Composite fireproof thermal insulation wall body

A technology for fireproofing and heat preservation and composite walls, applied in heat preservation, fire protection, walls, etc., can solve the problems of poor heat preservation performance and durability of the internal heat preservation mode, affecting interior decoration, and difficult construction, etc., to achieve good heat insulation effect and not difficult The effect of water seepage and improving the sealing connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

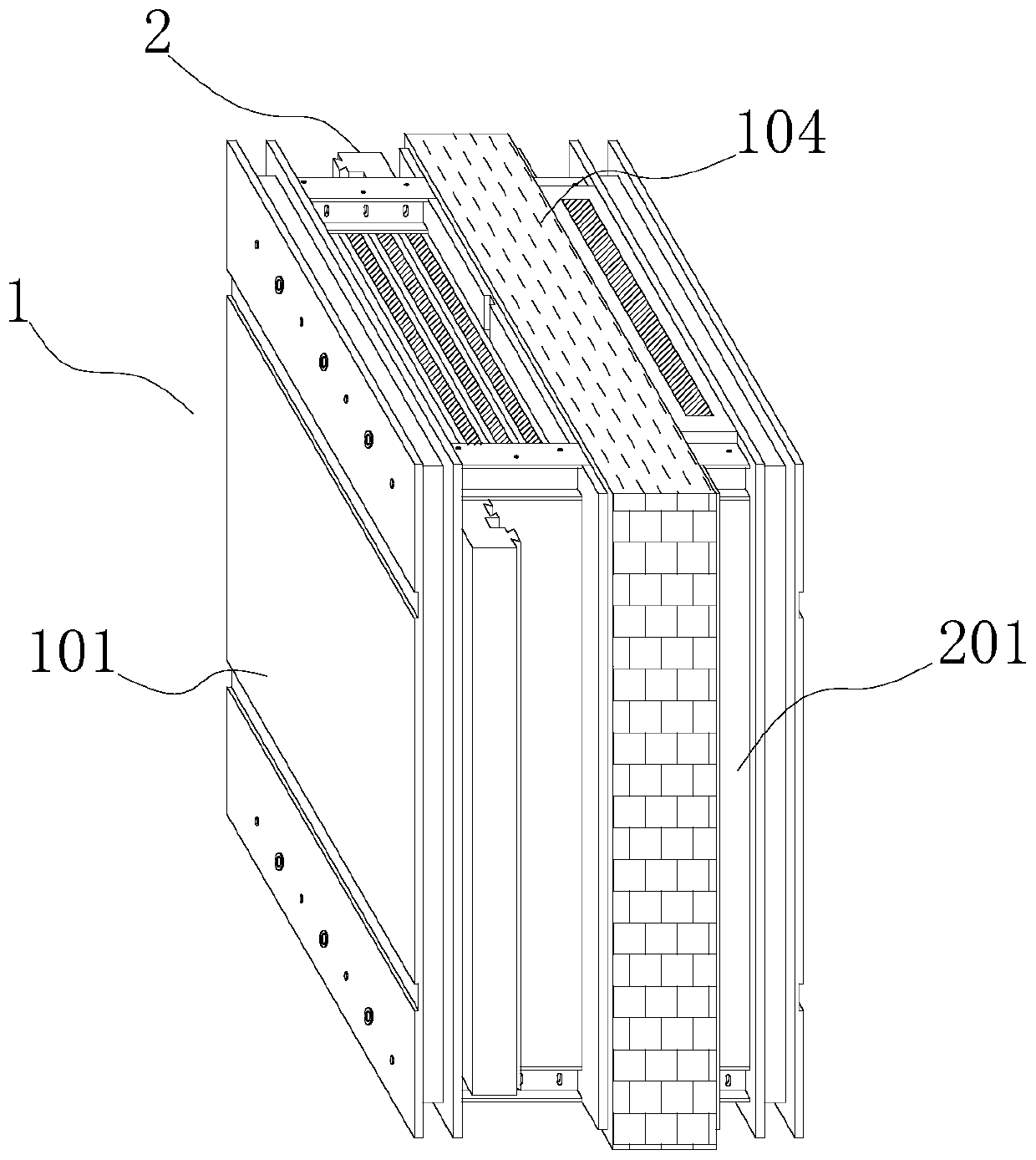

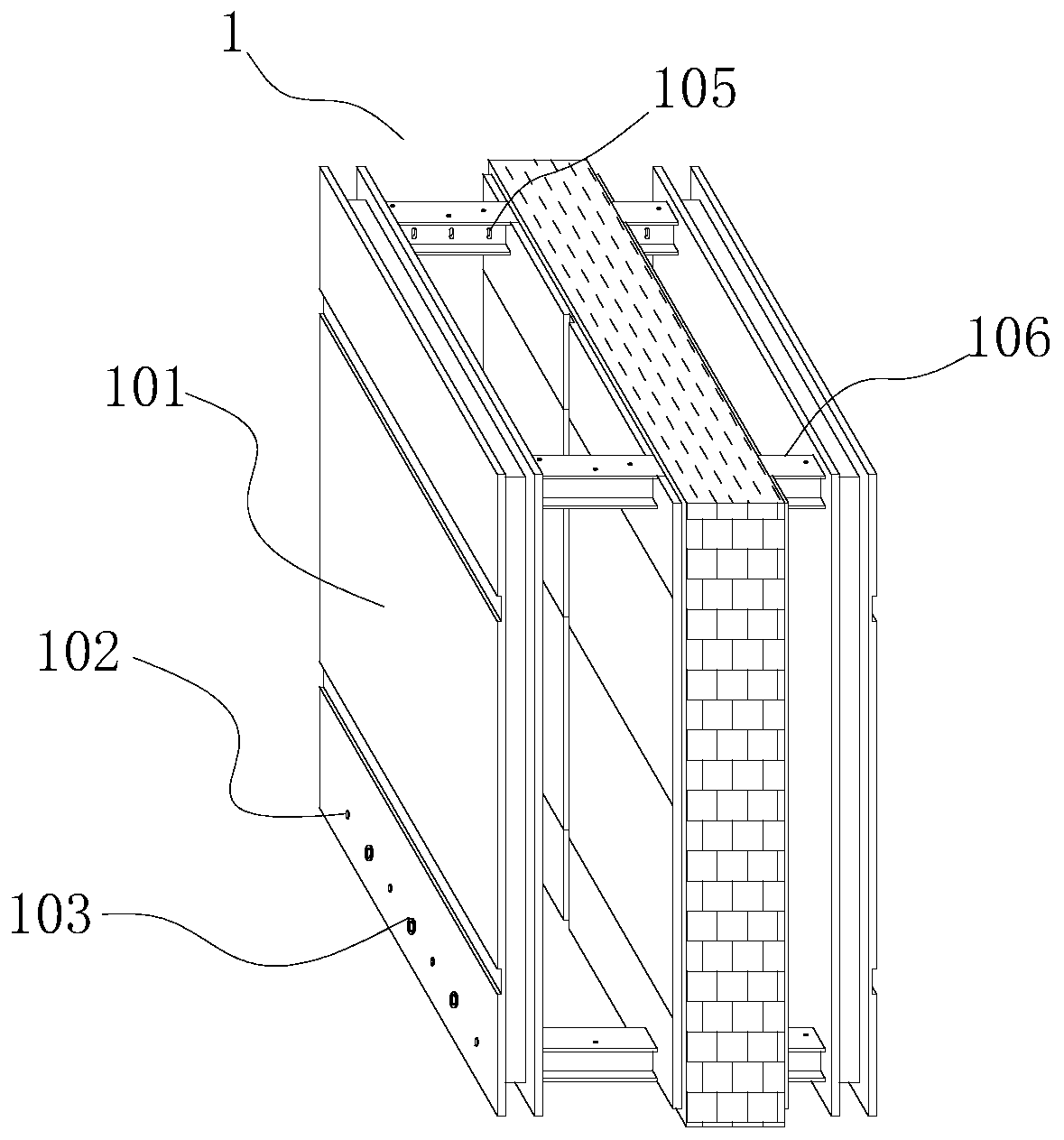

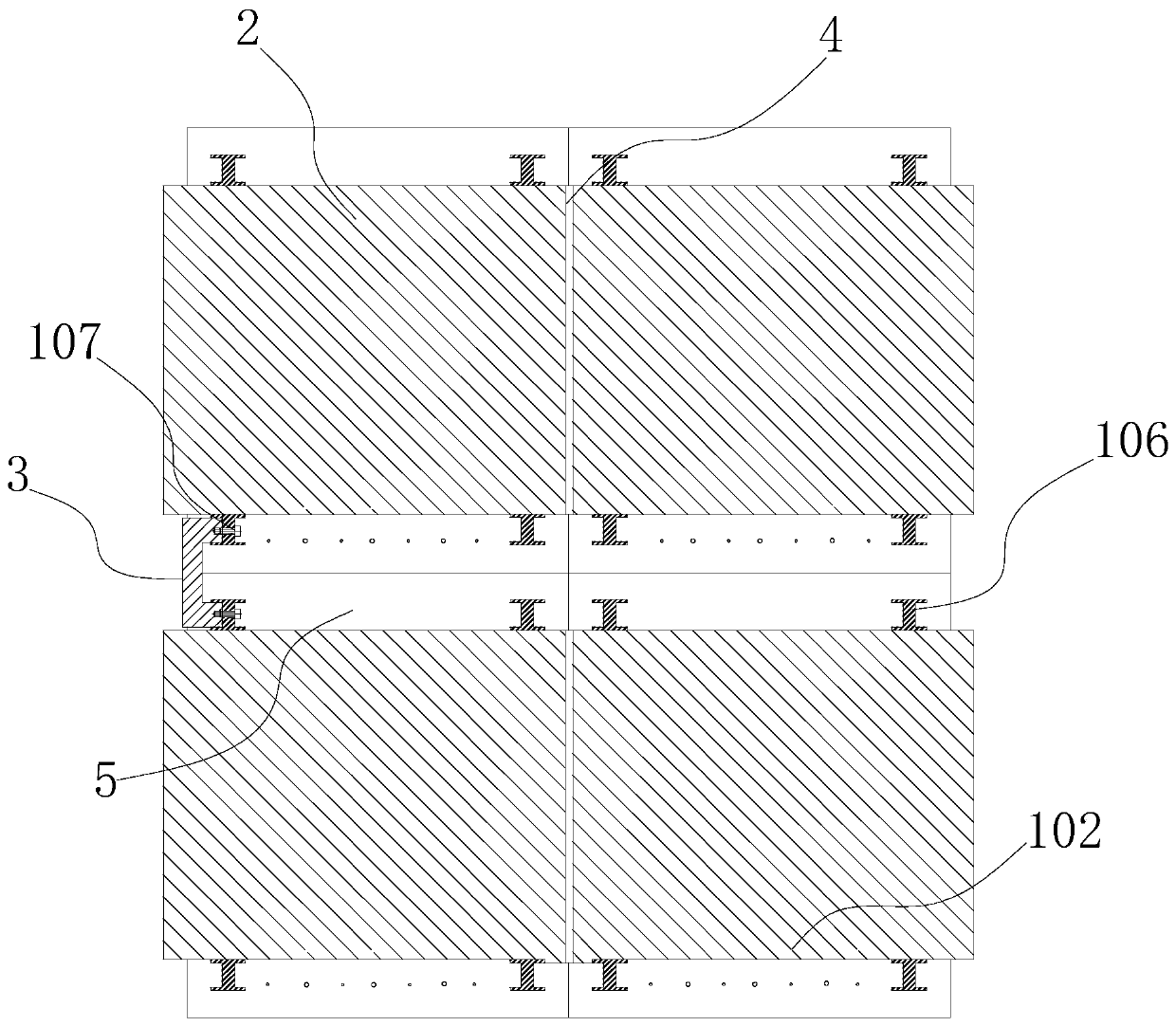

[0023] refer to figure 1 , 7 , the present invention provides a technical solution: a composite fireproof and thermal insulation wall, which is spliced by a plurality of assembled composite walls neatly and evenly arranged, and the assembled composite wall includes an external frame 1 and an internal function distribution layer 2 , the internal function distribution layer 2 is arranged in the external frame 1 and is closely attached to the external frame, and the internal function distribution layer 2 sequentially includes a heat insulation layer 204, a protective layer 203, an anti-corrosion moisture-proof layer 202 and a fireproof layer 201 , the external frame 1 includes an exterior wall panel 101 and a load-bearing wall 104, two exterior wall panels 101 are provided, and the two exterior wall panels 101 are respectively fixed on both sides of the load-bearing wall 104, so The left side of the load-bearing wall 104 is the inside of the building wall, the right side of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com