Bathroom shower room chassis and construction method thereof

A construction method and technology for a shower room, applied in showers, sanitary equipment, indoor sanitary piping devices, etc., can solve the problems of breeding bacteria, easy immersion in water, affecting health, etc., reducing the operation of bottom filling, waterproofing Good performance, not easy to change the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

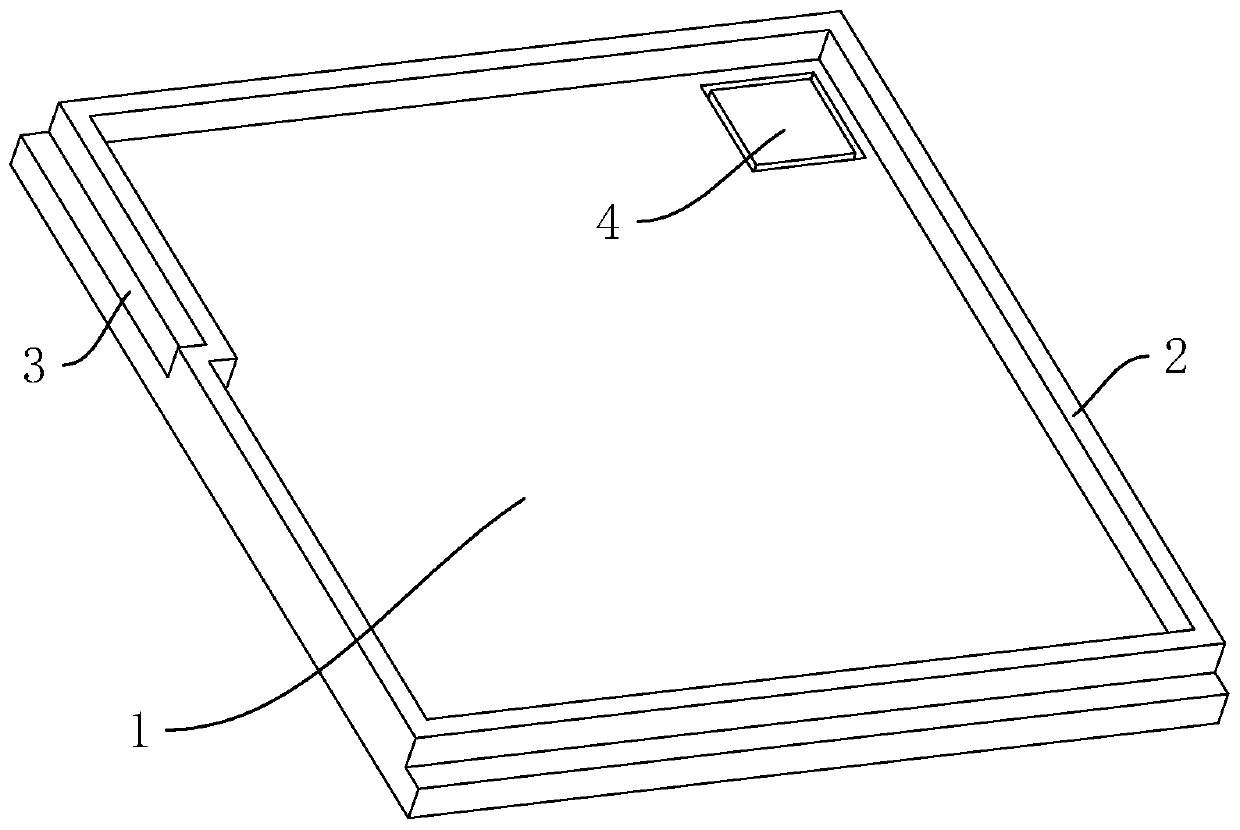

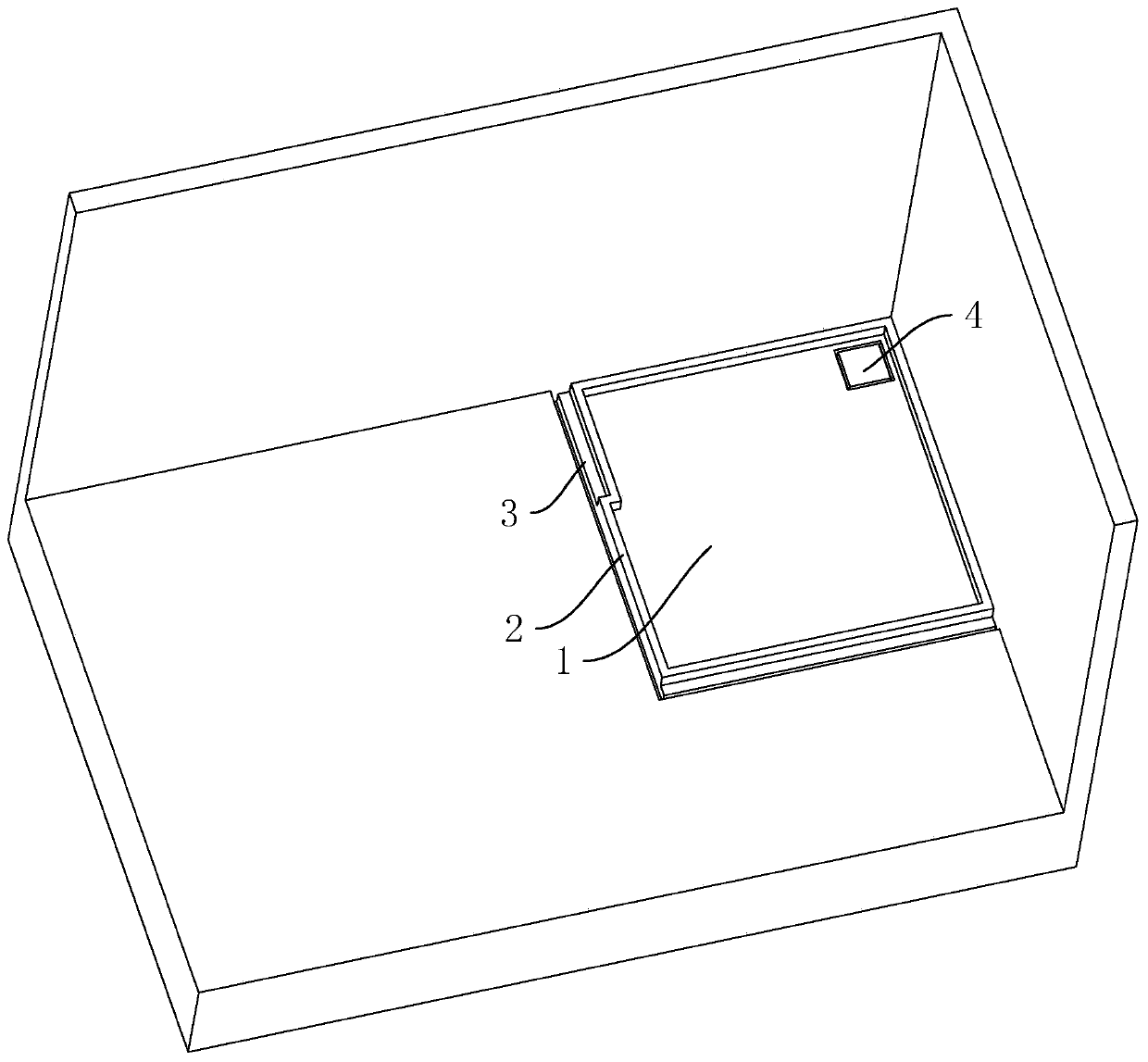

[0053] A bathroom shower room chassis, such as figure 1 As shown, it includes an integrally arranged marble base plate 1 and a waterproof ring 2 arranged on the marble base plate 1. The waterproof ring 2 is arranged on the upper end surface of the marble base plate 1. The waterproof ring 2 is formed by cutting the marble base plate 1 so that the waterproof ring 2 and the marble base plate 1 set in one piece. The outer wall of the waterproof ring 2 is flush with the outer wall of the marble base 1, and the thickness of the waterproof ring 2 is 5-20mm.

[0054] One side of the waterproof ring 2 is recessed inward to form the installation groove 3, and the side wall adjacent to the waterproof ring 2 and the installation groove 3 is indented inward by 3-8mm. When the chassis of the shower room is used to erect a partition, the installation groove 3 And the indentation can be used for the installation and positioning of the partition. The lower bottom of the partition directly tou...

Embodiment 2

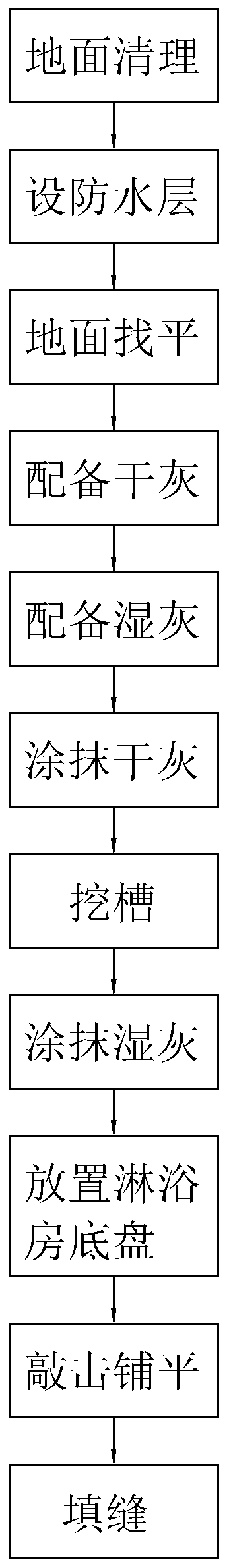

[0058] A construction method for the chassis of a bathroom shower room, such as image 3 shown, including the following steps:

[0059] S1 Ground cleaning, use a grinder to grind the base ground to remove impurities, floating dust and sand on the ground. Grind the ground level with more local elevations. After sanding, sweep away the dust and vacuum it up.

[0060] S11 is equipped with a waterproof layer, and the bathroom floor is equipped with a waterproof layer. The floor is further dedusted by blowing air, and then the first layer of waterproof emulsion is applied with a roller brush. The first layer of waterproof emulsion is applied in the form of horizontal coating; Two layers of waterproof emulsion, the second layer of waterproof emulsion is applied in the vertical coating method; after the second layer is dry, the third layer of waterproof emulsion is applied in the horizontal coating method, and the waterproof layer construction is completed after drying. The waterp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com