High-impermeability anti-crack concrete and preparation process thereof

A concrete and high-resistance technology, applied in the field of high-impermeability and anti-crack concrete and its preparation, can solve the problems of reducing the service life of concrete, cracking, and general concrete impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A high impermeability and anti-cracking concrete, comprising the following raw materials in parts by weight: 100 parts of cement, 30 parts of fly ash, 35 parts of sand, 5 parts of calcium lignosulfonate, 20 parts of reinforcing emulsion, and 10 parts of ethylenediamine;

[0041] Described high impermeability concrete is made by following steps:

[0042] Step S1: Add fly ash, sand, and enhanced emulsion into a ball mill for ball milling until the specific surface area is 500m 2 / kg, the particle size is 10 μm, and the first mixed slurry is obtained;

[0043] Step S2: adding the first mixed slurry, cement, and calcium lignosulfonate into the stirring tank, and stirring until uniform at a rotating speed of 200 r / min to obtain the second mixed slurry;

[0044] Step S3: Add the second mixed slurry and ethylenediamine into the stirring tank, and stir until uniform at a rotating speed of 150 r / min to prepare high impermeability concrete.

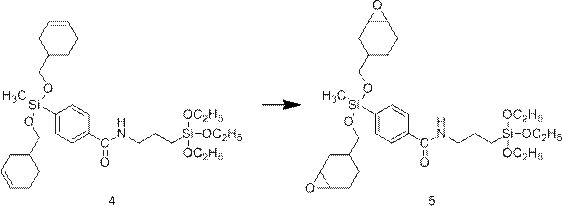

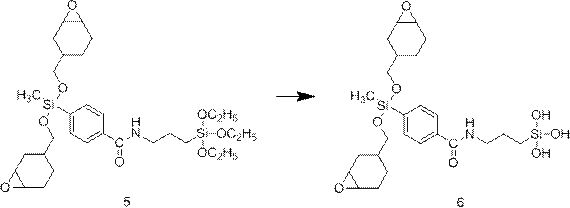

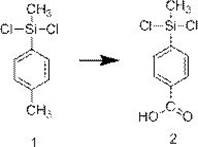

[0045] Described enhanced emulsion is...

Embodiment 2

[0051] A high impermeability and anti-cracking concrete, comprising the following raw materials in parts by weight: 105 parts of cement, 33 parts of fly ash, 35 parts of sand, 6 parts of calcium lignosulfonate, 34 parts of reinforcing emulsion, and 12 parts of ethylenediamine;

[0052] Described high impermeability concrete is made by following steps:

[0053] Step S1: Add fly ash, sand, and enhanced emulsion into a ball mill for ball milling until the specific surface area is 500m 2 / kg, the particle size is 15 μm, and the first mixed slurry is obtained;

[0054] Step S2: adding the first mixed slurry, cement, and calcium lignosulfonate into the stirring tank, and stirring until uniform at a rotating speed of 200 r / min to obtain the second mixed slurry;

[0055] Step S3: Add the second mixed slurry and ethylenediamine into the stirring tank, and stir until uniform at a rotating speed of 200 r / min to prepare high-impermeability concrete.

[0056] Described enhanced emulsion ...

Embodiment 3

[0062] A high impermeability and anti-cracking concrete, comprising the following raw materials in parts by weight: 115 parts of cement, 38 parts of fly ash, 45 parts of sand, 7 parts of calcium lignosulfonate, 28 parts of reinforcing emulsion, and 14 parts of ethylenediamine;

[0063] Described high impermeability concrete is made by following steps:

[0064] Step S1: Add fly ash, sand, and enhanced emulsion into a ball mill for ball milling until the specific surface area is 800m 2 / kg, the particle size is 10 μm, and the first mixed slurry is obtained;

[0065] Step S2: Add the first mixed slurry, cement, and calcium lignosulfonate into the stirring tank, and stir until uniform at a rotating speed of 300 r / min to obtain the second mixed slurry;

[0066] Step S3: Add the second mixed slurry and ethylenediamine into the stirring tank, and stir until uniform at a rotating speed of 150 r / min to prepare high impermeability concrete.

[0067] Described enhanced emulsion is made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com