Sand aerated concrete impervious building blocks

A technology for aeration of concrete and sand, used in climate sustainability, sustainable waste treatment, solid waste management, etc. artificial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A sand air-entrained concrete anti-seepage block, each component includes the following formula in weight percentage:

[0037] Ground Quartz Sand 46%

[0038] Circulating Mortar 18%

[0039] Cement 21.52%

[0040] Lime 11%

[0041] Gypsum 3%

[0042] Aluminum powder 0.08%

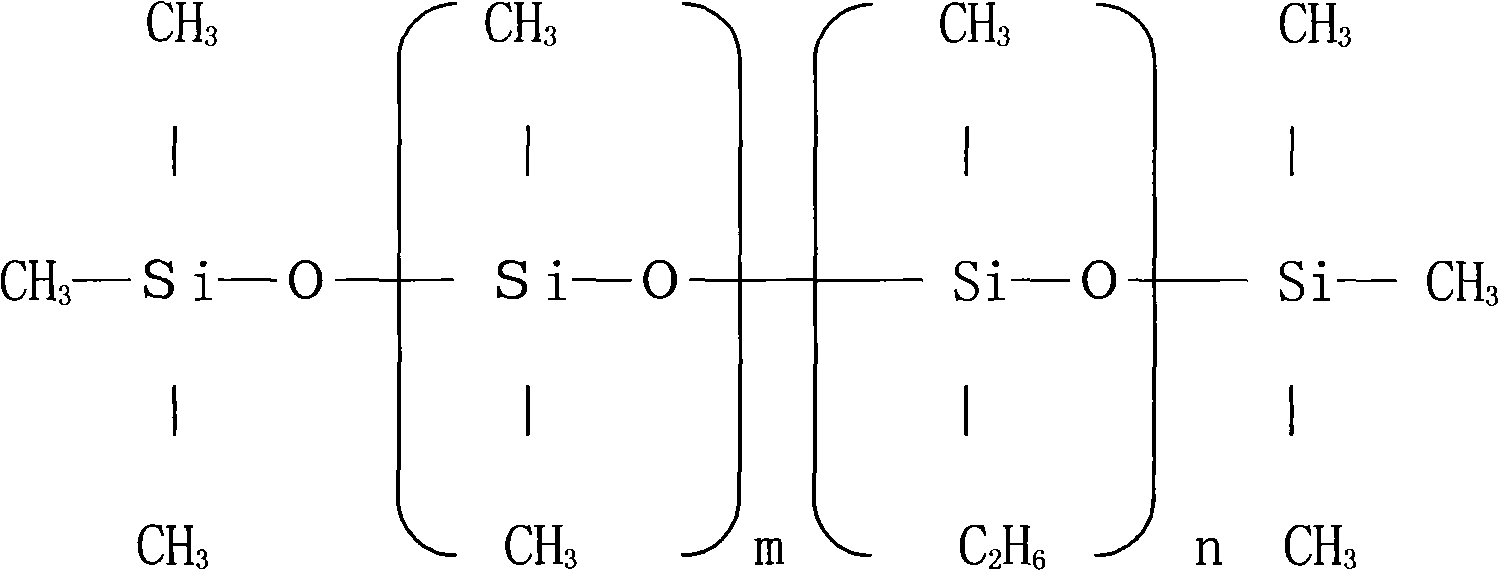

[0043] Hydrophobic water repellent 0.4%.

[0044] The preparation method is as follows: according to the formula, each component is mixed and batched, stirred, statically stopped (including gas generation and hydration process, about 2.5 to 3.5 hours), cutting (including mold turning, six-sided cutting process, specifically, after cutting When using steel wire rope and cutter to cut six sides of the embryo body, the notch and shape of the product can be formed at the same time, so that the shape and size are more accurate, and the surface of the product will not produce oil stains), at a high temperature of 180-200 °C, a high pressure of 10-12 Curing under standard atmospheric pressure for 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com