Construction method of lightweight concrete batten partition door opening

A technology of lightweight concrete and slatted partition walls, which is applied in the direction of windows/doors, window/door frames, building components, etc., can solve the difficulties in ensuring the construction quality of structural columns/embracing frames, the inability to observe the progress of concrete pouring, and the impact on The construction progress of structural columns/embracing frames and other issues are achieved to achieve the effects of low noise, light weight, and small construction land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0049] The invention provides a construction method for a door opening of a lightweight concrete slab partition wall, which comprises the following steps:

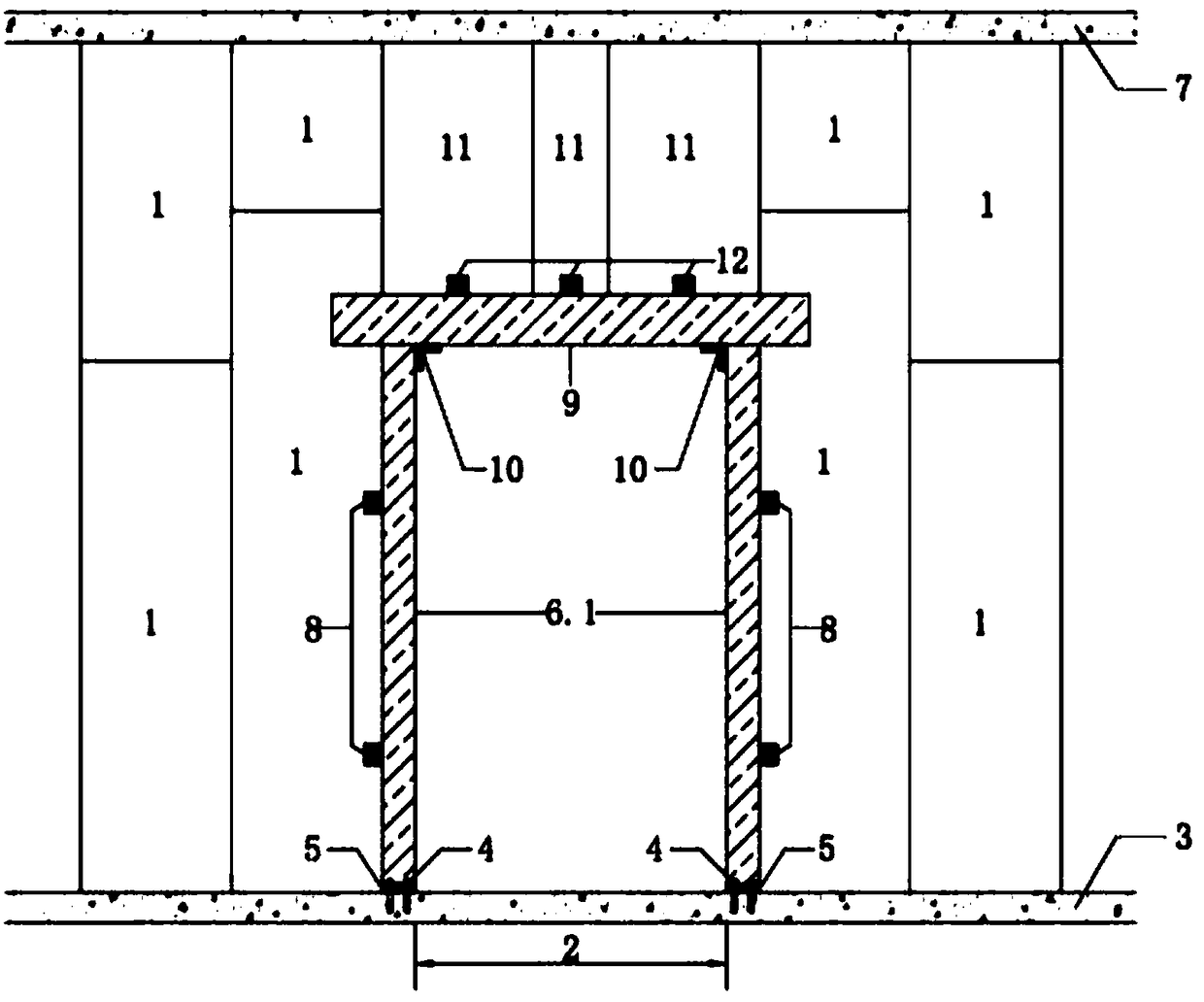

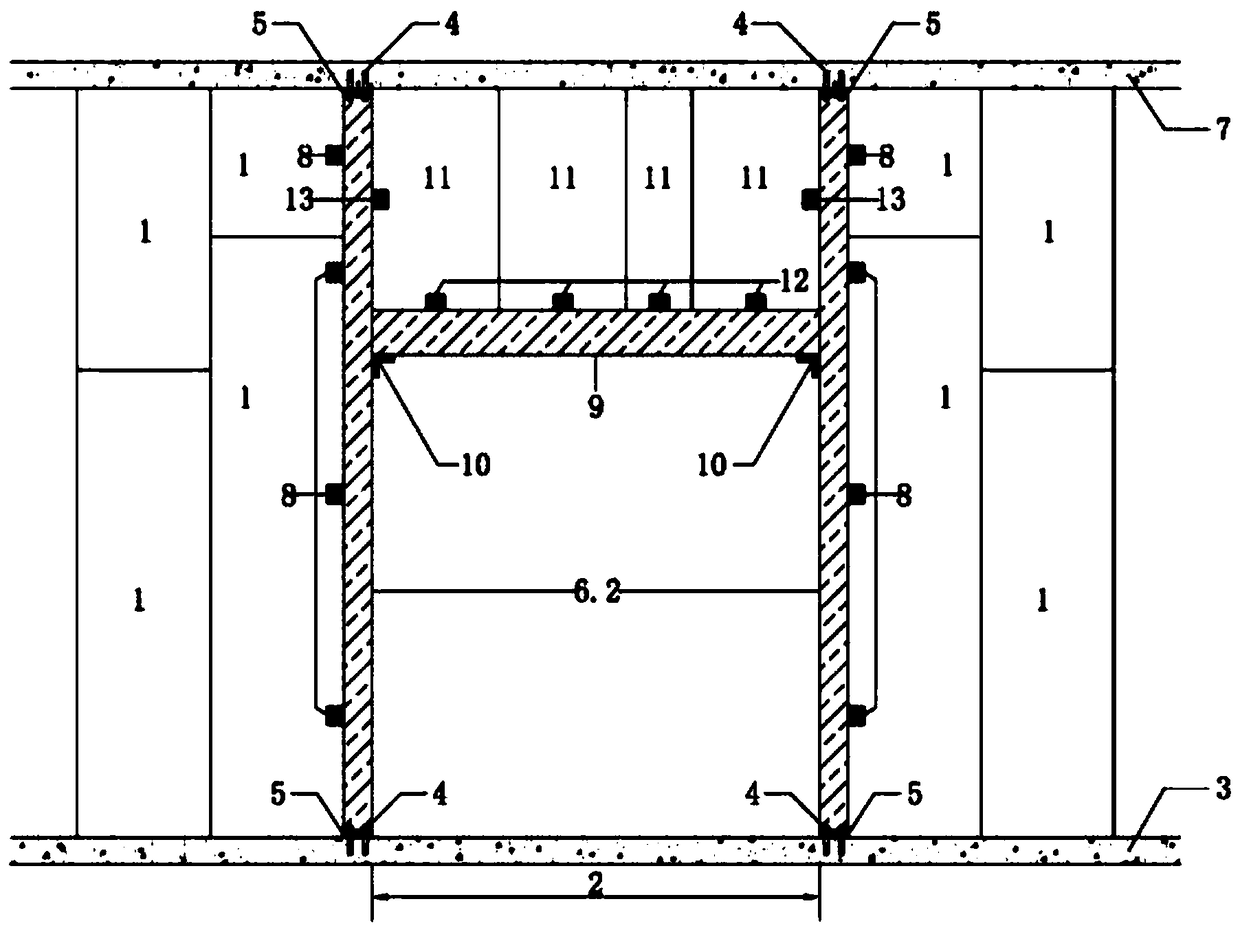

[0050] (1) Position and lay out the positions of side partition wall panel 1, top partition wall panel 11, door opening, structural column 6.2 or frame 6.1 and lintel 9 according to the architectural drawing and panel layout diagram;

[0051] (2) Drill a hole on the floor corresponding to the installation position of the structural column 6.2 or the frame 6.1, and then fix the galvanized steel plate 5 at the drilled position;

[0052] In this step, according to the requirements of the existing relevant construction specifications, when the width of the door opening 2 is less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com