Single-core metal connector

A metal connector and single-core technology, which is applied in the direction of connection, two-part connection device, connection part protection grounding/shielding device, etc., can solve the problem that the operator's finger touches the contact finger by mistake, poor internal sealing, and poor waterproof effect and other problems, to achieve the effect of not easy to seepage, good internal sealing and good shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

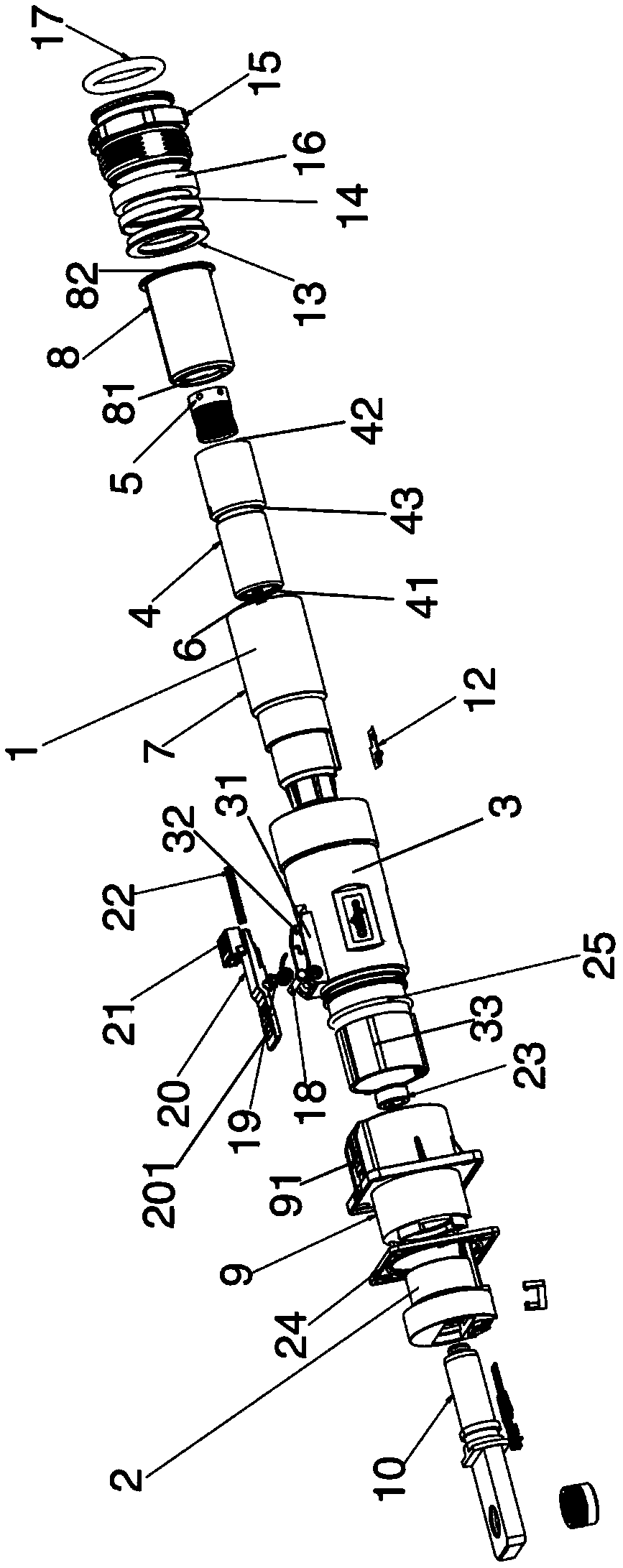

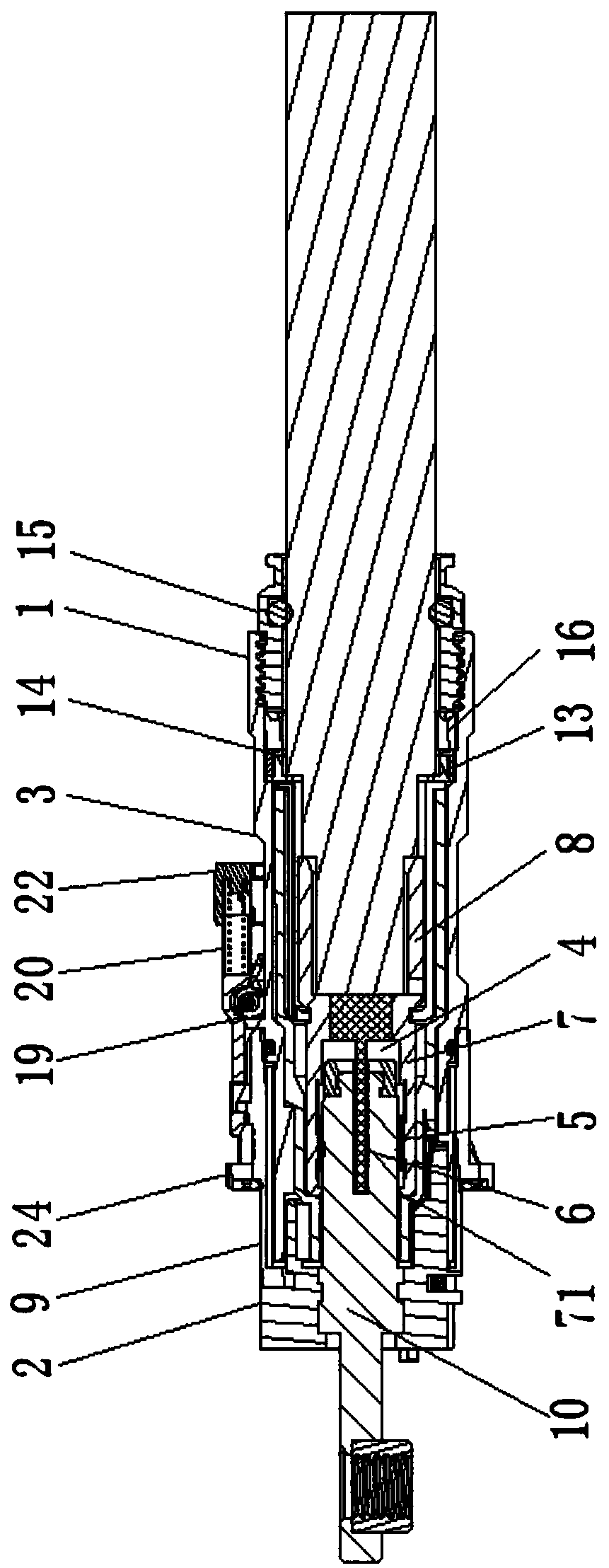

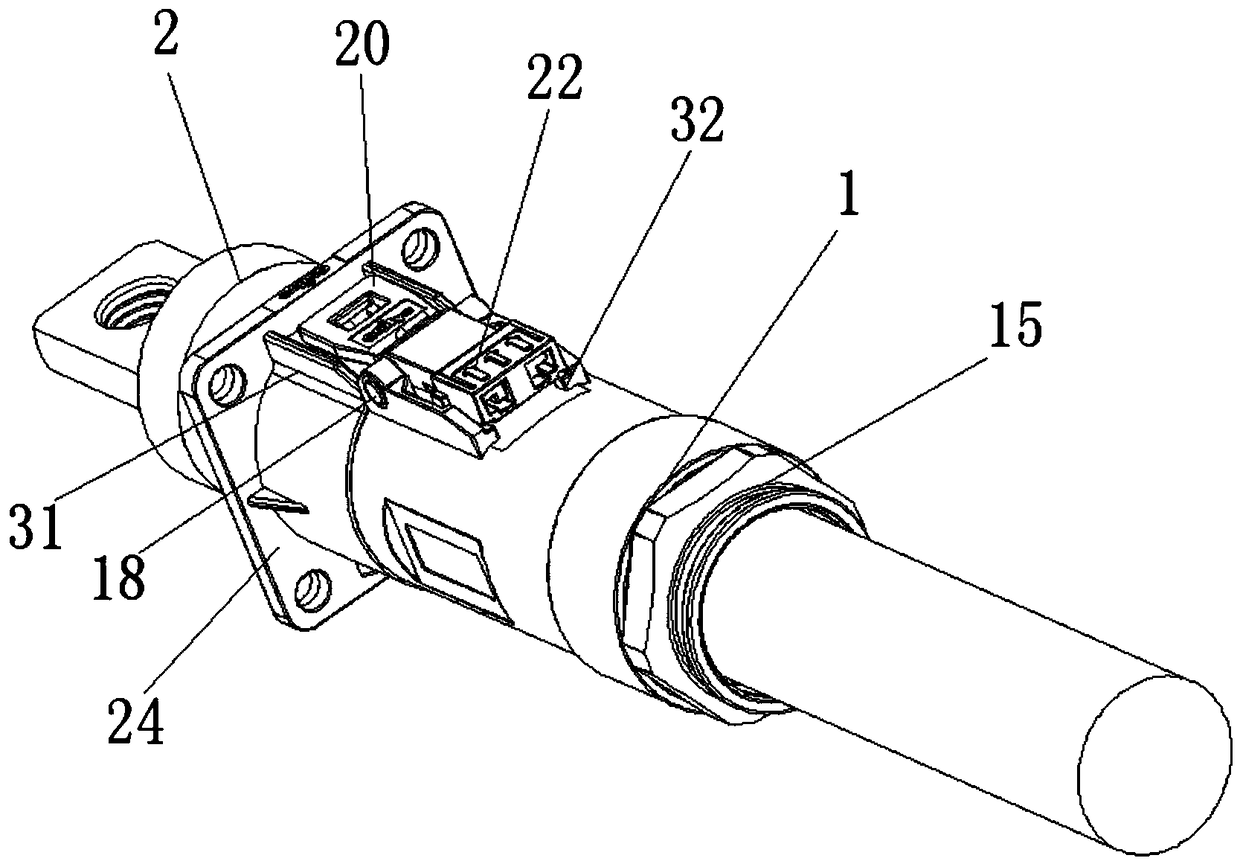

[0026] like Figure 1 to Figure 6 As shown, the present invention discloses a single-core metal connector, including a plug 1 and a socket 2 .

[0027] The plug 1 is composed of a metal plug shell 3 with openings at both ends and a tubular power female terminal 4 coaxially fixed inside the plug shell 3. The inside of the first end 41 of the power female terminal 4 is the same as The shaft is fixed with a hollow tubular shrapnel contact finger 5 and an insertion rod 6, the shrapnel contact finger 5 is closely matched with the inner wall of the power female terminal 4, and the insertion rod 6 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com