High-pressure grouting device for deepwater karst fissure development geology and construction method

A high-pressure grouting and karst technology, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of frequent occurrence and achieve the effect of small construction area, convenient operation and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

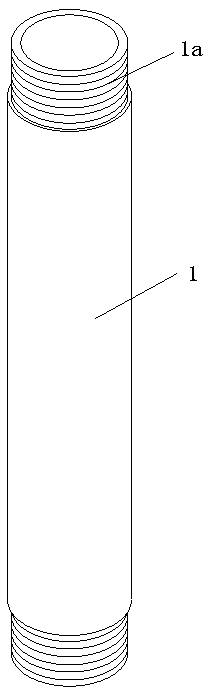

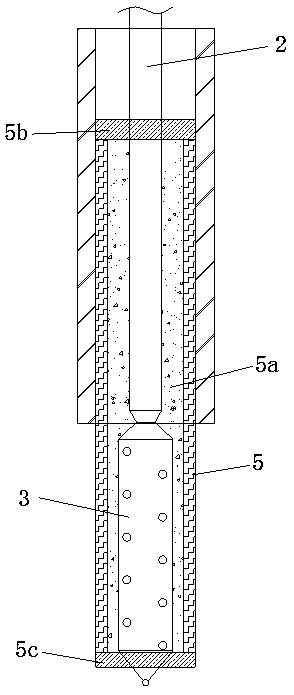

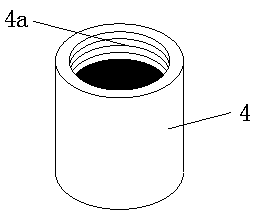

[0041] Embodiment 1, please refer to the attached Figure 1-5As shown, a geological high-pressure grouting device for deep-water karst fissures includes a casing 1, a slurry feeding pipe 2, a steel flower pipe 3, and a screw sleeve 4. The casing 1 is made of Q345 material, and the pipe diameter is φ150mm and There are two kinds of φ90mm. The wall thickness of the casing 1 of the two pipe diameters is 4-6 mm, and the two ends of the casing 1 are symmetrically provided with external thread sections 1a; There is a casing material protective layer 5, the diameter of the casing material protective layer 5 is about 5mm smaller than the diameter of the casing 1 with a pipe diameter specification of φ150mm, and the top and bottom of the casing material protective layer 5 are respectively A casing material top plug 5b and a casing material bottom plug 5c are provided; the casing material protective layer 5 is filled with a casing material 5a, and the casing material 5a is composed of e...

Example Embodiment

[0042] In the second embodiment, please refer to the attached Image 6 As shown, combining the type of grouting device and the installation method expressed in the above-mentioned first embodiment, a construction method of geological high-pressure grouting with deep-water karst fractures is provided, and the method includes the following five steps:

[0043] Step 1, material preparation: prepare the grouting raw materials and grouting equipment required for grouting, and place the grouting raw materials and grouting equipment on the floating platform. The grouting equipment includes the grouting device expressed in the first embodiment. type and other grouting equipment;

[0044] Step 2. Positioning: According to the hole layout of the design drawing, carry out point stakeout, move the floating platform to the design hole position for fixing, and then accurately stake out again after fixing;

[0045] Step 3: Drilling: Move the drilling rig to the orifice, lower the casing 1 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com