Full-automatic material distribution tablet subpackage device and subpackage method thereof

A fully automatic tablet technology, applied in the packaging material feeding device, the device that makes the drug into a special physical or taking form, packaging, etc., can solve the problems of low work efficiency and secondary pollution of the tablet, and achieve fast and accurate Direct encapsulation, good effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

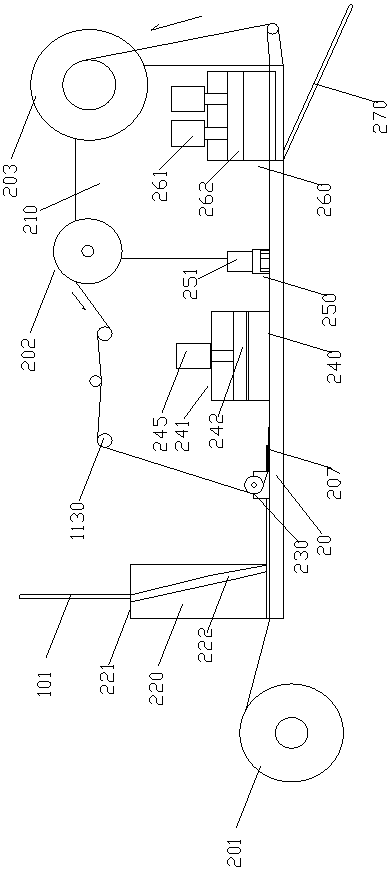

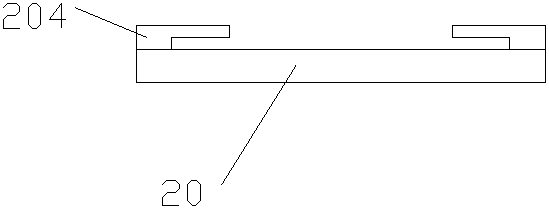

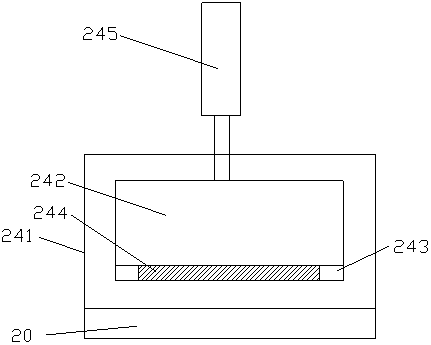

[0024] Such as Figure 1~6 As shown, the automatic distributing tablet dispensing device includes a coating device 10 and a communication pipe 101 arranged at the discharge end of the coating device. There is a tablet packaging platform 20 below the communication pipe, and a tablet packaging platform 20 is fixed on the top of the tablet packaging platform 20. Packaging frame 210, the front side of the packaging platform is provided with a lower mold cylinder 201 that outputs the lower template, and the packaging frame is provided with an upper roller 202 for outputting the upper film and a recovery roller 203 for recovering the lower template. The tablet packaging platform Along the conveying direction of the lower template, there are arranged in sequence a particle guide device 220, a film guide roller 230, a pressing mechanism 240 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com