Soft soil foundation reinforcing method based on cement concrete cored piles

A cement concrete and soft soil foundation technology, which is applied in soil protection, foundation structure engineering, construction, etc., can solve the problems of poor verticality control of core piles, reduced bearing capacity of pile composite foundations, and large construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

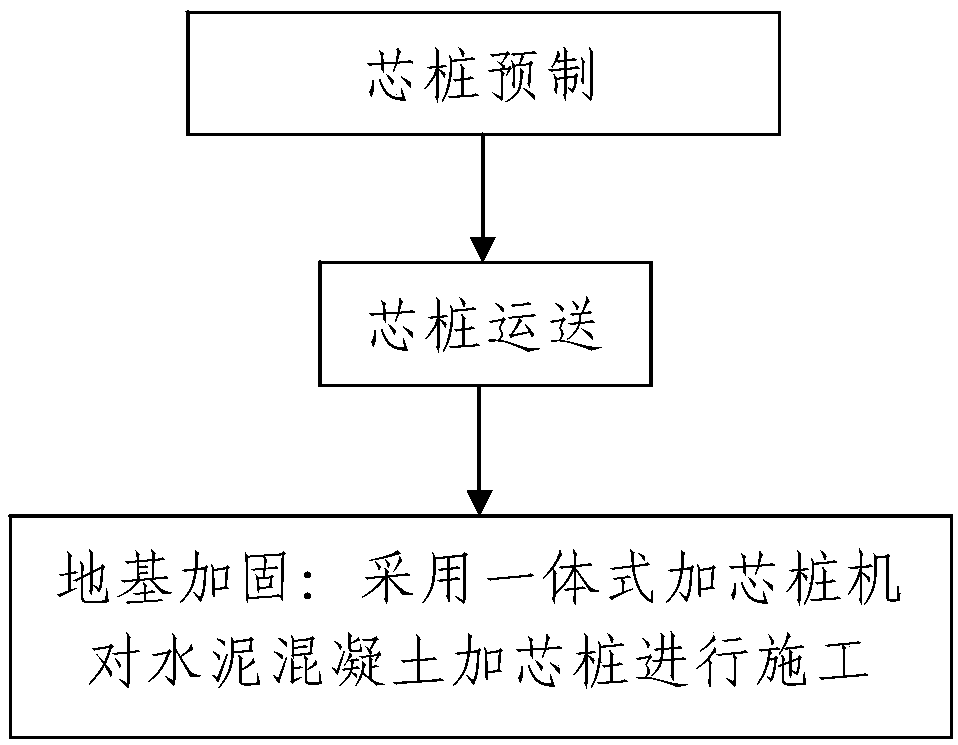

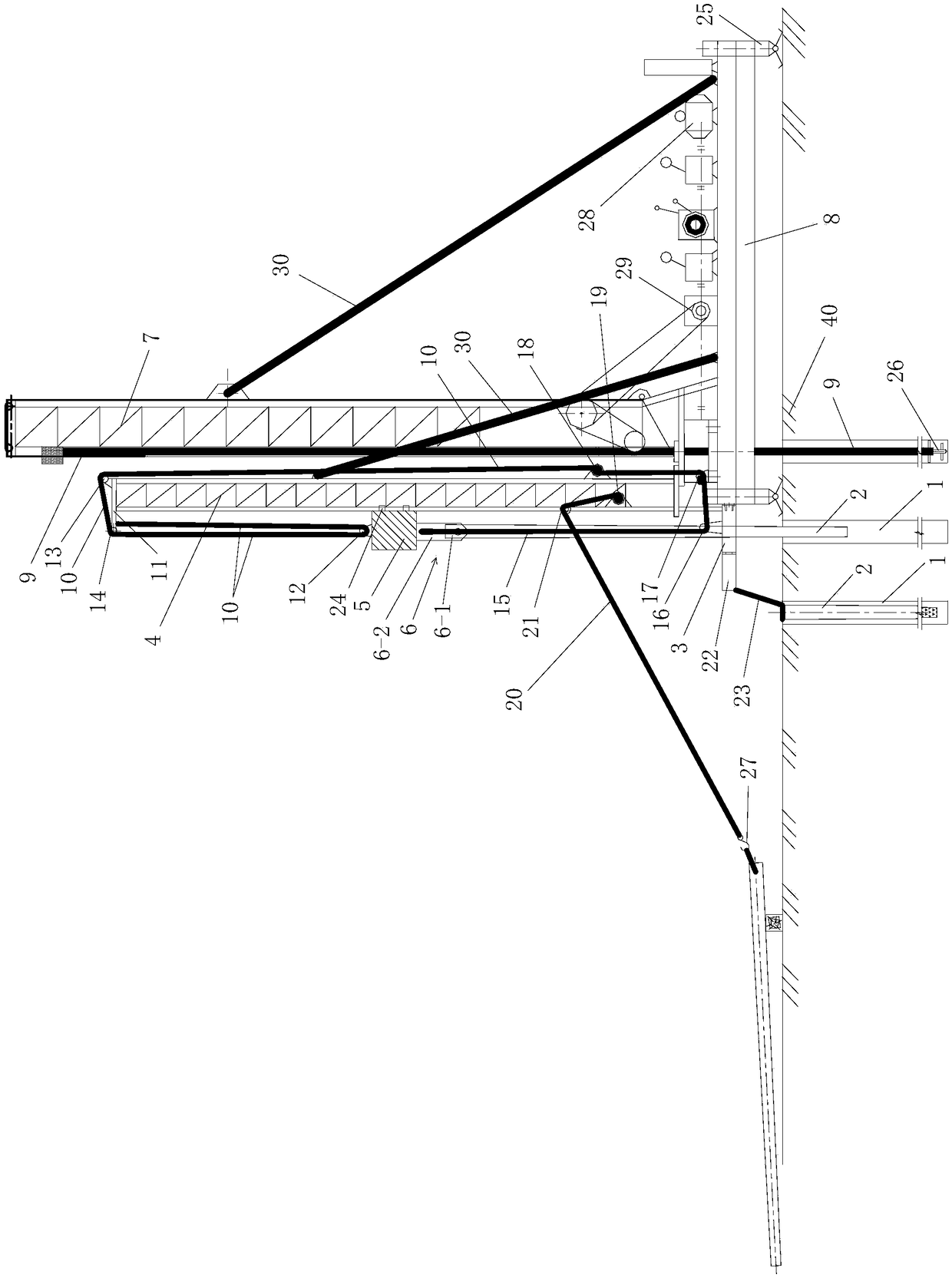

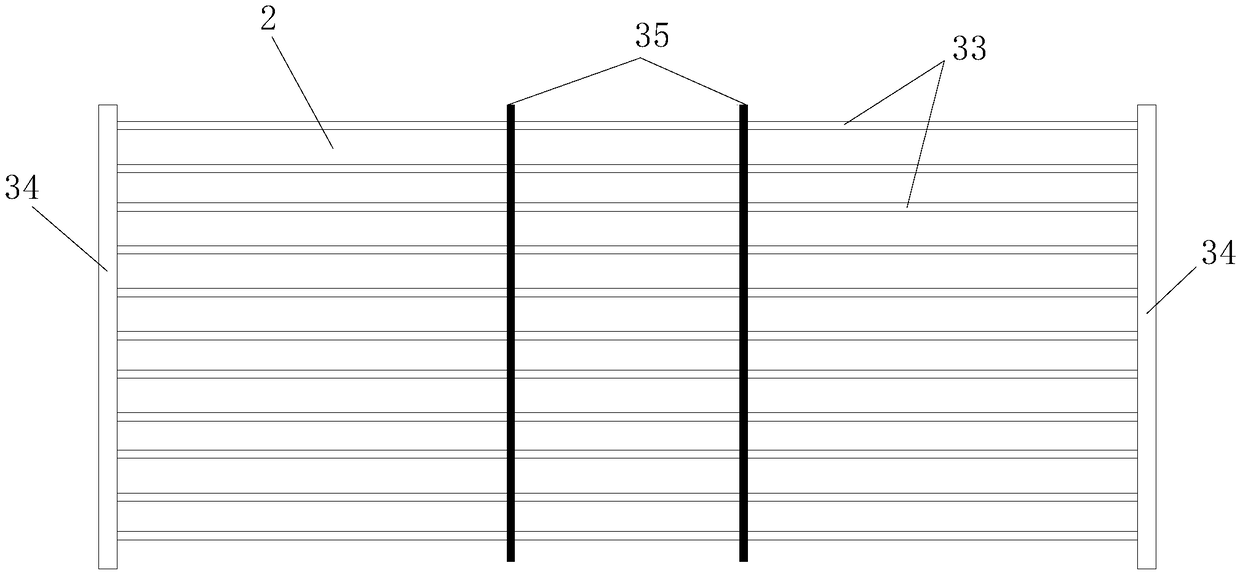

[0080] Such as figure 1 A soft soil foundation reinforcement method based on cement concrete cored piles is shown, using a plurality of vertically arranged cement concrete cored piles to reinforce the soft soil foundation 40, and the plurality of cement concrete cored piles The structures are all the same; each of the cement concrete cored piles includes a cement mixing pile 1 and a core pile 2 pressed into the cement mixing pile 1 from top to bottom, and the core pile 2 is located in the inner middle of the cement mixing pile 1, The core pile 2 is a reinforced concrete core pile;

[0081] When the soft soil foundation 40 is reinforced, the following steps are included:

[0082] Step 1. Prefabrication of core piles: Prefabricate the core piles 2 of the plurality of cement concrete cored piles used to reinforce the soft soil foundation 40, respectively, to obtain a plurality of prefabricated core piles 2;

[0083] Step 2, transporting the core piles: using transport equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com