Three-layer composite hot melt adhesive film for bonding metal and polar functional plastic and processing technique thereof

A hot-melt adhesive film and layer compounding technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of poor fusion, low bonding strength of hot-melt adhesive films, etc. Problems, to achieve the effect of convenient bonding, solving the problem of low bonding strength and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

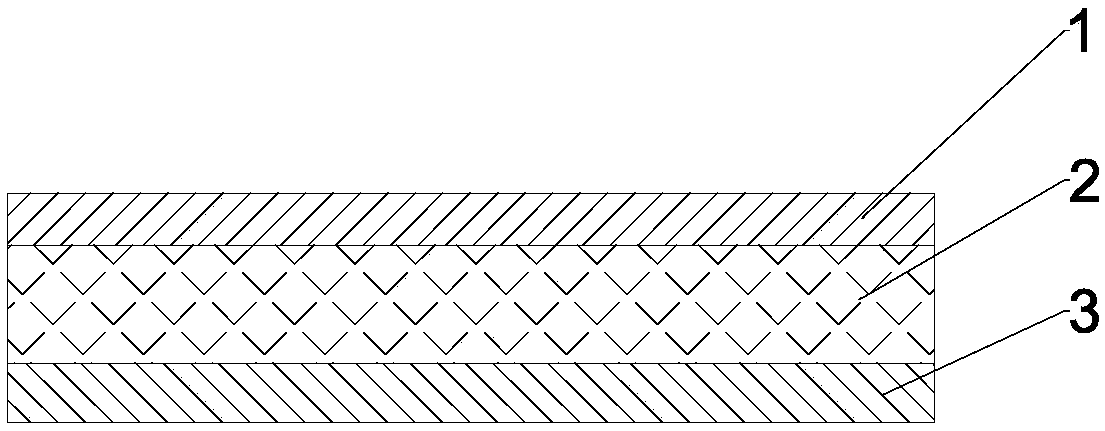

[0032] Schematic diagram of the structure of the three-layer composite film figure 1 shown. Specifically, the components and parts by weight of the inner layer glue, the outer layer glue, and the transition glue are as follows.

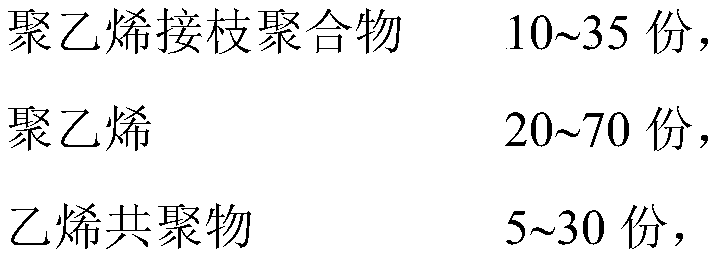

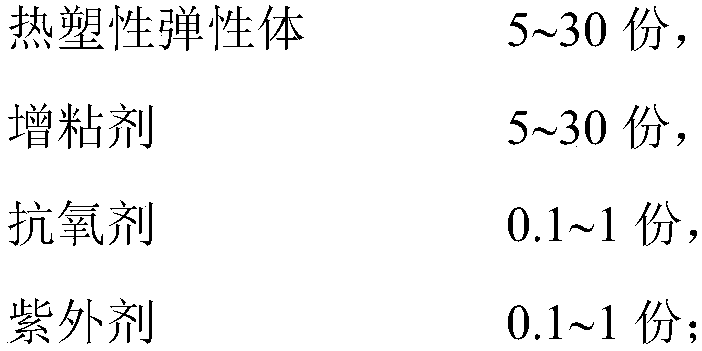

[0033] Inner glue A1

[0034]

[0035] Inner glue A2

[0036]

[0037] When preparing the inner layer rubber, the raw materials of the inner layer rubber are added to a twin-screw extruder for granulation, and the extrusion temperature is 150-210°C, preferably 170-210°C.

[0038] Outer glue B1

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com