High-altitude sliding hoisting device of corridor truss of mountain and implementing method of high-altitude sliding hoisting device

A hoisting device and truss technology, which is applied in the field of high-altitude sliding hoisting devices for trusses in corridors in mountainous areas, can solve the problems of unsuitable installation and construction of high-altitude corridors, inconvenient implementation and application, and delays in construction periods, so as to save transportation costs and shorten construction periods , The effect of reducing the construction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

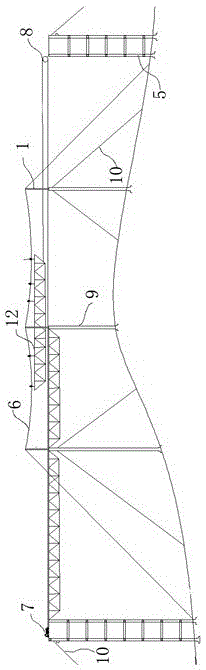

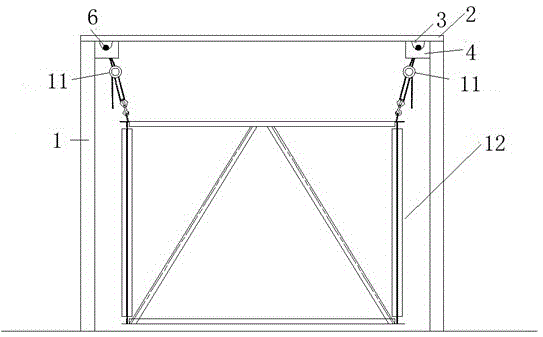

[0038] Such as figure 1 , 2 As shown, this embodiment provides a high-altitude sliding hoisting device for a mountain corridor truss, which is used to solve the problem that hoisting methods such as cranes and climbing poles cannot be used in steep mountainous areas. The hoisting device mainly includes a bracket, a sliding frame, a sliding cable and a traction mechanism. The support is a four-column support column, which is arranged at both ends of the installation platform.

[0039] The sliding frame is composed of upright columns, and its structure is a rectangular parallelepiped frame or a cube frame. In this embodiment, the sliding frame is made of Φ219 steel pipes to make six upright columns each 2 meters long. Specifically, on both sides of the top of the continuous three-span concrete support Two columns are anchored each, the distance between the columns is greater than the width of the two chords of the corridor truss, and the top of the columns is welded with a bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com