Fully-fabricated building system with grid steel structure

A full-assembly, grid technology, applied in building components, building structures, special buildings, etc., can solve problems such as a large number of construction equipment, ambient air and noise pollution, and obstruction of roads, saving labor hours, eliminating The effect of white pollution and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

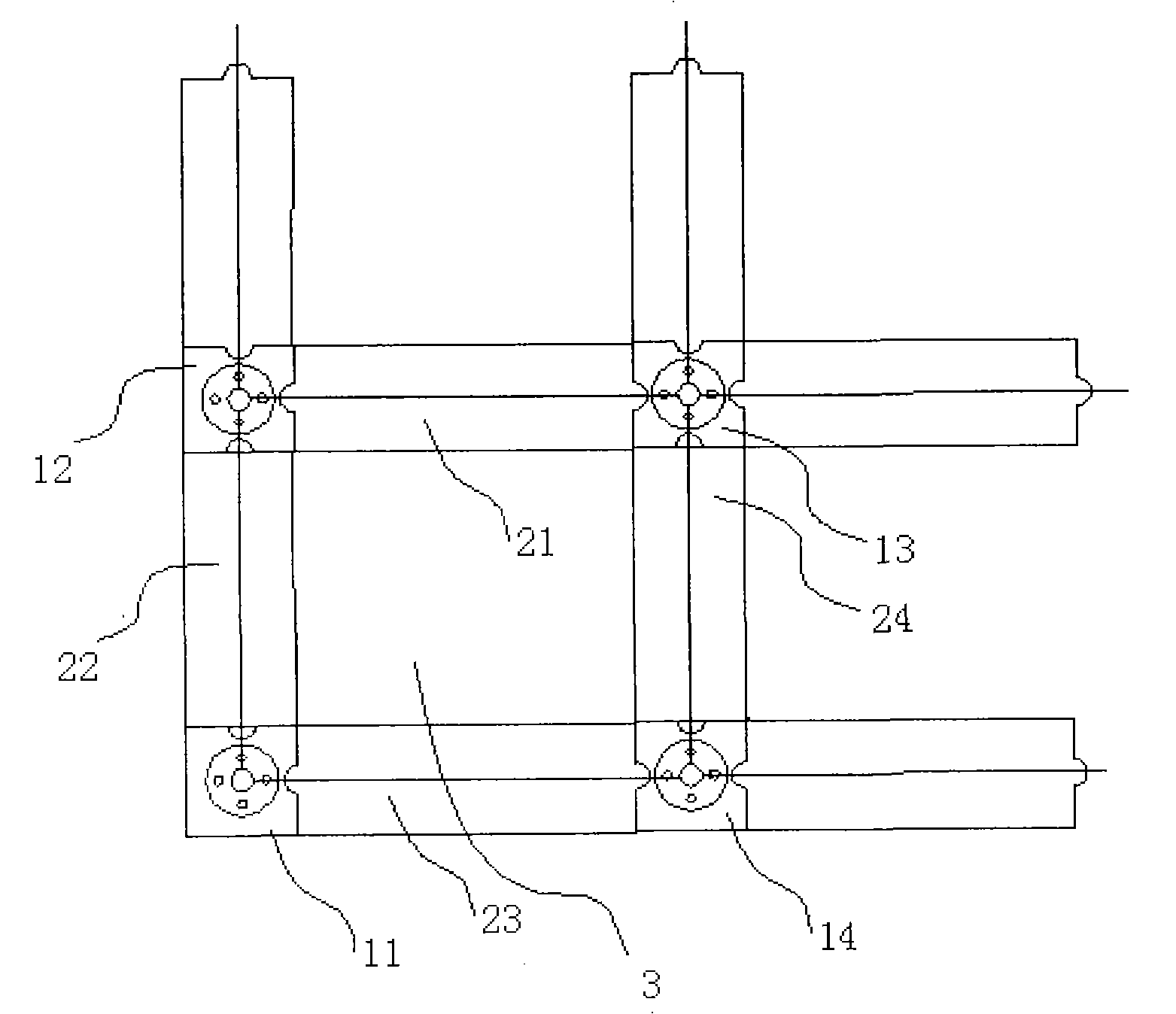

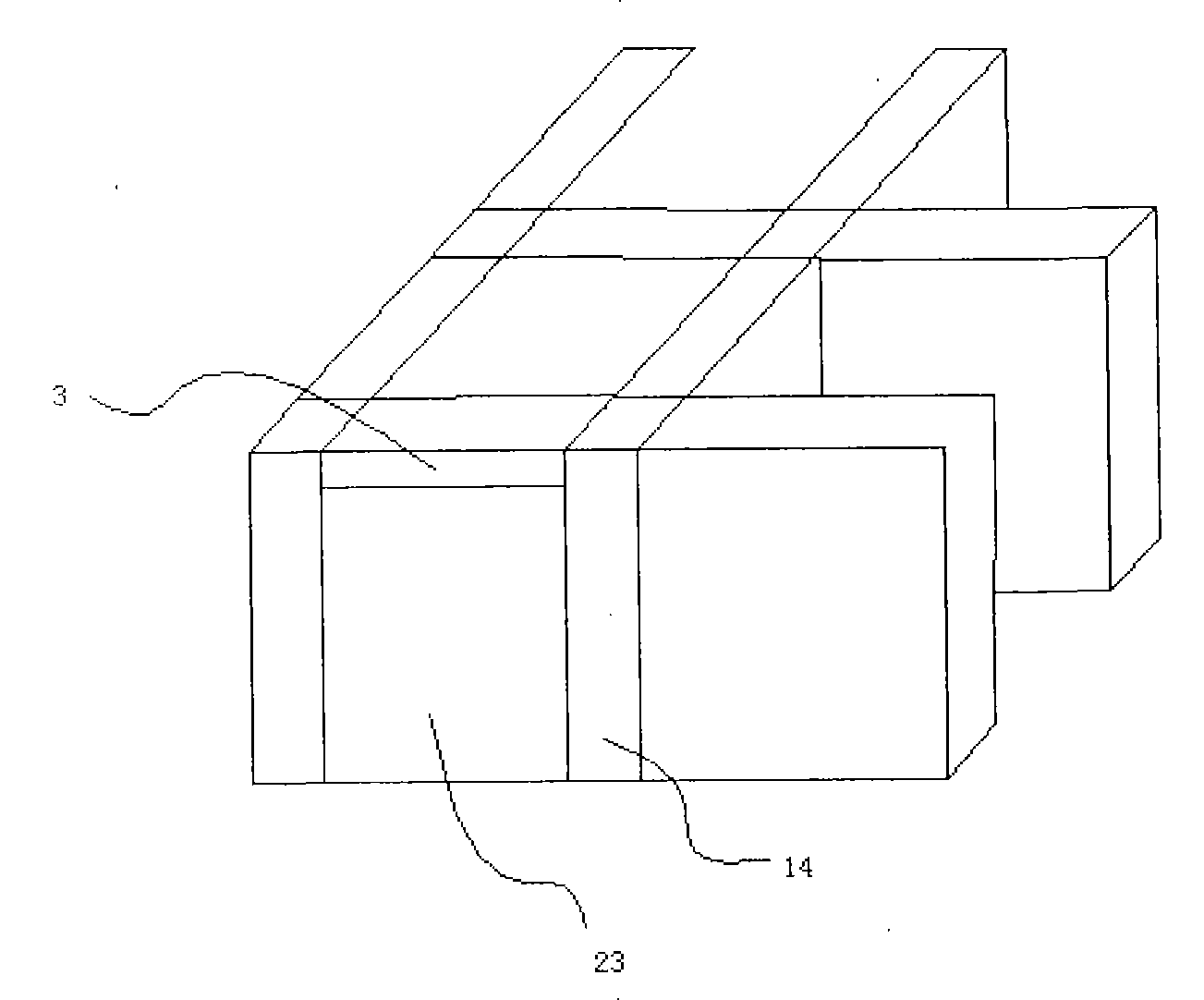

[0020] see figure 1 , figure 2 , a grid steel structure fully assembled house system, including wall panels 21, 22, 23, 24, the thickness of the wall panels is 20 cm, floor slabs 3 and load-bearing composite columns 11, 12, 13, 14, and load-bearing composite columns 11 . , It can be assembled into many multi-storey houses during specific assembly.

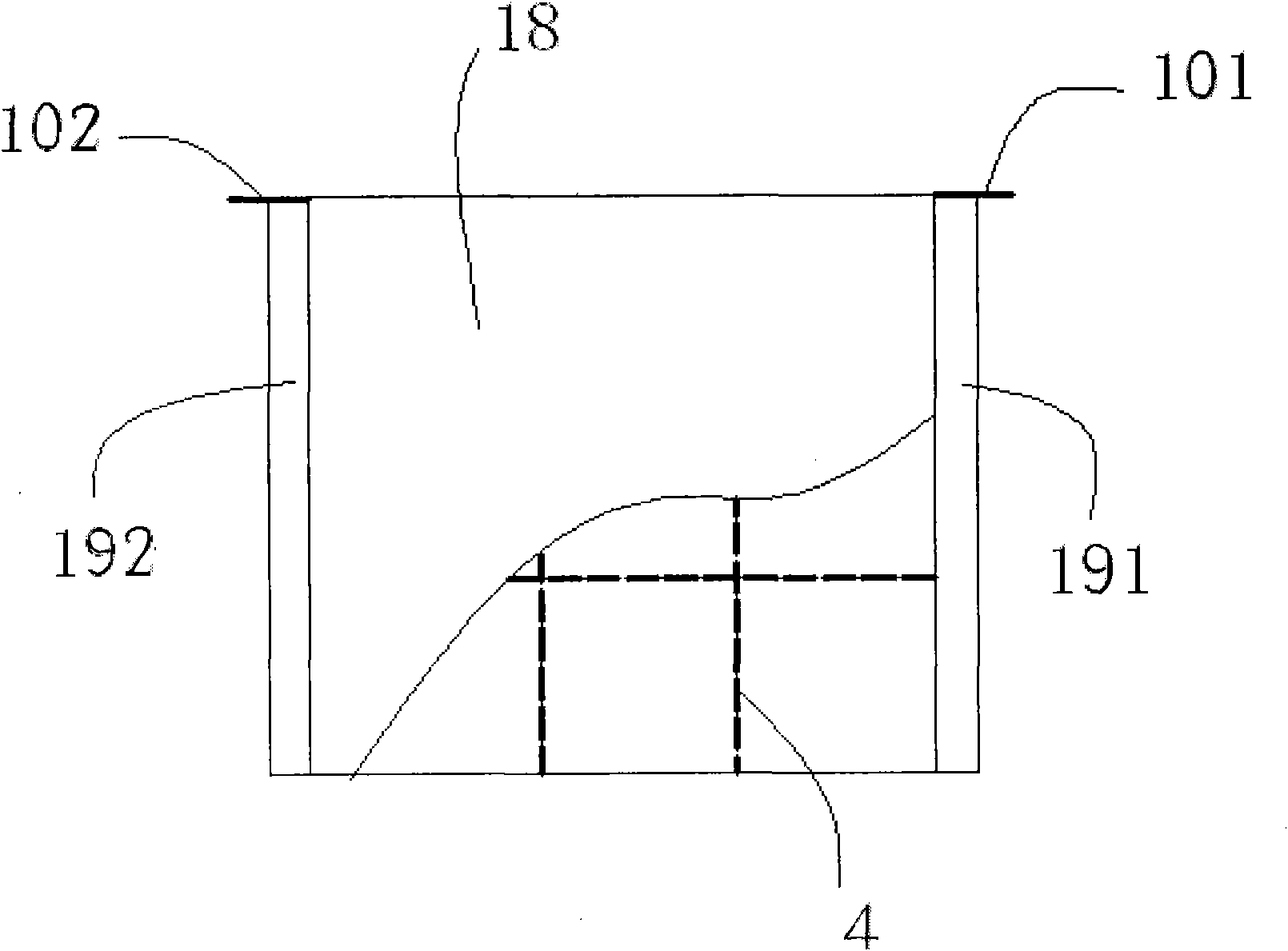

[0021] see image 3 , Figure 4 , the wallboards 21, 22, 23, 24 include the grid steel frame 4 and the rubber powder particle layer 18 cast on the two sides of the grid steel frame 4, and the two ends of the wallboards 21, 22, 23, 24 are respectively provided with Protruding chucks 191, 192, and door openings (not shown) are provided on one side of the wallboard, and the grid steel frames on both sides of the top of the wallboards 21, 22, 23, 24 extend out of the wallboards respectively One section, respectively 101 and 102, is used to ride on the load-bearing composite column and support the wallboard with the load-bearing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com