general external thermal insulation plastering mortar has a pH of 12 in the northern region, the cationic sealing primer can ensure excellent water resistance, alkali resistance, and salt-folding resistance, and avoid blooming and efflorescence of the paint. Water-based fluorocarbon finish wall paint can greatly improve the stain resistance of the paint, so that the building will still look brand new after a few years. The function of the same color primer for the exterior wall is to improve the hiding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com