Patents

Literature

302results about How to "Meet energy saving requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Room temperature control method

InactiveCN102679505AThe theoretical formula is simpleEasy to debugSpace heating and ventilation safety systemsLighting and heating apparatusRadiation temperatureControl mode

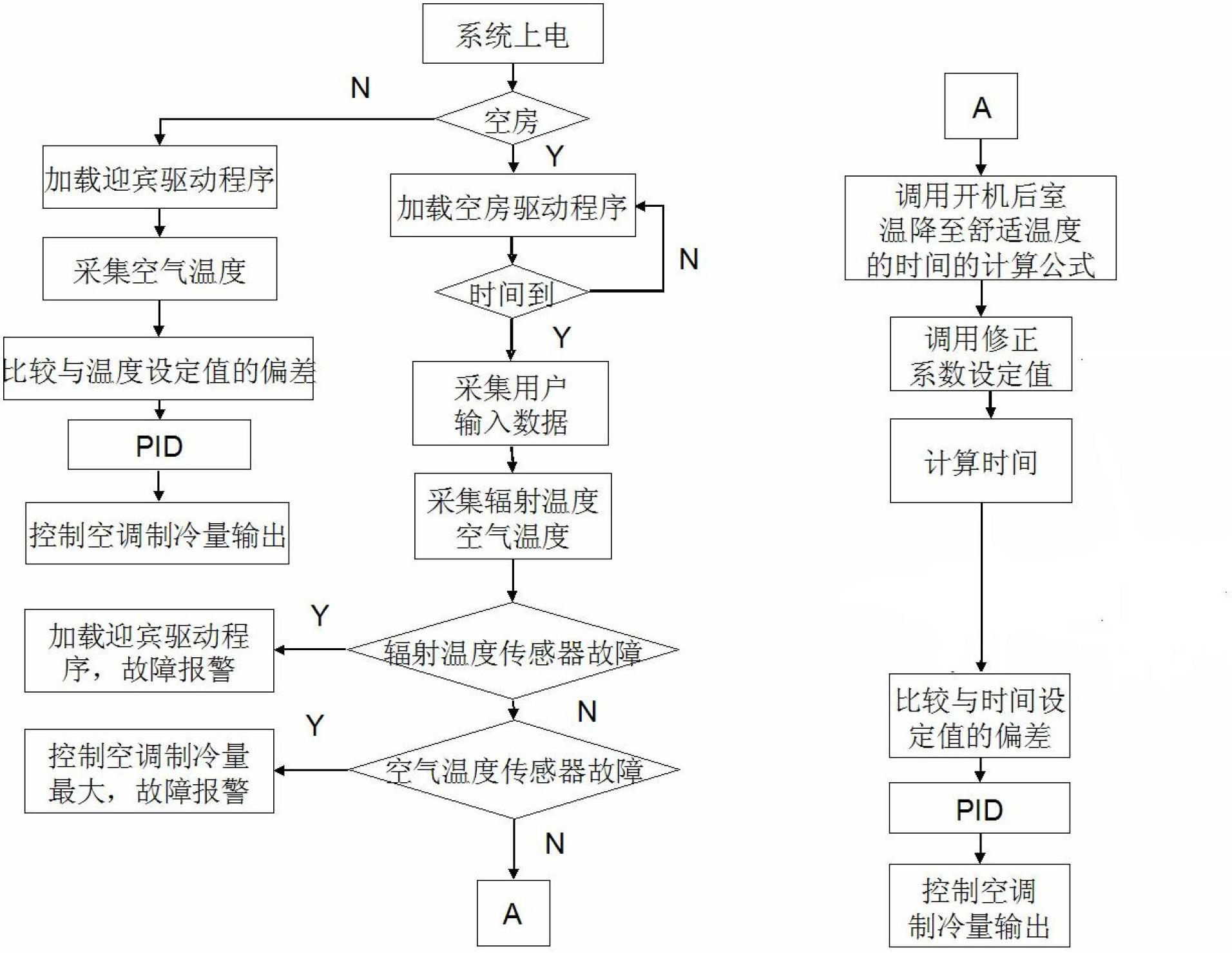

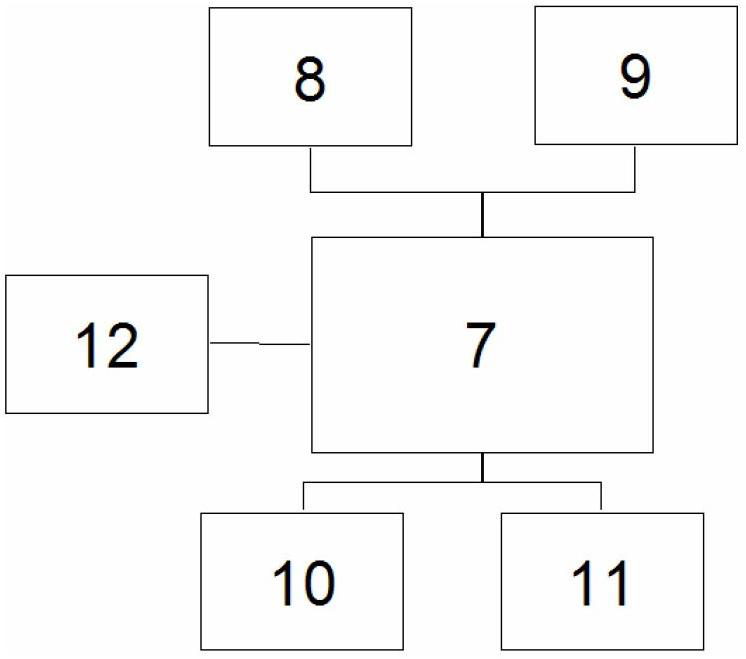

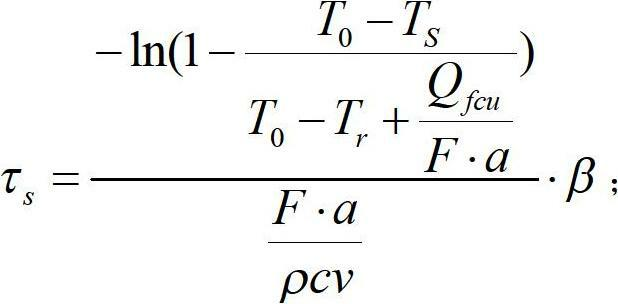

The invention discloses a room temperature control method which mainly comprises a control method under an empty room pattern, and also comprises a control mode under a guest greeting pattern. Comfort temperature acquisition in set time is taken as a control target after people live again, the comfort degree and satisfaction degree of people can be considered when people just live, and the energy-saving requirement of an air conditioning system by scientific control of room temperature under the empty room pattern can be met. According to the invention, a sensor is not required to be installed outdoors, the heat gaining condition of air in a room can be monitored and the time of predicting room temperature to comfortable temperature after starting up can be forecast by only collecting air temperature and average radiation temperature under the empty room pattern; and the method is especially suitable for room temperature control of guest rooms of star-level hotels under the empty room pattern, and also can be applied to air conditioner forecasting control of other living buildings when in startup and shutdown in advance.

Owner:CHONGQING UNIV

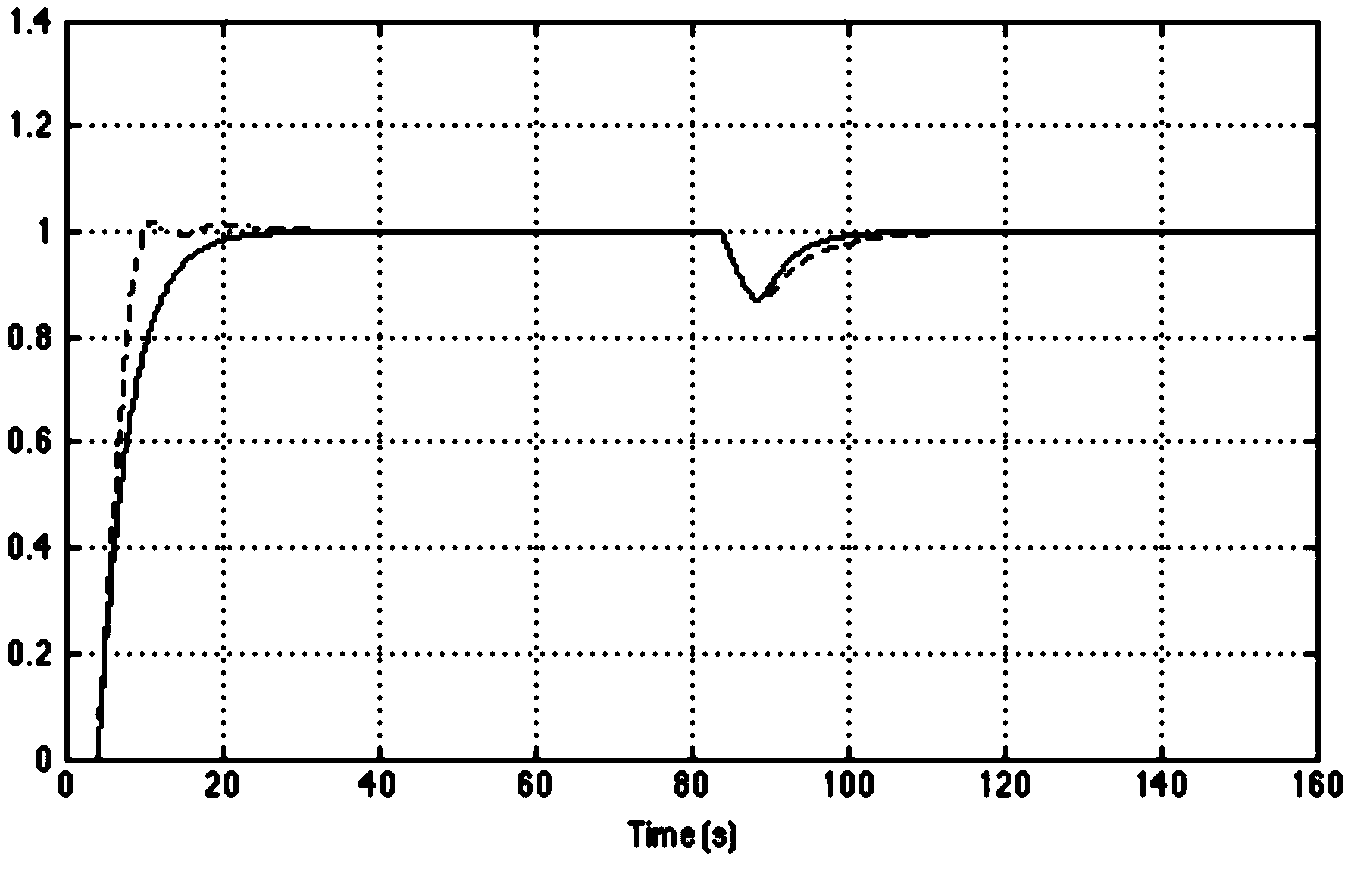

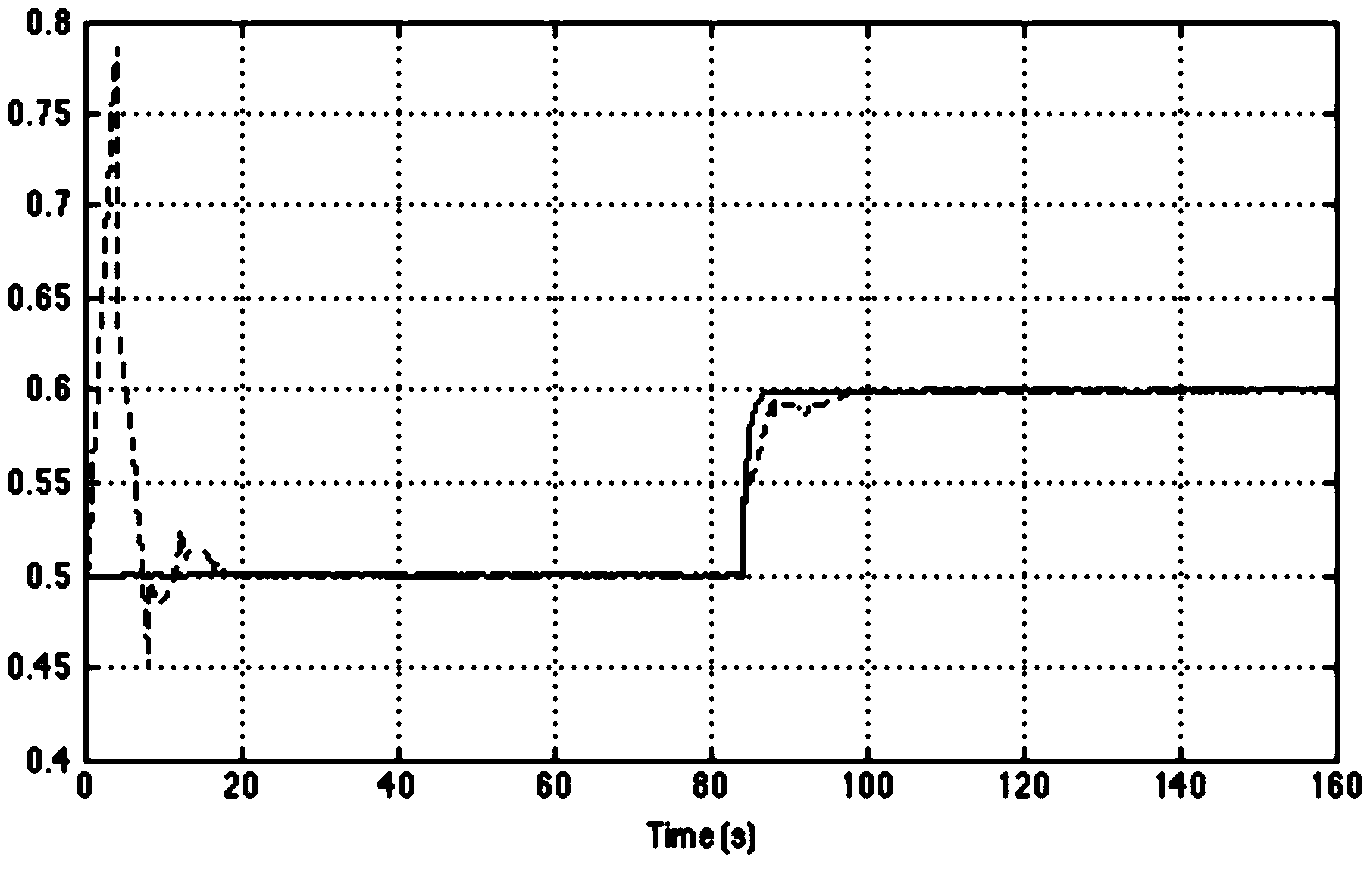

Design and setting method for active disturbance rejection control system of time delay system

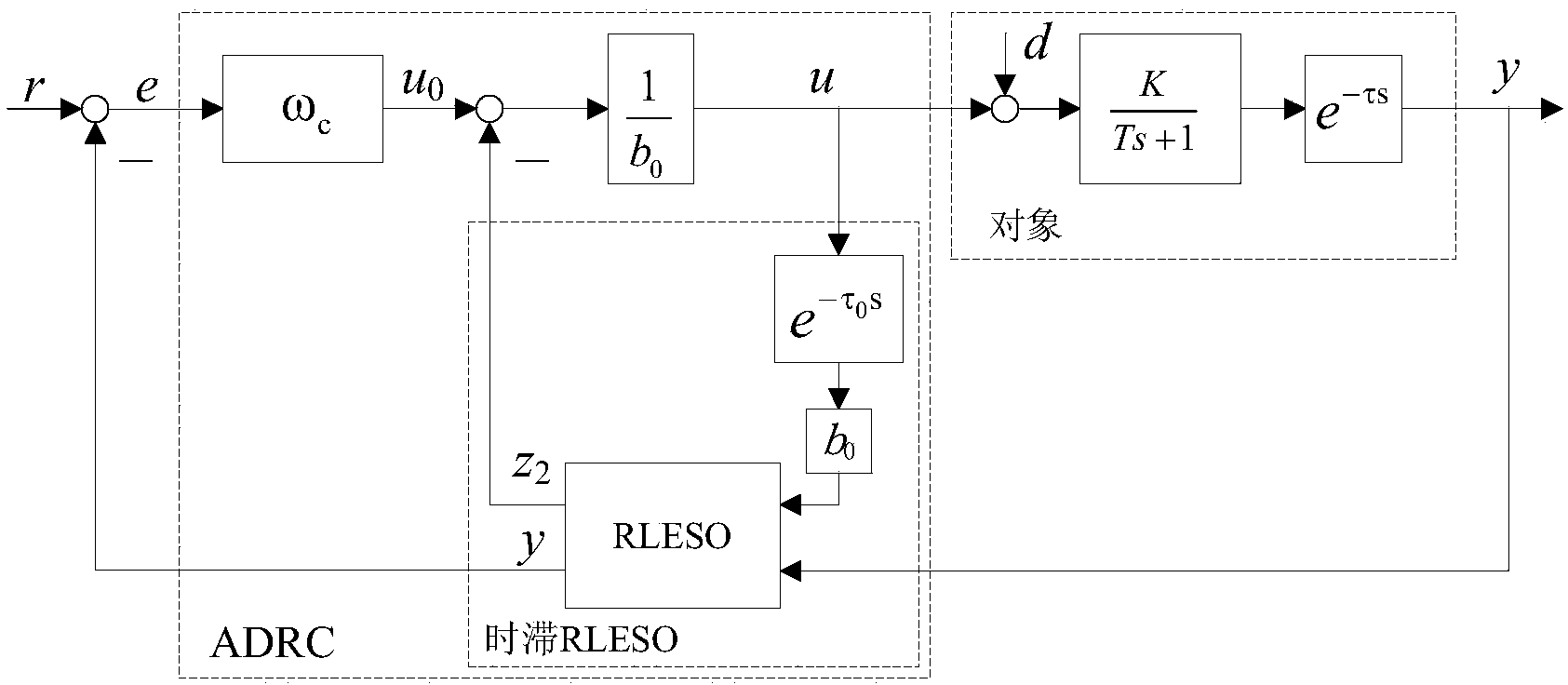

The invention particularly relates to a design and setting method for an active disturbance rejection control system of a time delay system. According to the method, based on the active disturbance rejection technology, firstly, complex controlled objects are fit into a one-order inertial element plus dead time delay mathematic model, meanwhile, time delay comes down to the disturbance quantity, a time delay reduction linear extended state observer is applied to estimation of unknown total disturbance including the time delay, active compensation for the influences of the total disturbance on the system is achieved, the time delay system is restored into a system in an integrator tandem type in an ADRC standard, and then compensation for the time delay system is achieved; finally, a closed-loop transfer function of the system is deduced, a dead time delay link in a characteristic equation is eliminated, and the numerical relationship between an ADRC single-parameter setting formula with universality and adjustable parameters is correspondingly provided. The simulation result verifies that designed practical ADRC has good stability, rapidity, accuracy and disturbance rejection.

Owner:UNIV OF SCI & TECH BEIJING

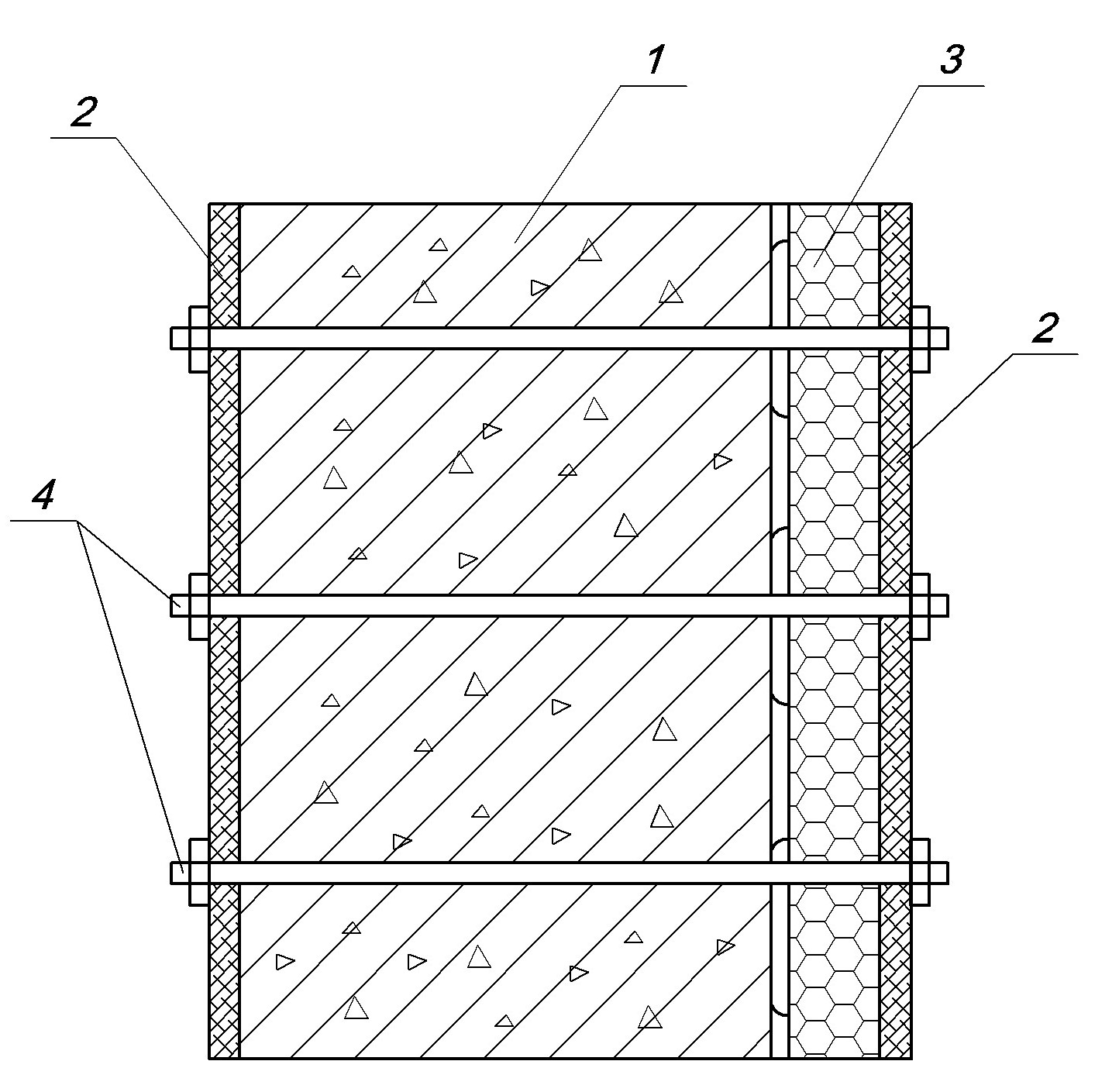

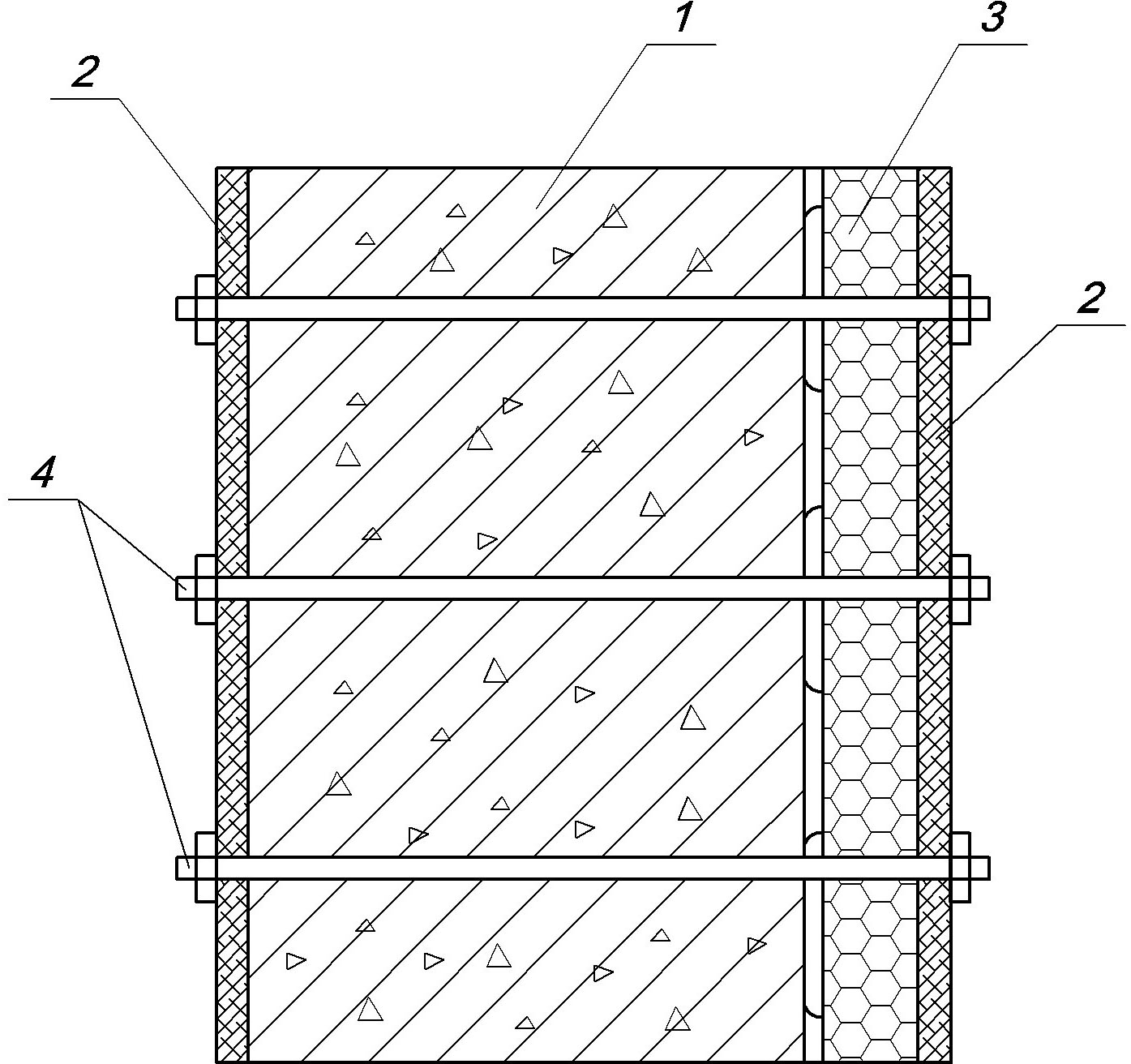

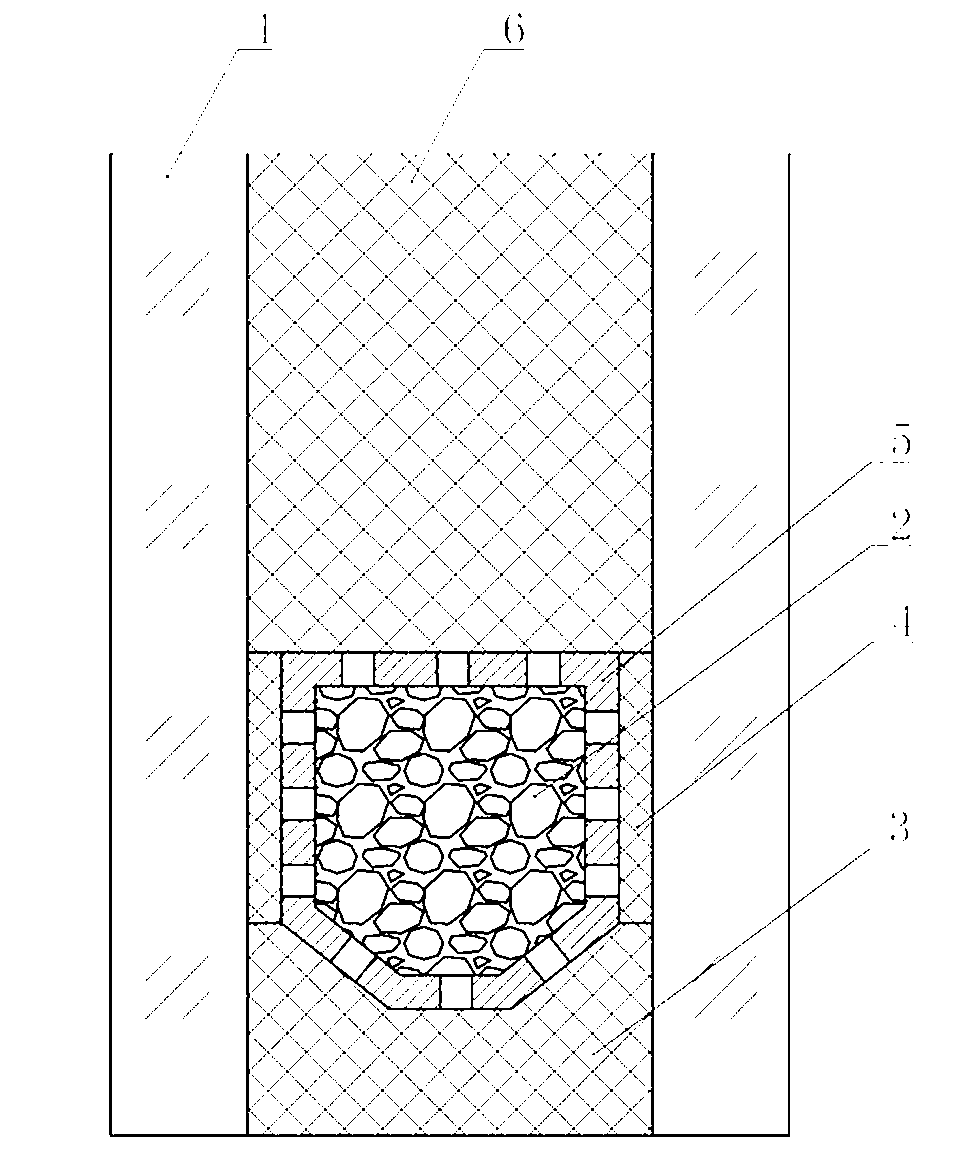

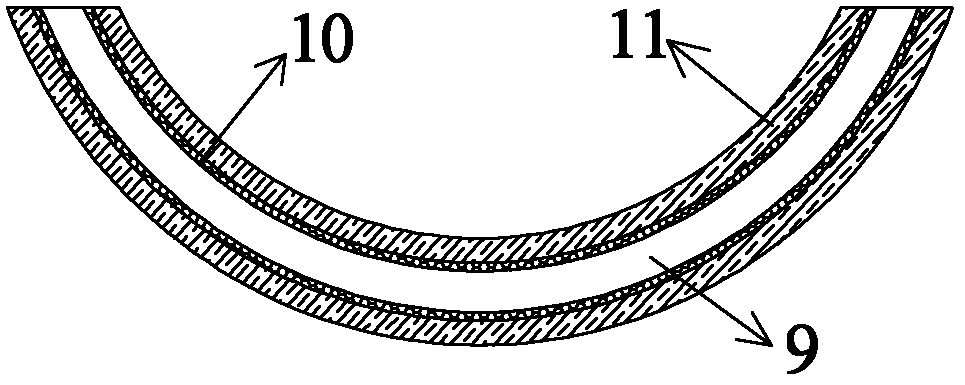

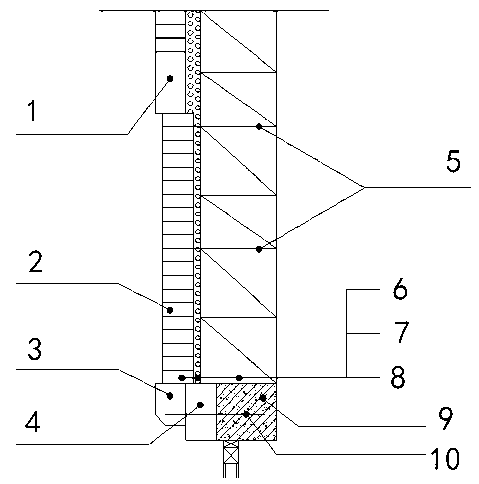

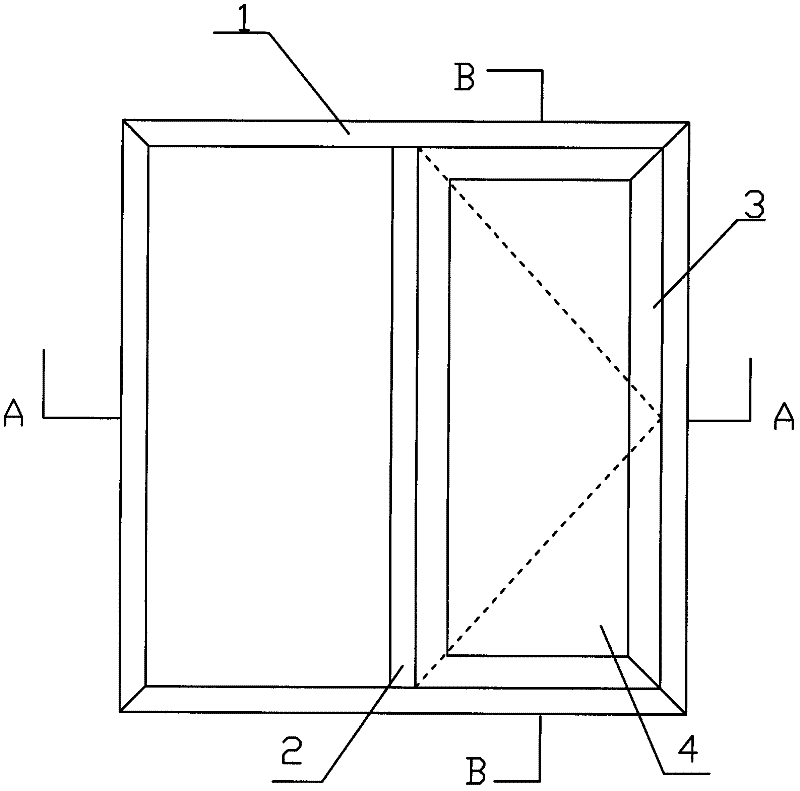

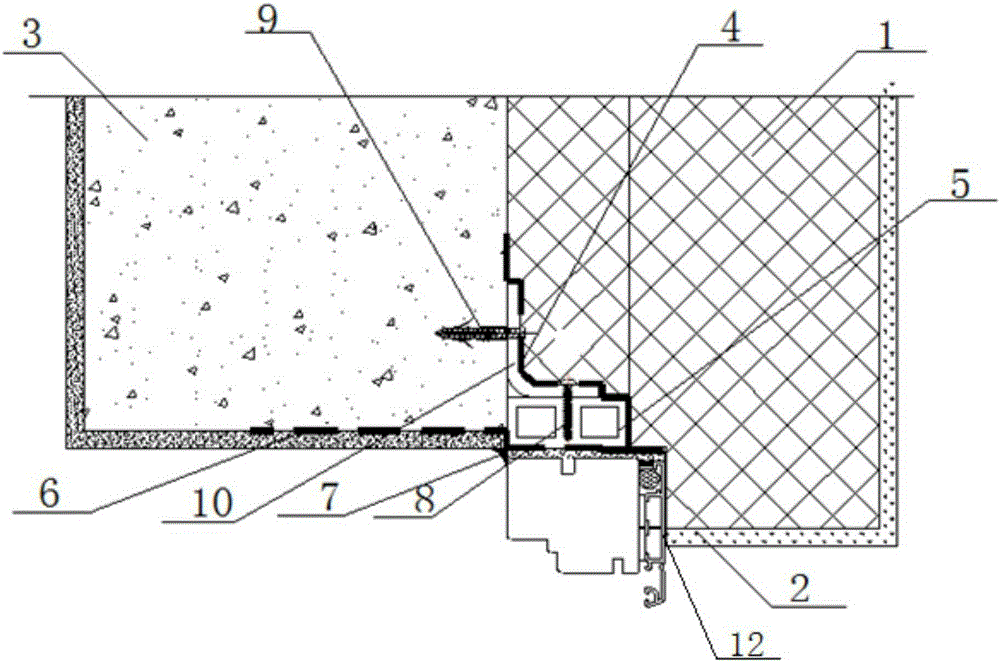

Fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and exterior wall heat-preservation construction process

InactiveCN102071797AMeet flatness requirementsReduce thicknessWallsBuilding material handlingInsulation layerReinforced concrete

The invention relates to a fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and an exterior wall heat-preservation construction process. The heat-preservation template is formed by compounding an expandable polystyrene (EPS) aggregate layer on the surface on one side of a fiber concrete plate. The process comprises the following steps that: a fiber concrete template and a fiber concrete composite heat-preservation template are vertically fixed on the two sides of the position of a pre-built wall body respectively, wherein the fiber concrete template and the fiber concrete composite heat-preservation template are fixed together through pull bolts; and reinforcements are arranged and concrete is poured between the fiber concrete template and the fiber concrete composite heat-preservation template, so that a reinforced concrete bearing wall body is formed. The integrated permanent dismantle-free heat-preservation template meets the requirements on heat preservation of an exterior wall and flatness of a plaster layer in place of the exterior wall template, an outer heat-preservation layer and the plaster layer. In the process, the template is not required to be removed, the heat preservation, heat insulation and water proofing performance are good, the thickness of the wall body is reduced, a great amount of materials and labor are saved, the construction period can be shortened, and the energy conservation requirement and the requirements on adhesion between the permanent template and a basic layer and flatness of a surface layer can be met. The template is suitable for high-rise and small high-rise buildings; the dwelling environment can be improved; the building function quality is improved; the building development benefit is improved; and the template has a wide application prospect.

Owner:ZHENGZHOU UNIV +2

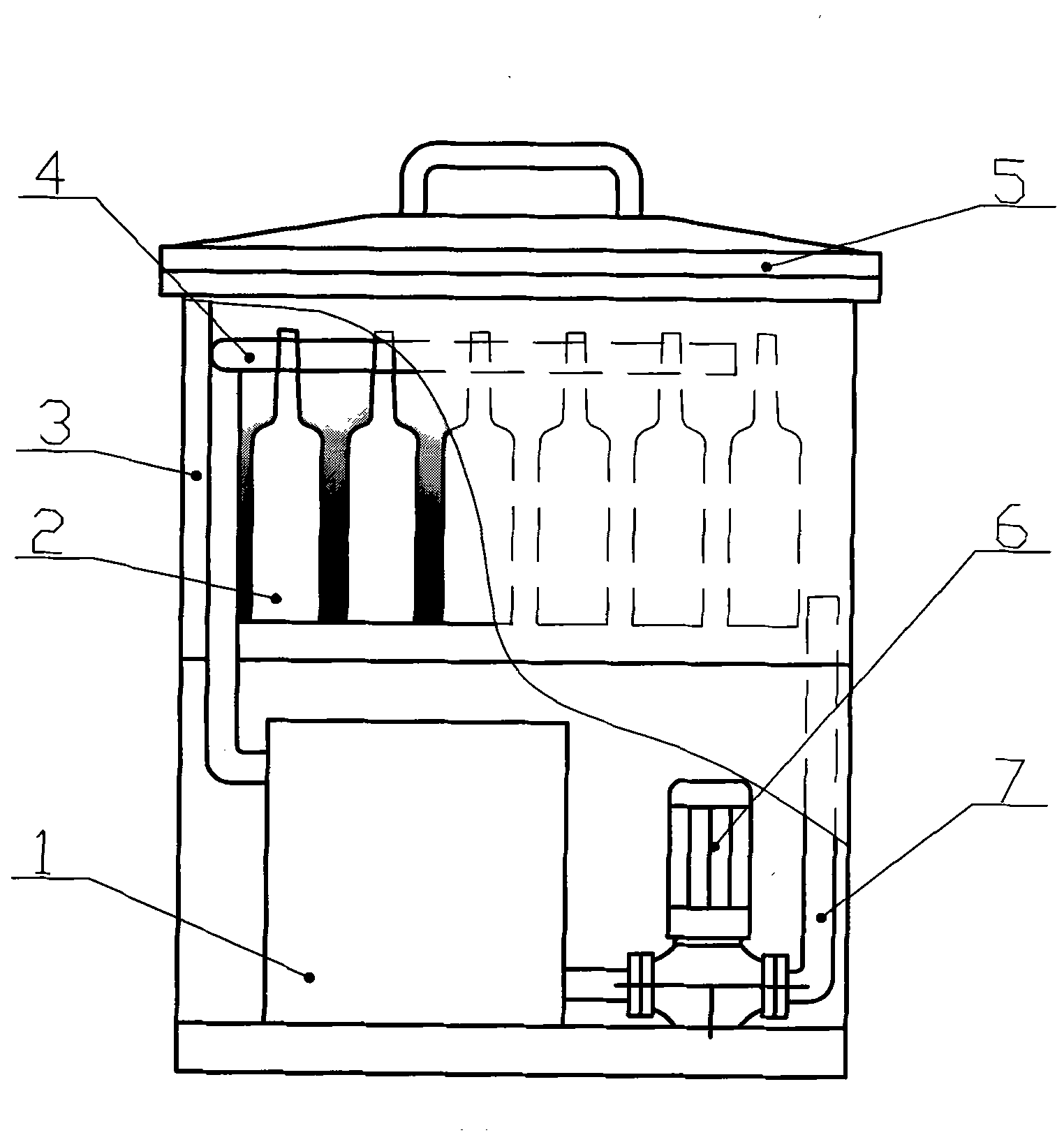

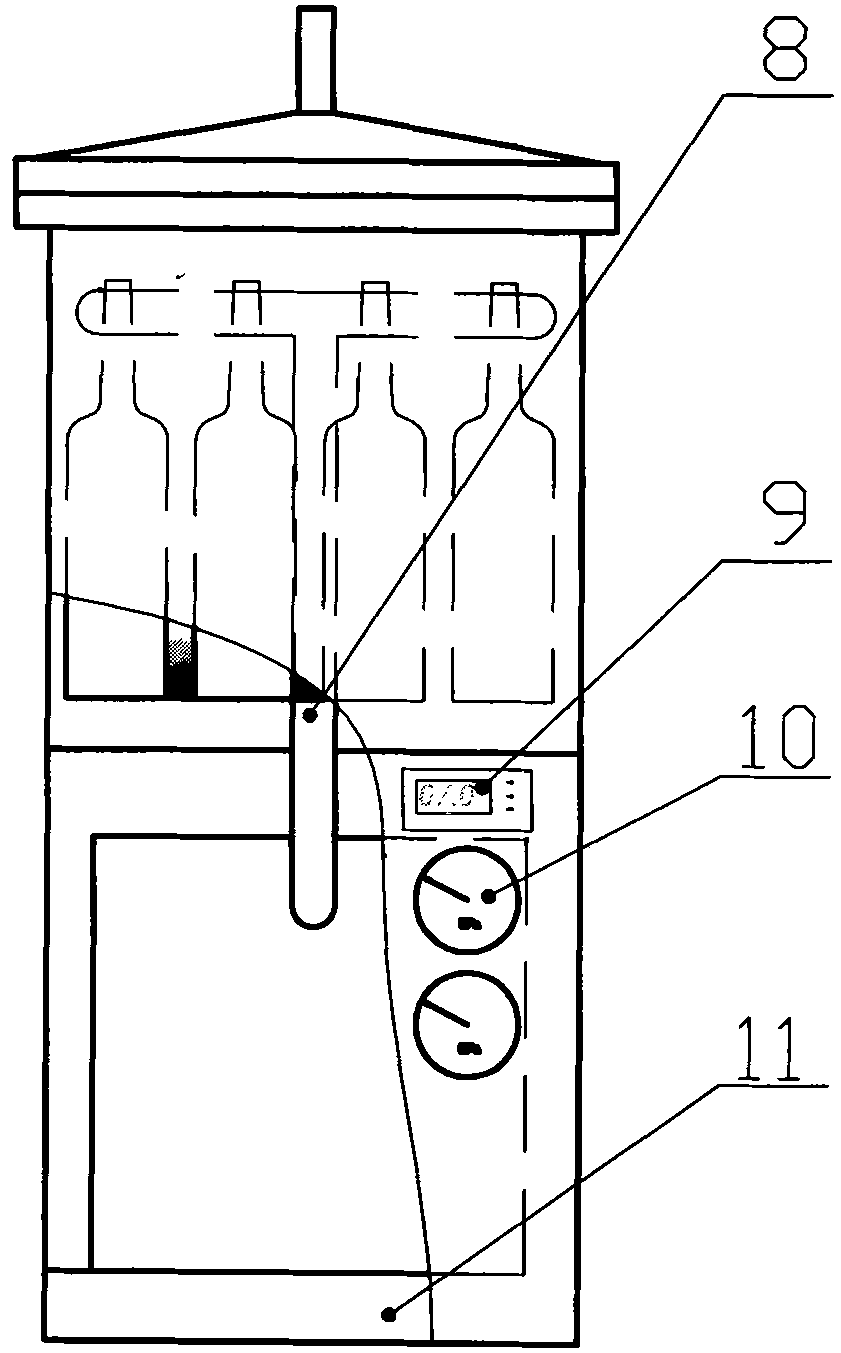

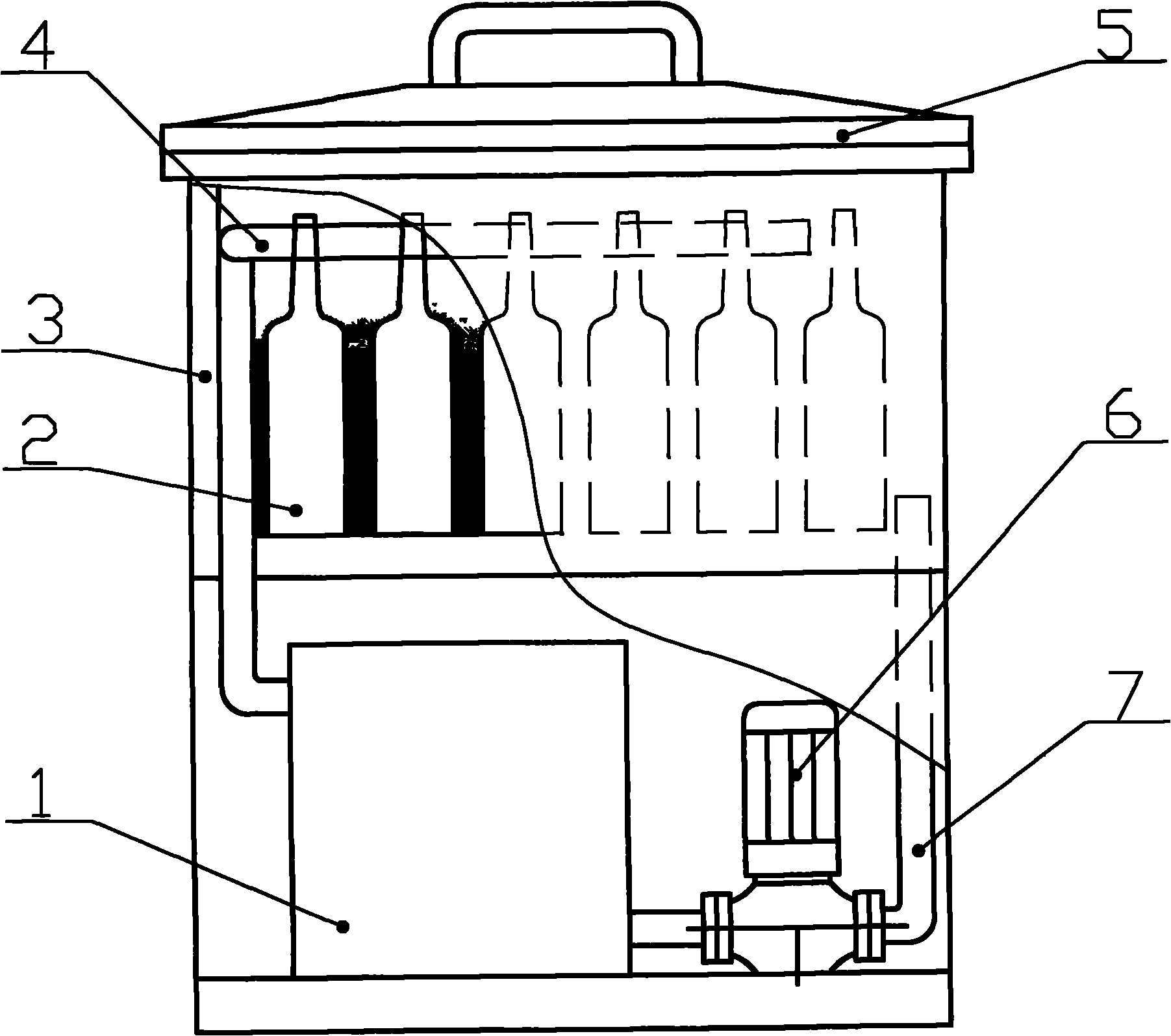

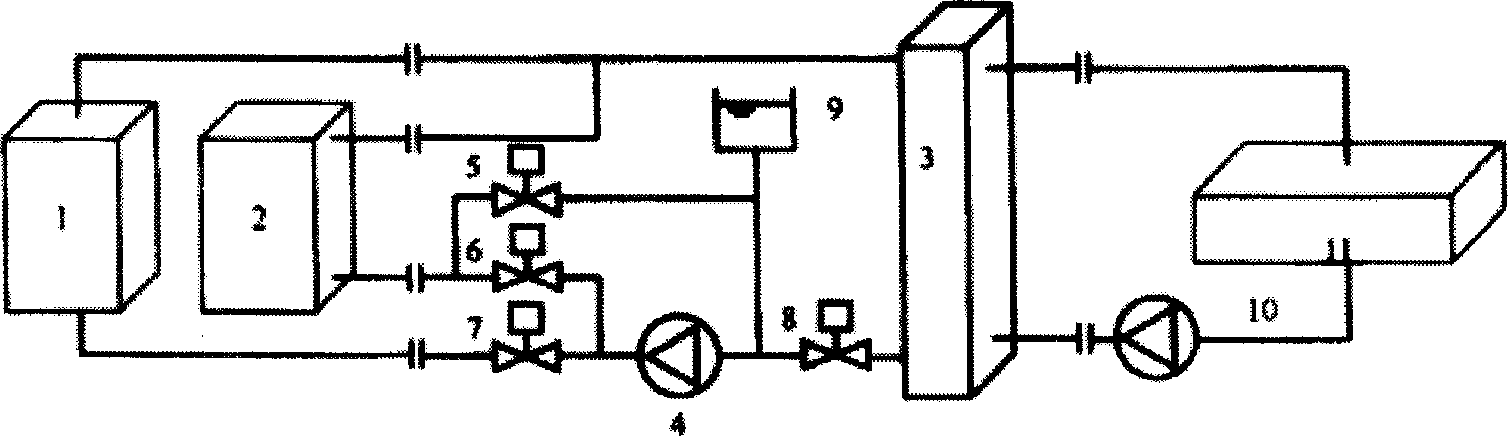

Small packaged beer and beverage rapid cooling device

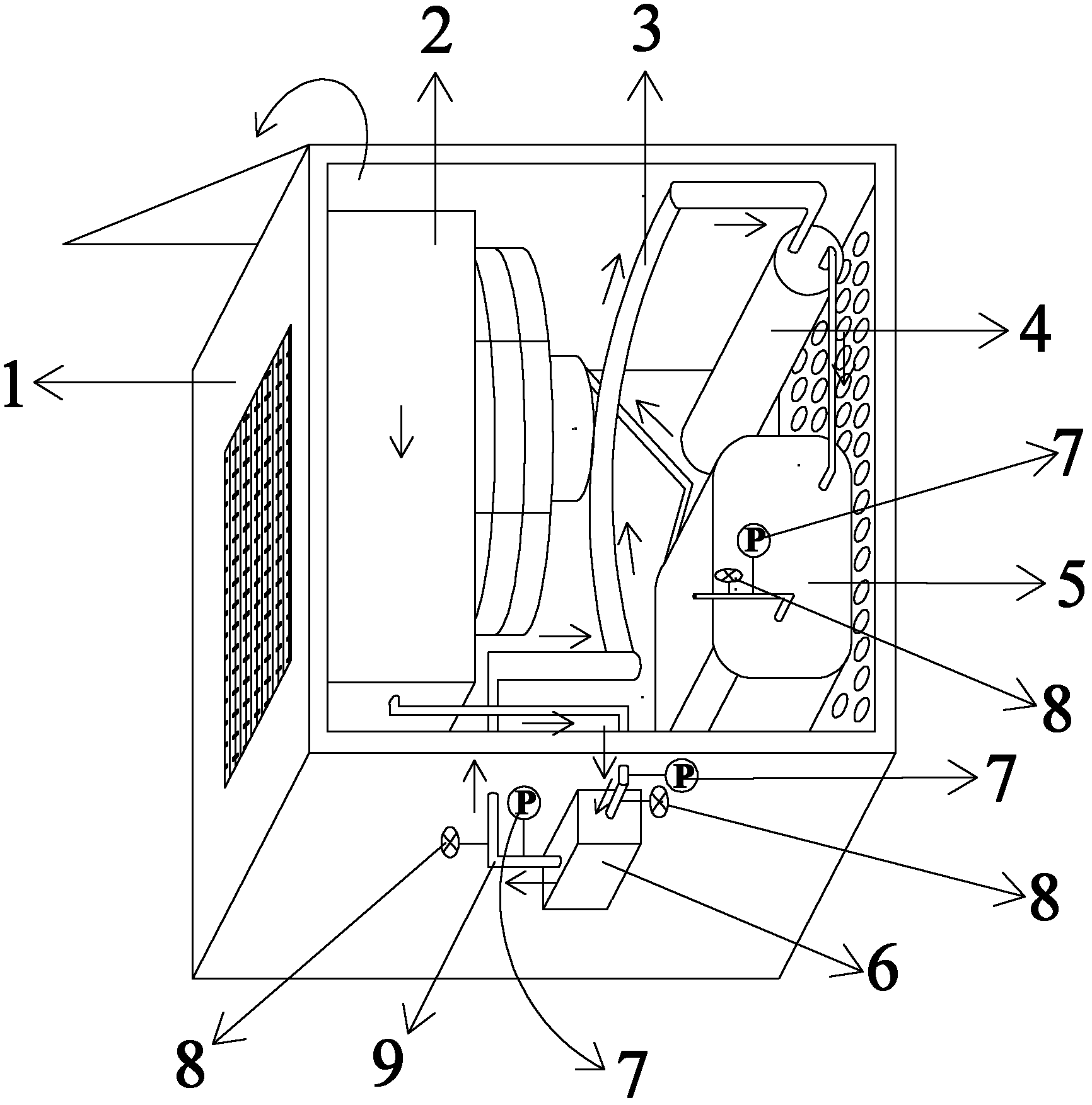

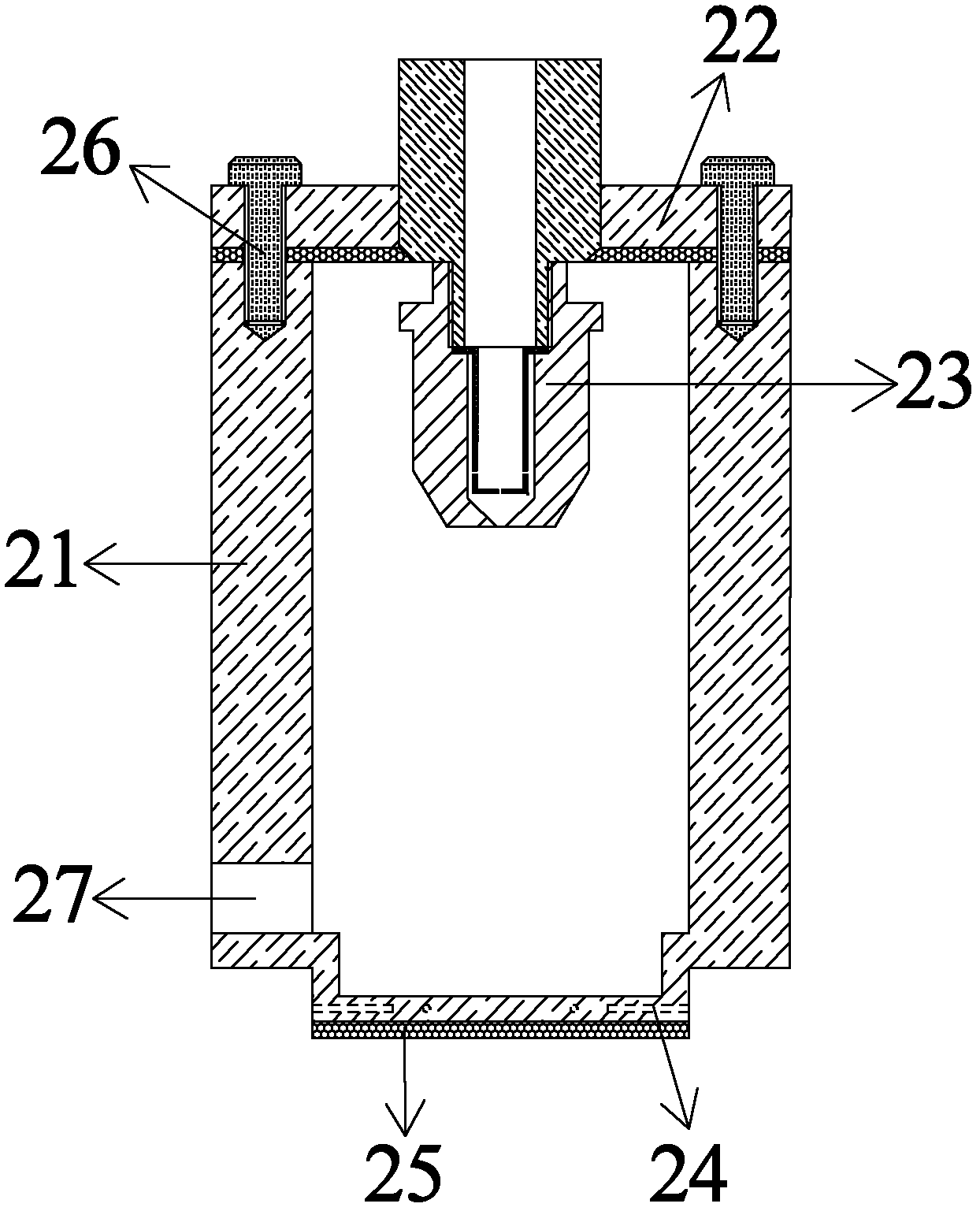

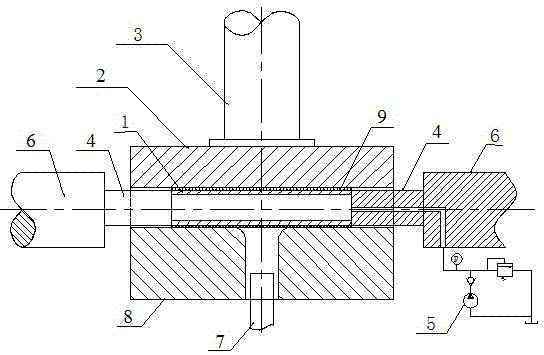

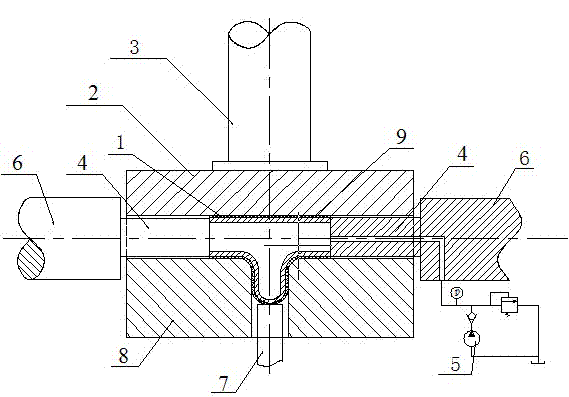

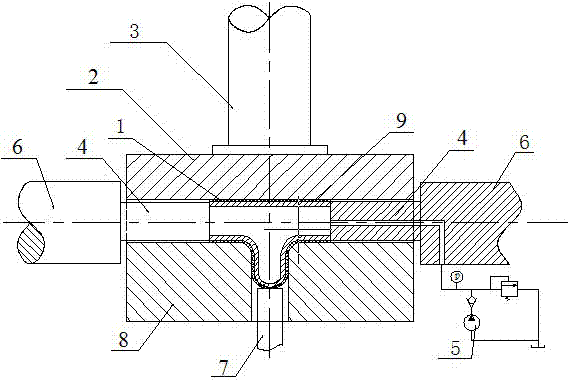

InactiveCN101806528ARapid coolingSuitable for tasteDomestic cooling apparatusLighting and heating apparatusEngineeringSmall footprint

The invention discloses a small packaged beer and beverage rapid cooling device. The device comprises a refrigerating unit, a cooling tank and an electrical control part, wherein a water circulation system is arranged between the refrigerating unit and the cooling tank, the evaporator of the refrigerating unit is connected with the cooling tank through a water inlet pipe; and after cold water performs heat transfer in the cooling tank, the obtained water flows back to the evaporator of the refrigerating unit through a return pipe and a circulating pump. The invention utilizes the refrigeration technology and heat conduction theory, uses the refrigerating medium for continuous cooling and adopts the types of flow and direct contact to fast cool beverage. Compared with the common air-cooling method, the method of the invention has the advantages of fast cooling rate, large yield, adjustable capacity, simple operation, low operating cost, wide application range, small floor space, light weight and the like.

Owner:林崇实

Transparent-aerogel vacuum glass and manufacturing method thereof

ActiveCN102839893ALow thermal conductivityHigh strengthClimate change adaptationWindows/door improvementRubber ringDesiccant

The invention provides transparent-aerogel vacuum glass and a manufacturing method of the vacuum glass. The transparent-aerogel vacuum glass comprises glass panes, desiccating agent aluminum bars and a sealing rubber ring. The desiccating agent aluminum bars are arranged inside the periphery between the two glass panes, the sealing rubber ring is used to seal the outside of each of the desiccating agent aluminum bars, a hollow interlayer is formed between the two glass panes, and then the hollow interlayer is vacuumized. The transparent-aerogel vacuum glass is characterized in that transparent aerogel is placed inside the hollow interlayer. The transparent-aerogel vacuum glass has the advantages that since thermal conductivity coefficient of the aerogel is quite low, by matching of the aerogel and special properties of a piece of vacuum glass, the requirement of energy conservation can be met; and since the aerogel is high in strength, and external pressure bearing capacity is large, whole strength of the transparent-aerogel vacuum glass is greatly enhanced, and the transparent-aerogel vacuum glass is not prone to break.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

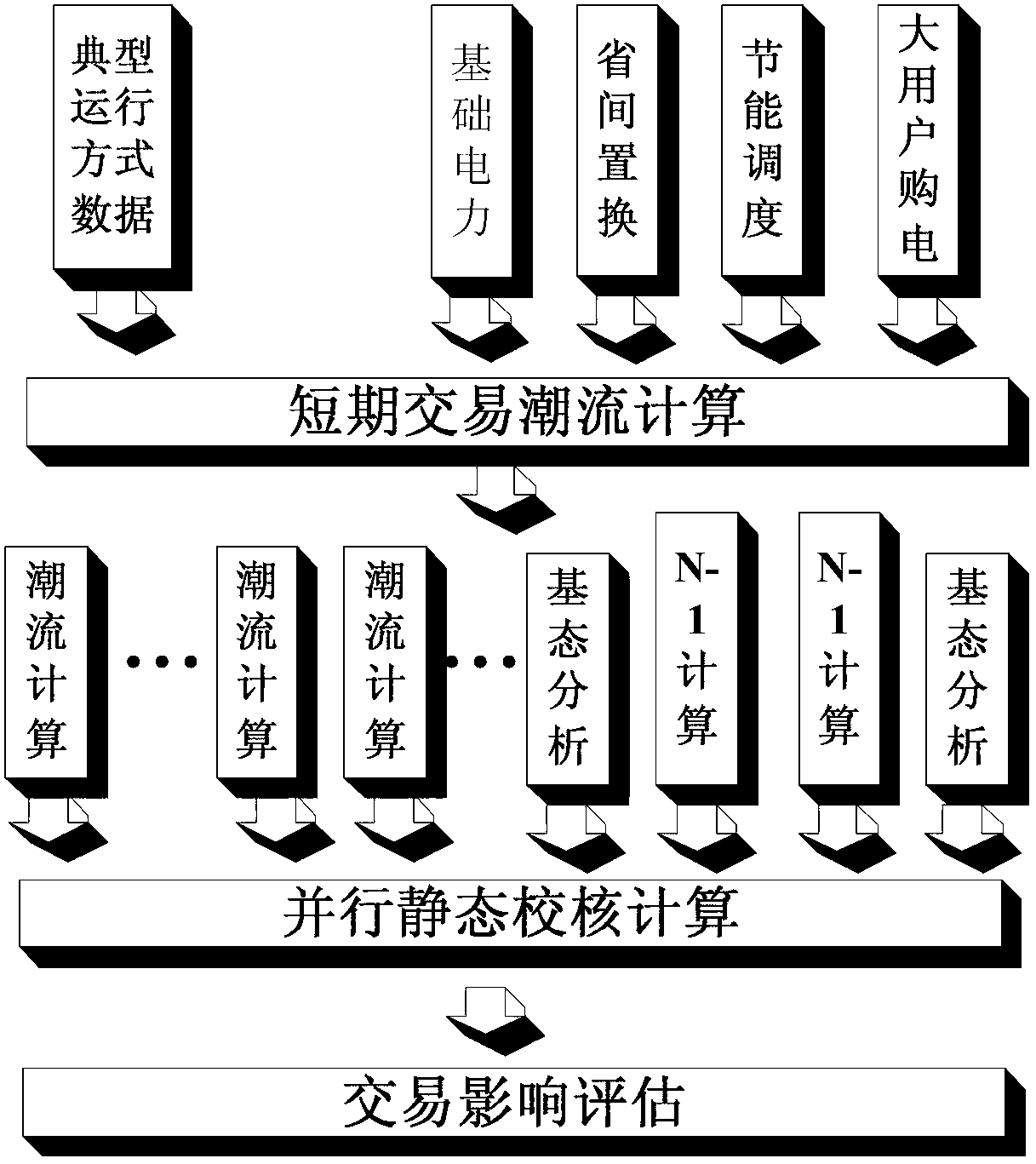

Method for checking short-term trade plan safety

ActiveCN103020853AImprove calibration calculation efficiencyCalculation speedBuying/selling/leasing transactionsInformation technology support systemElectric power systemPower grid

The invention relates to a method of the field of electrical power system planning and computational analyzing, and in particular relates to a method for checking short-term trade plan safety. The method comprises the following steps of: 1, short-term trade plan load flow calculation; 2, short-term trade ground state load flow analysis; 3, short-term trade plan static state load flow analysis; 4, short-term trade plan impact assessment; and 5, short-term trade parallel check. The method for checking the short-term trade plan safety provided in the invention is easy to realize, and moreover, power grid load flow which reflects the execution condition of short-term trade can be obtained; and the requirements from aspects of energy conservation, environmental friendliness and safe, stable and economic operation of a conventional power grid on technological innovation are satisfied.

Owner:CHINA ELECTRIC POWER RES INST +1

Temperature optical energy-saving control method for plastic dryer

ActiveCN103399486AHigh precisionMeet energy saving requirementsAdaptive controlNetwork methodOptical transfer function

The invention discloses a temperature optical energy-saving control method for a plastic dryer. According to the method, running characteristics of the plastic dryer under different working conditions are considered, a predictive control strategy on the basis of multi-model switching is adopted to identify dynamic characteristics of an air temperature of the plastic dryer and a switching system model of an object under each typical working condition is established; then an optical target function with constraint is established by utilizing a switching rule and a mixed neural network is formed by a neural network for processing a continuous variable and a neural network for processing a discrete binary variable together; and finally, the switching system is subjected to optimization solution by utilizing the mixed neural network method. According to the invention, a controlled system can be in the optical running state under each typical working condition, so that accuracy of controlling the air temperature of the plastic dryer is improved.

Owner:HANGZHOU DIANZI UNIV

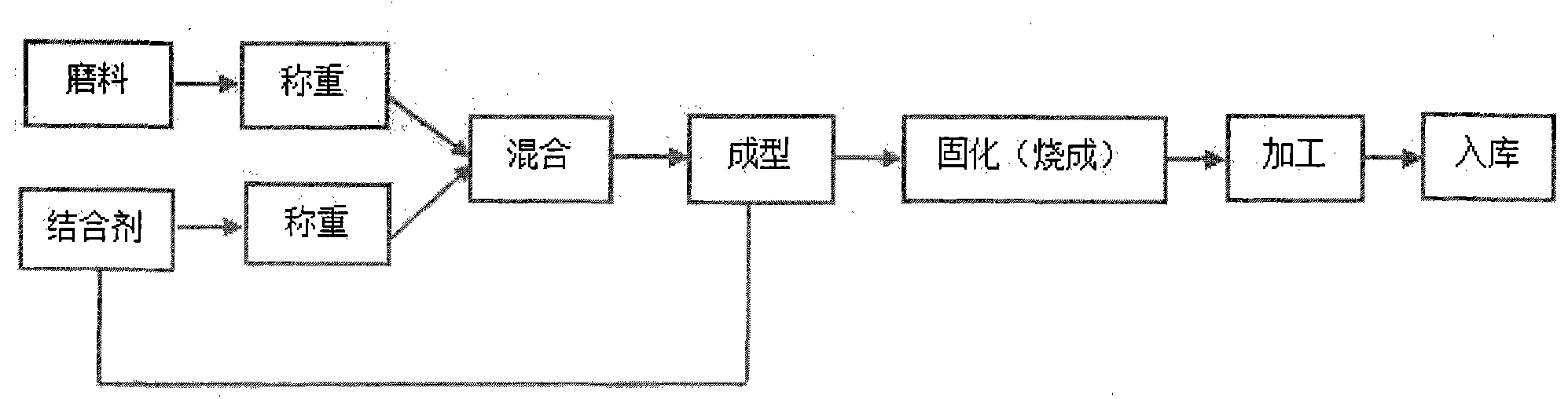

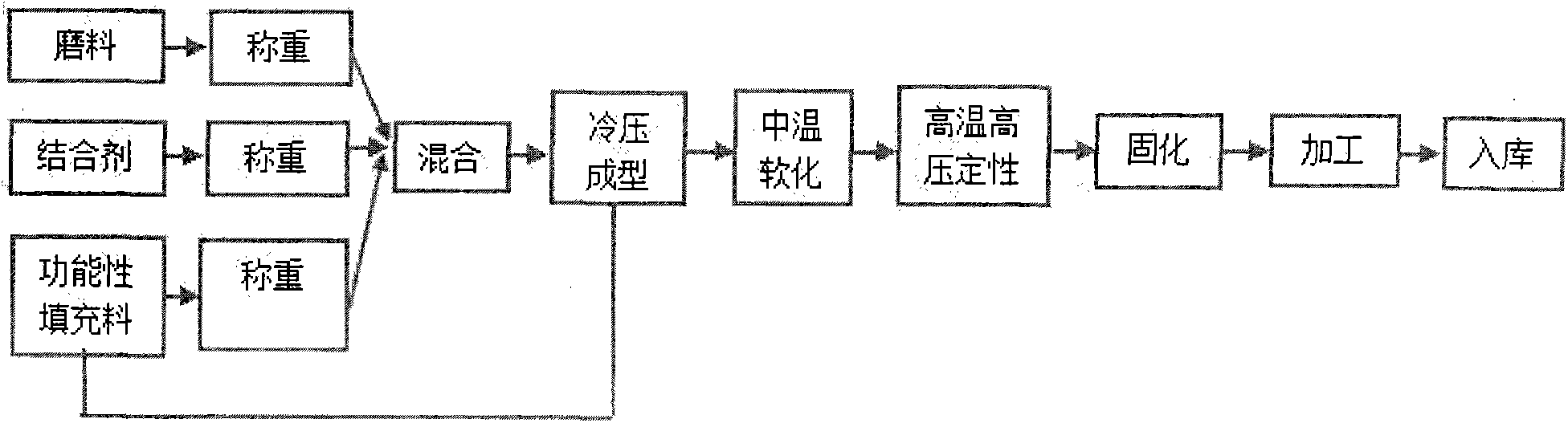

Grinding wheel manufacturing method

InactiveCN103962978AIncrease grinding ratioImprove efficiencyAbrasion apparatusGrinding devicesRoom temperatureMixed materials

The invention discloses a grinding wheel manufacturing method which comprises the following steps of material mixing, wherein quantified grinding materials and binding agents are mixed and prepared according to a technical formula; extrusion forming, wherein the prepared mixed materials are added in a die cavity to be extruded and formed; curing and sintering, wherein a formed grinding wheel is placed in a curing oven or a curing kiln for curing. In the material mixing process, a certain ratio of functional filling with is further added to be mixed with the grinding materials and the binding agents. After the mixed materials are extruded and formed at normal temperature, the mixed materials are subjected to at least one more extrusion after being softened at intermediate temperature. Compared with the prior art, the utilization rate of the grinding wheel grinding materials is improved in the way that the new functional filling is added in the material mixing process on the basis of the existing production technology, the intermediate-temperature softening process and the high-temperature and high-pressure forming process are added based on the primary cold press forming, an assembling line production mode is adopted, production efficiency is improved, and produced grinding wheels have the advantages of being good in binding power, high in grinding efficiency and abrasion resistance, little in dust, and the like.

Owner:田继华

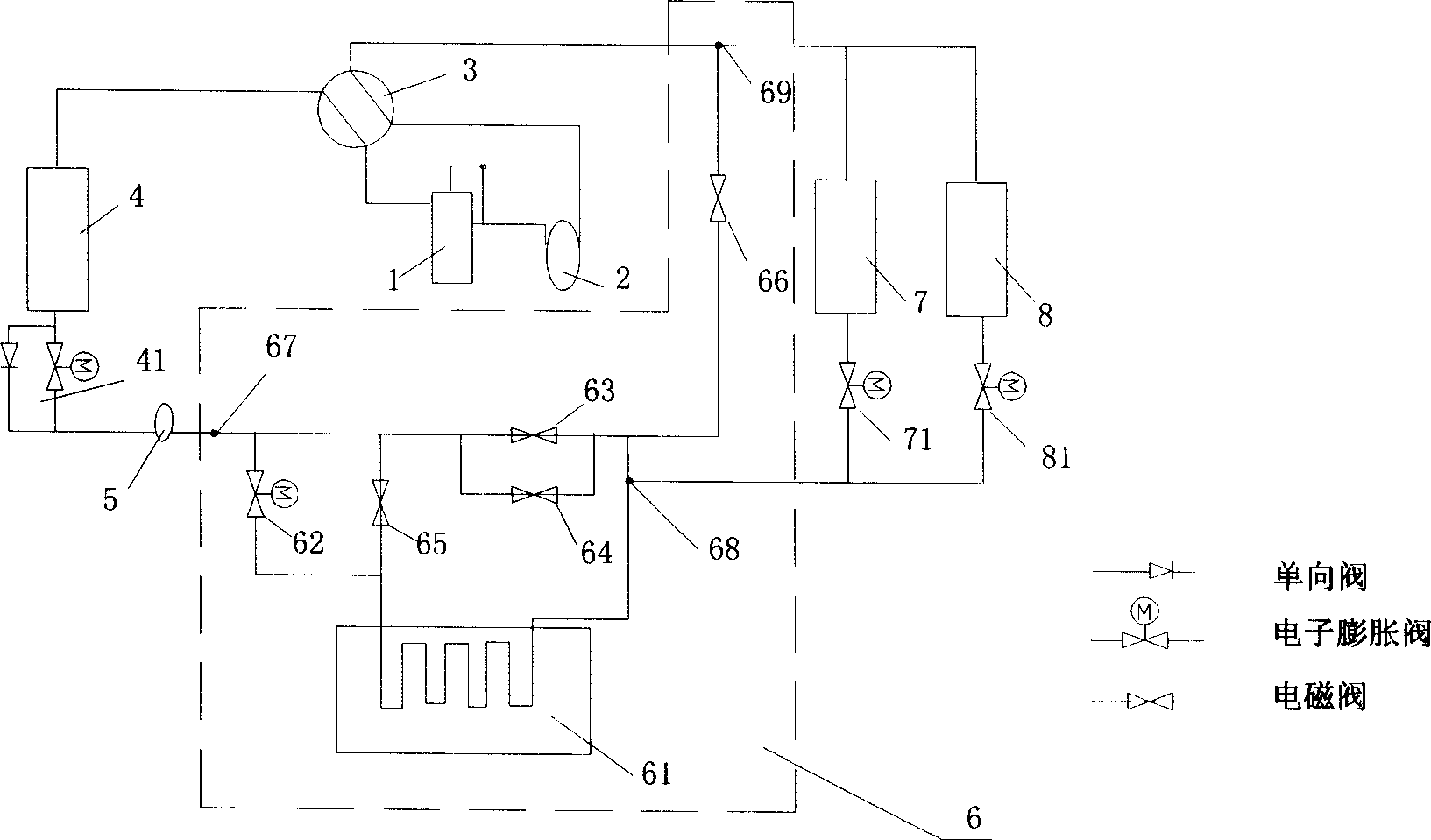

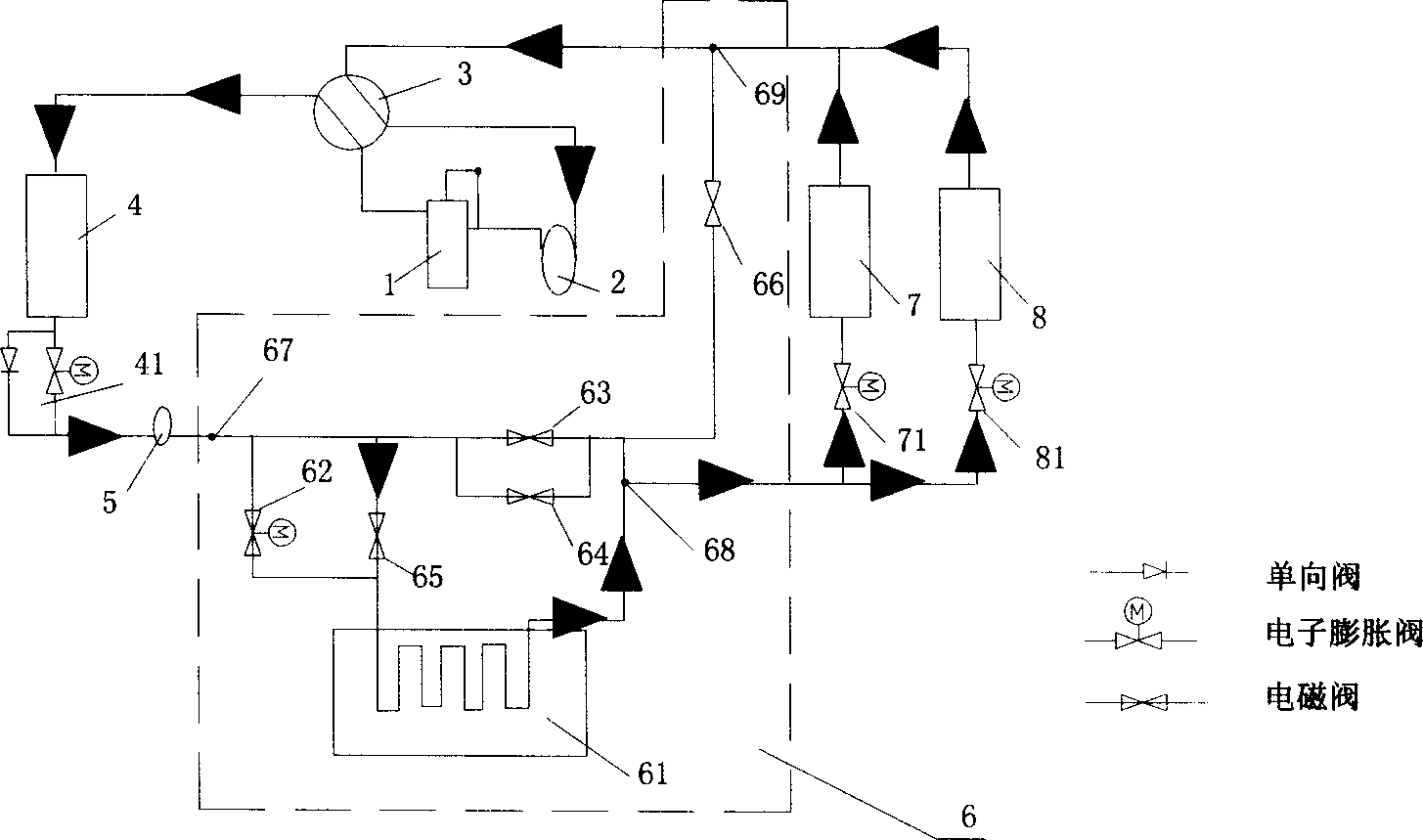

Ice cold accumulation set, air conditioning system using same and controlling method thereof

InactiveCN1825011AImprove performanceEasy to controlSpace heating and ventilation safety systemsLighting and heating apparatusMagnetic valveAir conditioning

In the invention, a supercooled ice cold-storage unit comprises an ice-storage device, a closed circulating pipeline and three external connection points. On the closed circulating pipeline passing through the ice-storage device there is a electronic expansion valve and three magnetic valves, and one magnetic valve is in parallel connection with the electronic expansion valve and the other magnetic valves are in parallel. The first external connection point is located on one side of the electronic expansion valve, the second one is located between the magnetic valve and the ice-storage device and the third one is located at once end of the magnetic valve.

Owner:GREE ELECTRIC APPLIANCES INC

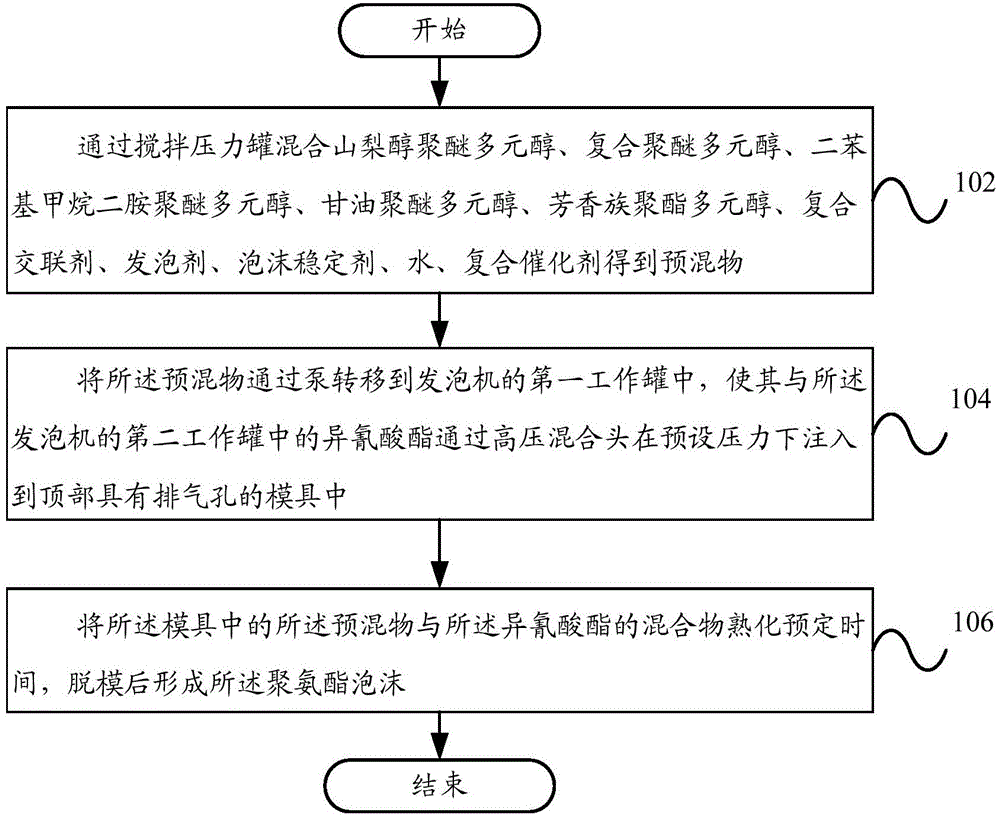

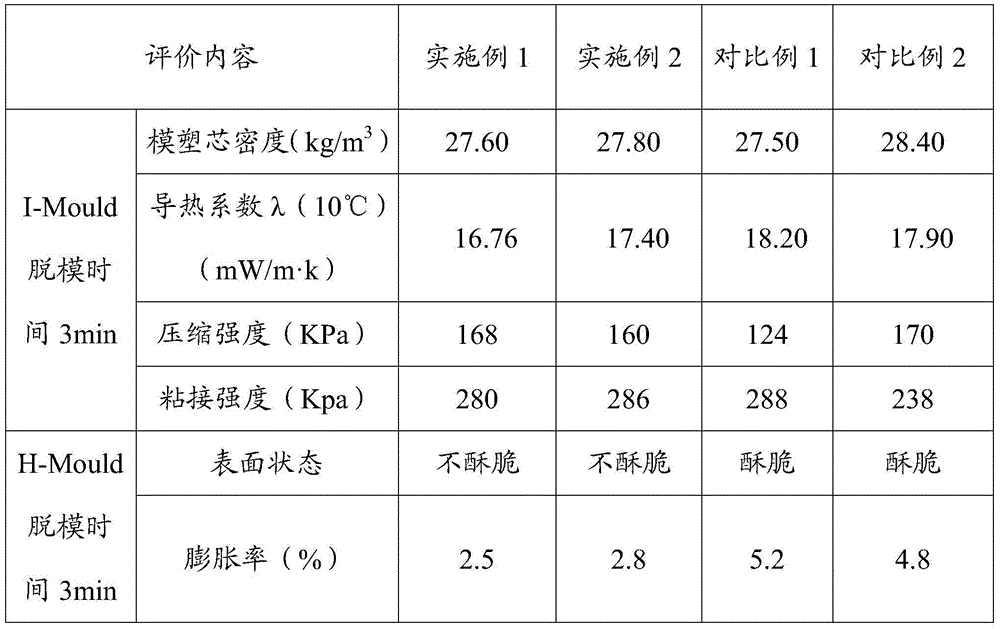

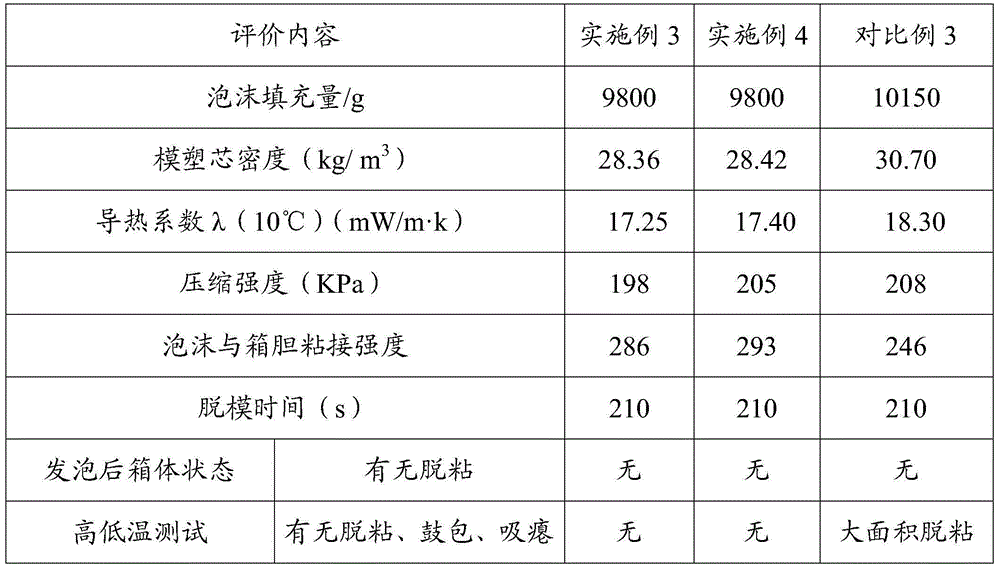

Polyurethane composition, polyurethane foam as well as manufacture method thereof and fridge

The invention discloses a polyurethane composition, polyurethane foam as well as a manufacture method thereof and a fridge. The polyurethane composition comprises the following raw materials in parts by weight: 25-60 parts of sorbitol polyether polyol, 15-40 parts of composite polyether polyol, 3-30 parts of diphenylmethane diamine polyether polyol, 3-15 parts of glycerin polyether polyol, 3-20 parts of aromatic polyether polyol, 0-5 parts of composite crosslinking agent, 1-55 parts of foaming agent, 1.0-5.0 parts of foam stabilizer, 0.5-2.0 parts of water, 1.0-3.5 parts of composite catalyst and 120-160 parts of isocyanate, wherein the index of the isocyanate is 0.95-1.10. The polyurethane composition provided by the technical solution is low in density and heat conductivity coefficient and strong in adhesive property. The fridge containing the polyurethane composition is good in insulation effect and low in energy consumption.

Owner:HEFEI HUALING CO LTD +1

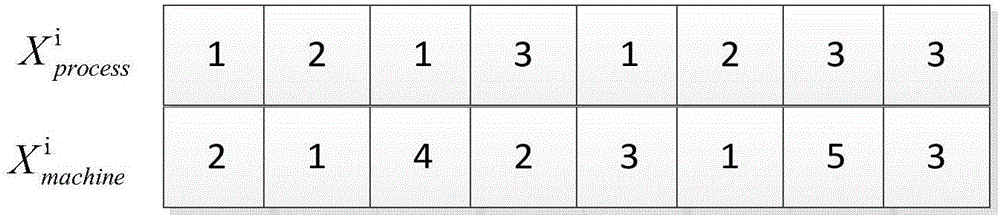

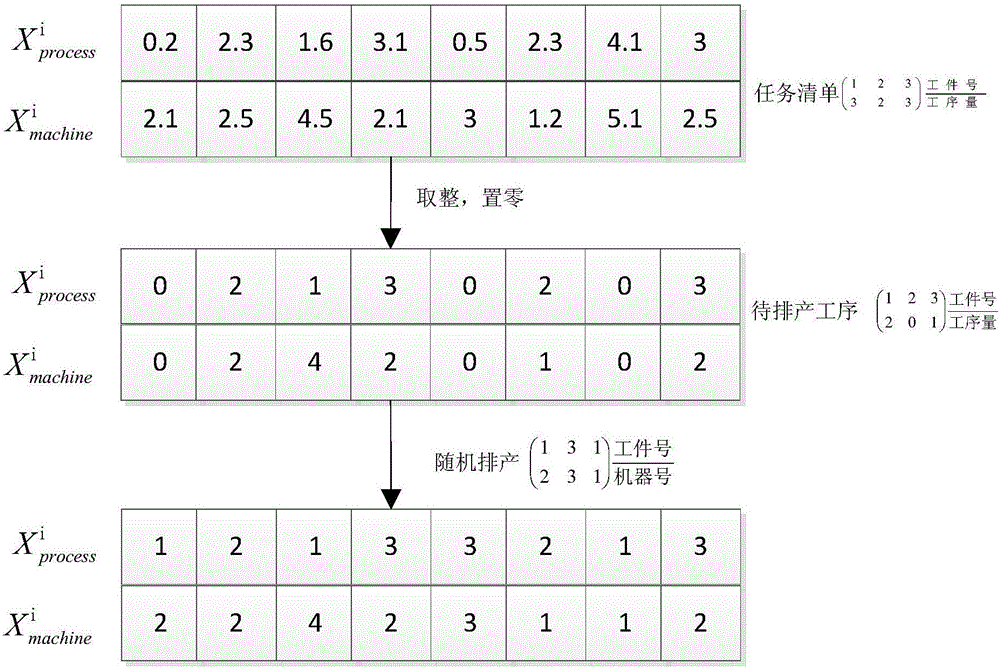

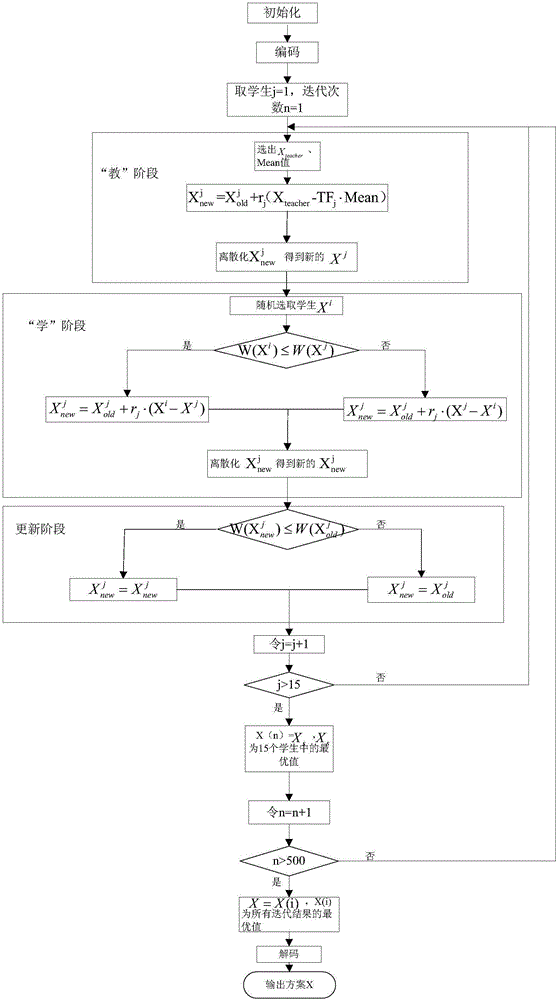

Teaching-and-learning-algorithm-based static scheduling optimization system for discrete manufacturing shop

InactiveCN105843197ANormal production orderContribute to rationalityTotal factory controlProgramme total factory controlStatic dispatchDiscrete manufacturing

The invention discloses a teaching-and-learning-algorithm-based static scheduling optimization system for a discrete manufacturing shop. The system comprises a data server, an operation server, and a terminal display screen. A scheduling optimization client is embedded into the operation server and is used for carrying out optimization-algorithm-based reasonable scheduling arrangement on a processing task on the day by analyzing the processing task and consulting various detailed information of the data server, wherein the specific optimization algorithm employs a teaching and learning algorithm. A generation scheduling scheme is decoded; de-compilation processing is carried out according to dual-layer definition on a student during coding; a processing tool and a processing sequence of a workpiece are expressed successively. And then the optimized scheduling scheme is displayed on a terminal display screen, so that the production staff and the management staff in the shop can obtain current specific processing task arrangement information in real time. According to the invention, with the teaching and learning algorithm, the system has advantages of fast convergence speed and high optimization searching capability and adapts to the complex situation in practical production well.

Owner:JIANGNAN UNIV

Sand aerated concrete impervious building blocks

InactiveCN101323513ASave materialLabor savingConstruction materialSolid waste managementFoaming agentAtmospheric pressure

The invention relates to a sand-air impervious concrete masonry block adopting thin quartz sand, cement, lime and gypsum as main base materials and adopting aluminum powder as foaming agent; wherein, the sand-air impervious concrete block comprises a hydrophobic waterproof agent which occupies 0.02 to 0.40 percent of the total amount according to the weight percentage. The preparation method comprises the steps as follows: the components are mixed to form a mixture according to the formulation, and then the mixture is stirred, settled, cut and later maintained for 10 to 12 hours under high temperature of 180 to 200 DEG C and high pressure of 10 to 12 standard atmospheric pressures so as to obtain the sand-air impervious concrete masonry block. The invention has the advantage that a certain proportion impervious materials are added into the material of the masonry block so as to manufacture the masonry block provided with the impervious capability; after the masonry block is adopted as the single material for walling, then the block is provided impervious capability after walling by the block. The sand-air impervious concrete masonry block can be regarded as the novel walling material without adopting the waterproof material to reach the waterproof and impervious requirement.

Owner:上海伊通有限公司

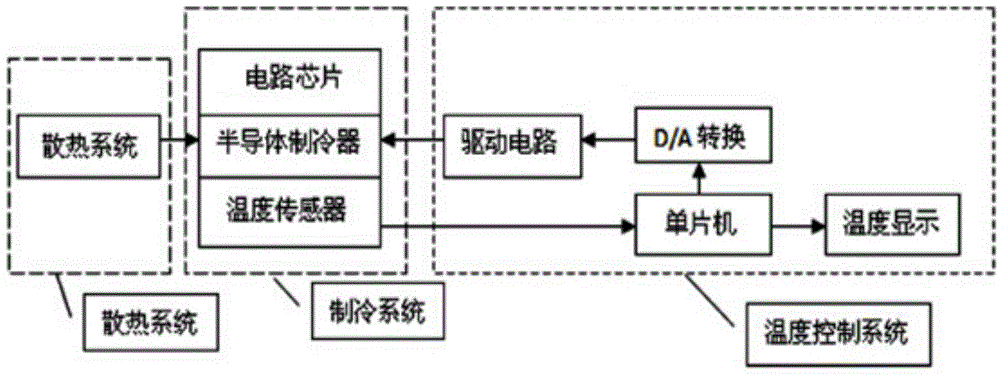

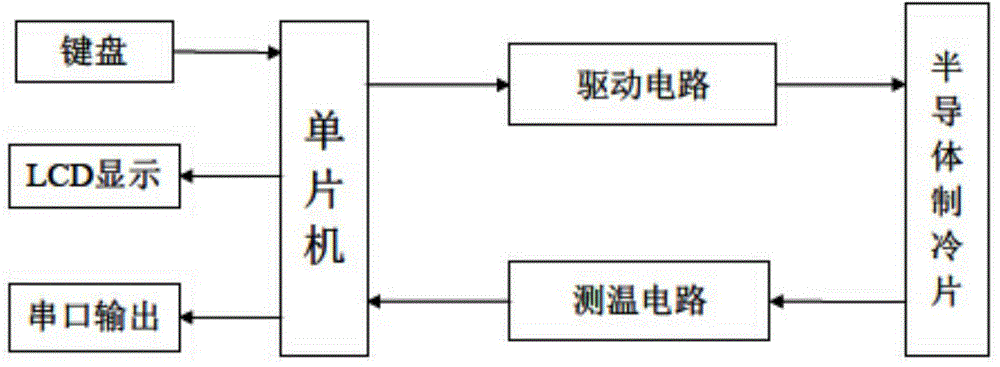

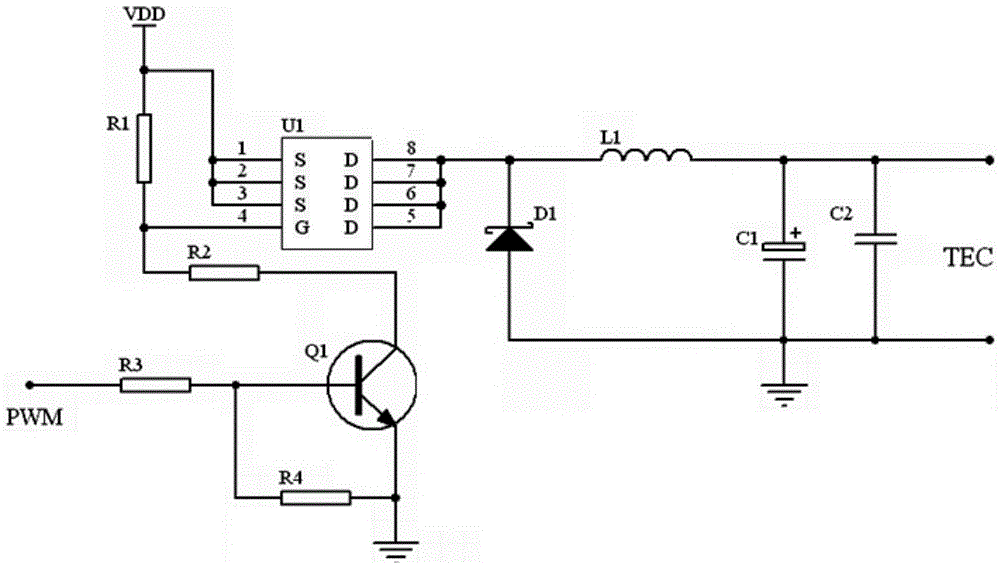

Noise reduction and temperature control system based on semiconductor refrigeration mechanism

ActiveCN104062990AImprove efficiencyImprove working precisionAuxillary controllers with auxillary heating devicesEngineeringNoise reduction

The invention discloses a noise reduction and temperature control system based on a semiconductor refrigeration mechanism. The noise reduction and temperature control system based on the semiconductor refrigeration mechanism comprises a heat radiating system, a refrigeration system and a temperature control system. The heat radiating system adopts a heat tube heat radiating fin, the refrigeration system comprises a circuit chip, a semiconductor refrigerator and a temperature sensor, and the temperature control system comprises a driving circuit, a D / A converter, a single chip microcomputer and a temperature displayer. The noise reduction and temperature control system is designed based on the Peltier effect and can create a low-temperature working environment for a circuit chip, reduce multiple types of noise relevant with the temperature, effectively improve signal to noise ratio and widen a dynamic range. The noise reduction and temperature control system based on the semiconductor refrigeration mechanism is simple in structure and low in cost and has the advantages of being free of refrigerants, good in environment-friendly performance, free of moving parts, low in vibration and noise and the like.

Owner:吴丹

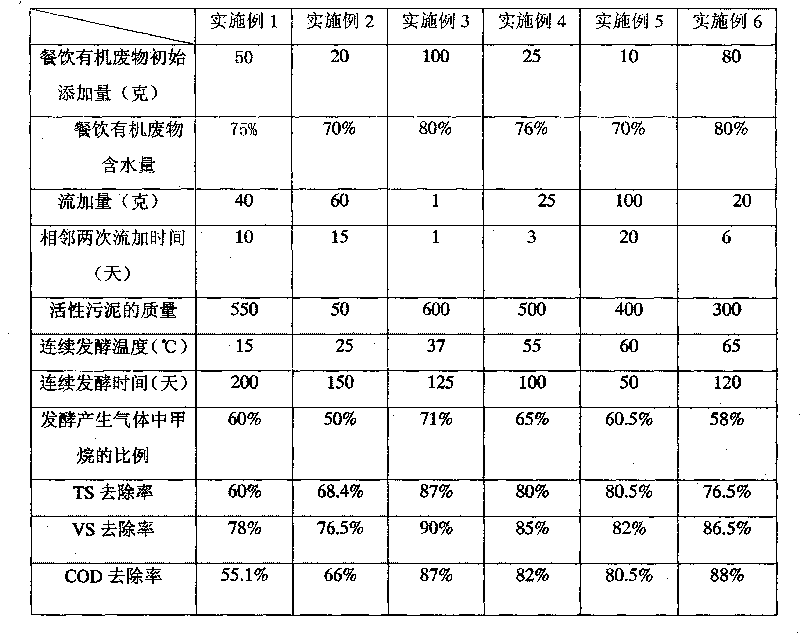

Method for producing methane as clean energy source by utilizing catering organic waste

ActiveCN101724655AReduce processing costsThe process steps are simpleWaste based fuelFermentationActivated sludgeClean energy

The invention relates to a method for producing a clean energy source by a continuous feeding type anaerobic fermentation method, particularly to a continuous feeding type anaerobic fermentation method for preparing methane by fermenting catering organic waste. The method for producing the clean energy source through continuous feeding type anaerobic fermentation can be widely used for preparing the methane which is a clean energy source through the anaerobic fermentation of the catering organic waste, straws, animal excreta in farms and other organic waste. The method comprises the following steps of: draining partial moisture of the collected catering organic waste to enable the water content thereof to be not more than 80 percent, and then adding the processed catering organic waste and acclimated anaerobic activated sludge in a definite proportion into a reactor for fermentation. The catering organic waste is added into the reactor by adopting a continuous feeding method in the fermentation process, and a fermentation raw material is added once at regular intervals. An addition period is a gas production vigorous period. The addition is 0.1-10 percent of the volume of the reactor. An anaerobic state is strictly controlled in the whole process so as to facilitate the growth of anaerobes.

Owner:BEIJING UNIV OF CHEM TECH

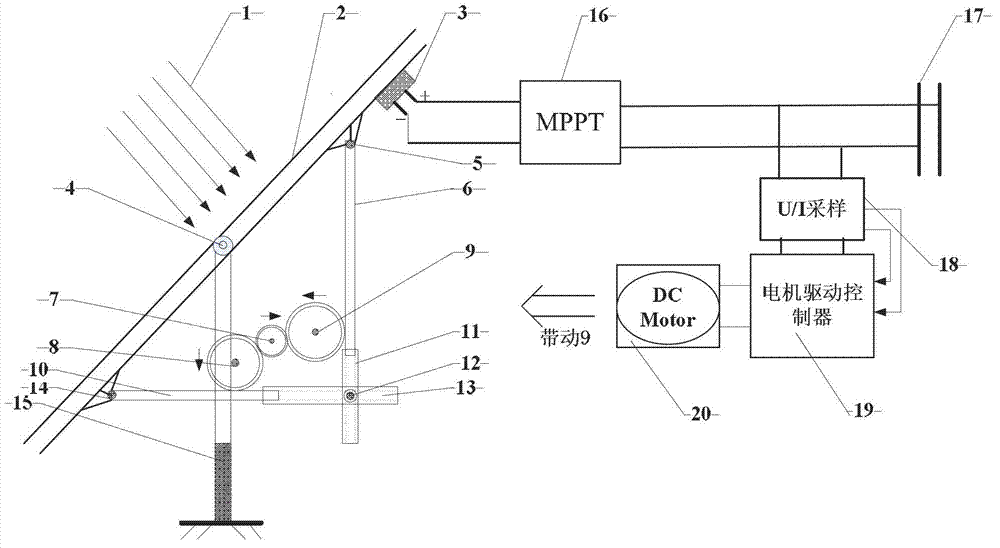

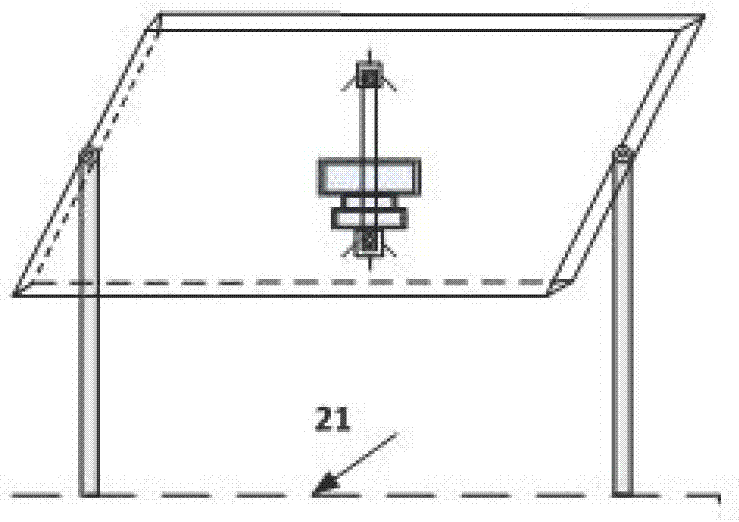

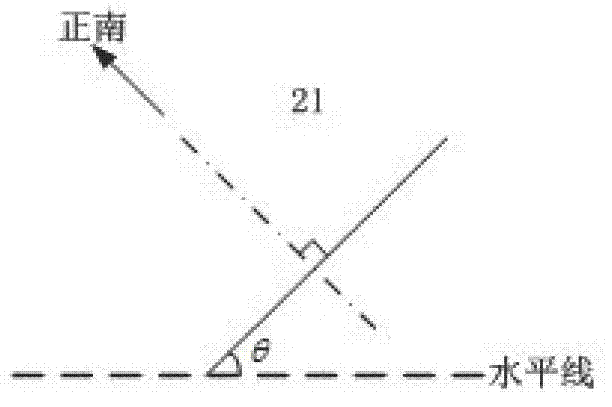

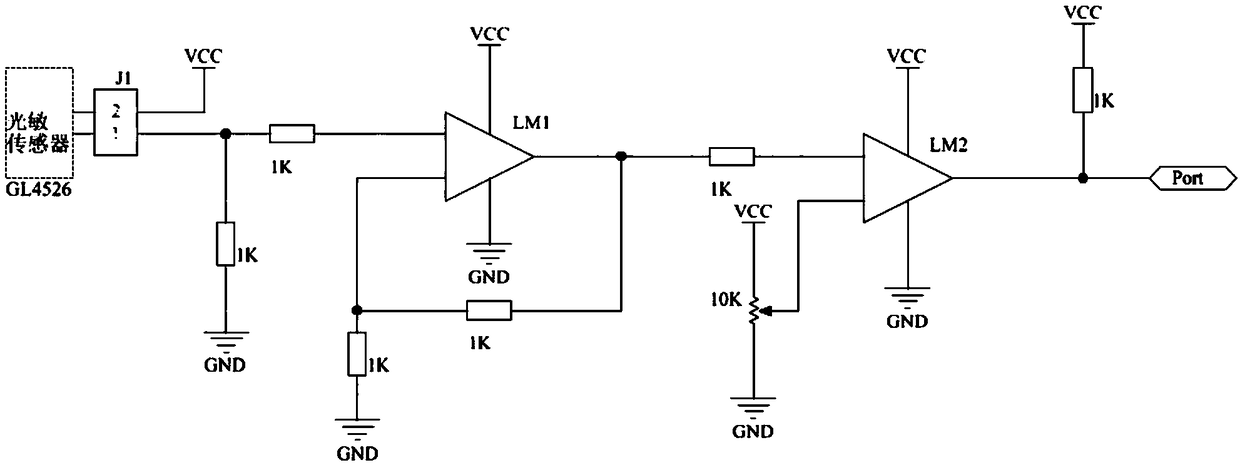

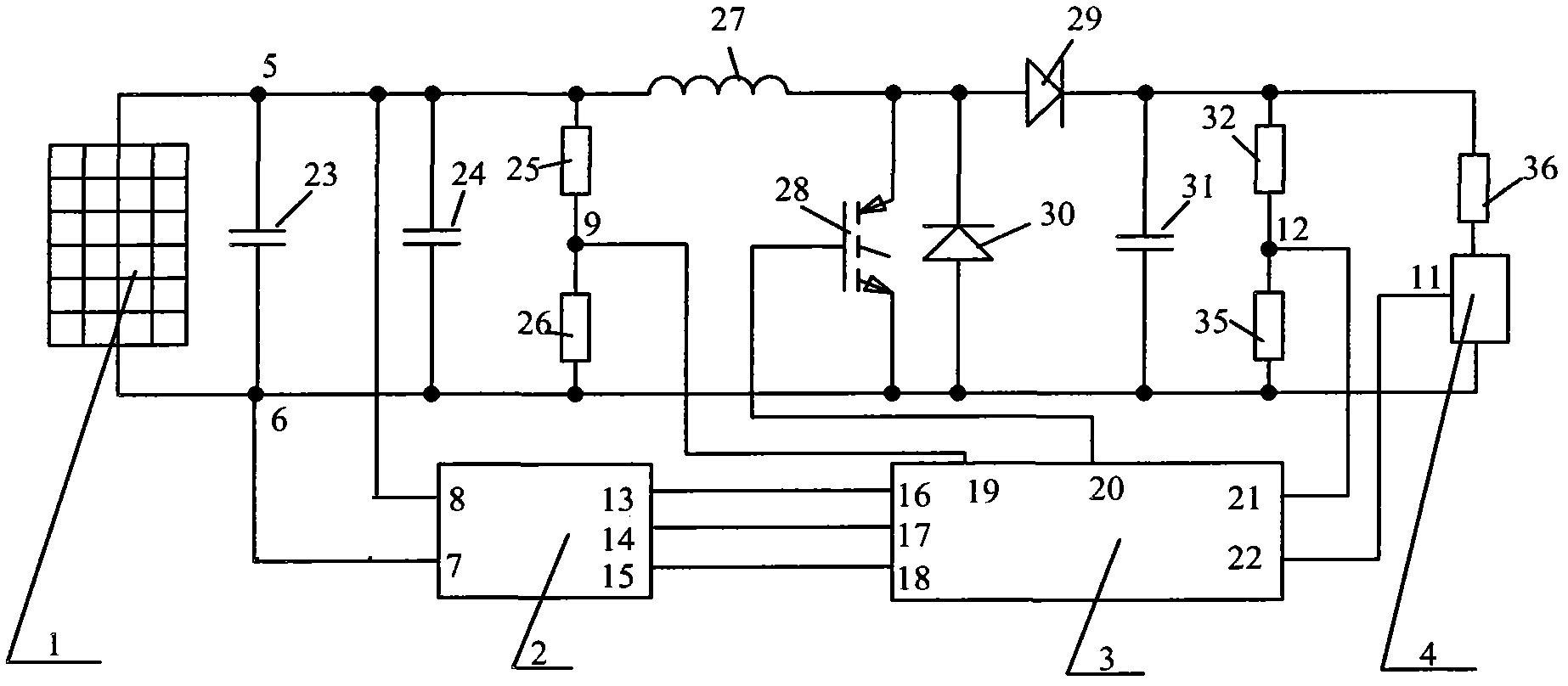

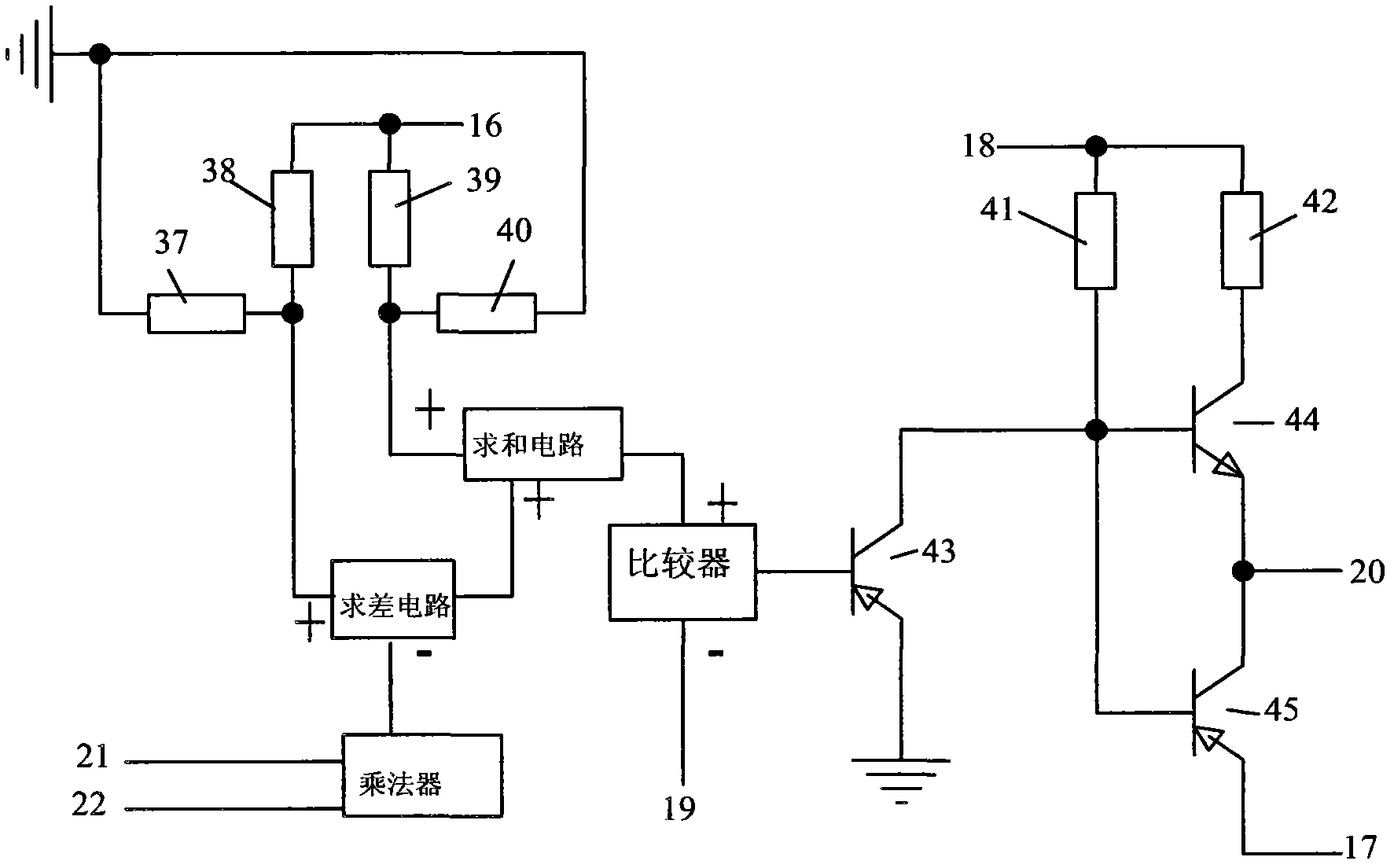

Automatic tracking device and method of maximum exposure dose of photovoltaic cell

ActiveCN102778898ASimple structureMaximum exposure automatic tracking fastPhotovoltaic supportsControl using feedbackElectricityMotor drive

The invention discloses an automatic tracking device and method of maximum exposure dose of a photovoltaic cell. An automatic tracking device comprises a photovoltaic cell, a transmission system and a control circuit, wherein the photovoltaic cell comprises a photovoltaic cell plate and a fixed support for supporting the photovoltaic cell plate, the photovoltaic cell plate is symmetrically hinged to the fixed support, the transmission system is respectively connected with two ends of the photovoltaic cell plate and arranged on the middle portion of the edges of the two ends, and the control circuit comprises a current voltage sampling circuit and a motor driving circuit. The current voltage sampling circuit is electrically connected with the photovoltaic cell plate, the motor driving circuit is electrically connected with the transmission system, and the current voltage sampling circuit is electrically connected with the motor driving circuit. The practical automatic tracking device of the maximum exposure dose of the photovoltaic cell is designed, the system structure is simple, no external power supply is needed, and rapid automatic tracking of the maximum exposure dose of the photovoltaic cell can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

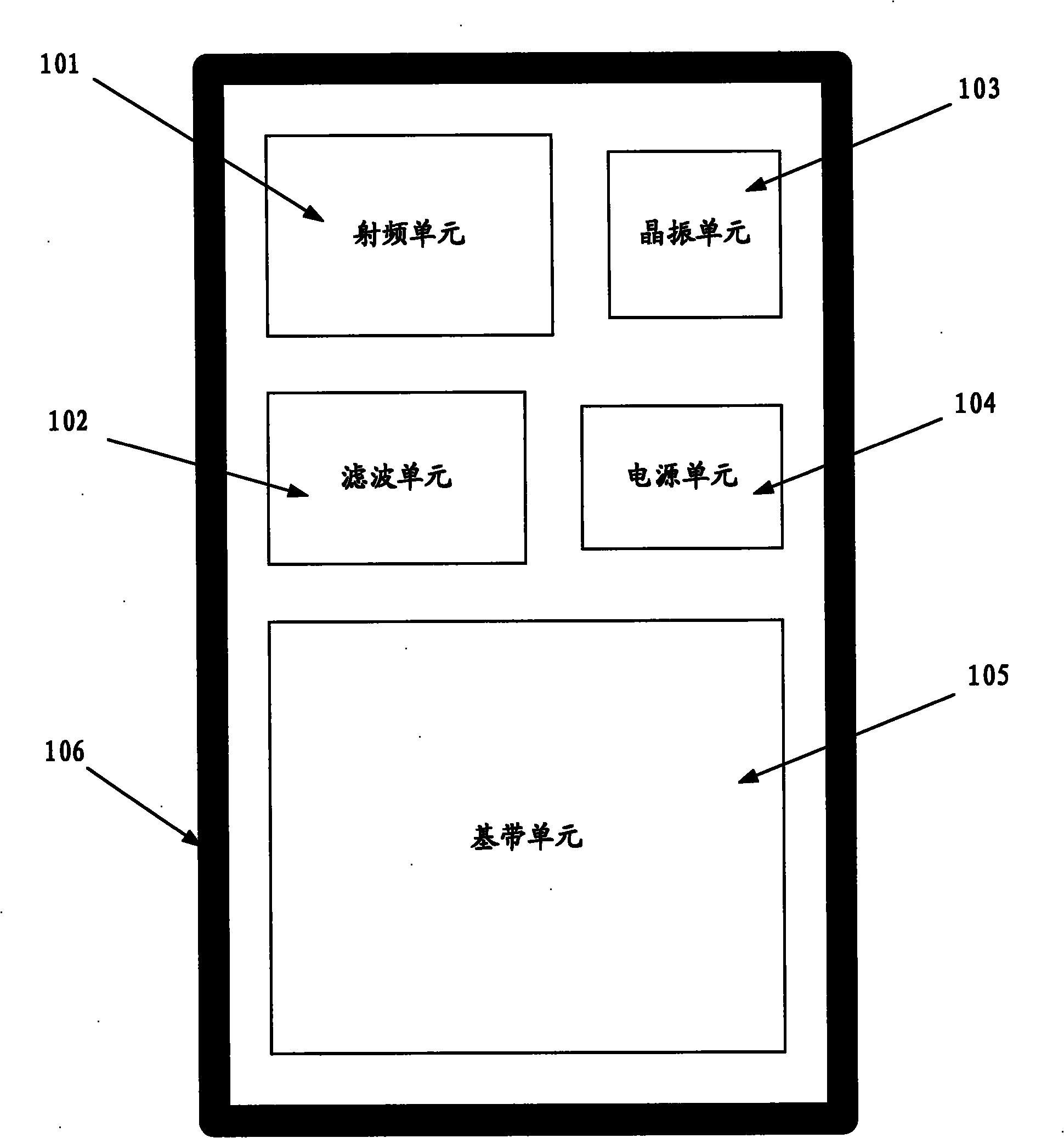

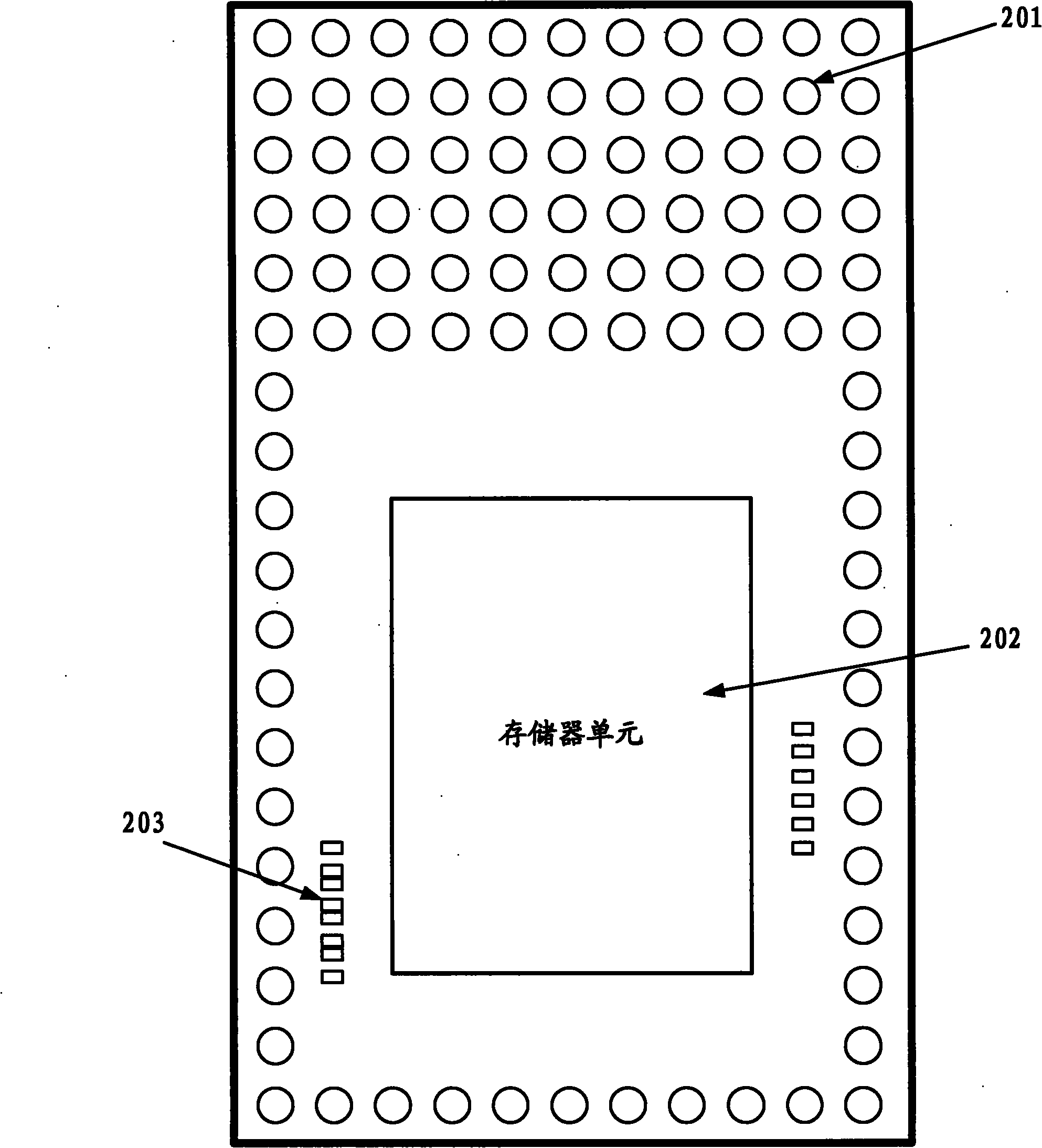

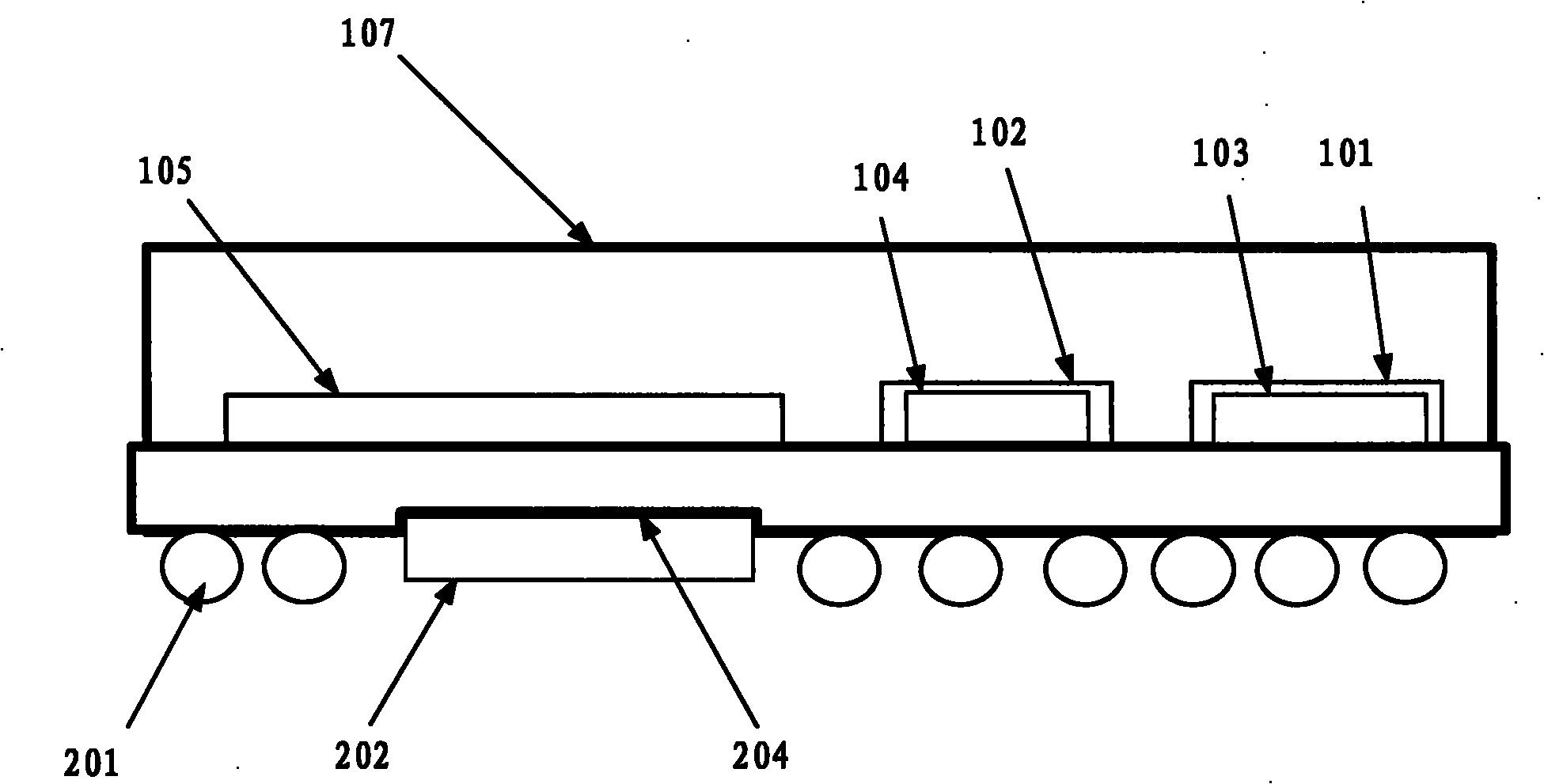

Wireless communication module

InactiveCN102215043AEasy to integrateReduce volumeTransmissionWireless communicationEvolution-Data OptimizedCode division multiple access

The invention belongs to the field of mobile communication, and relates to a wireless communication module, in particular to a high-performance small-sized module of a code division multiple access (CDMA) evolution-data optimized (EV-DO) mobile terminal. The small-sized module is applicable to a third generation (3G) user terminal. The wireless communication module is characterized in that: board-level connection is carried out by ball grid array (BGA) package; the level of integration is high; the size is small; good electrical performance and an external interface function are realized; and requirements of a customer can be well met. The wireless communication module comprises a radio frequency front end, a transmitting and receiving channel, a base band processing part, a memory and a power manager, wherein the base band processing part and the radio frequency front end are placed on a top layer of a circuit board; a shielding cover is arranged on the top layer to guarantee an excellent electromagnetic compatibility function of the module; the memory is placed on a bottom layer of the circuit board; and the bottom layer adopts an advanced BGA technology to guarantee reliable connection during the application of the module.

Owner:NATIONZ TECH INC

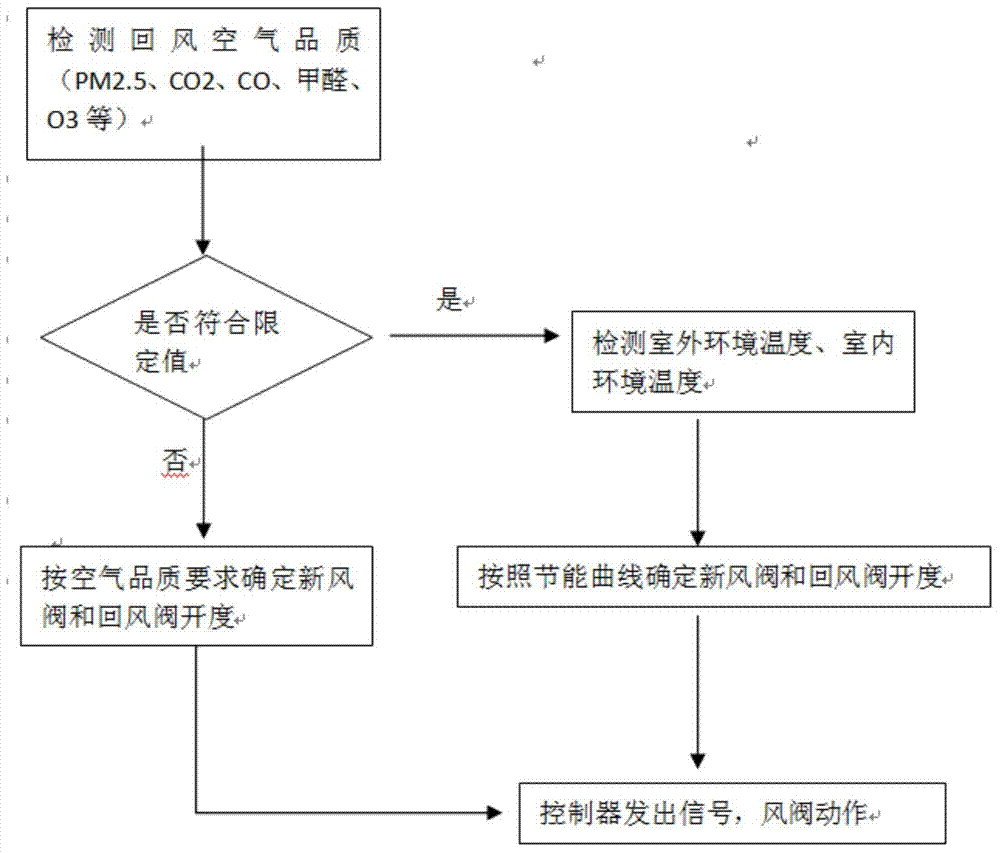

Fresh air system and air valve opening control method thereof

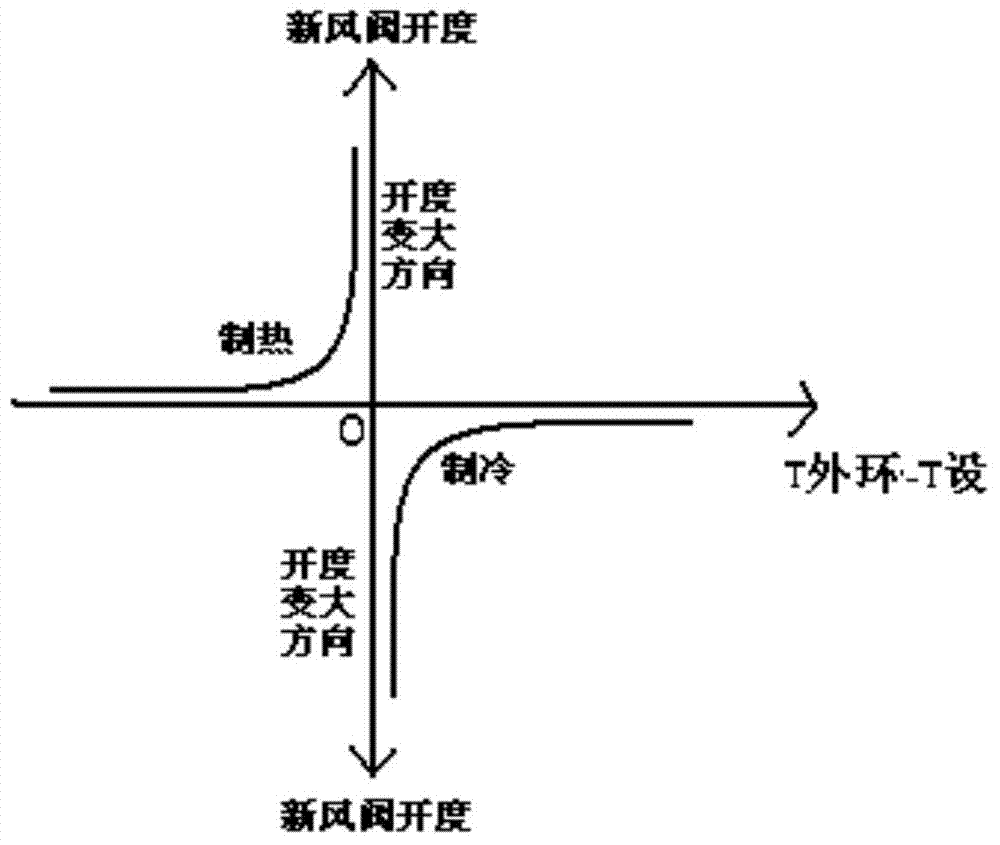

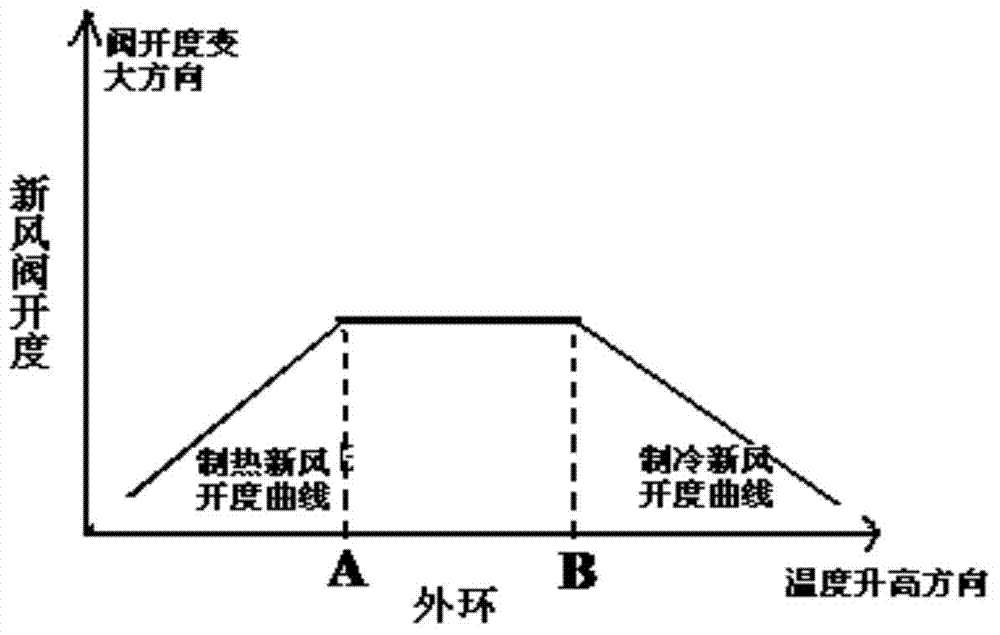

ActiveCN104776558AMeet energy saving requirementsReduce openingMechanical apparatusSpace heating and ventilation safety systemsFresh airIndustrial engineering

The invention discloses a fresh air system and an air valve opening control method thereof. The air valve opening control method of the fresh air system comprises the following steps: S10, detecting the air quality of return air; S20, judging whether the air quality of the return air meets the set requirement or not, and when the set requirement is met, entering S30; when the set requirement is not met, entering S40; S30, introducing fresh air according to a fresh air mode so as to increase the opening of a fresh air valve and / or reduce the opening of a return air valve; S40, determining the opening of the fresh air valve and the return air valve according to an energy saving curve. According to the air valve opening control method disclosed by the invention, energy-saving optimization can be realized on the basis that the air valve opening is intelligently regulated.

Owner:GREE ELECTRIC APPLIANCES INC

Portable temperature-equalizing type spraying cooling circulating system for high-power electronic component

InactiveCN102625642AGood application effectTroubleshooting the presence of a liquid phaseCooling/ventilation/heating modificationsVapor–liquid separatorEngineering

The invention discloses a portable temperature-equalizing type spraying cooling circulating system for a high-power electronic component. The circulating system comprises a compressor, a spraying cooler and an air condenser, wherein an outlet of the compressor is connected with an inlet of the air condenser through a connecting pipeline; the outlet of the air condenser is connected with the inlet of the spraying cooler through the connecting pipeline; the circulating system is characterized by being provided with a gas-liquid separator and an auxiliary heating device; the outlet of the spraying cooler is connected with the inlet of the gas-liquid separator through a fluid conveying pipeline; the auxiliary heating device is arranged on the fluid conveying pipeline; the outlet of the gas-liquid separator is connected with the inlet of the compressor through the connecting pipeline; and a to-be-cooled piece is fixedly arranged on the spraying cooler. The auxiliary heating device and the gas-liquid separator are utilized in the circulating system provided by the invention to solve the problems that liquid phase exists before a refrigerant enters into the compressor and residual liquid after being subjected to spraying cooling cannot directly enter into the compressor for recompressing, so that spraying cooling closed circulation is realized and energy source is saved.

Owner:CHONGQING UNIV

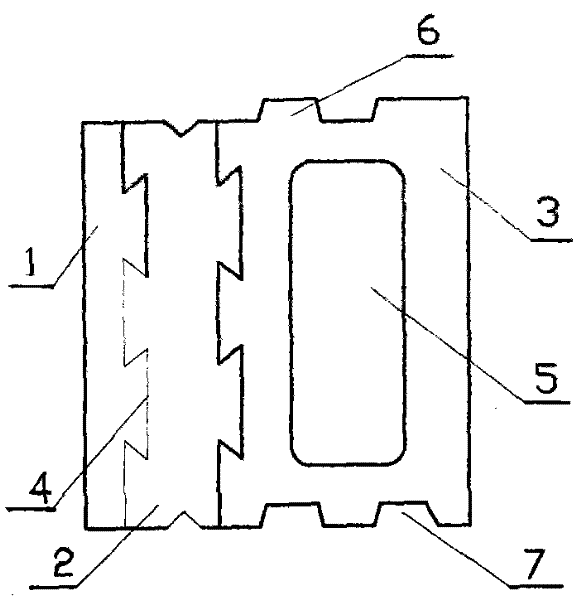

Composite self-heat-insulation concrete hollow building block and production method thereof

InactiveCN102304955ACompletely cut offMeet energy saving requirementsConstruction materialSolid waste managementInsulation layerArchitectural engineering

The invention discloses a composite self-heat-insulation concrete hollow building block comprising an internal member, a heat-insulation member and an external member, wherein the internal member and the external member are made by adding cement, water granulated slag and water into fly ash as a main raw material; the heat-insulation member is made from foaming resin; the internal member and the external member are used for clamping the heat-insulation member through a dovetail groove to ensure that a building block, a heat-insulation material and a protection layer are tightly bonded together so as to improve the tensile strength among the protection layer, a heat-insulation layer and the building block; a through hole is arranged in the center of the external member to reduce the weight of the external member and improve heat insulation and sound insulation effects; and a convex lock head and a concave lock groove are respectively designed at two ends of the external member so that an interlocking mechanism is formed between building blocks. The building block provided by the invention has the advantages of favorable self-heat-insulation property, convenience for construction in masonry, smooth masonry wall surface, great reduction of building plastering thickness; and meanwhile the shock resistant capacity of a building wall is improved due to the interlocking mechanism. The composite self-heat-insulation concrete hollow building block can be used for wall materials of buildings and structures.

Owner:中城建恒远(贵州六盘水)新型建材有限公司

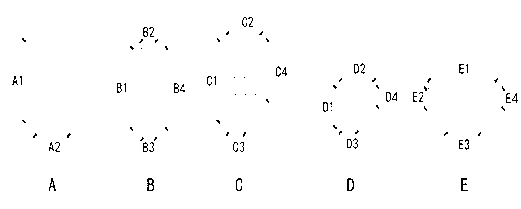

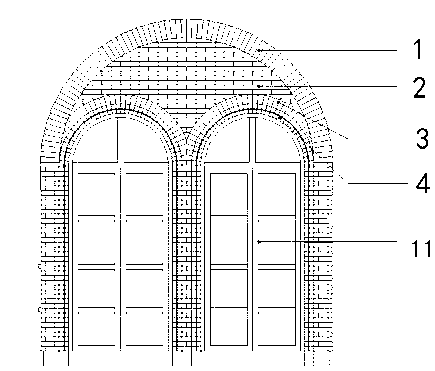

Construction method of bricked large-span multiple-arc-arch

ActiveCN102767283ASolve processing problemsBeautiful appearanceBuilding componentsBuilding material handlingBrickAxial pressure

The invention discloses a construction method of a bricked large-span multiple-arc-arch. The large-span multiple-arc-arch consists of a large arc arch with span being 3100mm arranged at the outer edge of a common facade wall body as well as a double-small-arc-arch, wherein the double-small-arc-arch is formed by two small arc arches whose spans are both 1500mm at the inner edge the common facade wall body. The construction method for constructing the large-span multiple-arc-arch comprises nine processes: 1) firing common shale perforated bricks and wedge-shaped and polygonal abnormal-shape perforated bricks; 2) erecting small circular arch moulding beds; 3) measuring the number of brick moulds; 4) constructing the second small arc arch; 5) cutting and machining the abnormal-shape bricks; 6) constructing the wall body; 7) constructing an arc concrete beam; 8) constructing a sand aerated inner haunch wall and filling expanded and vitrified small balls while constructing; and 9) pouring structural columns of the inner haunch wall. By the construction method, the difficulty that the bricked large-span multiple-arc-arch cannot be constructed by the traditional construction method is overcome; the bricked large-span multiple-arc-arch can bear axial pressure and has structural safety; and the service life of the bricked large-span multiple-arc-arch is guaranteed.

Owner:TIANJIN SANJIAN CONSTR ENG

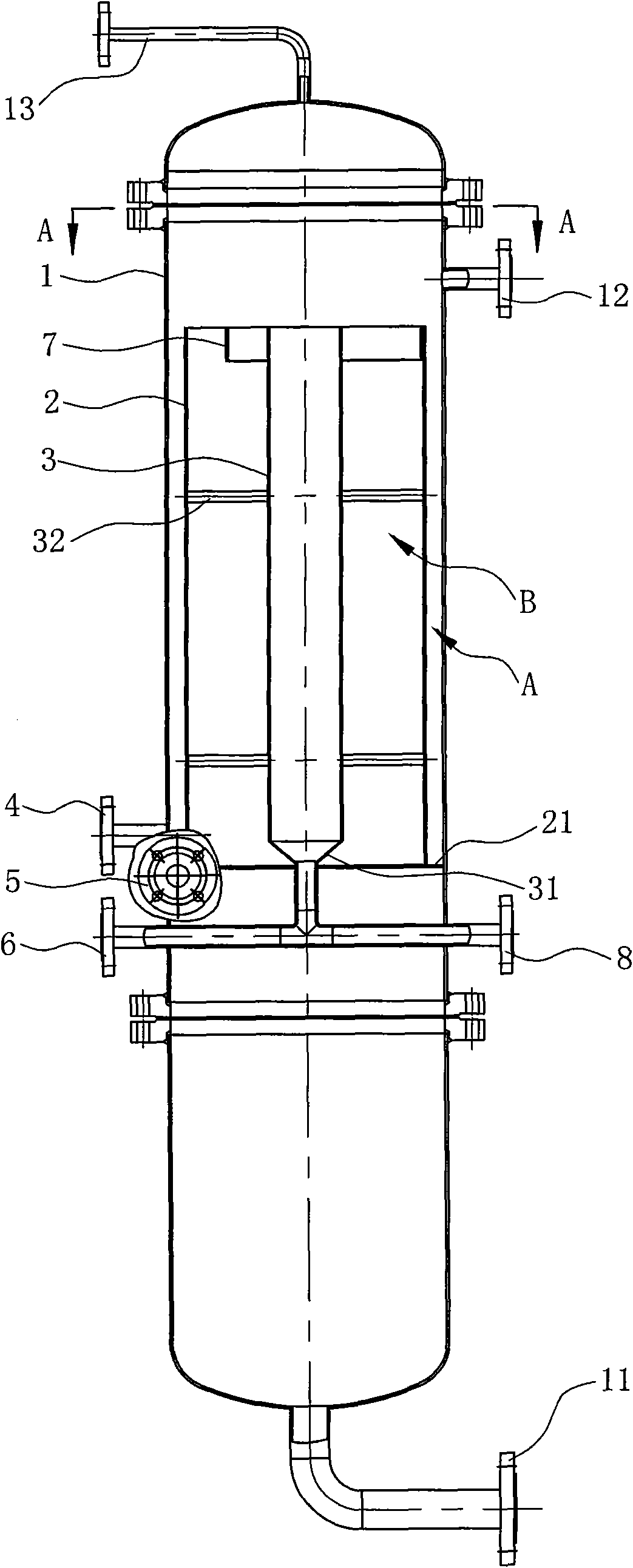

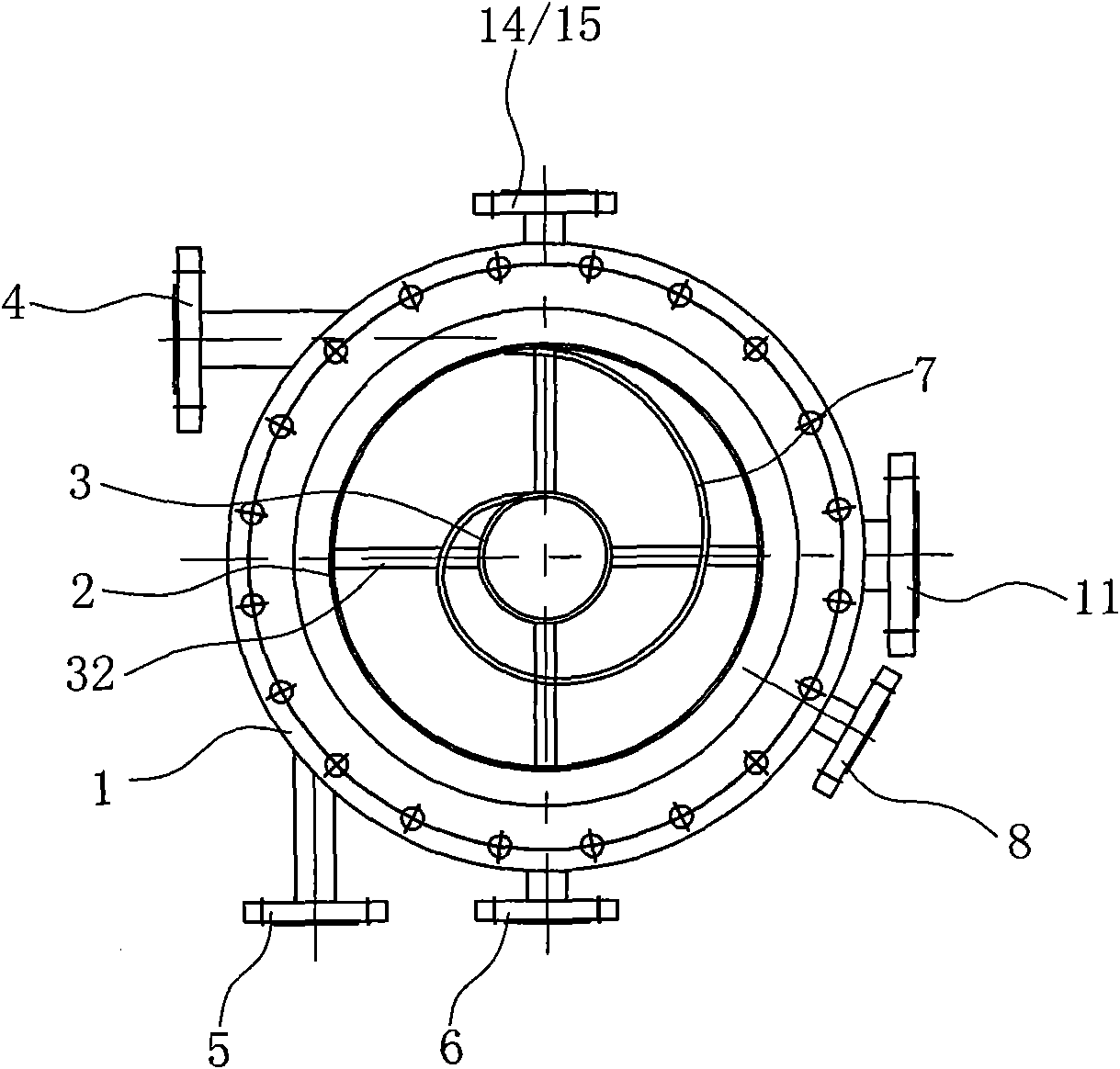

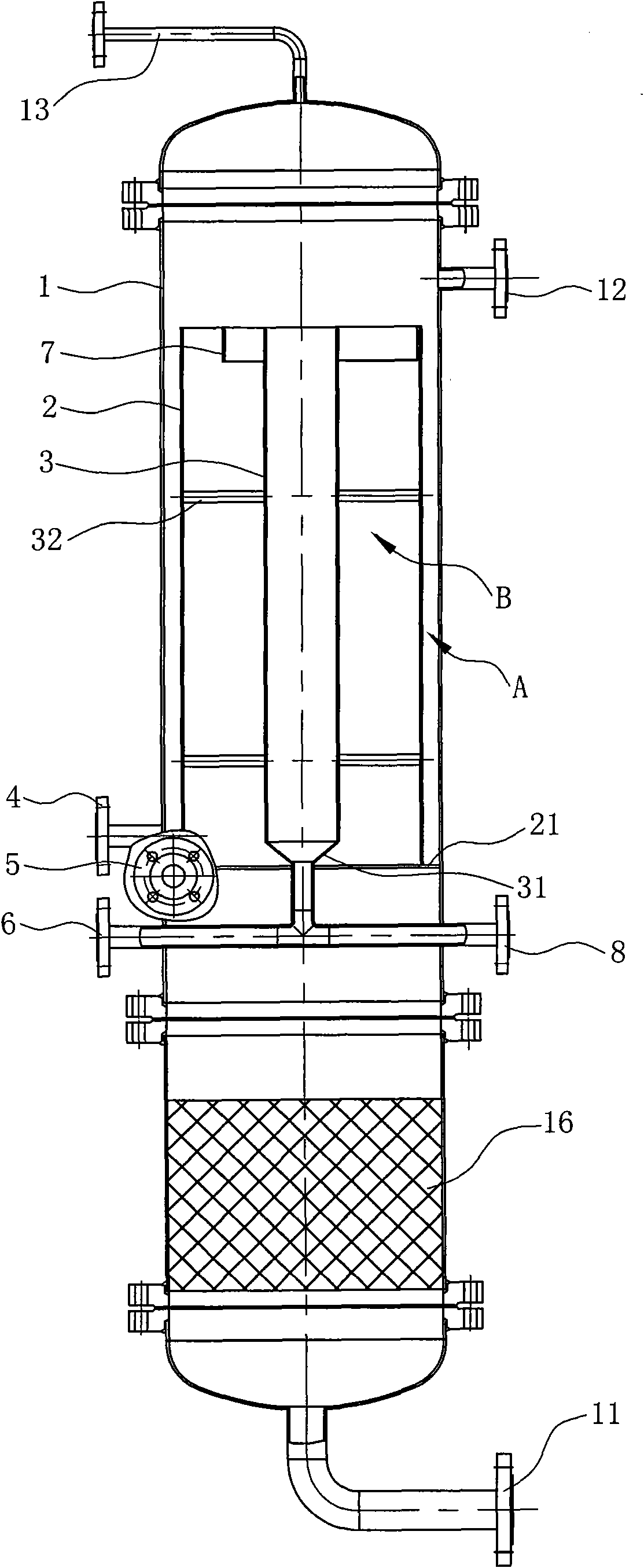

Pressure type air flotation separation device

ActiveCN101935081AAvoid interferenceThe separation interface is stableFatty/oily/floating substances removal devicesLiquid separationWater dischargeSmall particles

The invention discloses a pressure type air flotation separation device, which comprises a tank body (1), and an oil collecting barrel (3) and an air bubble flow rectifying barrel (2) which are arranged in the tank body (1), wherein an air bubble flow rectifying area (A) of which the bottom is sealed is formed between the outer side wall of the air bubble flow rectifying barrel (2) and the inner side wall of the tank body (1); a flotation separation area (B) of which the bottom is open is formed between the inner side wall of the air bubble flow rectifying barrel (2) and the outer side wall of the oil collecting barrel (3); an oil-containing water inlet pipe (4) and a gas-dissolving water inlet pipe (5) are arranged on the tank body (1) tangentially; and a water discharge pipe (11) is arranged at the bottom of the tank body (1). Compared with the prior art, the pressure type air flotation separation device has the advantages that: the interference of large air bubbles with the oil-water flotation separation area is avoided, the oil-water separation interface is more stable and the separation efficiency is high; mutual fusion of micro air bubbles is inhibited, so that the success rate of the contact and adhesion between the micro air bubbles and oil drops with small particle sizes is improved considerably; and thus, the oil-water separation effect is improved considerably. In addition, the device adopts a sealed tank body, so harmful gases are prevented from leaking to the outside.

Owner:浙江海牛海洋工程有限公司

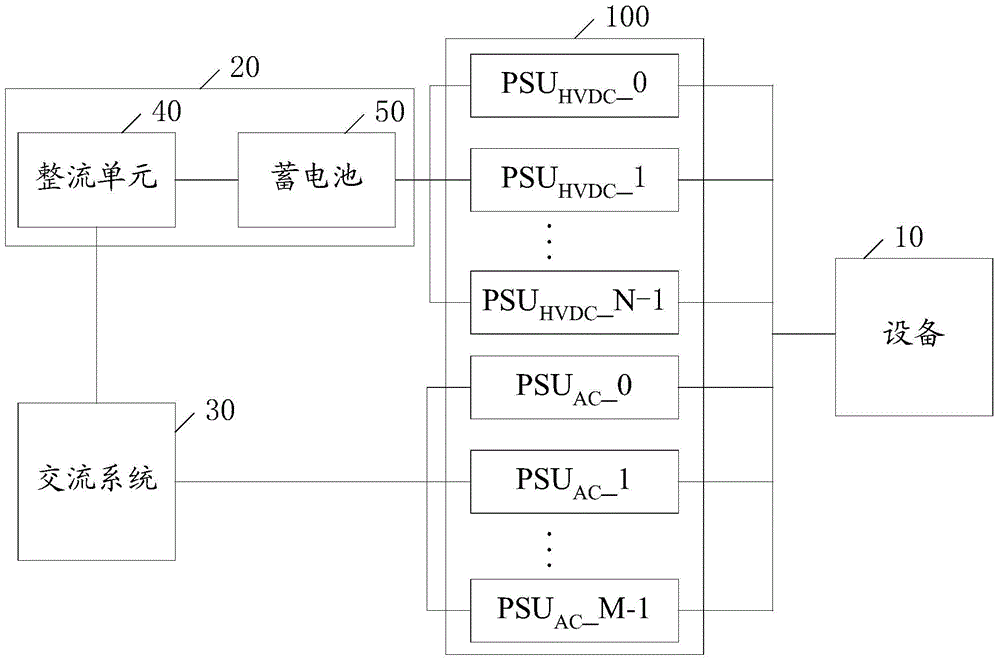

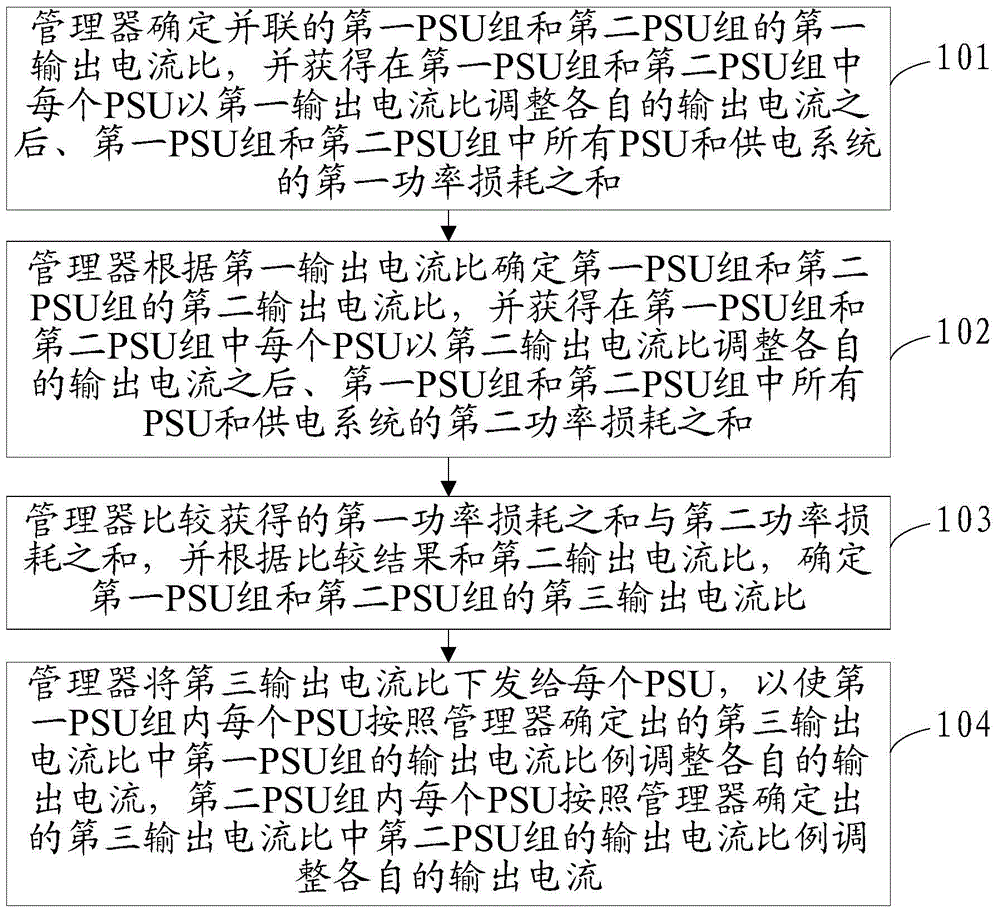

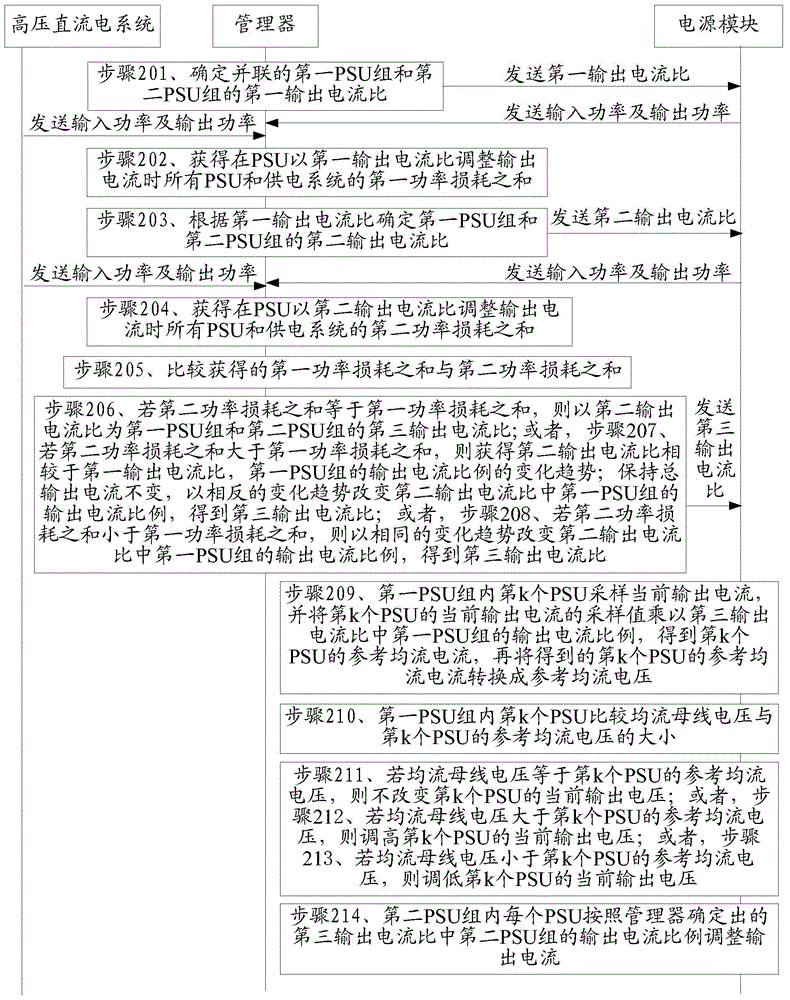

Current sharing method and system of power supply module and manager

ActiveCN104600830AReduce power lossMeet energy saving requirementsEmergency power supply arrangementsComputer moduleHigh-voltage direct current

The invention discloses a current sharing method and a current sharing system of a power supply module and a manager, and belongs to the field of power supply modules. The method includes the steps that: the manager determines a first output current ratio of a first PSU (Power Supply Module) set to a second PSU set which are in parallel, and obtains the sum of first power loss of all PSUs and a power supply system in the first PSU set and the second PSU set after the output current of each PSU in the PSU set and the second PSU set is regulated according to the first output current ratio; the first PSU set includes one or more parallel PSUs and is directly powered by a high voltage direct current system, and the second PSU set is powered by an alternating current system; a second output current ratio is determined and the sum of second power loss is obtained according to the first output current ratio; the sum of the first power loss is compared with the sum of the second power loss, and a third output current ratio is determined according to the comparison result and the second output current ratio; the third output current ratio is sent to the PSUs in the first PSU set and the second PSU set to allow the PSUs in the first PSU set and the second PSU set to regulate the output current according to the third output current ratio.

Owner:HUAWEI TECH CO LTD

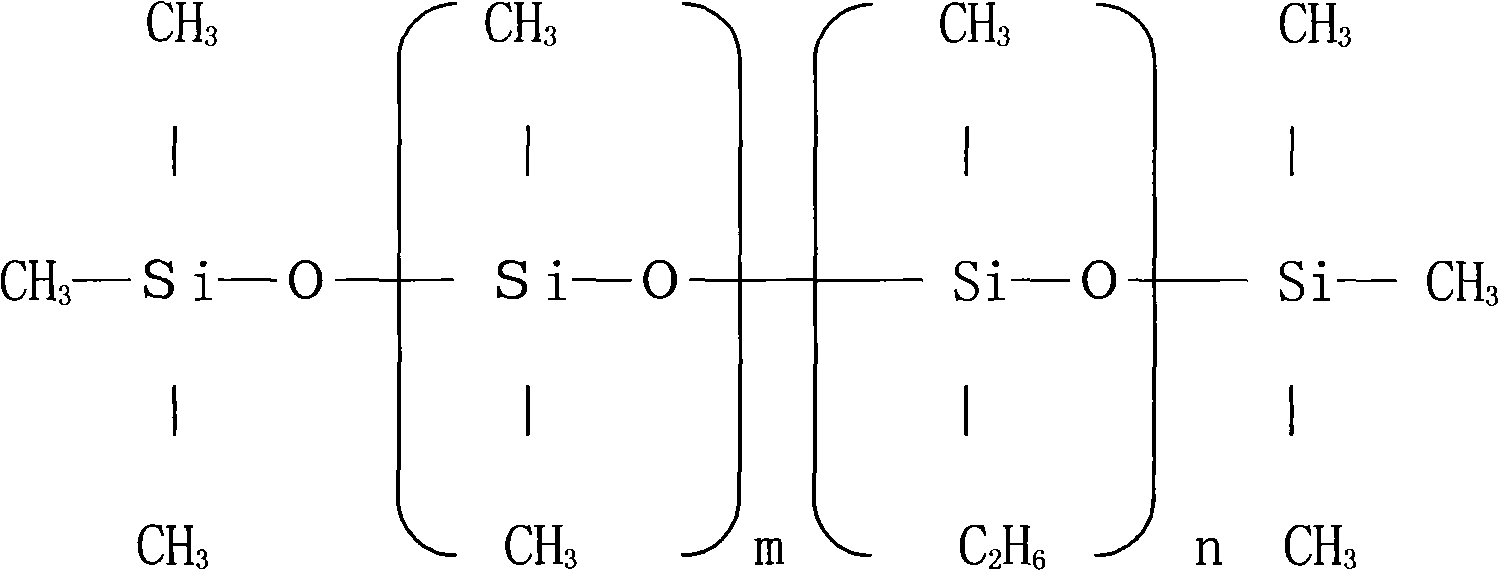

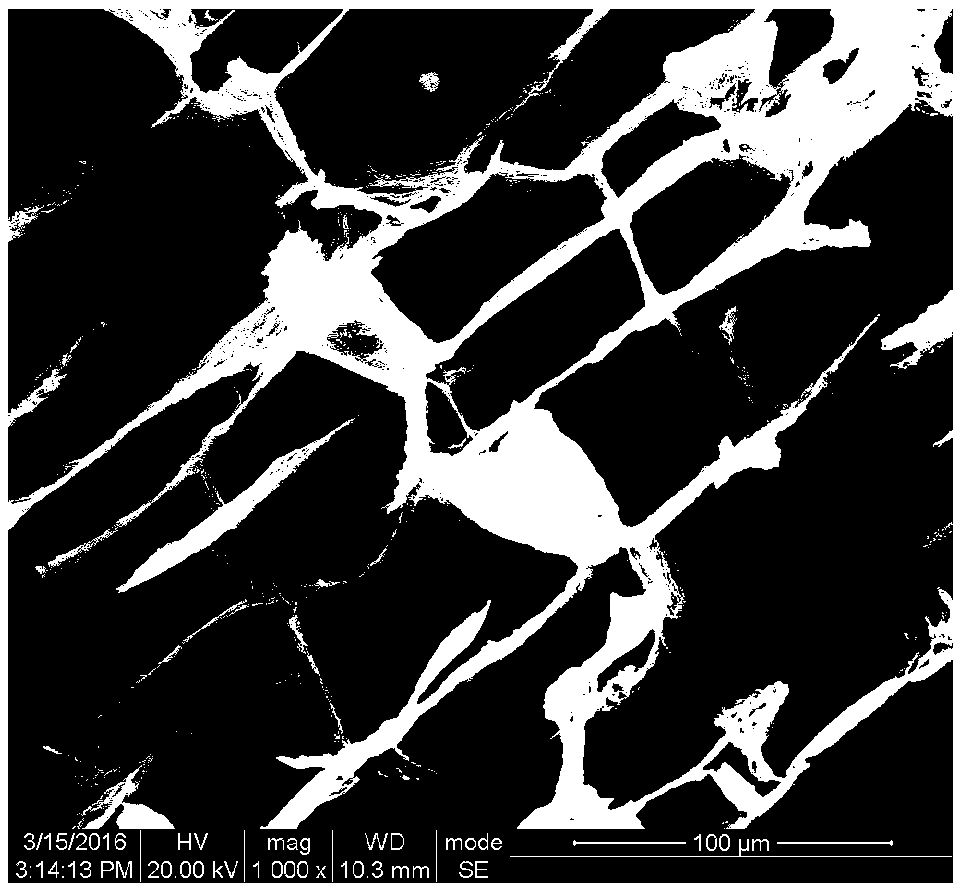

High-strength low-heat-conductivity grade A noninflammable aerogel foam and preparation and application thereof

ActiveCN108264372ALow thermal conductivityGood mechanical propertiesCeramicwareHigh intensityLimiting oxygen index

The invention provides a high-strength low-heat-conductivity superhydrophobic polymer matrix noninflammable aerogel material, comprising, by weight, 0.5-10.0 parts of inorganic particles, 0.03-2.0 parts of a branched polymer binder, 0-2.0 parts of a crosslinkable polymer, 0-1.0 part of a crosslinking agent, and 0-3 parts of a surfactant. The invention also discloses a preparation method of the material; the material has the density of 5-100 kg / m<3>, specific modulus of 10-150 MP cm<3> / g, heat conductivity coefficient of 0.010-0.070 W / (m K), extreme oxygen index of higher than 50%, combustion heat value of 1.0-4.0 MJ / kg, good superhydrophobicity and water contact angle of greater than 150.0 DEG. Before and after combustion, the material has high strength and structural stability, and secondary damage possibly caused by shrinking or collapse after burning is decreased to maximum extent.

Owner:SICHUAN UNIV

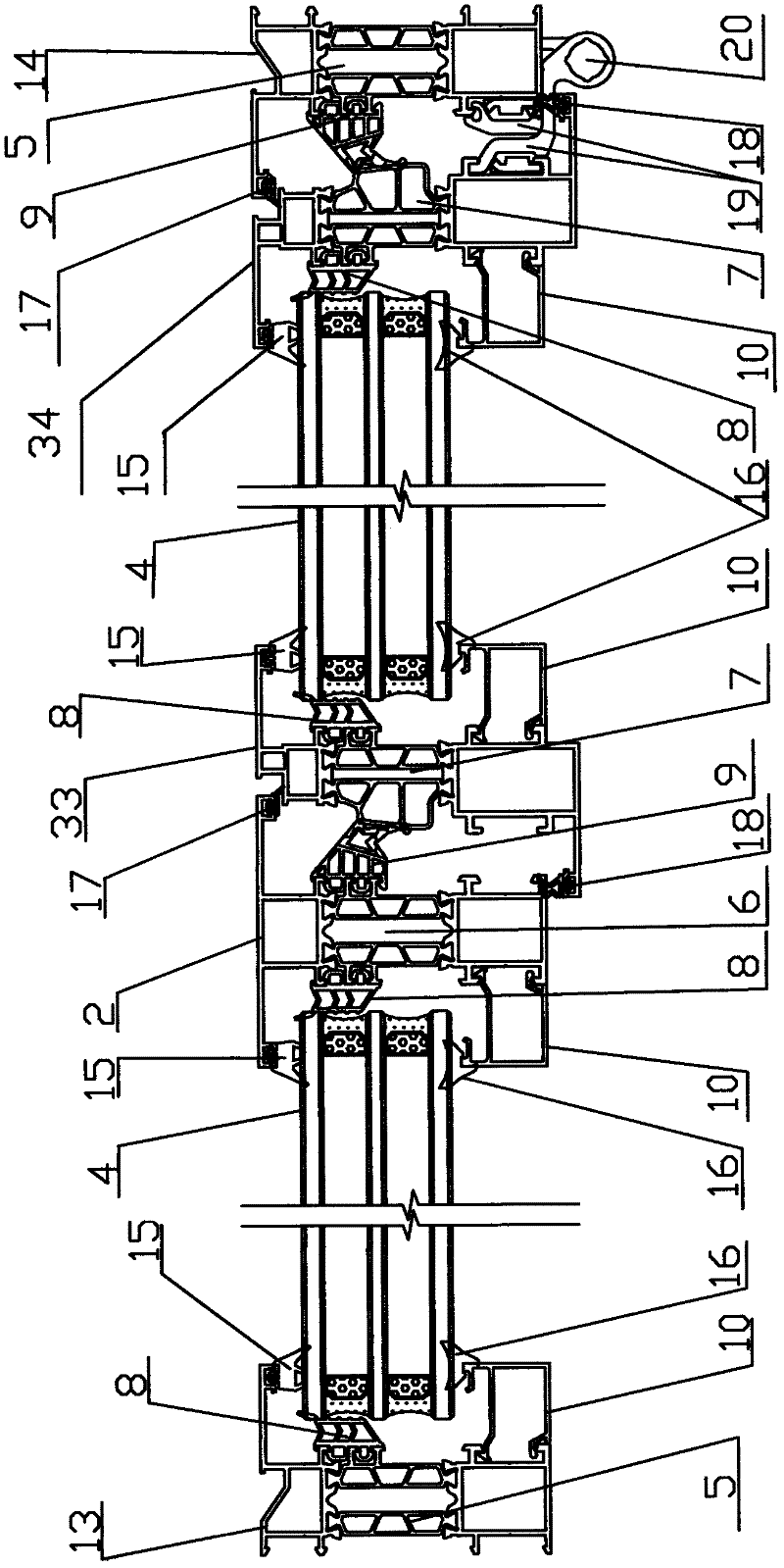

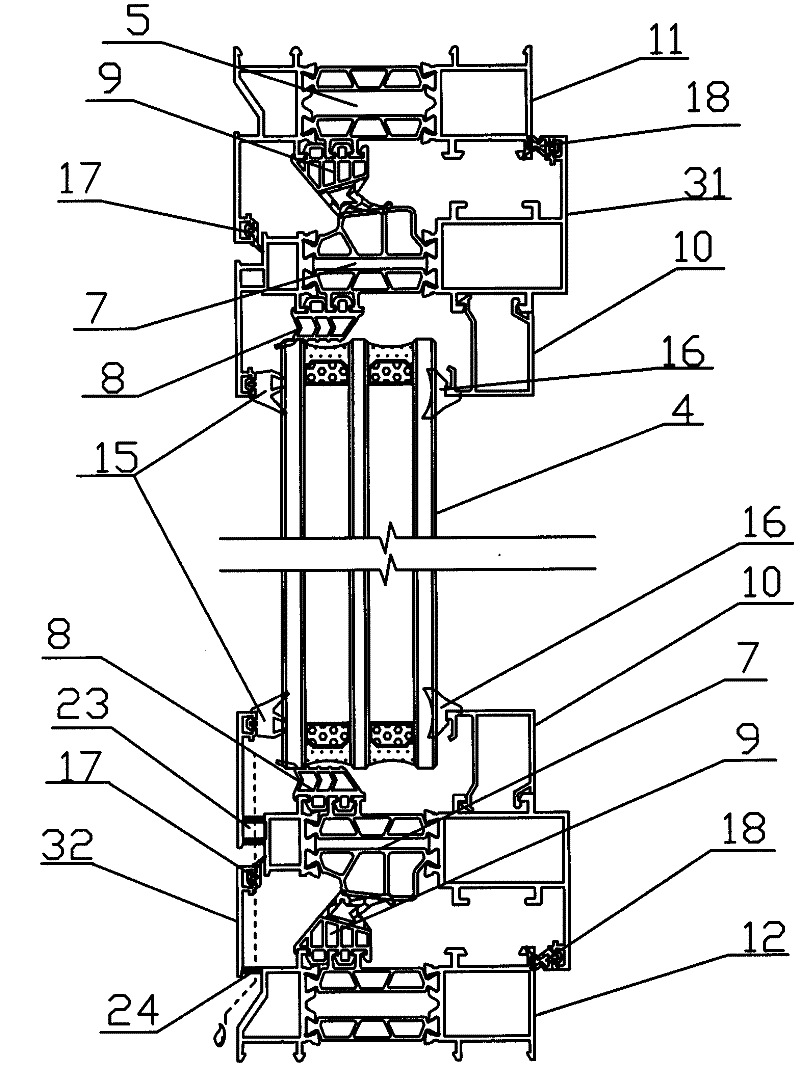

Energy-saving, environment-friendly, broken-bridge and heat-insulating aluminum alloy doors and windows

InactiveCN102587793AGood sound insulationReduce heat radiationSealing arrangementsUnits with parallel planesWaterproofingMullion

The invention discloses energy-saving, environment-friendly, broken-bridge and heat-insulating aluminum alloy doors and windows. The frames, the mullions and the fan frames of the doors and windows are respectively composed of outdoor and indoor aluminum profiles and heat insulating strips. The heat insulating strips include three structures: a heat insulating strip A for the frames of identical width, a heat insulating strip B for the mullions and a heat insulating strip C for the fan frames. The heat insulating strips A, B and C, heat insulating supporting rubber strips and constant-pressure rubber strips are in multi-cavity structures. Outdoor insulating glass is fixed through outside sealing rubber strips in a press-joint manner, indoor insulating glass is fixed through inside sealing rubber strips in a press-joint manner, the middle is fixedly supported by insulating supporting rubber strips, the insulating supporting rubber strips are fixedly connected with the heat insulating strips A, B and C respectively, and the insulating strip B is fixedly connected with the insulating strip C by the aid of the constant-pressure rubber strips. The energy-saving, environment-friendly, broken-bridge and heat-insulating aluminum alloy doors and windows are fine in waterproofing, heat and sound insulating effects, and high in energy saving rate and can meet national or regional demands for energy conservation.

Owner:HEBEI ORIENT SUNDAR WINDOW

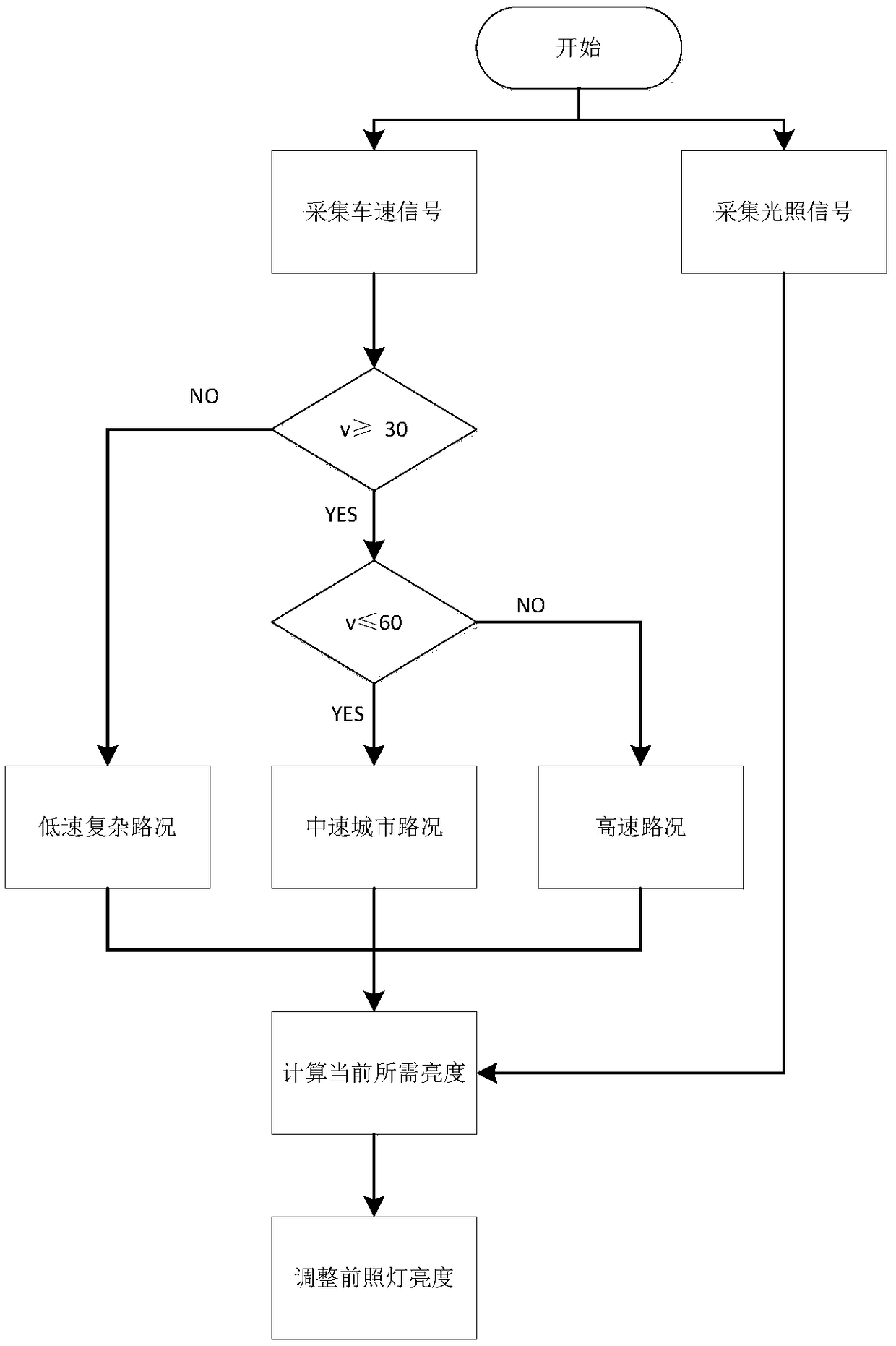

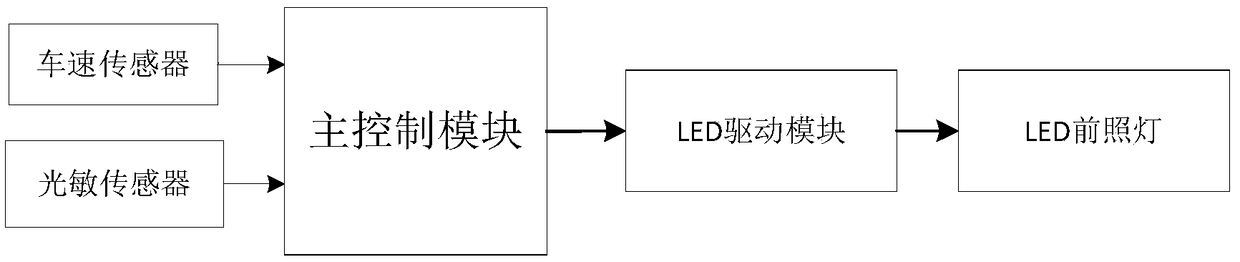

Brightness-adjustable car intelligent headlamp system based on environment, and method

InactiveCN108657062AReduce the impact of lightReduce light pollutionVehicle headlampsOptical signallingLight pollutionSimulation

The invention discloses a brightness-adjustable car intelligent headlamp system based on the environment, and a method. The current environment of a car is preliminarily judged according to the car speed and light intensity, and the illumination brightness of the headlamp is adjusted based on the light intensity in the current environment, and the effects of energy saving and light pollution reduction are taken into account while meeting the lighting requirements. A design of the brightness-adjustable car intelligent headlamp system based on the environment is provided, and the brightness of the car lamp can be adjusted by collecting the environmental information through a sensor and judging by a master controller. The system comprises the sensor, the master controller and an actuator, thelighting brightness of the headlamp can be adjusted according to the driving state and the environmental information of the car, and energy is saved while providing a better road lighting effect fora driver.

Owner:JIANGSU UNIV

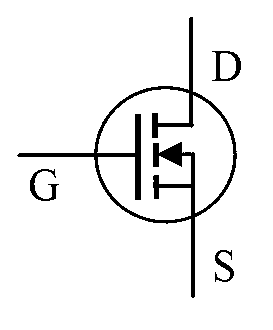

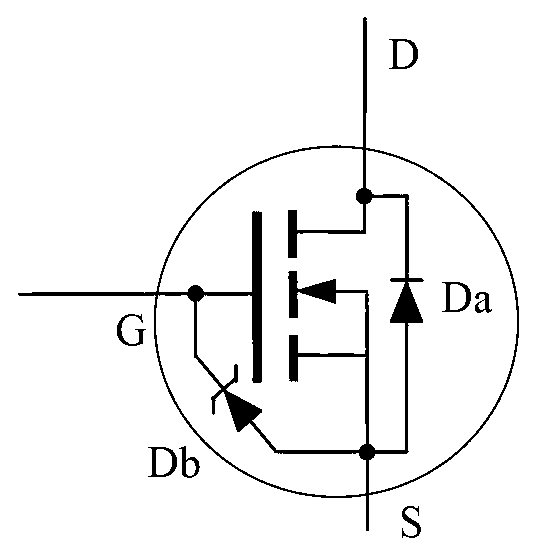

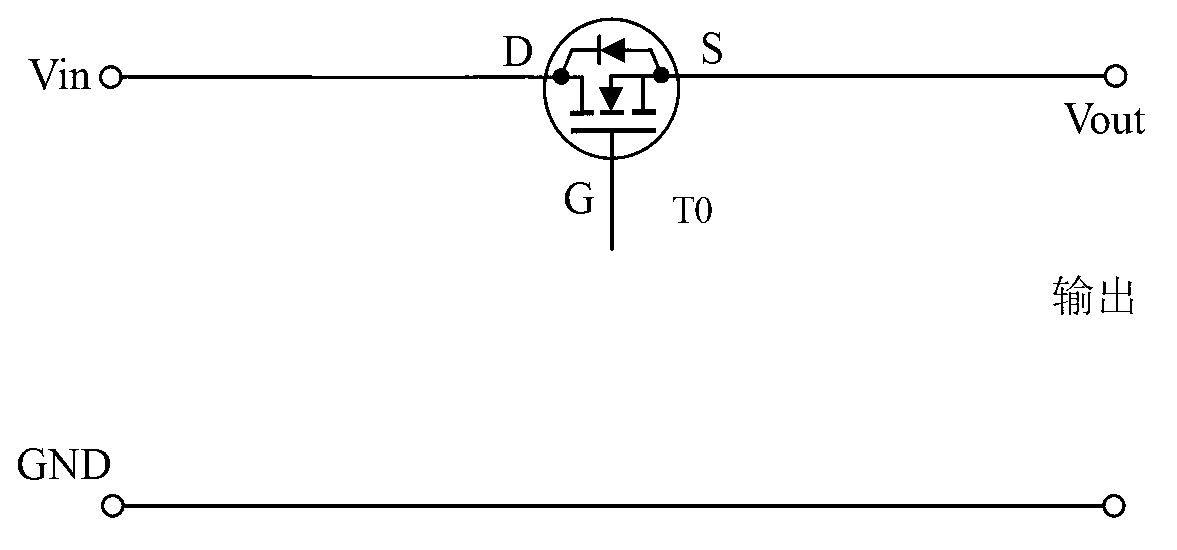

Boosted circuit

ActiveCN103078493AReduce power consumptionMeet energy saving requirementsAc-dc conversion without reversalDc-dc conversionCapacitanceHemt circuits

The invention discloses a boosted circuit which is composed of four unit circuits including a surge suppression circuit, a linear voltage stabilizing circuit, an oscillator circuit and a voltage doubling rectifying circuit, wherein after power voltage is filtered and reduced by the surge suppression circuit, stable voltage is output by the linear voltage stabilizing circuit; through the oscillator circuit, a square wave or a sine wave of which a peak-to-peak value is close to the output voltage of the linear voltage stabilizing circuit is generated; and after capacitive coupling of the voltage doubling rectifying circuit is performed on the square wave or the sine wave, voltage high than the power voltage is output through voltage doubling rectification and used for driving a power MOS (Metal Oxide Semiconductor) tube. The boosted circuit is characterized in that the output voltage of the linear voltage stabilizing output end of the linear voltage stabilizing circuit is slightly greater than the driving voltage of a grid electrode of the MOS tube, and the working current of the oscillator circuit is lower than 2 mA, so as to implement boosting with no-load power consumption lower than 100 milliwatt and satisfy the energy saving requirement of the new age.

Owner:MORNSUN GUANGZHOU SCI & TECH

Method for extruding and forming stainless steel three-way joint

InactiveCN102240700AEasy to cleanImprove processing qualityExtrusion profiling toolsSolution treatmentEmulsion

The invention discloses a method for extruding and forming a stainless steel three-way joint, comprising the following steps of: 1), preparing a stainless steel tube billet (1), surface of which is wrapped by a layer of plastic film (9); 2), extruding and forming the stainless steel tube billet (1) so as to obtain a semi-finished product of the three-way joint, wherein a liquid filling medium in a liquid filling system in a tube is emulsion formed by modulating emulsified oil and water; and 3), performing solid solution treatment, surface grinding and groove processing of the semi-finished product of the three-way joint. According to the method for extruding and forming the stainless steel three-way joint disclosed by the invention, the emulsion is ingeniously used as the liquid filling medium; energy-saving and environmental protection requests can be satisfied; the three-way joint extruded and formed by the invention is cleaned easily; the emulsion of the liquid filling medium in the tube can be recycled; stainless steel metal tee joints and the environment cannot be polluted; furthermore, a layer of plastic film is ingeniously wrapped on the stainless steel tube billet in advance; the surface of the formed three-way joint can be effectively prevented from generating defects; and the processing quality of the three-way joint is obviously improved.

Owner:江苏兴洋管业股份有限公司

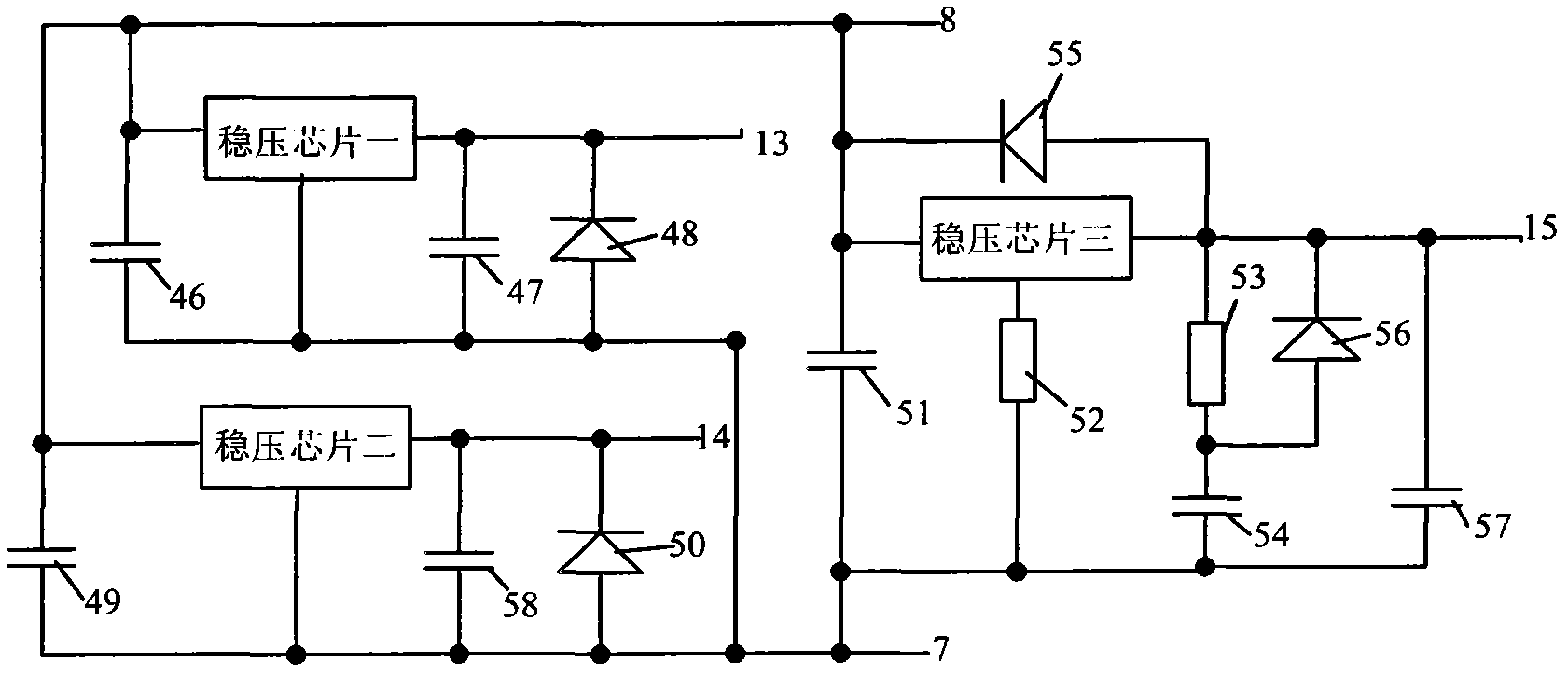

Automatic voltage regulating circuit and method for solar photovoltaic power generation system

InactiveCN102081419AAchieve constant power outputThe problem of saving energyPhotovoltaicsPhotovoltaic energy generationMicrocontrollerCapacitance

The invention provides an automatic voltage regulating circuit for a solar photovoltaic power generation system. The circuit comprises an auxiliary power circuit, an input voltage regulating capacitor, a voltage boosting inductor, an insulated gate transistor, a freewheel diode, a first diode, a second diode, a control drive circuit, an output voltage regulating capacitor, a load and a sampling circuit, wherein the voltage boosting inductor is connected with the input voltage regulating capacitor and the insulated gate transistor; the insulated gate transistor is connected with the control drive circuit and the input voltage regulating capacitor; the freewheel diode is connected with the insulated gate transistor; the first diode and the second diode are connected with the insulated gate transistor and the load; the output voltage regulating capacitor is connected with the first diode, the second diode and the freewheel diode; the load is connected with the output voltage regulating capacitor and an acquisition circuit respectively; and the acquisition circuit is connected with the input voltage regulating capacitor, the load, the output voltage regulating capacitor and the control drive circuit. The invention also provides an automatic voltage regulating method for implementing the method. Constant power output and power supply to the load can be realized without support of asinglechip.

Owner:SOUTH CHINA UNIV OF TECH

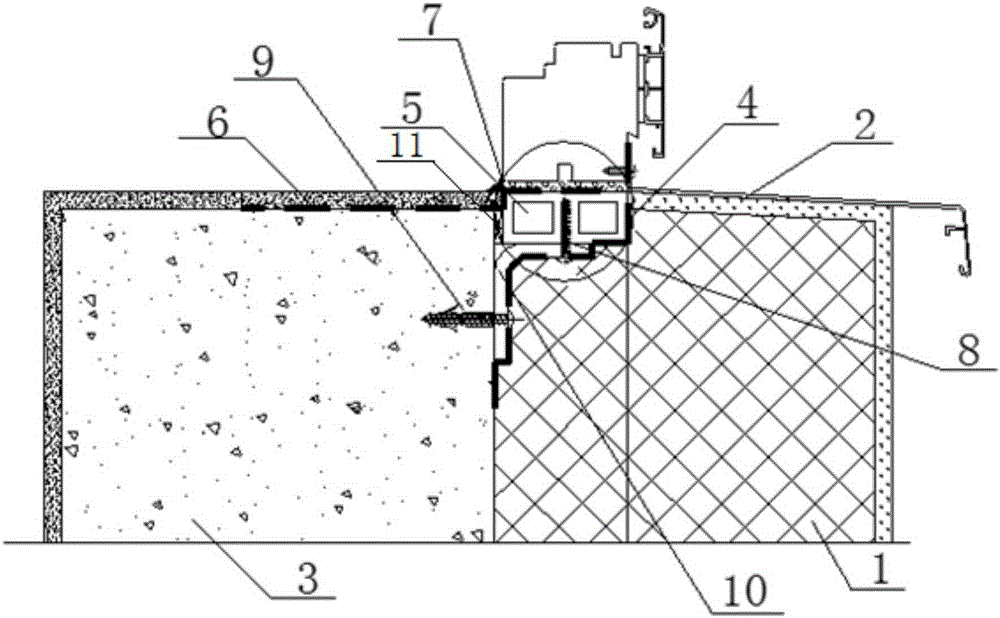

Passive window with auxiliary frame and installation method thereof

InactiveCN105201335ATo overcome the defect that the maintenance needs to remove the wallGuaranteed air tightnessFrame fasteningBase framesWindow openingEngineering

The invention discloses a passive window structure with an auxiliary frame and an installation method thereof. The installation method comprises the following steps: (1) installing the auxiliary frame on a wall at the outer side of a window opening, embedding in an outer insulating layer, and enabling four sides of the auxiliary frame to be respectively consistent with the window opening in verticality and levelness; (2) after the auxiliary frame is installed, sticking a waterproof and breathable membrane on the outer surface of the auxiliary frame, sticking a waterproof and gas-isolated membrane on the front of the auxiliary frame, and installing positioning lines on the outside top surface and two side surfaces of the auxiliary frame; and (3) connecting the auxiliary frame with the passive window to finish installation. After the auxiliary frame of the passive window is adopted, the passive window disclosed by the invention is simpler in structure, can completely meet the energy-saving requirement, is more reasonable in design, is energy-saving and environment-friendly, is reduced in cost, convenient in installation and standardized in installation, thoroughly solves the connection problem of passive window installation and external insulation construction, and is increased in installation yield.

Owner:常州玖洲联横建材有限公司

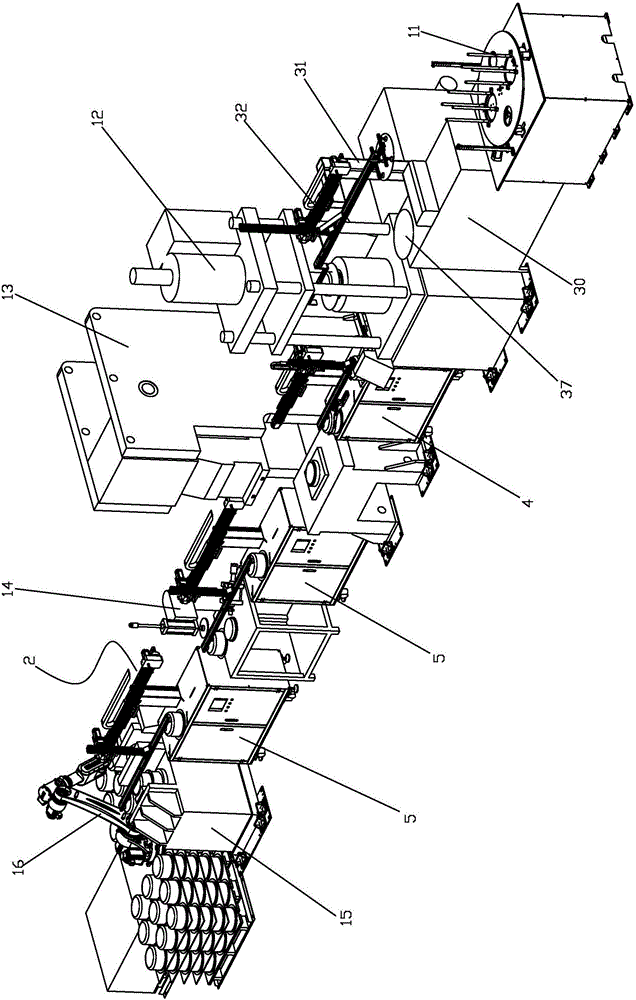

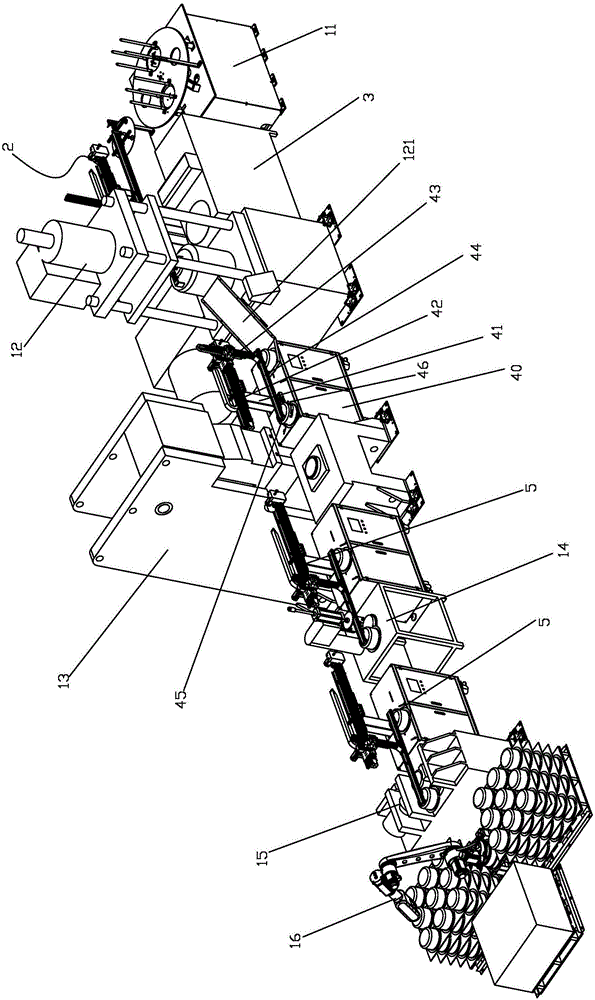

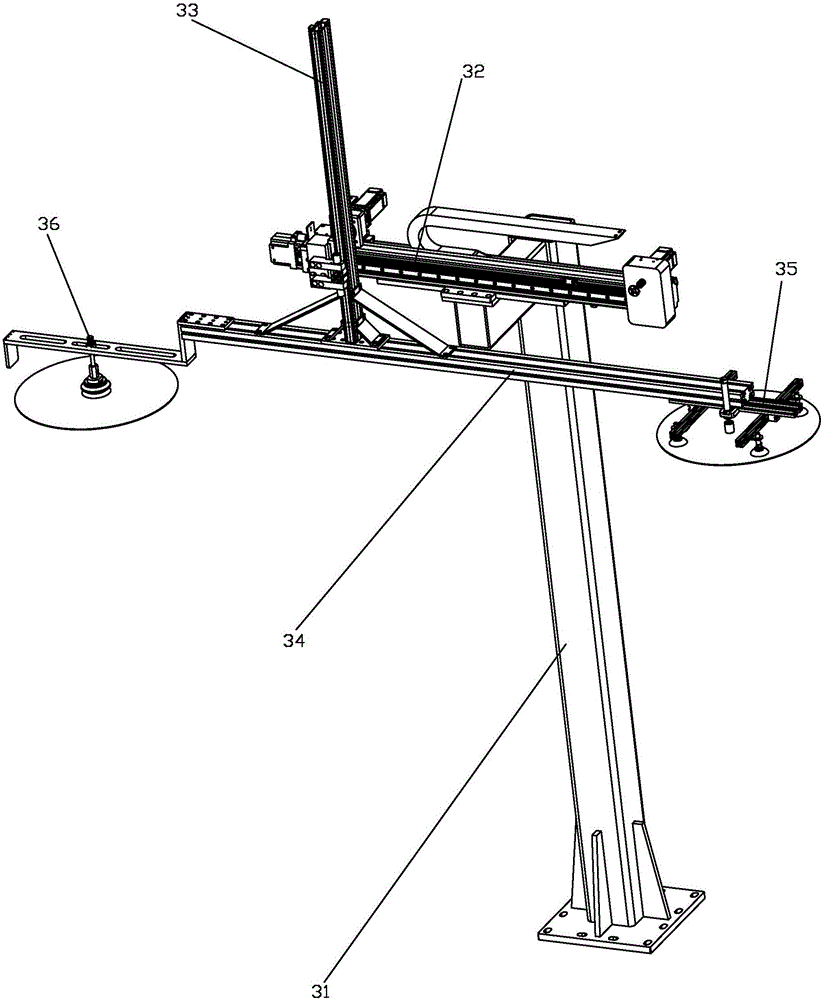

Full-automatic intelligent punching production system based on remote control

InactiveCN105834291AControllable production speedReduce the quantity in processMetal-working feeding devicesOther manufacturing equipments/toolsProduction lineAutomatic train control

The invention discloses a full-automatic intelligent punching production system based on remote control. According to the technical scheme, the full-automatic intelligent punching production system is characterized by comprising an automatic feeding device, an automatic drawing molding device, an automatic edge trimming device, an automatic edge curling device, an automatic labeling device and an automatic stacking device which are arranged in sequence, and further comprising an automatic control system used for controlling the production line to operate in a remote mode. The automatic control system comprises a first pushing robot, a second pushing robot and third pushing robots, wherein the first pushing robot is arranged between the automatic feeding device and the automatic drawing molding device and used for automatically transferring and pushing semi-finished products; the second pushing robot is arranged between the automatic drawing molding device and the automatic edge trimming device; and the third pushing robots are arranged between the automatic edge trimming device and the automatic edge curling device and between the automatic edge curling device and the automatic labeling device. According to the full-automatic intelligent punching production system based on remote control, unmanned automated operation can be realized in all manufacture procedures, the semi-finished products can be transferred automatically between the manufacture procedures, and therefore automatic production is achieved in a real sense.

Owner:GUANGDONG CLAW ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com