Portable temperature-equalizing type spraying cooling circulating system for high-power electronic component

A technology of spray cooling and electronic components, which is applied in the field of portable uniform temperature spray cooling circulation system of high-power electronic components, can solve the problems of high refrigeration efficiency, residual liquid shortage, etc., achieve high refrigeration efficiency, stable temperature control, and enhance practical application performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

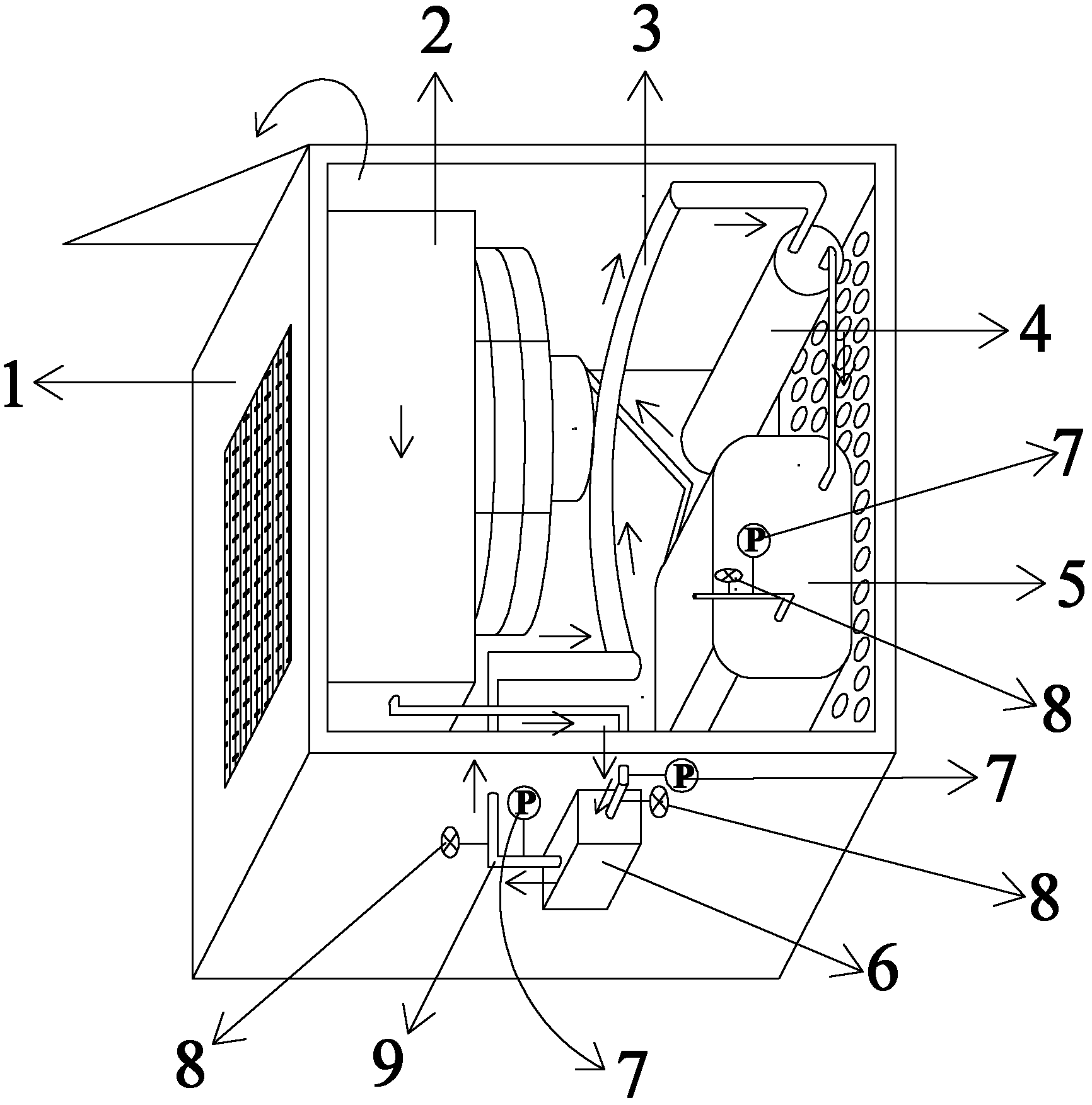

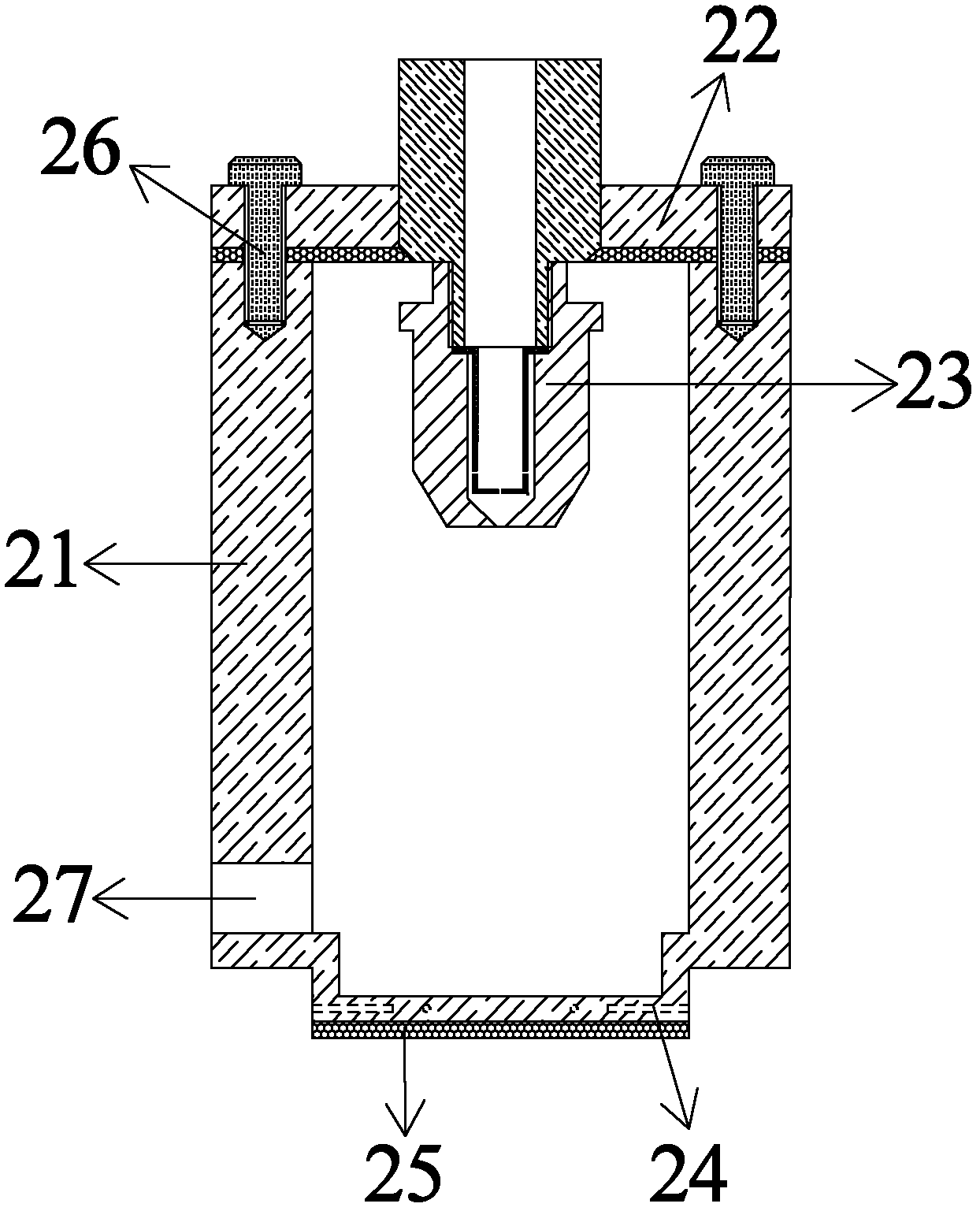

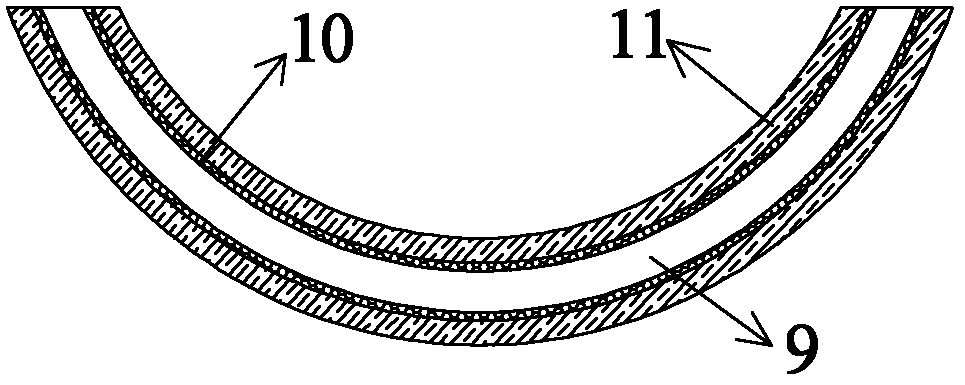

[0015] see Figure 1 to Figure 3 , high-power electronic components portable uniform temperature spray cooling circulation system, consisting of shell 1, air condenser 2, auxiliary heat device 3, gas-liquid separator 4, compressor 5, spray cooler 6 and pressure gauge 7, valve 8 and The fluid delivery pipeline 9 is formed, and the device 25 to be cooled is fixed on the spray cooler 6 and sealed with a sealant; the outlet of the compressor 5 is connected to the inlet of the air condenser 2 through a connecting pipe, and the outlet of the air condenser 2 is connected through a connecting pipe It is connected with the inlet of the spray cooler 6; the outlet of the spray cooler 6 is connected with the inlet of the gas-liquid separator 4 through a fluid delivery pipeline 9, and the auxiliary heat is provided on the fluid delivery pipeline 9 In the device 3, the outlet of the gas-liquid separator 4 is connected to the inlet of the compressor 5 through a connecting pipe; the spray coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com