Metal profiled plate

It is a technology of metal pressing and metal plate, which is applied to roofs, roofs, buildings, etc. that use flat/curved panels. It can solve the problems of loose connection, rain leakage or water seepage, and achieve a structure that is not easy to seepage, beautiful in appearance, and easy to install. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

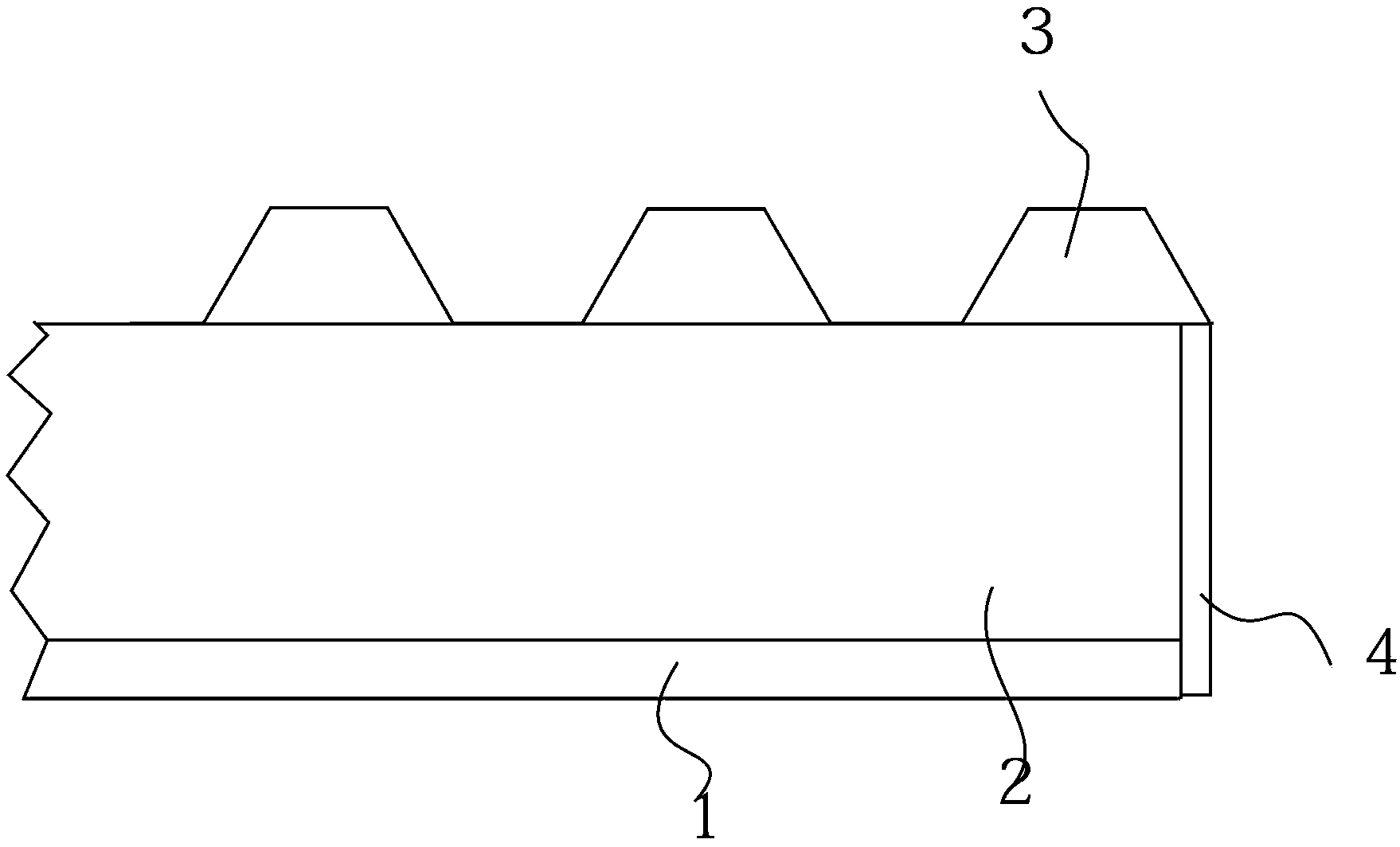

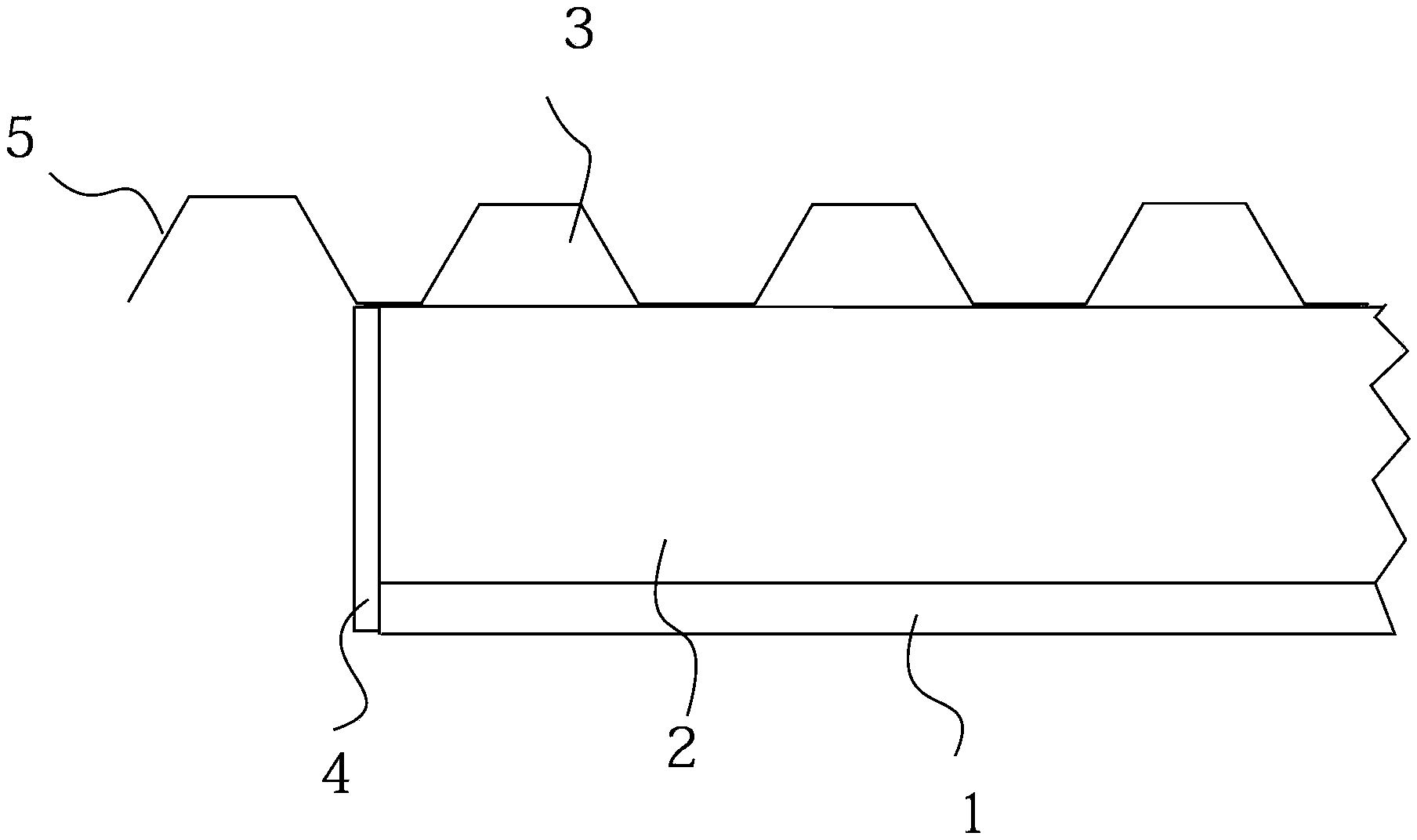

[0014] like figure 1 , 2 Shown is the structural schematic diagram of the metal profiled plate of the present invention, a kind of metal profiled plate, comprises anti-rust coating 1, metal plate layer, insulation layer 2, trapezoidal part 3 and connector 5; The bottom is a metal plate layer, the surface of the metal plate layer is coated with an antirust coating 1, and a trapezoidal piece 3 is installed on the top of the heat preservation layer 2, and the trapezoidal piece 3 is arranged on the extension of the heat preservation layer 2 There is a connecting piece 5 which is press-fitted with the trapezoidal piece 3 .

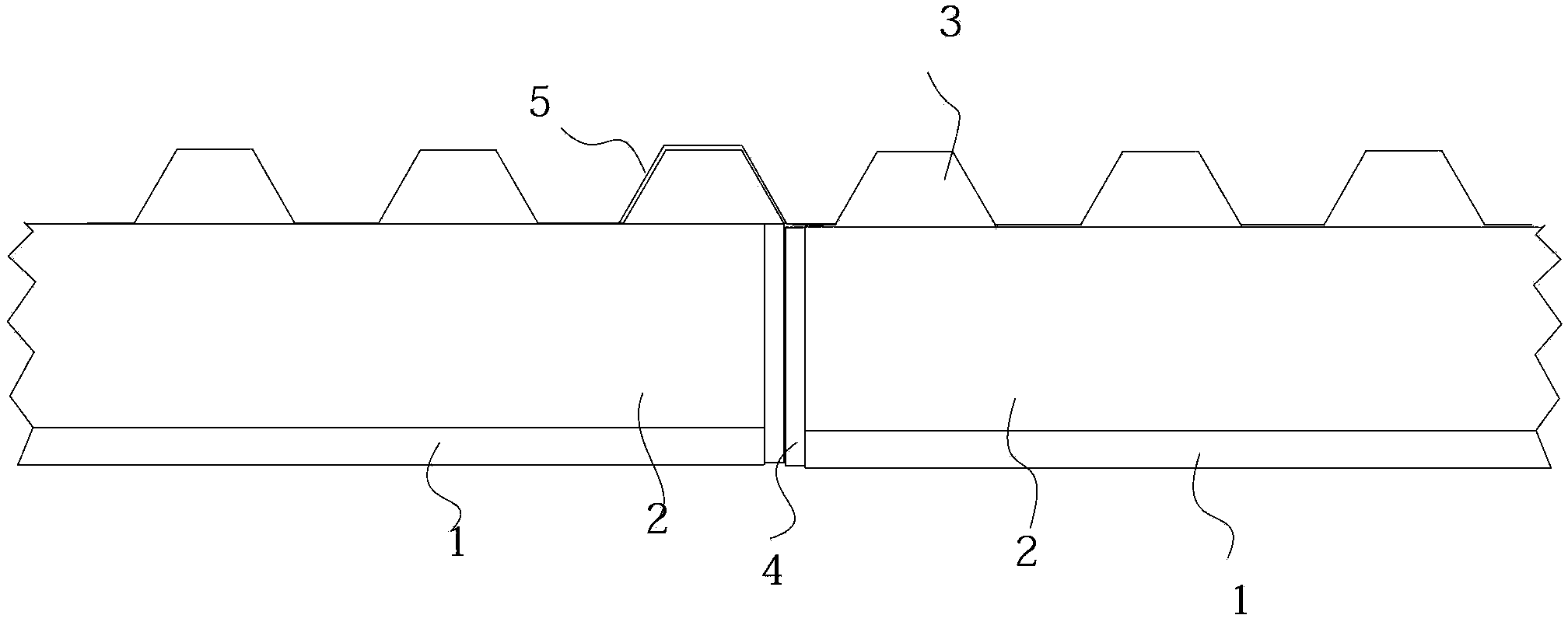

[0015] image 3 Shown is the structural schematic diagram of the connection of the right side and the left side of the metal profiled plate of the present utility model, and the junction of the thermal insulation layer 2 and the thermal insulation layer 2 is provided with a rubber strip 4, so that two adjacent metal profiled plates Just can be more firmly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com