Hard polyethylene pipe with high impact resistance

A rigid polyvinyl chloride, high impact resistance technology, applied in the direction of rigid pipes, pipes, pipes/pipe joints/fittings, etc., can solve problems such as rupture, pipe leakage, low impact strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] The present invention comprises by weight: 240 parts of PVC, 8.0 parts of heat stabilizer zinc stearate, 0.8 parts of lubricant PE wax, 2.5 parts of titanium dioxide, 14 parts of impact modifier MBS resin, 13 parts of processing aid ACR401, Made from 4.5 parts of calcium carbonate; first mix the above components evenly to obtain a mixture, heat the mixture to 120°C, then cool to 45°C, and place the cooled mixture at room temperature for 9 hours at 18°C, then use an extruder to Next, extrusion molding, cooling at 12°C after extrusion molding, the pipe of the present invention is obtained.

Embodiment 2

[0008] The present invention comprises by weight: 260 parts of PVC, 9 parts of heat stabilizer tribasic lead sulfate, 1 part of lubricant paraffin, 2.2 parts of titanium dioxide, 16 parts of impact modifier chlorinated polyethylene CPE, processing aid Made from 12 parts of ACR201 and 5.5 parts of calcium carbonate; first, mix the above components uniformly to obtain a mixture, heat the mixture to 140°C, then cool to 35°C, and place the cooled mixture at room temperature 20°C for 10 hours, then use an extruder Extrude at 175°C and cool at 17°C after extrusion to obtain the pipe of the present invention.

Embodiment 3

[0010] The present invention comprises by weight: 275 parts of PVC, 10 parts of heat stabilizer barium stearate, 1.2 parts of lubricant stearic acid, 2.8 parts of titanium dioxide, 19 parts of impact modifier ethylene-vinyl acetate copolymer EVA, It is made of 4 parts of processing aid AMS and 6 parts of calcium carbonate; first mix the above components evenly to obtain a mixture, heat the mixture to 110°C, then cool to 50°C, and place the cooled mixture at room temperature 23°C for 11 hours, Use an extruder to extrude at 210°C, and cool at 20°C after extrusion to obtain the pipe of the present invention.

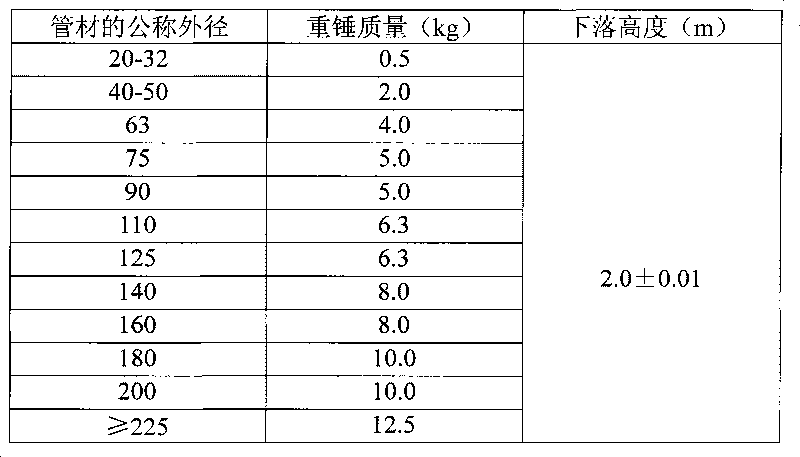

[0011] The present invention can stably pass the quite high drop weight impact test drawn up by our factory, and the test conditions are as shown in Table 1:

[0012] Table 1. Drop-weight impact test conditions for high-impact rigid PVC pipes (0°C)

[0013]

[0014] The requirements in Table 1 are far higher than the requirements in GB / T10002.1-2006 on the impact resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com