Pressure type air flotation separation device

An air flotation separation and pressure technology, which is applied in liquid separation, separation methods, grease/oily substance/float removal devices, etc. Oil-water separation efficiency and other issues, to avoid the leakage of harmful gases, improve the oil-water separation effect, and stabilize the oil-water separation interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

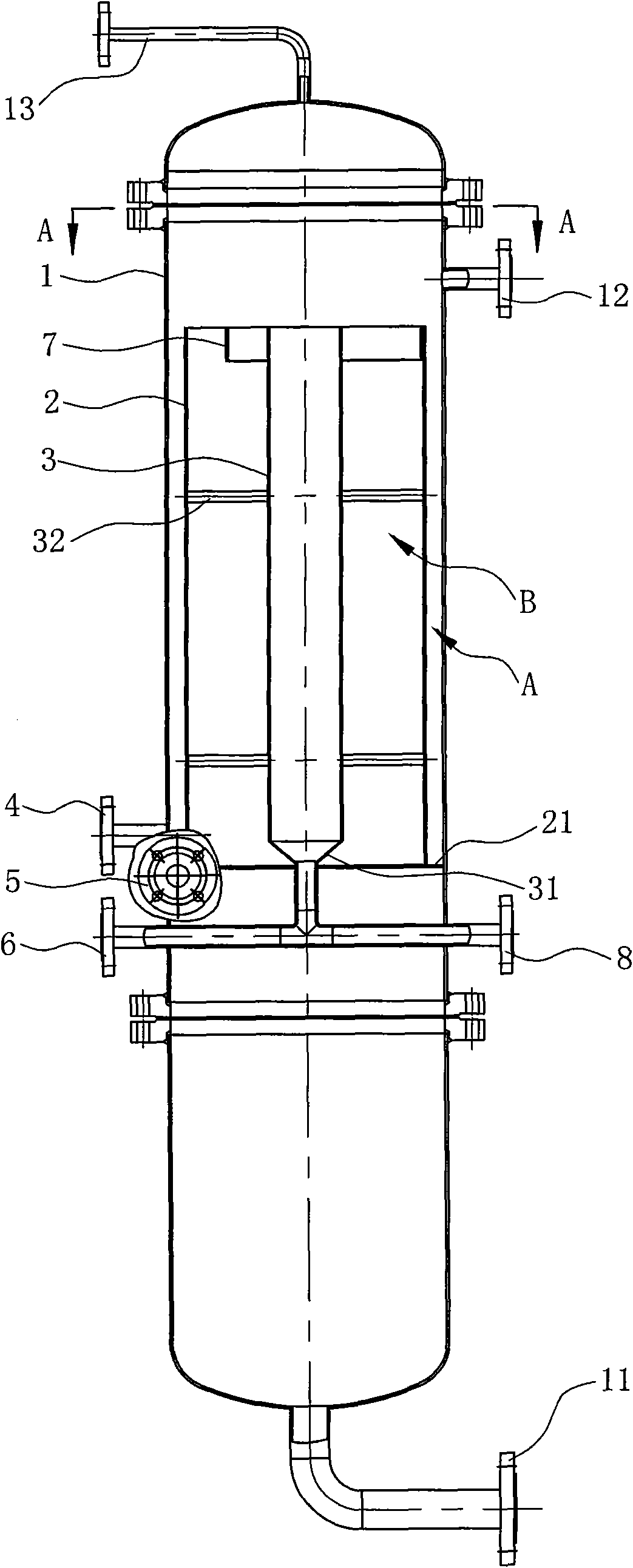

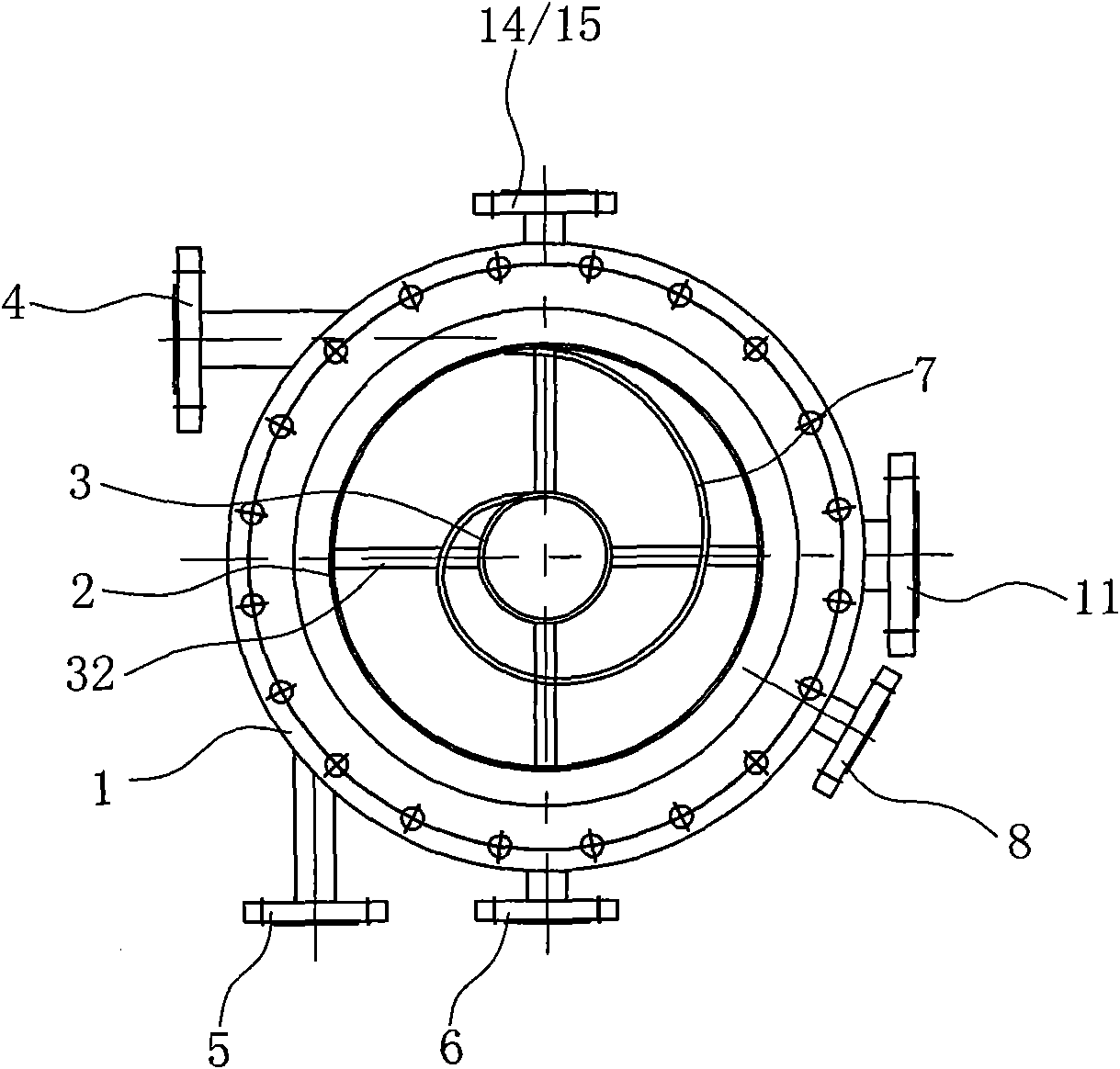

[0034] Such as figure 1 , figure 2 As shown, the pressure type air flotation separation device includes a tank body 1, a bubble rectifier 2 and an oil receiver 3 arranged in the tank body 1;

[0035] Wherein, the oil receiver 3 is a cylindrical cylinder with a funnel-shaped bottom 31, fixed to the air flotation rectifier 2 by two sets of divergent and evenly distributed fixing rods 32 arranged on the periphery of the oil receiver 3, The bubble rectifier 2 is sleeved outside the oil receiver 3, and an annular bottom plate 21 is arranged between the bottom of the bubble rectifier 2 and the inner wall of the tank body 1, so that the bubble rectifier 2 and the tank body 1 are fixed and the oil is collected. The cylinder 3 and the bubble rectifier cylinder 2 are fixed relative to the tank body 1 and arranged coaxially with the tank body 1;

[0036] A bubble rectifying area A with a closed bottom is formed between the outer wall of the bubble rectifying cylinder 2 and the inner w...

Embodiment 2

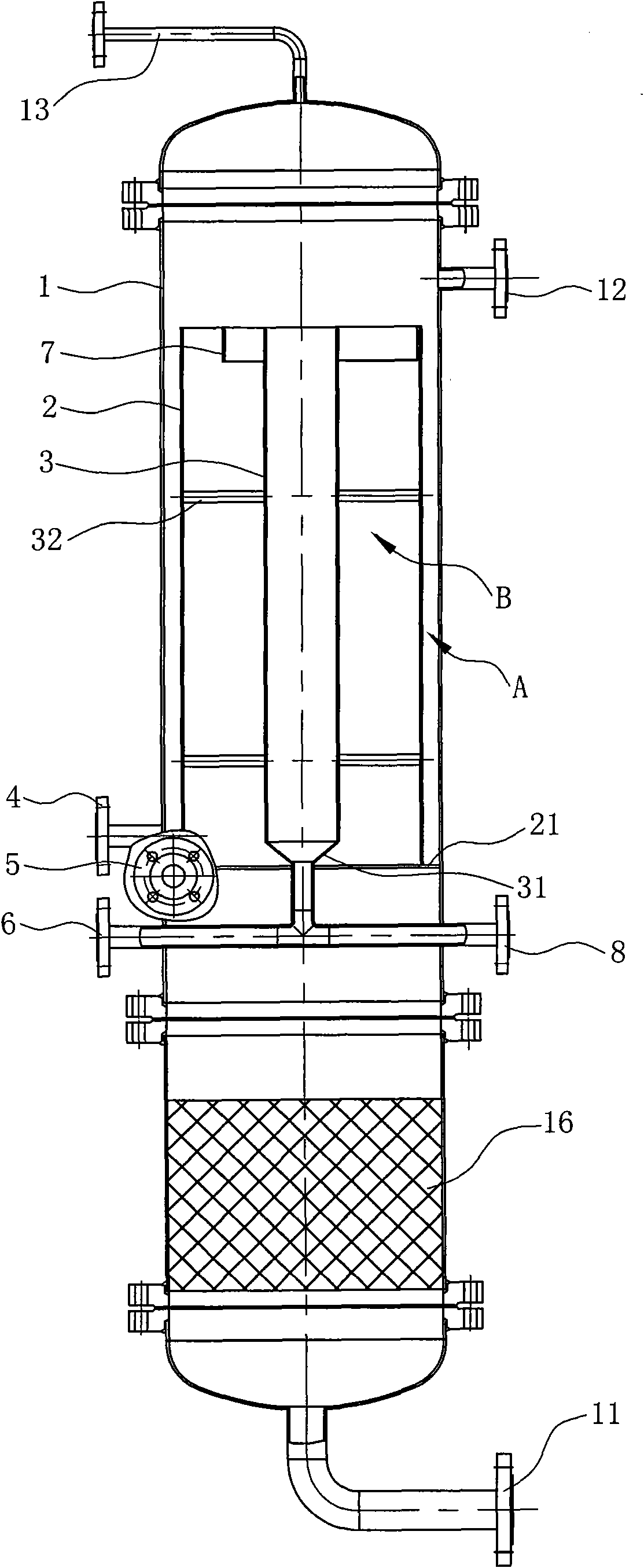

[0047] Such as image 3 As shown, the difference between the second embodiment of the present invention and the first embodiment is that a packing layer 16 is arranged in the tank body 1 below the air bubble rectifier 2, and the oil droplets are captured by the entrapment and adsorption effect of the packing layer 16. , which greatly simplifies the oil removal process and can complete the intensive treatment of oily water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com