Integrated packaged LED display module and manufacturing method thereof

A technology for LED lamp modules and packaging modules, which is applied in the direction of identification devices, instruments, etc., can solve the problems of insufficient sharpness of image edge resolution and affect the clarity of LED display screen images, so as to improve horizontal and vertical viewing angles, increase yield and Optical effect, the effect of clear display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

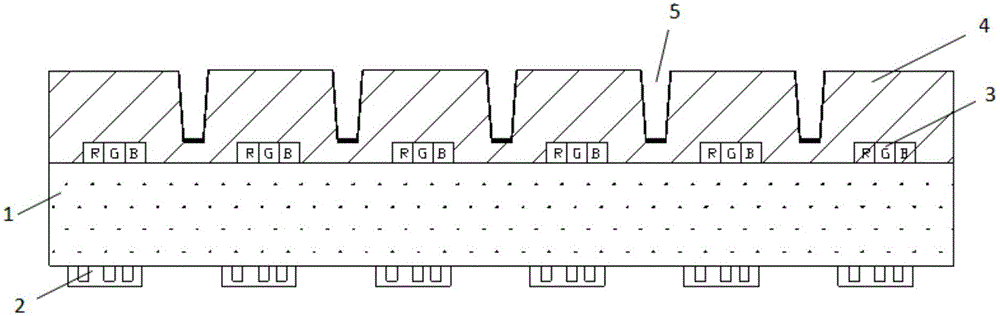

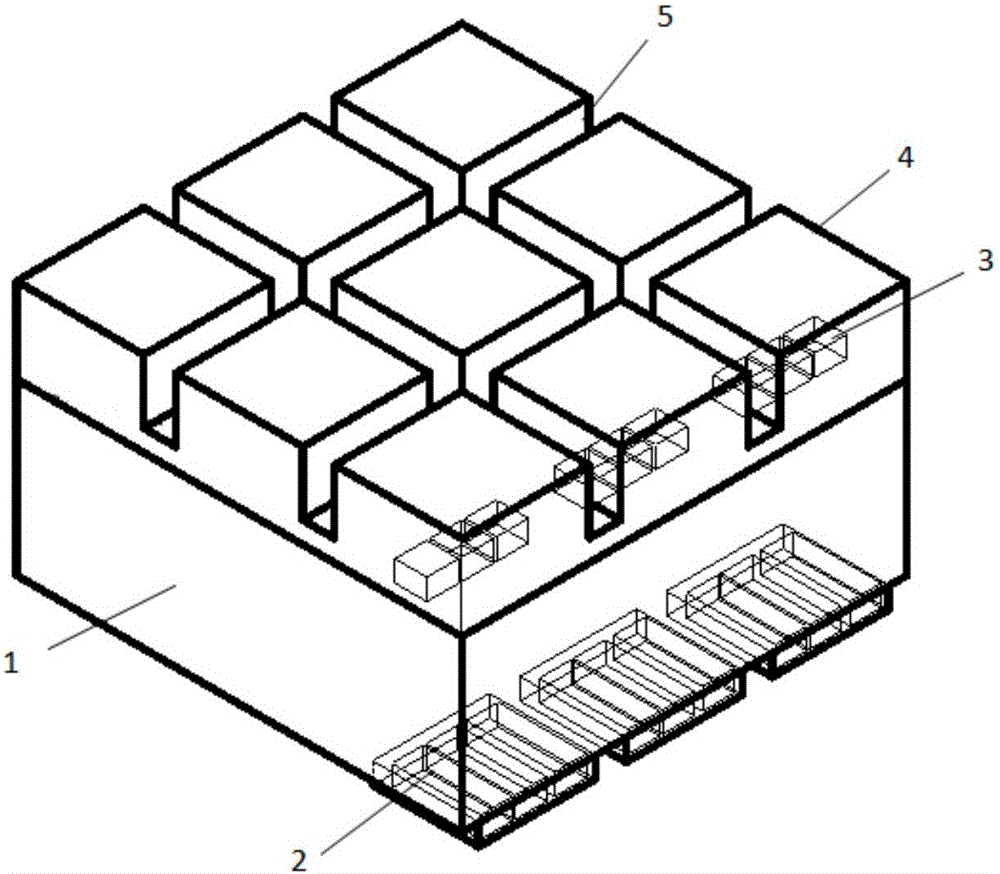

[0046] In this embodiment, combined with figure 1 Be explained:

[0047] Dot pitch d=1.5mm, dot matrix arrangement with a resolution of 80*80 integrated LED display packaging module, the display packaging module includes driver IC2, driver circuit board 1, LED lamp module 3, packaging glue 4, driver IC2 welding On the back of the driving circuit board 1, the LED light module 3 is fixed on the front of the driving circuit board 1, wherein the blue and green LED chips have a size of 7 mils*9 mils, and the red LED chip has a size of 6 mils*6 mils. The thickness of the encapsulant 4 is not specifically limited. A groove 5 is provided on the encapsulant 4 between each LED lamp module 3. In this embodiment, the groove 5 is directly molded by molding equipment. The depth d of the groove 5 is not specifically limited, and the depth d is smaller than that of the encapsulant. 4 thickness p and greater than the height h of the LED chip. The width and draft angle of the groove 5 are no...

Embodiment 3

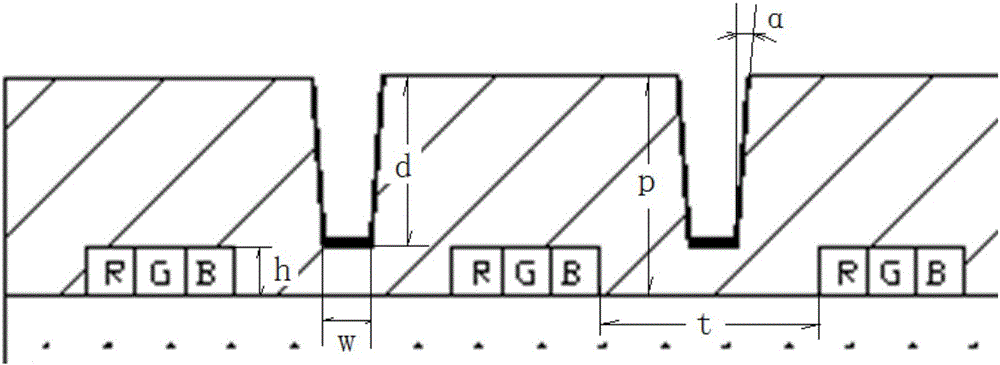

[0051] In this embodiment, combined with figure 1 and image 3 Be explained:

[0052] In this embodiment, the dot pitch d=1.5mm, the dot matrix arrangement with a resolution of 80*80 is integrated into the LED display packaging module, and the display packaging module includes a driver IC2, a driver circuit board 1, an LED lamp module 3, and a packaging glue 4. The driver IC 2 is welded on the back of the driver circuit board 1, and the LED light module 3 is fixed on the front of the driver circuit board 1. The size of the blue and green LED chips is 7mils*9mils, and the size of the red LED chips is 6mils*6mils. The thickness of the display module encapsulant 4 is not specifically limited. A groove 5 is provided on the packaging glue 4 between each LED lamp module 3. In this embodiment, the groove 5 is directly molded by molding equipment. The depth d of the groove 5 is specifically limited, and the depth d is smaller than the packaging glue. 4 thickness p, and greater than...

Embodiment 4

[0055] In this embodiment, combined with figure 1 , image 3 Be explained:

[0056] In this embodiment, the dot pitch d=1.5mm, the dot matrix arrangement with a resolution of 80*80 is integrated into the LED display packaging module, and the display packaging module includes a driver IC2, a driver circuit board 1, an LED lamp module 3, and a packaging glue 4. The drive IC 2 is welded on the back of the drive circuit board 1, and the LED light module 3 is fixed on the front of the drive circuit board 1, where the blue and green LED chip size is 7mils*9mils, and the red LED chip size is 6mils*6mils . The thickness of the display module encapsulant 4 is not specifically limited. Grooves 5 are provided on the encapsulant 4 between the LED lamp modules 3. In this embodiment, the grooves 5 are directly molded by molding equipment, and the depth of the grooves 5 is specifically limited, and the depth d is smaller than the thickness of the encapsulant 4. p, and the thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com