Patents

Literature

64results about How to "Solve the impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel-structure-use nuclear-radiation-resistant paint

InactiveCN102850910AImprove radiation resistanceGuaranteed service lifeEpoxy resin coatingsEpoxyNuclear radiation

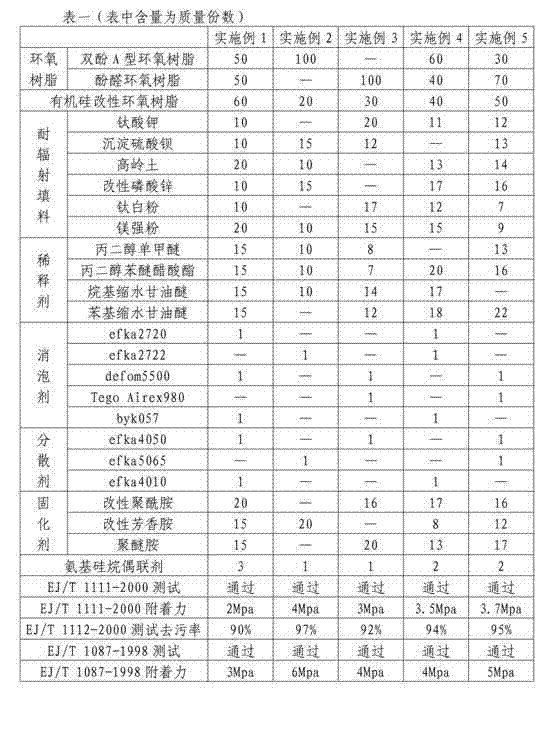

The invention discloses a steel-structure-use nuclear-radiation-resistant paint which is characterized in that the paint comprises main agents, a curing agent, and a coupling agent. The main agents comprise epoxy resin, organosilicon modified epoxy resin, a radiation-resistant filling agent, a diluting agent, and a processing auxiliary agent. The paint is prepared from the components of, by mass: 100 parts of epoxy resin, 20-60 parts of organosilicon modified epoxy resin, 50-80 parts of radiation-resistant filling agent, 30-60 parts of the diluting agent, 2-5 parts of the processing auxiliary agent, 25-50 parts of the curing agent, and 1-3 parts of the coupling agent. A mass percentage ratio of the main agents to the curing agent is 6-11:1. The steel-structure-use nuclear-radiation-resistant paint provided by the invention has excellent radiation resistance and decontamination property. The paint does not precipitate environment-polluting harmful substances.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

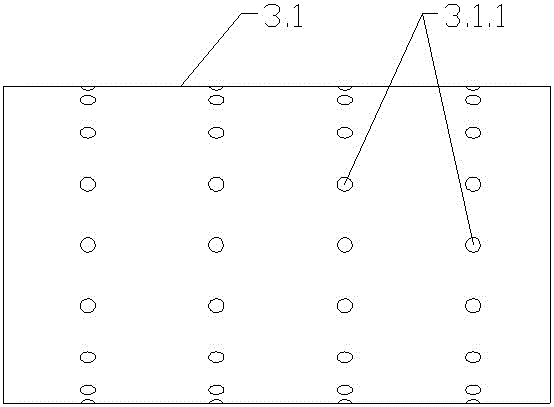

Sand aerated concrete impervious building blocks

InactiveCN101323513ASave materialLabor savingConstruction materialSolid waste managementFoaming agentAtmospheric pressure

The invention relates to a sand-air impervious concrete masonry block adopting thin quartz sand, cement, lime and gypsum as main base materials and adopting aluminum powder as foaming agent; wherein, the sand-air impervious concrete block comprises a hydrophobic waterproof agent which occupies 0.02 to 0.40 percent of the total amount according to the weight percentage. The preparation method comprises the steps as follows: the components are mixed to form a mixture according to the formulation, and then the mixture is stirred, settled, cut and later maintained for 10 to 12 hours under high temperature of 180 to 200 DEG C and high pressure of 10 to 12 standard atmospheric pressures so as to obtain the sand-air impervious concrete masonry block. The invention has the advantage that a certain proportion impervious materials are added into the material of the masonry block so as to manufacture the masonry block provided with the impervious capability; after the masonry block is adopted as the single material for walling, then the block is provided impervious capability after walling by the block. The sand-air impervious concrete masonry block can be regarded as the novel walling material without adopting the waterproof material to reach the waterproof and impervious requirement.

Owner:上海伊通有限公司

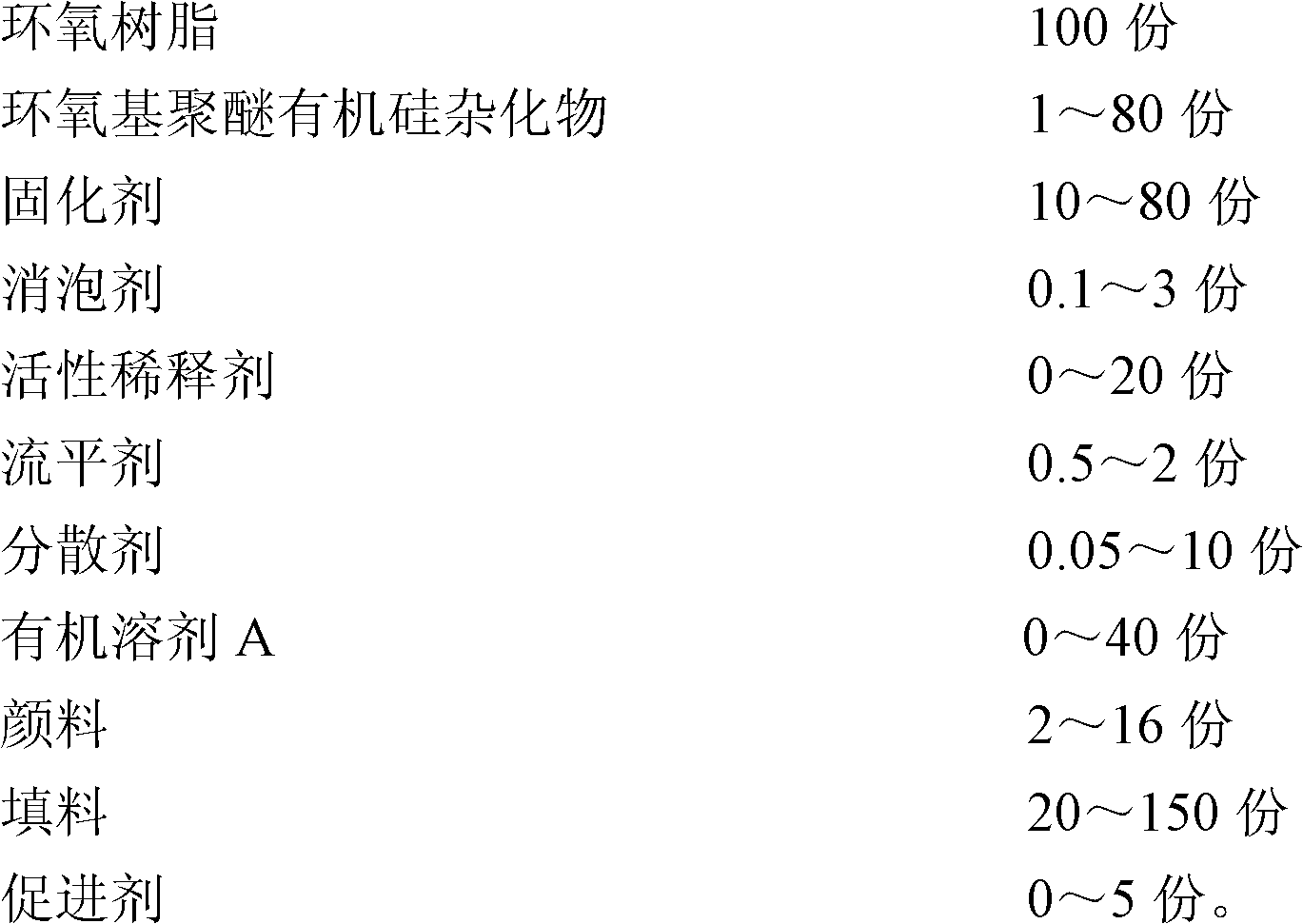

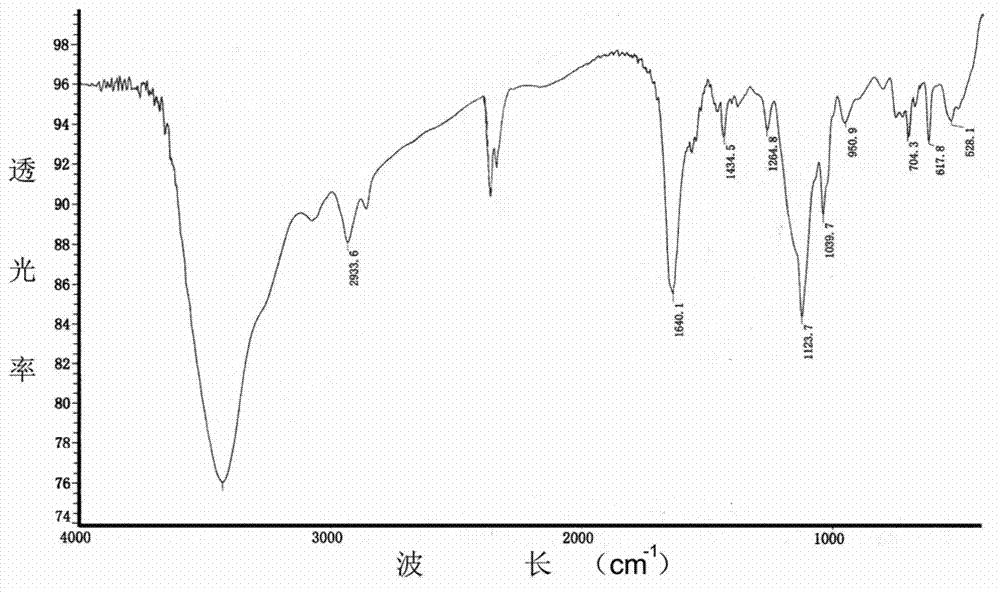

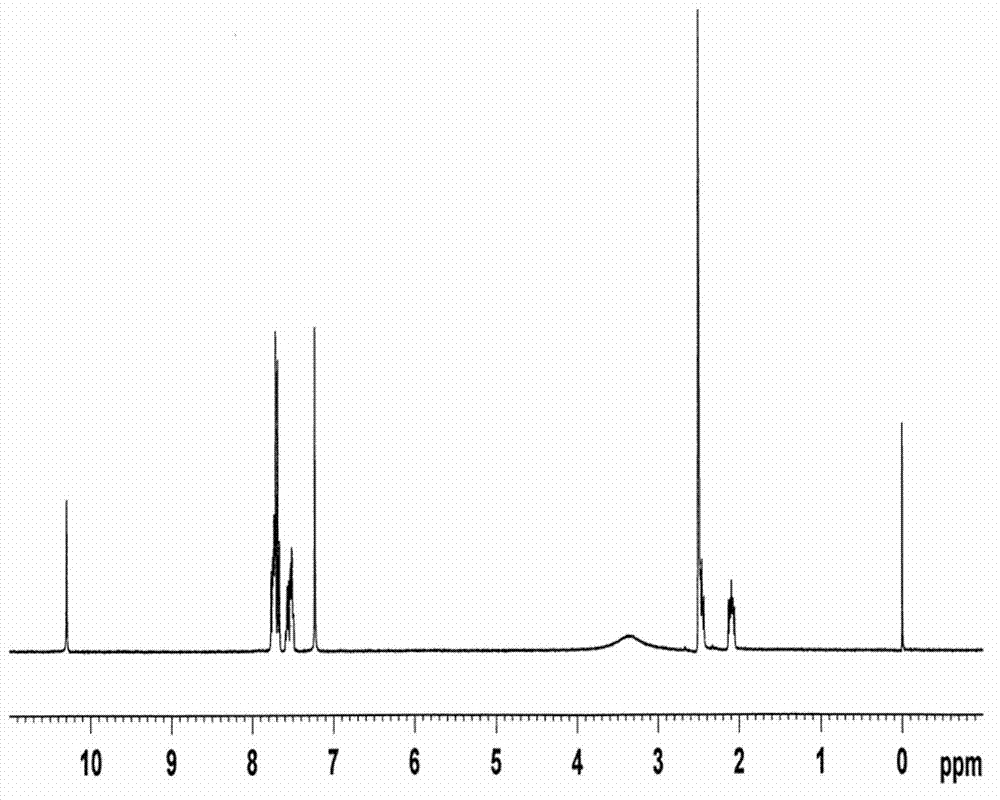

Epoxy floor coating containing epoxy polyether organosilicon hybrid and preparation method thereof

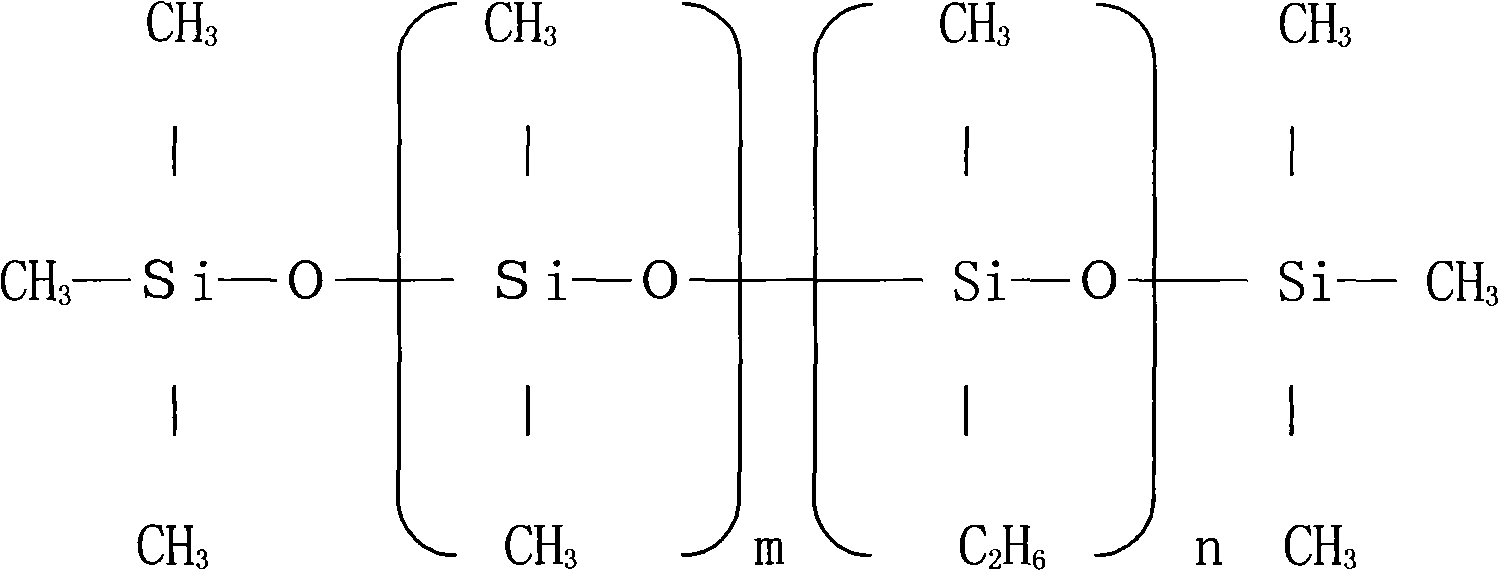

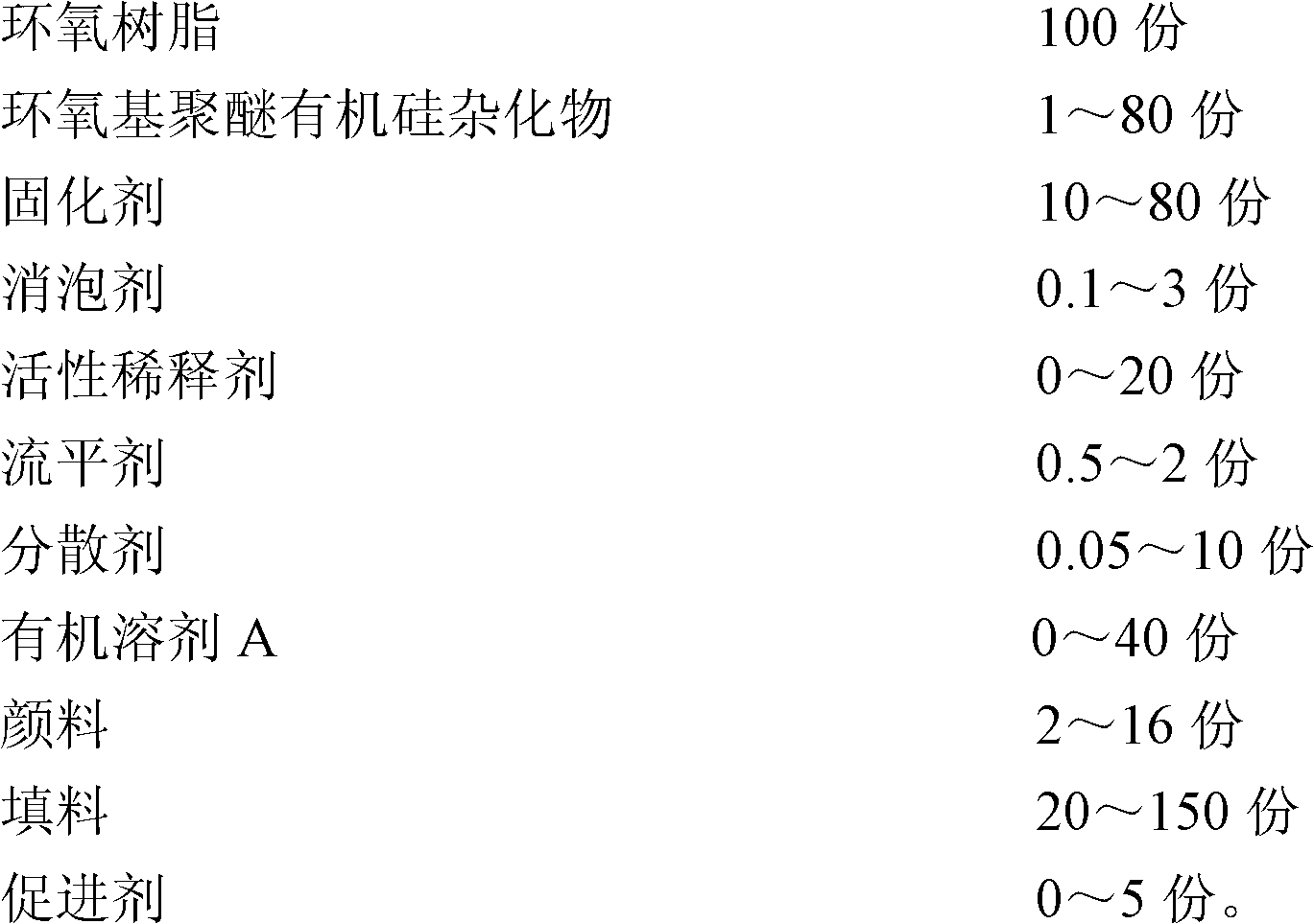

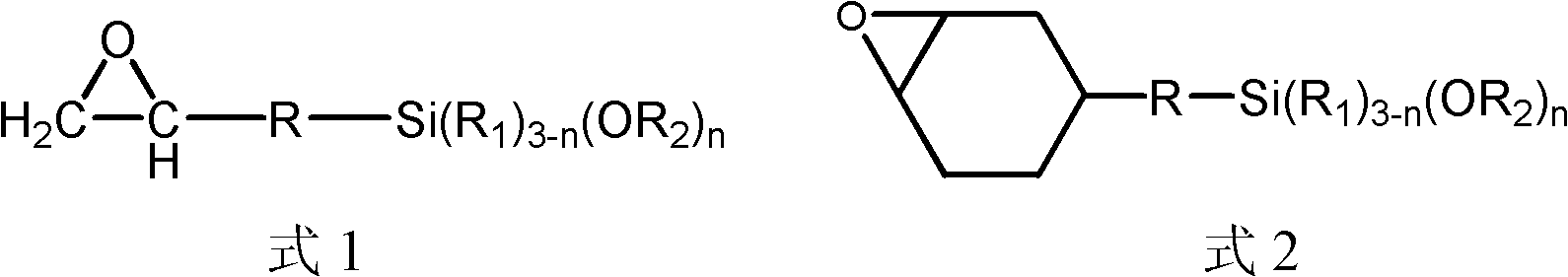

The invention discloses an epoxy floor coating containing epoxy polyether organosilicon hybrid and a preparation method thereof, belonging to the field of building materials. According to the method, the epoxy polyether organosilicon hybrid is prepared through hydrolytic polycondensation, and then 100 parts of an epoxy resin, 10 to 80 parts of a curing agent, 1 part to 80 parts of the epoxy polyether organosilicon hybrid, 0.1 part to 3 parts of an antifoaming agent, 0 to 20 parts of an active diluent, 0.5 part to 2 parts of a leveling agent, 0.05 part to 10 parts of a dispersant, 0 to 40 parts of an organic solvent, 2 to 16 parts of pigments, 20 to 150 parts of a filling material and 0 to 5 parts of a promoter are uniformly mixed so as to obtain the epoxy floor coating. Through modification by the epoxy polyether organosilicon hybrid, the epoxy floor coating provided in the invention has the following advantages compared to conventional epoxy floor coatings: a floor coated by the epoxy floor coating has a high hardness and good wear resistance, stain resistance and heat resistance; the preparation method has the advantages of a simple preparation process, easily available raw materials and convenient implementation, which enables production cost to be reduced and strong practicality to be obtained.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

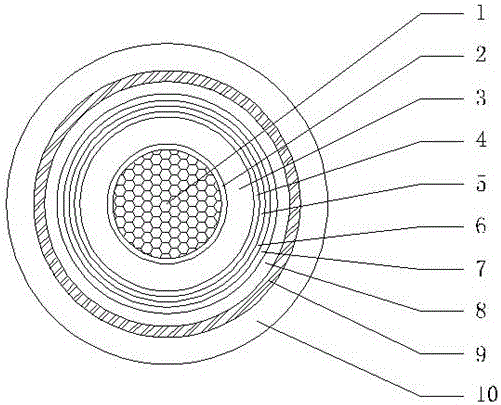

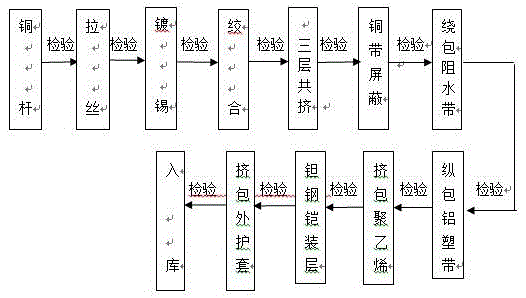

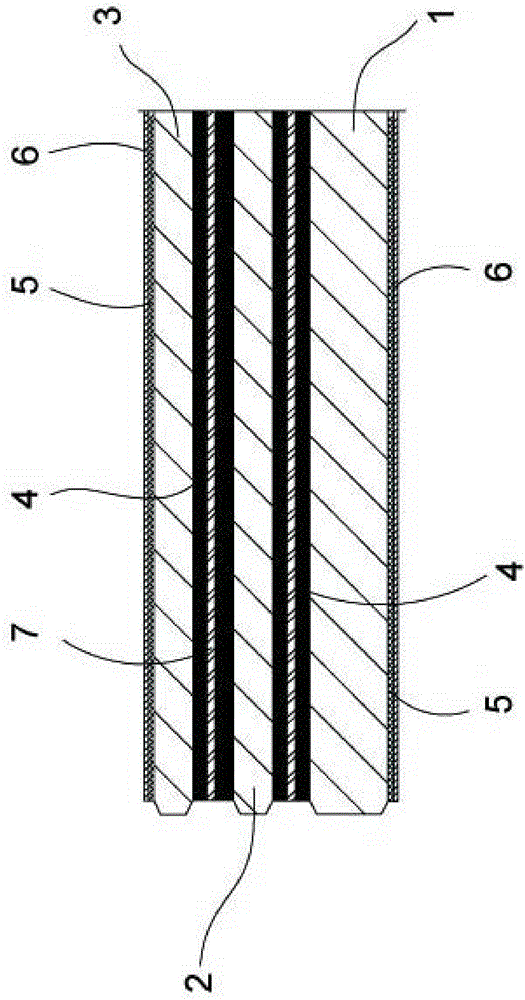

Graphene composite shielding anti-interference power cable for environment-friendly intelligent high-speed rail and fabrication method of graphene composite shielding anti-interference power cable

InactiveCN106098173AAccelerated corrosionImprove tensile propertiesPower cables with screens/conductive layersFlexible cablesCopper conductorInsulation layer

The invention discloses an environment-friendly intelligent high-speed rail graphene composite shielding anti-interference power cable and a preparation method thereof. The insulation layer and the insulation shielding layer form an insulated wire core; the outer layer of the insulating wire core is overlapped and wrapped with a metal inner shielding layer; The aluminum-plastic composite tape layer wrapped longitudinally is extruded with a polyethylene moisture barrier layer; the outer gap of the moisture barrier layer is wrapped with a double-layer tantalum steel alloy tape armor layer, and the outermost layer of the cable is extruded with an outer sheath. The invention has good insulation properties, mechanical properties, power transmission, anti-magnetic interference, lightning protection, flame retardant, halogen-free, low-smoke environmental protection, waterproof, corrosion resistance, radiation resistance and other properties; the structure is reasonable, the comprehensive performance is superior, and the product The performance index is superior to the requirements of international standards; and can produce good social and economic benefits.

Owner:WUXI CITY HENG HUI CABLE

Silicon micropowder reinforced polyethylene material and preparation method thereof

InactiveCN103642113ASolve poor tensile strength and impact resistanceSimple production methodSurface modificationContinuous production

The invention discloses a silicon micropowder reinforced polyethylene material and a preparation method thereof. The silicon micropowder reinforced polyethylene material contains the following ingredients in parts by weight: 40-98 parts of polyethylene, 1-50 parts of silicon micropowder, 0.1-5 parts of surface modifier and 0.1-5 parts of dispersant. According to the method, the silicon micropowder is mixed with polyethylene after the silicon micropowder is subjected to surface modification, the dispersant is added during mixing, and melt-extrusion granulation is carried out under the condition that the screw revolution rate and extrusion temperature of an extruder are set, so that a silicon micropowder modified polyethylene master batch with excellent performance is obtained. According to the silicon micropowder reinforced polyethylene material and the preparation method thereof, the disadvantages that the tensile strength and impact resistance of polyethylene are poor and the like can be effectively solved, the creep resistance and heat resistance of a polyethylene material are improved, and the comprehensive performance of a silicon micropowder modified polyethylene composite material is excellent, so that continuous production can be carried out.

Owner:GUIZHOU LANTU NEW MATERIALS

Fiber reinforced artificial stone tomb box and its manufacturing method

InactiveCN1776163AWide variety of sourcesImpact resistantUrnsCeramic shaping apparatusSuperplasticizerSlurry

This invention relates to a fiber reinforced artificial stone tomb box and making method, which contains fiber reinforced artificial stone made box unit with cavity and box cover with lower convex edge engaged with upper edge of box unit. The method contains mixing and agitating raw material into slurry, laying fiber net fabric in mold, putting slurry in mold, by molding, maintenance, stripping, repairing, finishing, spraying surface treating liquid to get products, raw material ratio is 30-60 part of cement, 40-65 part of fine aggregate, 1-4 part fiber filament, 1-8 part of anti-cracking permeability-reducing admixture, 0.2-1 part of superplasticizer, 1-5 part of silicate intensifier, 0-4 part of surface treating liquid, 0-0.5 part antifoaming agent and 0-0.5 part of paint. Said invention has advantages of fine anti-impact ability and impermeability, high strength, fine outline and low cost.

Owner:张正锋

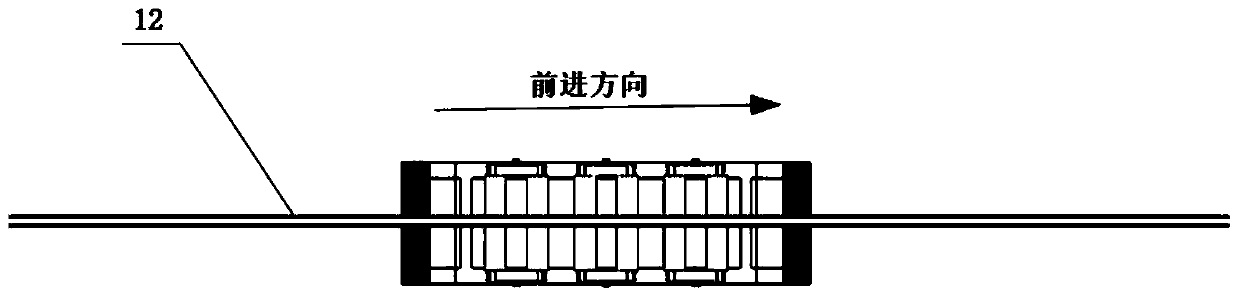

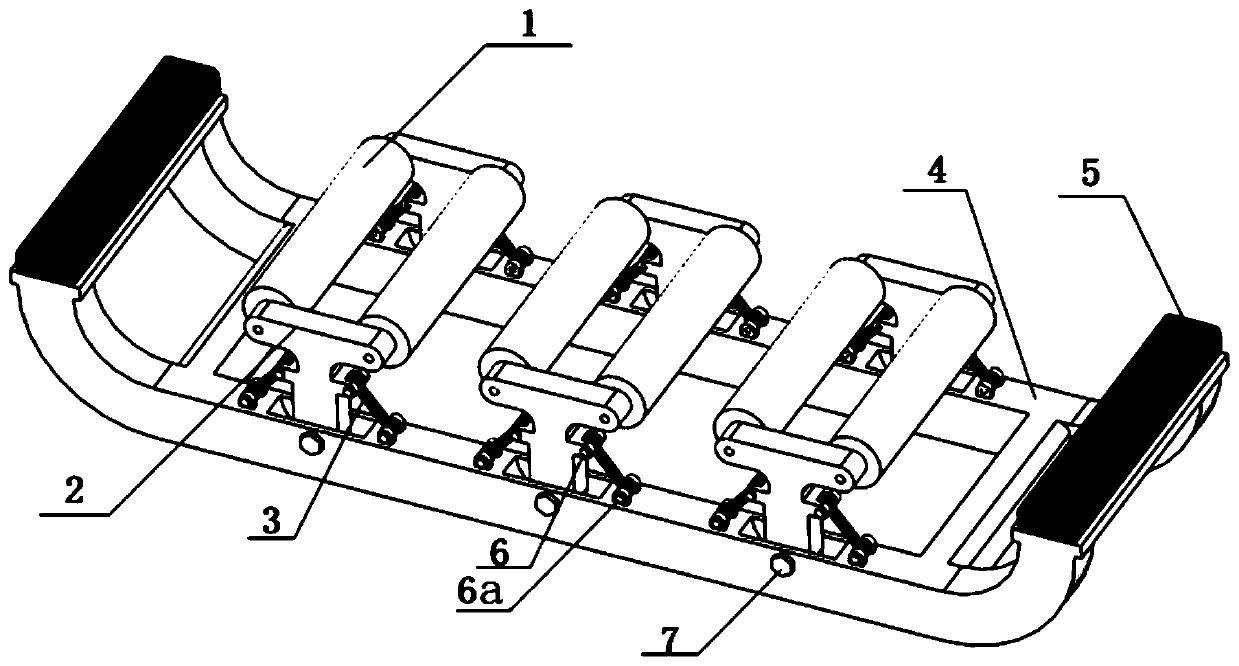

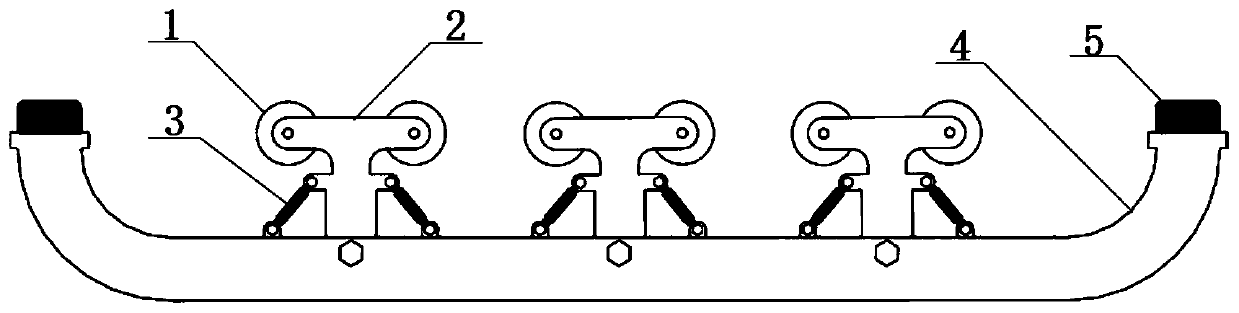

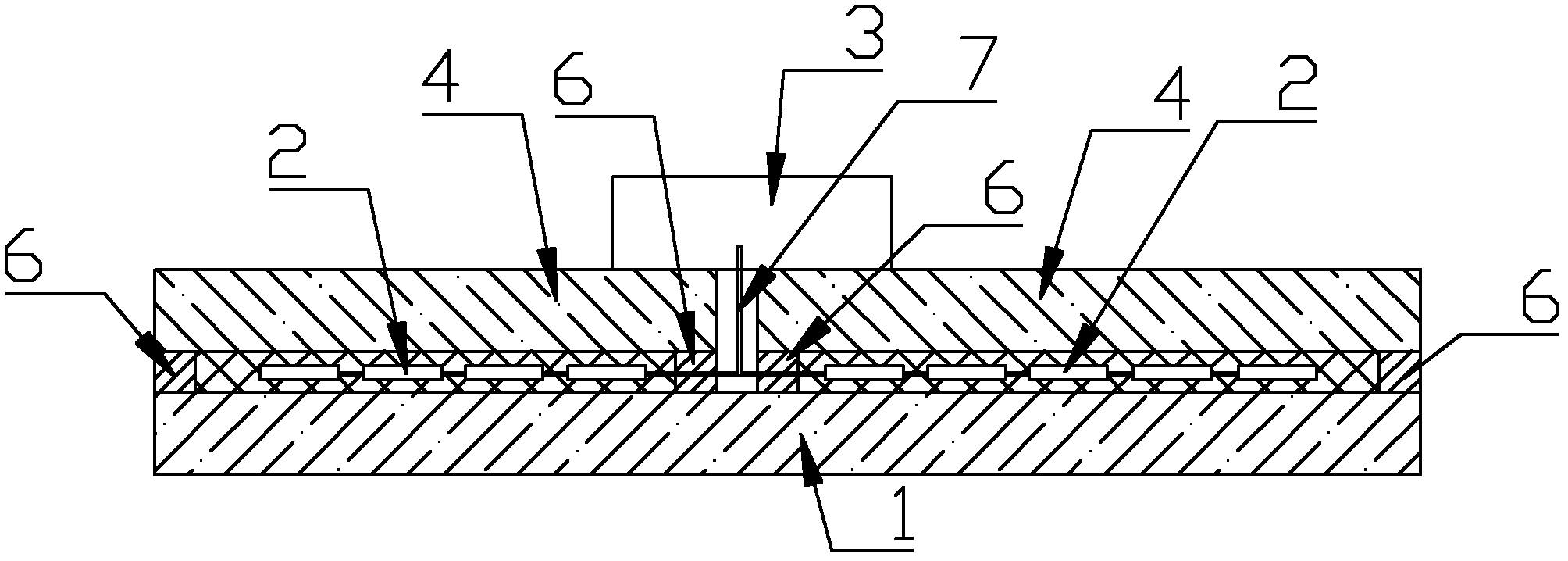

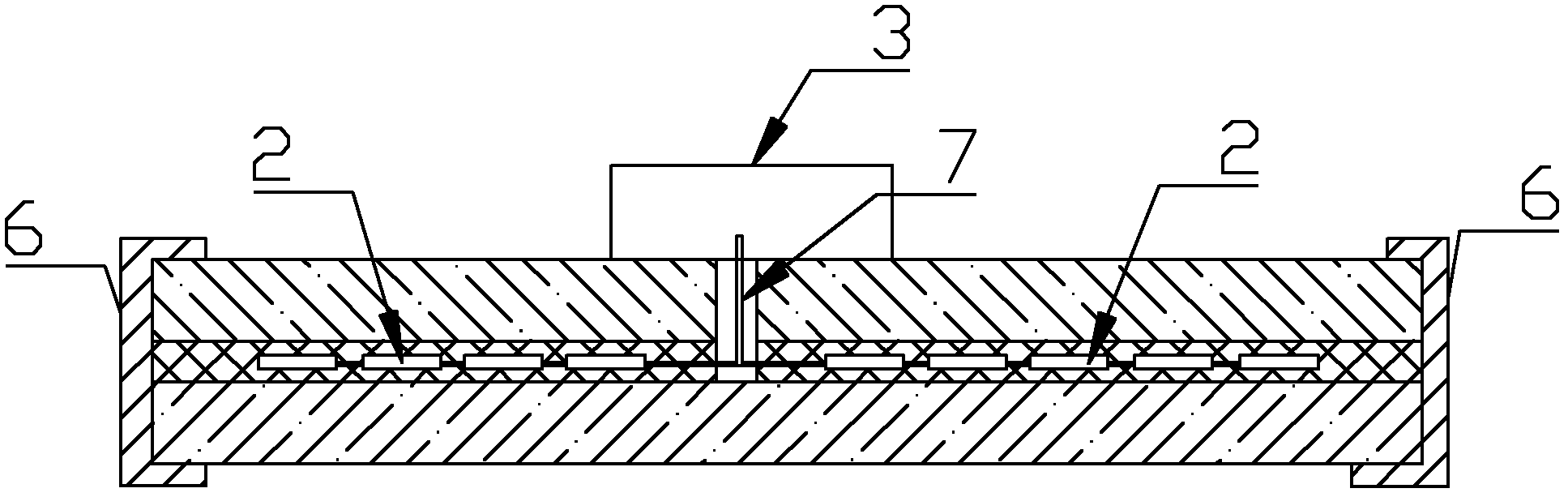

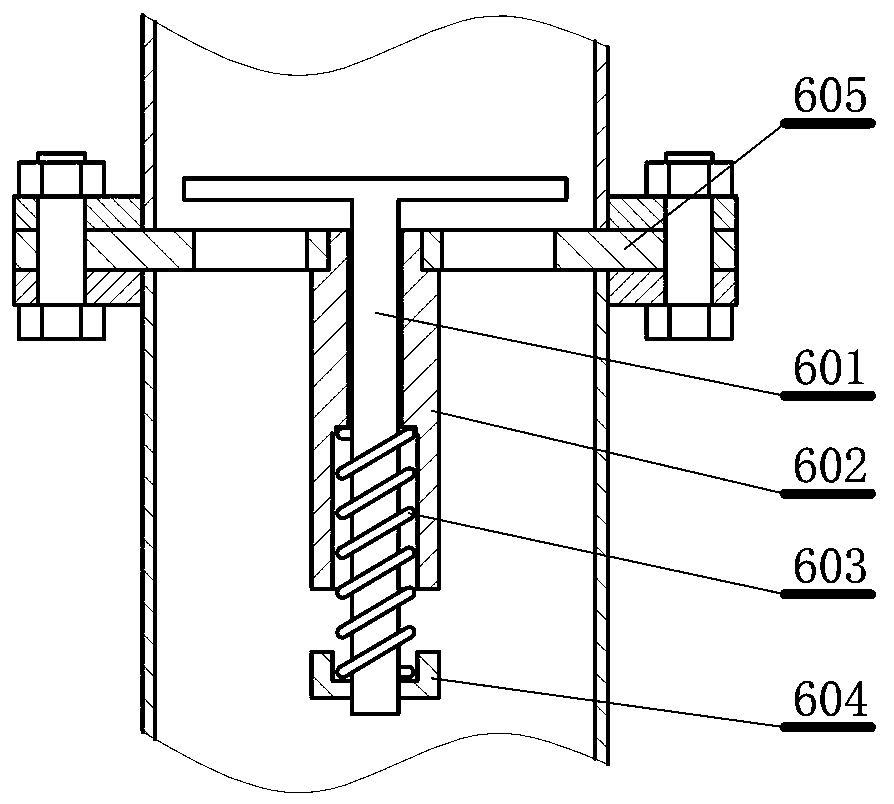

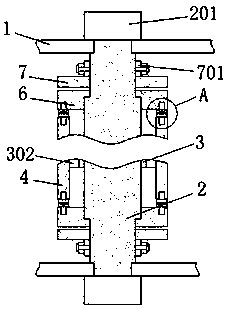

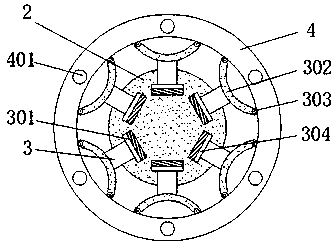

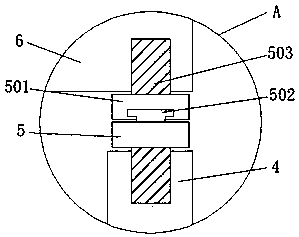

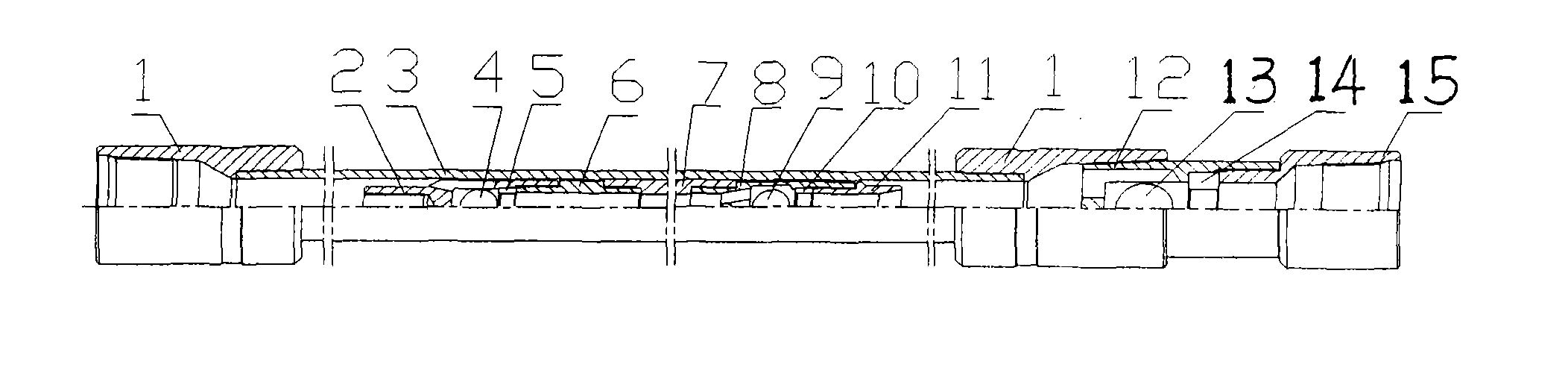

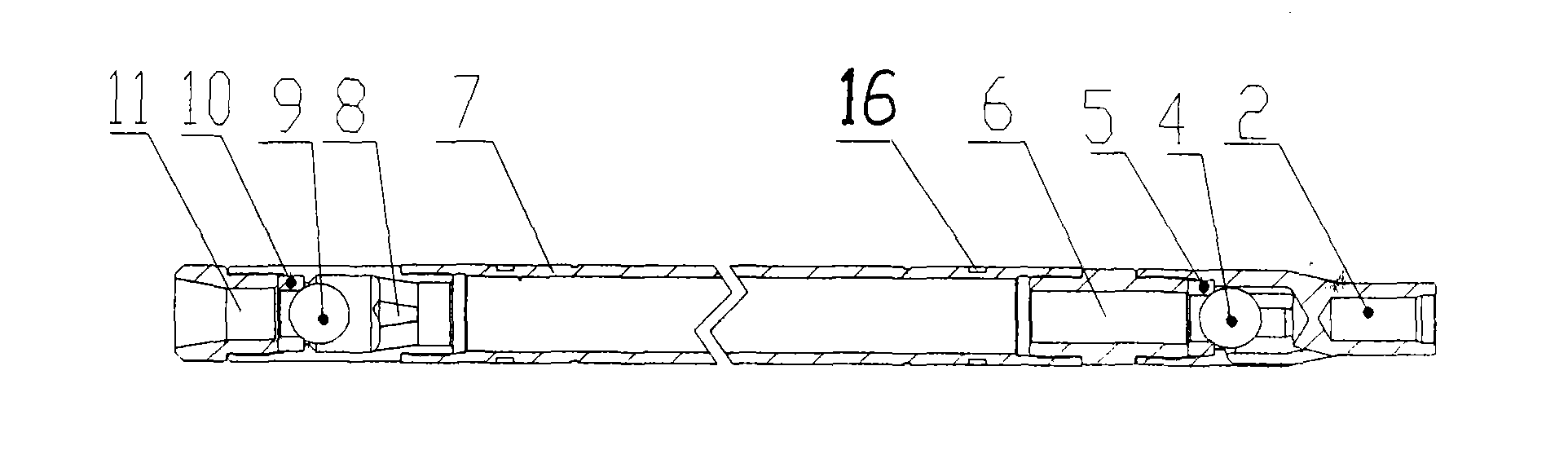

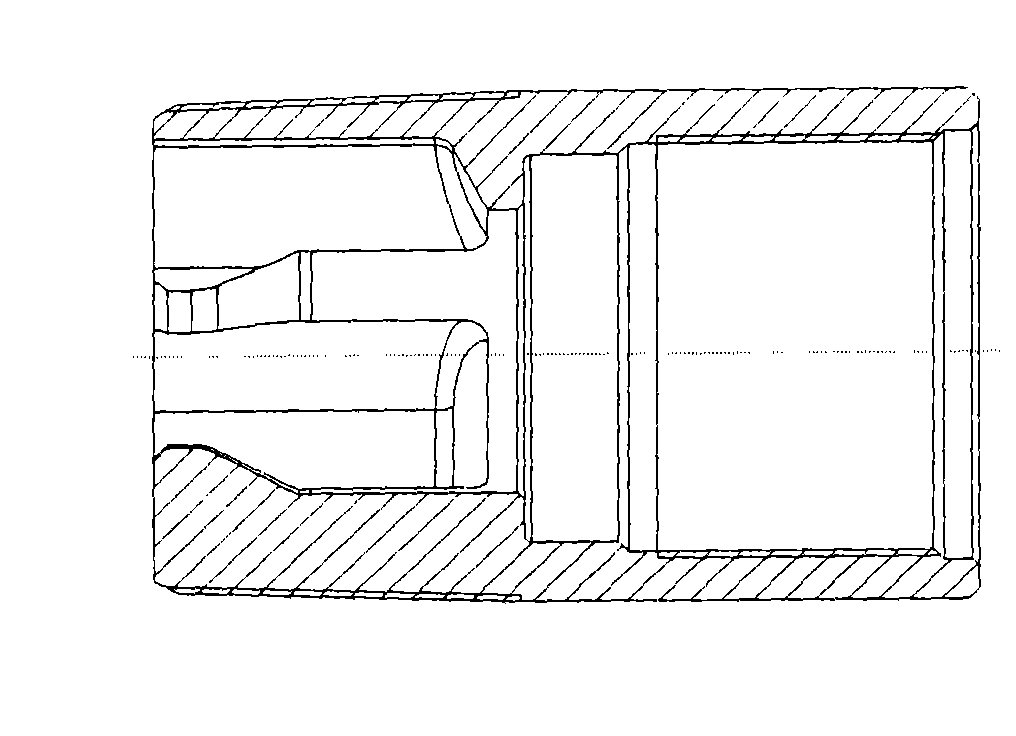

Self-lubricating modular metal roller electric locomotive pantograph head with damping structure

PendingCN110303891AHigh impact and wear resistanceImprove wear resistancePower current collectorsElectricityEngineering

The invention provides a self-lubricating modular metal roller electric locomotive pantograph head with a damping structure. Pure carbon sliding plates are arranged on the two upper end surfaces of aU-shaped insulating base, and more than one group of metal rollers are arranged on the horizontal bottom plate of the base; the setting mode of each group of metal rollers is as follows: the lower parts of every two T-shaped insulating supports extend into grooves of a horizontal bottom plate respectively, and are arranged on fixing bolts which are screwed into the outer side of the horizontal bottom plate through holes in the horizontal bottom plate, spring damping mechanisms are symmetrically arranged on the left side and the right side of each insulating support, and the two metal rollers are arranged between the two supports through fixing shafts; and the structure of the metal rollers are is characterized in that the metal cylinders sleeve the metal shafts through insulating bearings,annular current-receiving electric brushes are fixed on the metal shafts, and the outer surfaces of the annular current-receiving electric brushes are in contact with the inner walls of the metal rollers. The self-lubricating modular metal roller electric locomotive pantograph head has the self-lubricating effect, is in flexible contact with an arch net and forms rolling friction fit, and has thecharacteristics of being capable of adapting to requirements of traction power of a train, being longer in service life and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Corrugated guardrail plate

InactiveCN102535334AImprove impact resistanceImprove buffering effectFencingBridge structural detailsManufacturing technologyHigh probability

The invention discloses a corrugated guardrail plate comprising a baseplate fixedly connected with an obstruction block or a standing column, wherein corrugated plates respectively extend out of two sides of the baseplate; the baseplate is integrated with the corrugated plates; the corrugated plates protrude to the same side of the plate face of the baseplate and exceed the plate face of the baseplate; a smooth transition is adopted between the baseplate and each corrugated plate; both the baseplate and the corrugated plates extend in the length direction of the guardrail plate and are thermoplastic composite plates; and each thermoplastic composite plate comprises a reinforcing frame wrapped in a thermoplastic material layer. Aiming to overcome the defects of high probability of corrosion, high rigidity and poor collision energy absorption of a steel guardrail plate, small elastic modulus, large size and high cost of an all-plastic guardrail plate, and complex manufacturing technology and worse collision energy absorption of a plastic-steel guardrail plate, the invention provides the corrugated guardrail plate, which has the advantages of corrosion resistance and appropriately matched rigidity and flexibility and can reduce harm to a vehicle and personnel to the greatest extent.

Owner:HUNAN JINHONG TECH CO LTD

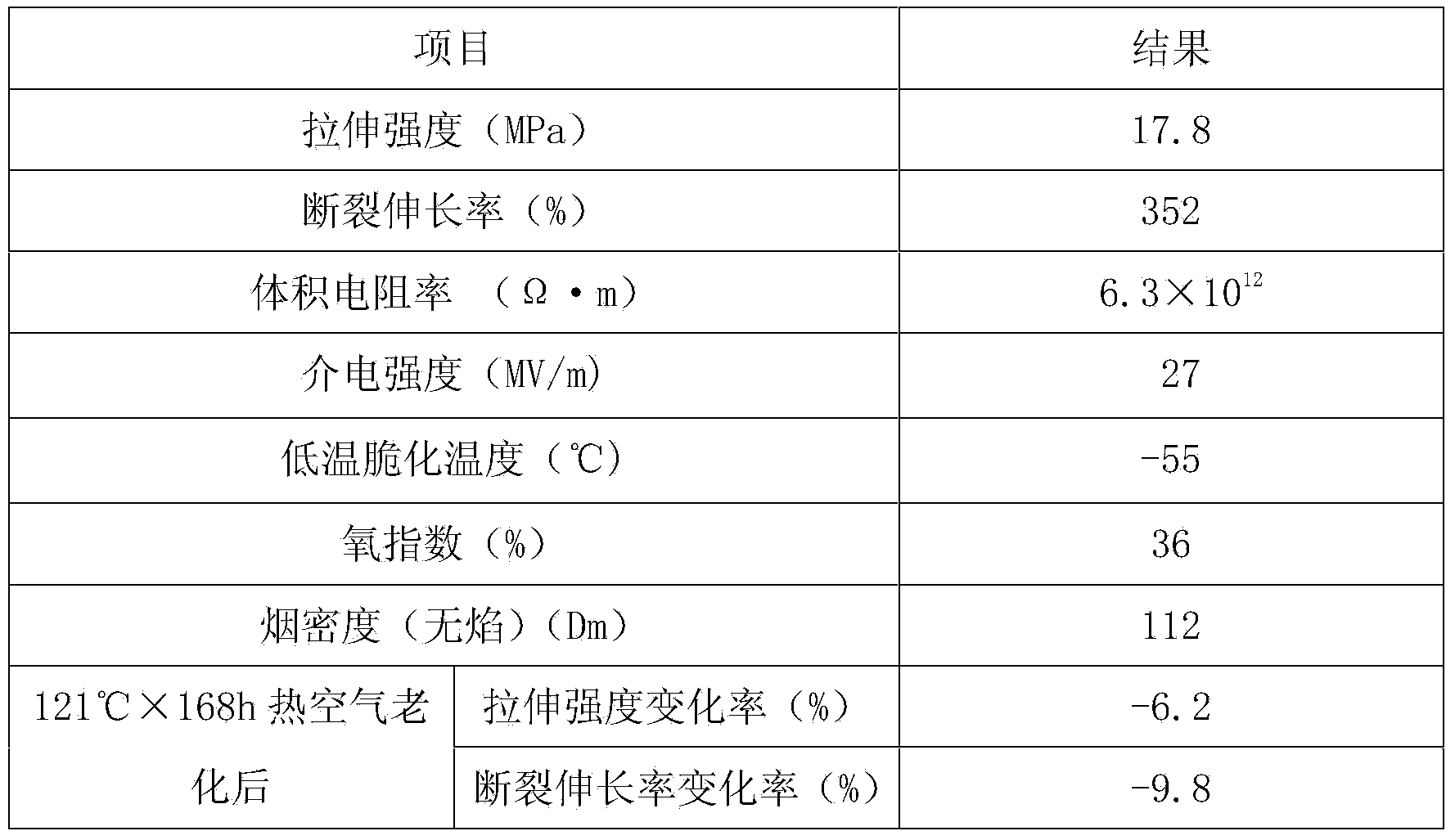

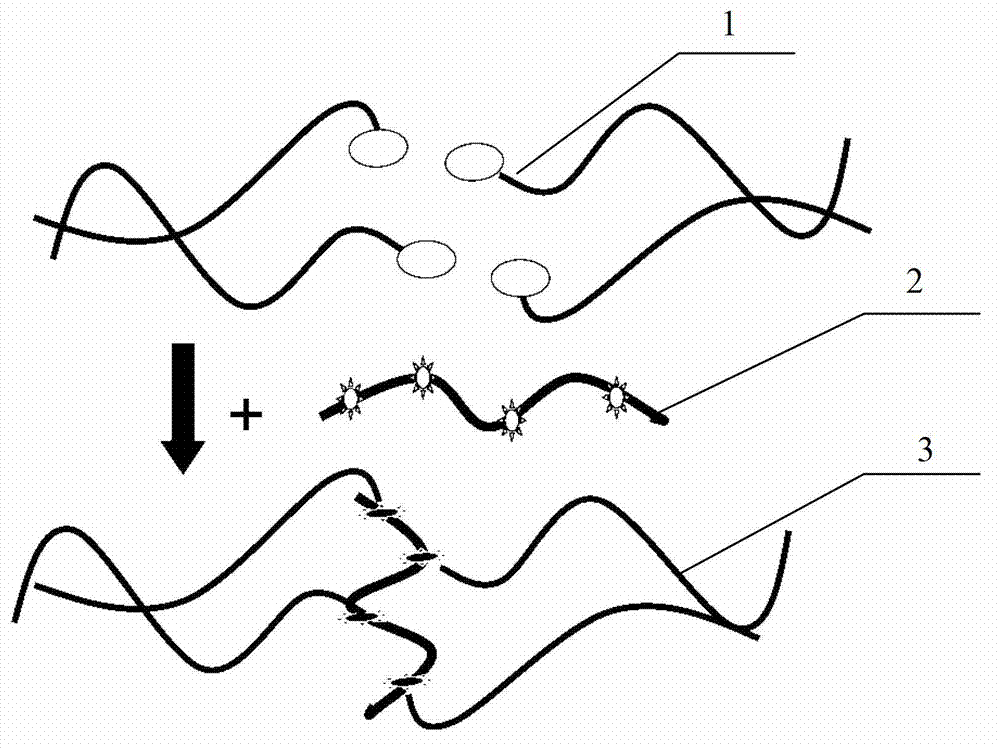

Modified polylactic acid commixture and preparation method thereof

The invention discloses a modified polylactic acid commixture which comprises the following components in parts by weight: 60-99 parts of polylactic acid, 1-40 parts of an anti-impact modifier, 0.1-5 parts of a nano physical compatibilizer, 0-60 parts of a filler, 0-2 parts of an antioxidant and 0-2 parts of anti-oxygen synergist, wherein the anti-impact modifier is at least one of an elastomer matrix polymer and a product prepped by grafting or copolymerizing the elastomer matrix polymer with functional groups. The invention further provides a preparation method of the modified polylactic acid commixture. Compared with the prior art, the modified polylactic acid commixture disclosed by the invention is capable of ensuring that other mechanical properties of polylactic acid can be at a relatively high level while the impact resistance of the polylactic acid is improved.

Owner:SHANGHAI KINGFA SCI & TECH +2

High-toughness and high-shock-resistance polyvinyl chloride cable material and preparation method thereof

The invention discloses a high-toughness and high-shock-resistance polyvinyl chloride (PVC) cable material and a preparation method thereof. The cable material is prepared by the following raw materials in parts by weight: 40-60 parts of SG-3 PVC resin, 15-25 parts of ABS (acrylonitrile-butadiene-styrene) resin, 10-15 parts of PPS (poly phenylene snlfide) resin, 4-8 parts of flexibilizer HP4051, 5-10 parts of dibutyl sebacate, 3-6 parts of dioctyl maleate, 4-8 parts of mica powder, 5-10 parts of antimony trioxide, 10-15 parts of activated calcium carbonate, 15-20 parts of carbon black N339, 4-8 parts of composite packing, 2-3 parts of stearoyl-rac-glycerol, 2-3 parts of calcium-zinc composite stabilizer, 0.5-1 part of antioxidant 1010, 1-2 parts of dicumyl peroxide, and 0.5-1 part of trimethylolpropane triacrylate. The cable material has very high shock resistance and toughness under severe conditions such as high temperature, high humidity, high cold and high voltage, solves the problems of poor shock resistance and toughness of the existing PVC cable material, and has good heat resistance, flame retardancy and dimensional stability.

Owner:JING FENG GRP

Cold resistant polyvinyl chloride cable material and preparation method thereof

The invention discloses a cold resistant polyvinyl chloride cable material and a preparation method, the cable material comprises the following raw materials by weight: 80-90 parts of SG-3 type PVC resin, 15-20 parts of fluorosilicone rubber, 10-15 parts of polytrifluorochloroethylene, 16-22 parts of dioctyl sebacate, 10-15 parts of dibutyl phthalate, 2-3 parts of lead sulfate tribasic, 1-2 parts of dibasic lead phosphate, 0.5-1 part of bisphenol A, 5-10 parts of nano kaolin, 10-15 parts of gas phase white carbon black, 8-12 parts of nano potash feldspar powder, 1-2 parts of zinc oxide, 0.5-1 part of calcium stearate, 1-2 parts of barium stearate, 2-4 parts of liquid paraffin, 12-16 parts of ammonium polyphosphate, 6-9 parts of barium metaborate and 4-6 parts of composite filling material. The cable material has excellent cold resistance, and can be normally used under low temperature of -50 DEG C--65 DEG C, the shock resistance is good, so that the problems of poor cold resistance and poor shock resistance under low temperature condition of the polyvinyl chloride cable material can be solved.

Owner:ANHUI RONGJIU OPTICAL FIBER COMM

P-N fire retardant, flame-retardant master batch, flame-retardant nylon engineering plastic and preparation method thereof

ActiveCN103087312AImprove flame retardant performanceReduce dosagePolymer scienceEngineering plastic

The invention relates to a nylon engineering plastic, particularly relates to a P-N fire retardant, a flame-retardant master batch, and a flame-retardant nylon engineering plastic. In order to solve the defects of poor fire resistance and mechanical property of the flame-retardant nylon engineering plastic in the prior art, the invention provides the P-N fire retardant, the flame-retardant master batch, the flame-retardant nylon engineering plastic and preparation methods thereof. The structural general formula of the P-N fire retardant provided by the invention is shown in the specification, wherein R1 is a benzyl or aryl functional group; R2 and R3 are alkyl or hydrogen; R4 and R5 are alkyl or hydrogen; n is greater than or equal to 2, preferably 2-6; and m represents the polymerization degree of polymer and is an integer greater than or equal to 1. The flame-retardant master batch provided by the invention comprises the fire retardant. The glass fiber reinforced flame-retardant nylon engineering plastic provided by the invention comprises the flame-retardant master batch. The fire retardant and the flame-retardant master batch provided by the invention are good in flame-retardant effect; and the provided nylon has better fire resistance and mechanical property.

Owner:NINGBO CHANGYANG TECH

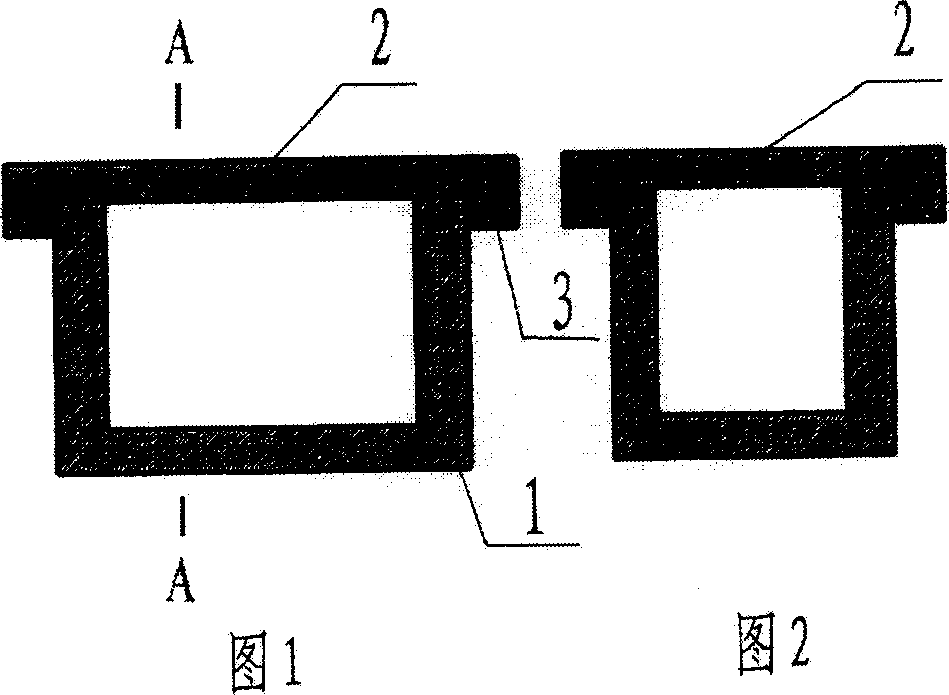

Double-glass photovoltaic module with back glass being separated

ActiveCN102637760ASolve the self-explosion problemSolve insulation problemsPhotovoltaic energy generationSemiconductor devicesStress concentrationBusbar

The invention relates to a double-glass photovoltaic module with back glass being separated, which comprises a face plate, a battery string and a back plate, wherein the battery string is packaged between the face plate and the back plate. Busbar strips of the battery string are connected with a terminal box on the back plate which is formed by integrally jointing back plate units, and the busbar strips of the battery string are led out through joints of the back plate units to be connected with the terminal box. Compared with traditional double-glass modules, the double-glass photovoltaic module has the advantages that the problems of cost increase of back perforation of the double-glass module and self-destruction of the module due to stress concentration at perforated positions can be solved, and the problem of poor impact resistance and insulating performance of the terminal box on the lateral side of the double-glass module is solved.

Owner:TRINA SOLAR CO LTD

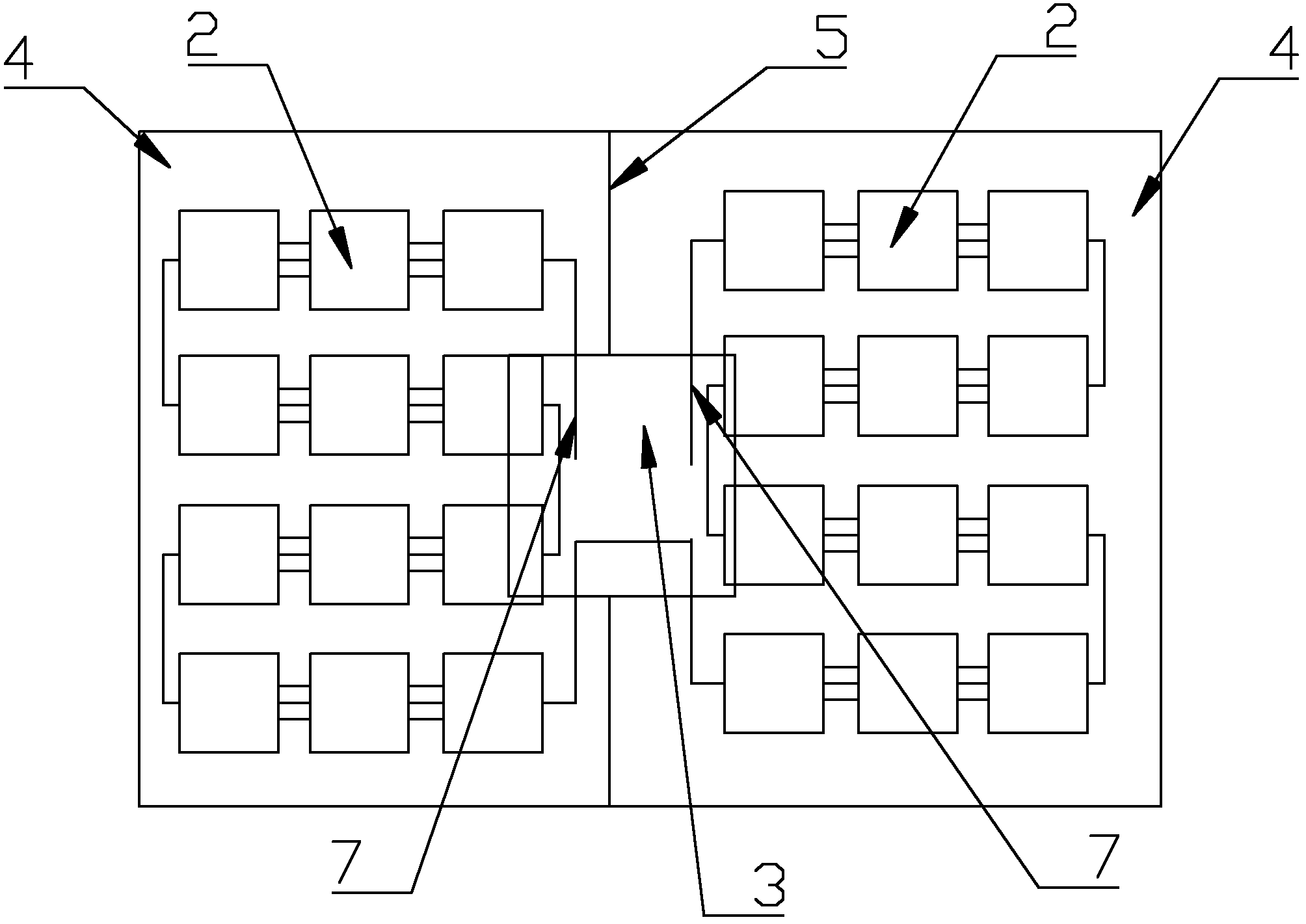

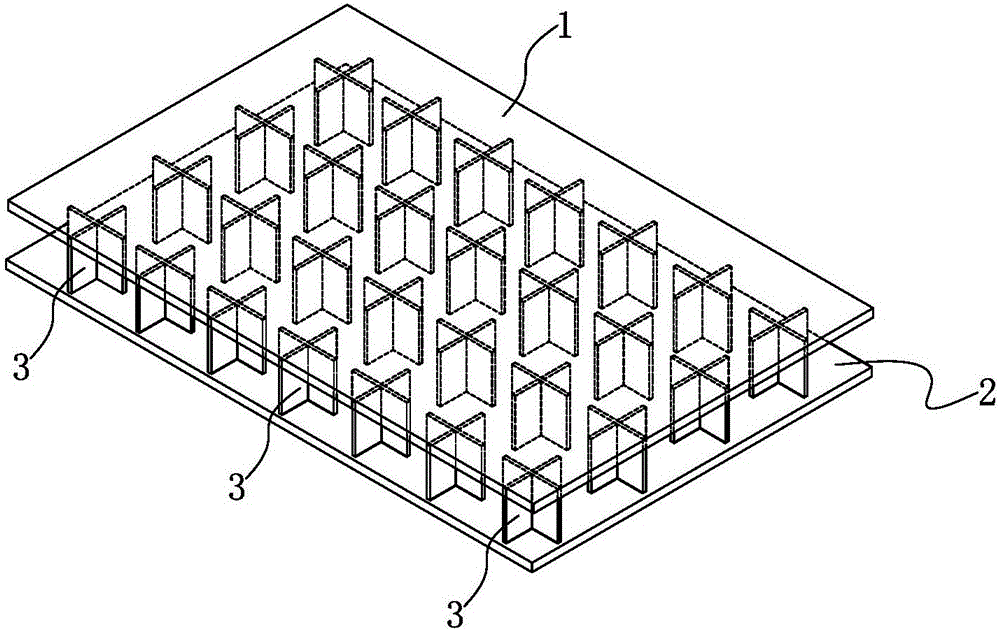

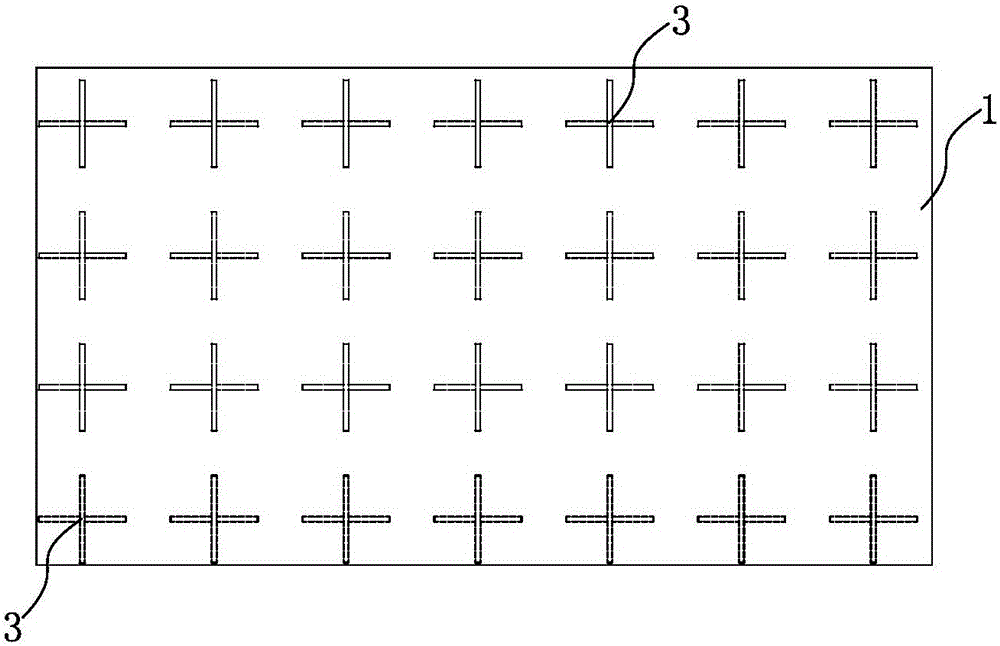

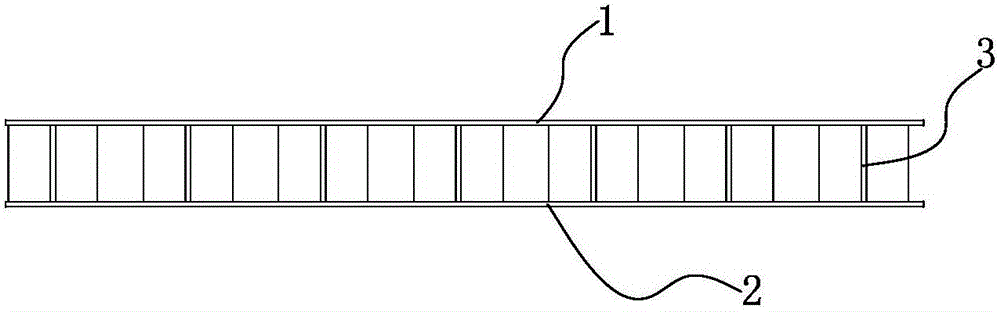

Shock resistance and noise reduction integrated lightweight cross-core latticed foam sandwich board and preparation method thereof

InactiveCN105856746AImprove noise reductionSolve the impact resistanceLamination ancillary operationsLaminationSandwich boardMetallic materials

The invention discloses a lightweight cross-core lattice foam sandwich panel integrating impact resistance and noise reduction and a preparation method thereof. The sandwich panel comprises: an upper panel and a lower panel arranged oppositely; the upper panel and the lower panel are made of metal materials; a plurality of skeletons placed between the upper panel and the lower panel; the skeleton is cross-shaped, with a first metal plate and a second metal plate perpendicular to each other and arranged crosswise; A plurality of skeletons are arranged in a display style between the upper panel and the lower panel; and a foam layer is filled in the gap formed between each said skeleton and the upper panel and the lower panel. The invention integrates impact resistance and noise reduction, and has the characteristics of being able to bear greater load under the same mass.

Owner:DALIAN UNIV OF TECH

Asphalt-reclaimed water-permeable pavior bricks and preparation method thereof

InactiveCN107021709ASolve the problem that waste cannot be reusedGood water permeabilitySingle unit pavingsSidewalk pavingsBrickAdditive ingredient

The invention provides asphalt-reclaimed water-permeable pavior bricks and a preparation method thereof and relates to the technical field of production of pavior bricks. Each pavior brick comprises a surface layer and a base layer, wherein the surface layer is prepared from the following raw materials in parts by weight: 30-40 parts of waste asphalt concrete, 20-28 parts of cement, 25-33 parts of sand, 5-10 parts of gravels, 4-6 parts of emulsified asphalt, 3-6 parts of mineral powder, 6-10 parts of glass fibers, 1.2-2.4 parts of polyvinyl acetate emulsion, 3-10 parts of clay, 0.8-1.6 parts of rubber powder, 5-10 parts of air entraining agent, 0.4-0.6 part of water reducer, 0.3-0.5 part of pigment powder and 1-3 parts of water; the base layer is prepared from the following raw materials in parts by weight: 30-35 parts of waste asphalt concrete, 22-24 parts of cement, 18-32 parts of sand, 17-23 parts of gravels and 2-3 parts of water. The preparation method comprises the following steps: (1) preparing surface layer ingredients; (2) preparing base layer ingredients; (3) carrying out molding, demolding, stacking and curing. According to the asphalt-reclaimed water-permeable pavior bricks and the preparation method thereof, the problems of the existing pavior bricks that recycling of waste cannot be achieved, the water permeability is poor, the volume weight is heavy, the skid resistance is poor, the compressive strength is low, the corrosion resistance is poor, and the shock resistance is poor are solved.

Owner:合肥慧林建材有限公司

Submerged arc surfacing manufacturing technology of looper roll for rolling mill

ActiveCN104785895AHigh hardnessParticlesArc welding apparatusWelding/cutting media/materialsFurnace temperatureManufacturing technology

The invention discloses a submerged arc surfacing manufacturing technology of a looper roll for a rolling mill. The technology specifically comprises the following steps that rough machining is carried out on a base material, the outer diameter of the machined base material is smaller than the size of a finished product by 6 mm, a DF-524A welding wire made of hard materials is adopted, HJ107 flux is selected and matched, surfacing is carried out on the base material through an inversion type direct current welding machine, and the outer diameter of the machined base material is larger than the outer diameter of the finished product by 3-5 mm; post-thermal treatment is carried out on the base material, the machined base material is kept for three hours under the condition of 600 DEG C, then cooling is carried out along with a furnace, the temperature of the furnace is reduced to 300 DEG C, then air cooling is carried out, a surfacing product is obtained, and after finish machining is carried out on the surfacing product according to an art work sheet to obtain the specific specification, the looper roll for the rolling mill is obtained. The looper roll has the advantages of being resistant to abrasion, long in service life and the like.

Owner:安徽东方新材料有限公司

Pipe made from copolymer of PVC/ acrylonitrile butadiene - styrene, and preparation method

InactiveCN1872529AAccelerated corrosionImprove heat resistanceSynthetic resin layered productsLaminationPolymer sciencePolyvinyl chloride

A polyvinyl chloride (PVC) / acrylonitrile-butadiene-styrene copolymer (ABS) tube is composed of an external hard PVC layer, an internal ABS layer, and a thermofusible adhesive layer as sandwich layer. It is prepared by three layers coextruding out method, which includes such steps as extruding out PVC-U layer by primary extruder while extruding internal ABS layer and adhesive sandwich layer by two secondary extruders, passing than through a common shaping die, sizing, cooling, winding, and packing.

Owner:金德管业集团有限公司

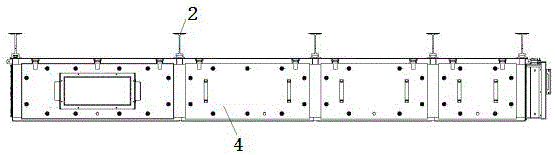

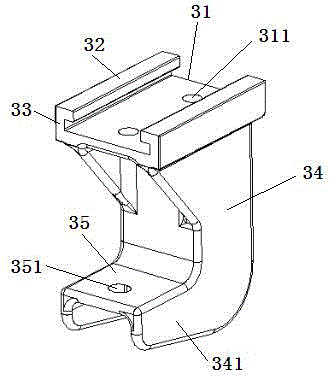

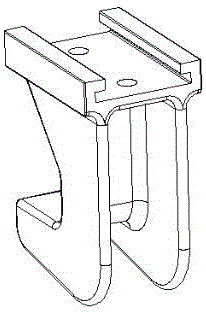

Underframe equipment hanging support capable of preventing falling and looseness as well as hanging structure

The invention discloses an underframe equipment hanging support capable of preventing falling and looseness as well as a hanging structure. The hanging support is hung on an underframe of a rail transit vehicle and used for mounting of underframe equipment. The hanging support comprises a T-shaped bolt, an underframe mounting surface, two vertical edges, two horizontal turned edges, two vertical plates and an underframe equipment mounting surface. At least one T-shaped bolt mounting hole is formed in the underframe mounting surface; the two vertical edges are symmetrically arranged on two side edges of the underframe mounting surface, one horizontal turned edge is arranged at the top of each of the two vertical edges; each horizontal turned edge, the vertical edge connected with the horizontal turned edge and the underframe mounting surface define a C-shaped groove; the two vertical plates are symmetrically arranged at the bottom of the underframe mounting surface, and a horizontal hook part is arranged at the bottom of each vertical plate; the underframe equipment mounting surface is fixed on the two hook parts horizontally. Underframe equipment falling caused by looseness or breakage of the bolt can be avoided, besides, the shock resistance is high, and bolt looseness can be prevented.

Owner:CRRC NANJING PUZHEN CO LTD

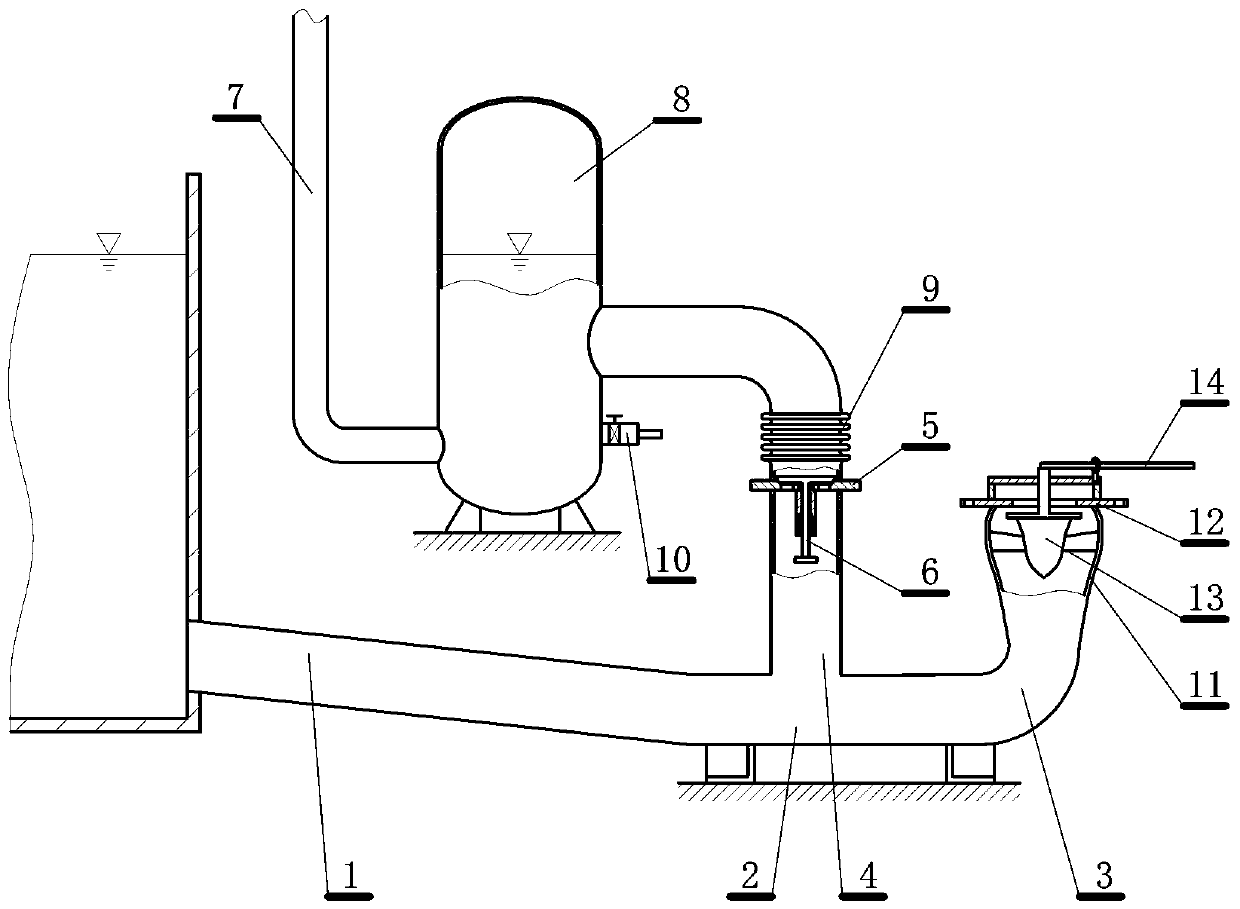

Split-type large water hammer pump and starting method thereof

PendingCN108019385ALight in massSolve the impact resistanceOperating means/releasing devices for valvesMachines/enginesWater escapePetrochemical

The invention relates to a split-type large water hammer pump and a starting method thereof. The split-type large water hammer pump comprises a power pipe, a bent pipe, a vertical water inlet pipe, areducing pipe, an air tank pipe, a water conveying valve, a connecting pipe and a water escape valve. The water conveying valve is equipped with a spring limiting facility. The connecting pipe is provided with detachable telescopic joints. An air tank is provided with an air supplementing facility. A water facing surface of a water escape valve clack is equipped with a flow guide body fixedly connected with the reducing pipe. The water escape valve is provided with a lever or a hydraulic opening mechanism. By arranging the flow guide body on the water escape valve, the mass of the water escapevalve clack is reduced. Therefore, an impact resistance problem of the water escape valve is resolved. The water conveying valve is provided with a limiting mode so that service lifetime of a water-conveying valve spring is prolonged. By arranging the starting mechanism, the problem that a conventional mode fails to start a large water hammer pump is resolved. The telescopic joints help resolve problems related to installation, transportation and maintenance of the large water hammer pump. Due to the air supplementing facility, the air tank is not excessively large. The water hammer pump canbe used in a large-scale hydraulic project, which saves a great deal of petrochemical energy.

Owner:北京宇豪胜水利科技咨询有限公司

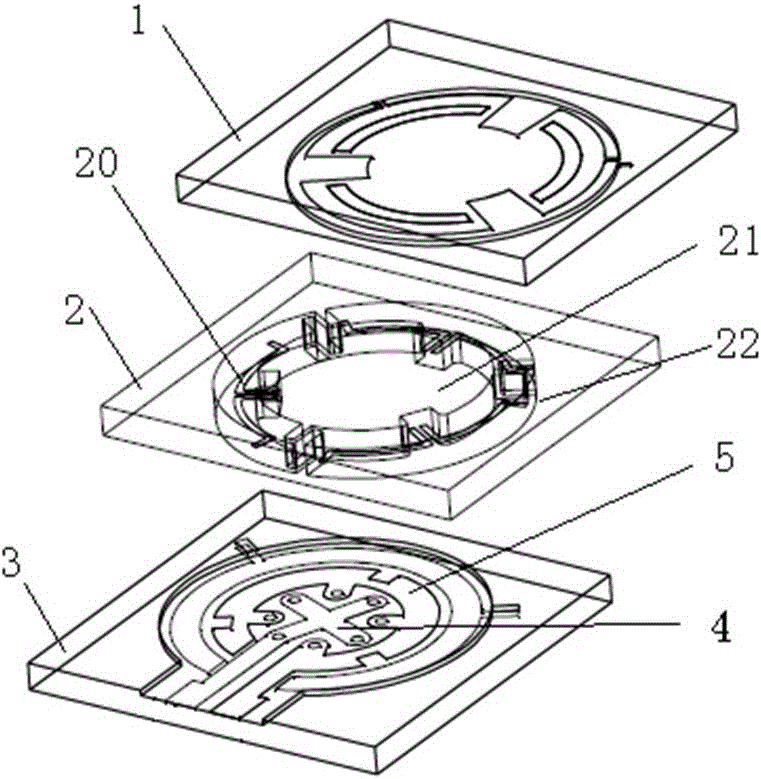

Micro inertial switch with Z-shaped beam structure

InactiveCN106384692ASmall footprintImprove the ability to resist lateral overloadElectric switchesShaped beamGlass cover

The invention provides a micro inertial switch with a Z-shaped beam structure. The micro inertial switch has a micro inertial switch chip which is processed according to MEMS technology and has a low g-value. The micro inertial switch is mainly composed of a glass cover plate, a mass block and spring beam silicon structure, a glass substrate, etc. The spring beam structure is a symmetrical Z-shaped beam. In operation, on the condition an overload function exists in a sensitive direction, the Z-shaped beam deforms elastically, and the mass block moves to contact bump points in the groove of the glass substrate. On the condition that overload reaches a certain threshold, a metal electrode on the mass block contacts with two random adjacent contact pump points in the groove of the substrate, so that the micro inertial switch is on. The micro inertial switch with the Z-shaped beam structure has advantages of high transverse overload resistance, high productivity, high reliability, etc. The micro inertial switch with the Z-shaped beam structure is suitable for the fields such as automobile and industrial production safety control and aeronautics and astronautics.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

High-performance polyvinyl chloride (PVC) plastic pipe

The invention discloses a high-performance polyvinyl chloride (PVC) plastic pipe. The high-performance PVC plastic pipe is characterized by comprising the following components in parts by weight: 20-30 parts of PVC resin, 10-20 parts of acrylic rubber, 3-4 parts of heat stabilizer, 5-10 parts of triphenyl phosphate, 5-15 parts of stearic acid, 2-6 parts of fire retardant, 10-15 parts of epoxy butyl oleate, and 10-12 parts of paraffin wax. The high-performance PVC plastic pipe prepared by the invention has excellent characteristics of high strength, good super-toughness, high-temperature resistance, impact resistance and corrosion resistance, and relative low cost; the vicat softening temperature can be up to over 120 DEG C; the problems of low temperature brittleness, impact resistance and the like of the traditional polyvinyl chloride pipe are solved.

Owner:QINGDAO HUARUI RUBBER IND EQUIP

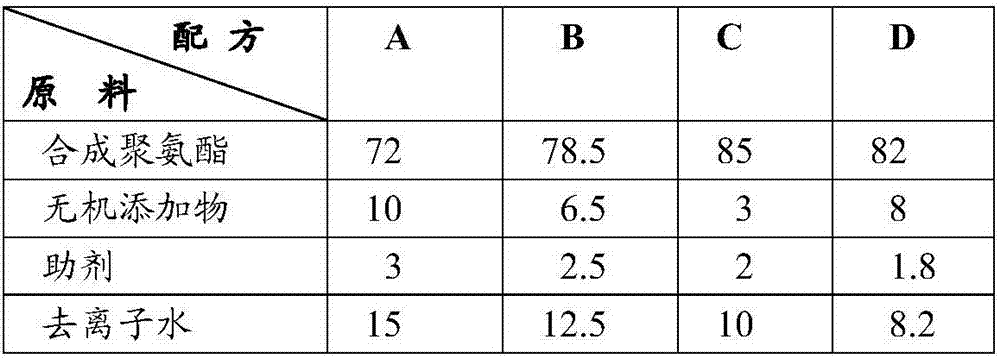

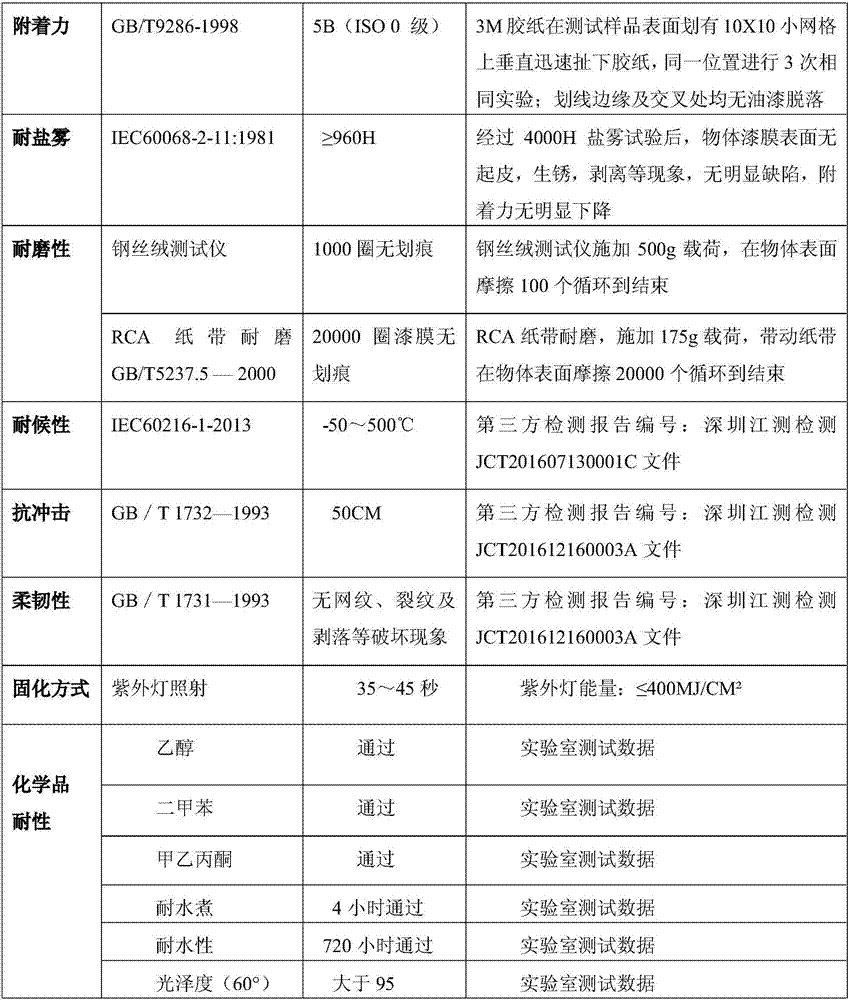

Aqueous photocurable coating with ultra low VOC emission and preparation method thereof

InactiveCN107083167AExcellent paint protectionGood hydrophobic and oleophobicAntifouling/underwater paintsPaints with biocidesIonChemistry

The invention discloses aqueous photocurable coating with ultra low VOC emission. The coating comprises the following raw materials in percentages by weight: 72-85% of synthetic polyurethane, 3-10% of an inorganic additive, 0.5-3% of an auxiliary agent, and 10-15% of deionized water. The synthetic polyurethane is a water-soluble hydroxy NCO three-dimensional crossing structure tree form polymer. The invention also discloses a preparation method of the aqueous photocurable coating with ultra low VOC emission. The coating realizes ultra low VOC emission, and is suitable for all materials; the coating does not contain a photoinitiator, and peculiar smell formed by initiator residual paint films is not generated; the coating has ultra high hardness and excellent lacquer protection effect; aqueous environmental protection is realized, in the condition with high hardness performance, high flexibility is provided, bending of paint films whose forward direction is more than 40 degrees and reverse direction is more than 180 degrees is realized, and shock resistance of the paint films is effectively solved.

Owner:深圳市泓壹科技有限公司

Protective glass for LED street lamp and manufacturing method of protective glass

InactiveCN109084276AThe production process is simpleSolve the impact resistanceProtective devices for lightingMaterial strength using single impulsive forceTemperature resistanceImpact test

The invention discloses protective glass for an LED street lamp and a manufacturing method of the protective glass, and belongs to the field of LED lighting. The problems are solved that existing LEDstreet lamp protective glass can not pass the IK impact test, and the toughening effect is greatly reduced if the surface of the glass is printed with a pattern. According to the technical scheme, theglass includes a glass body, the glass body is plate glass with two sides clear, and after outline cutting, polishing, cleaning, drying, full toughening treatment, testing, pattern silk-printing, baking, cooling and testing, the protective glass for the LED street lamp is made. The manufacturing process is simple, the plate glass with two sides clear is adopted, the toughening effect is not affected even if the surface of the glass is printed with the pattern, the qualified rate of the made protective glass for the LED street lamp is 100% in the IK impact test, and the protective glass for the LED street lamp has impact resistance, knocking resistance, high temperature resistance, low stress and strong acid and alkali resistance.

Owner:黎伟强

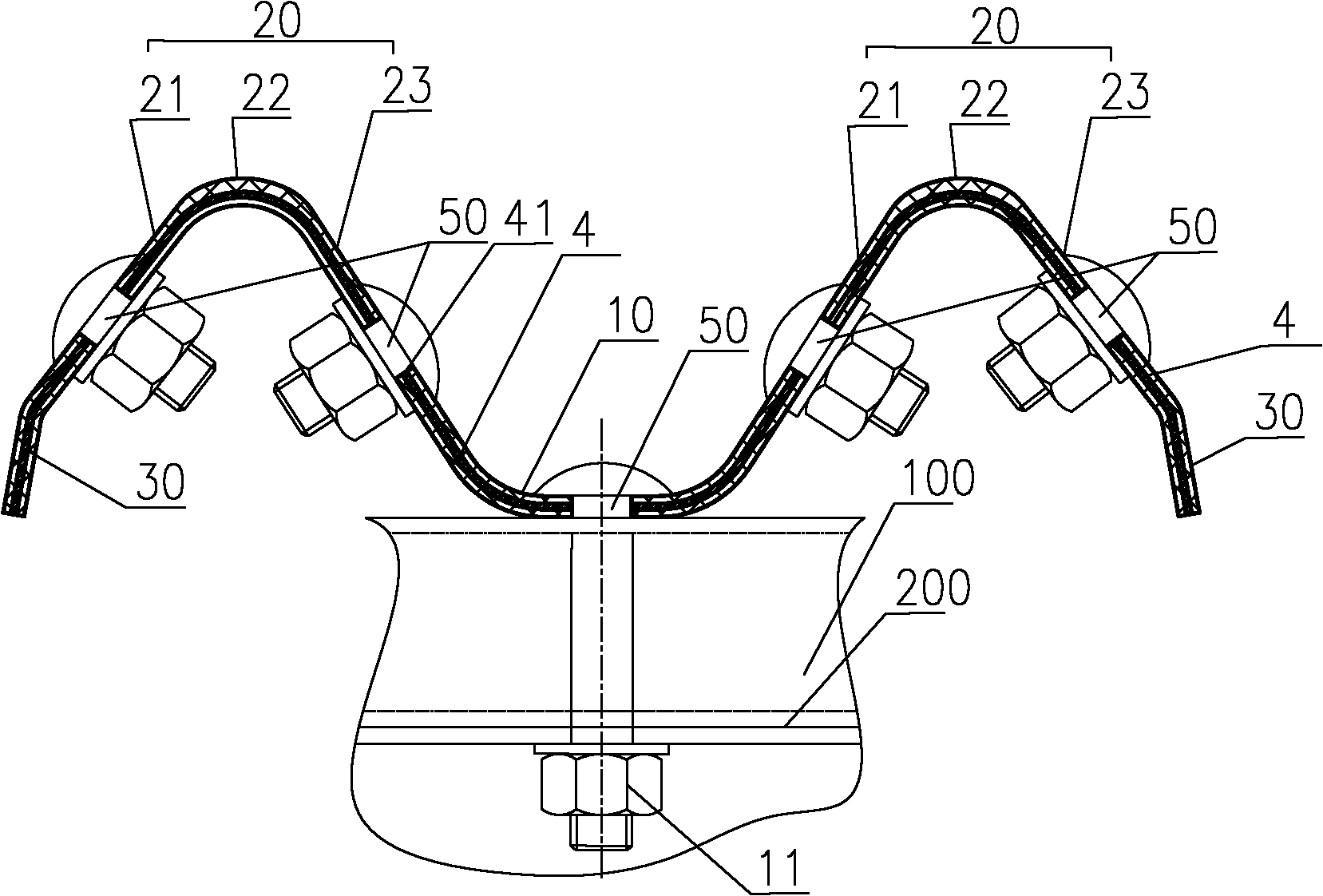

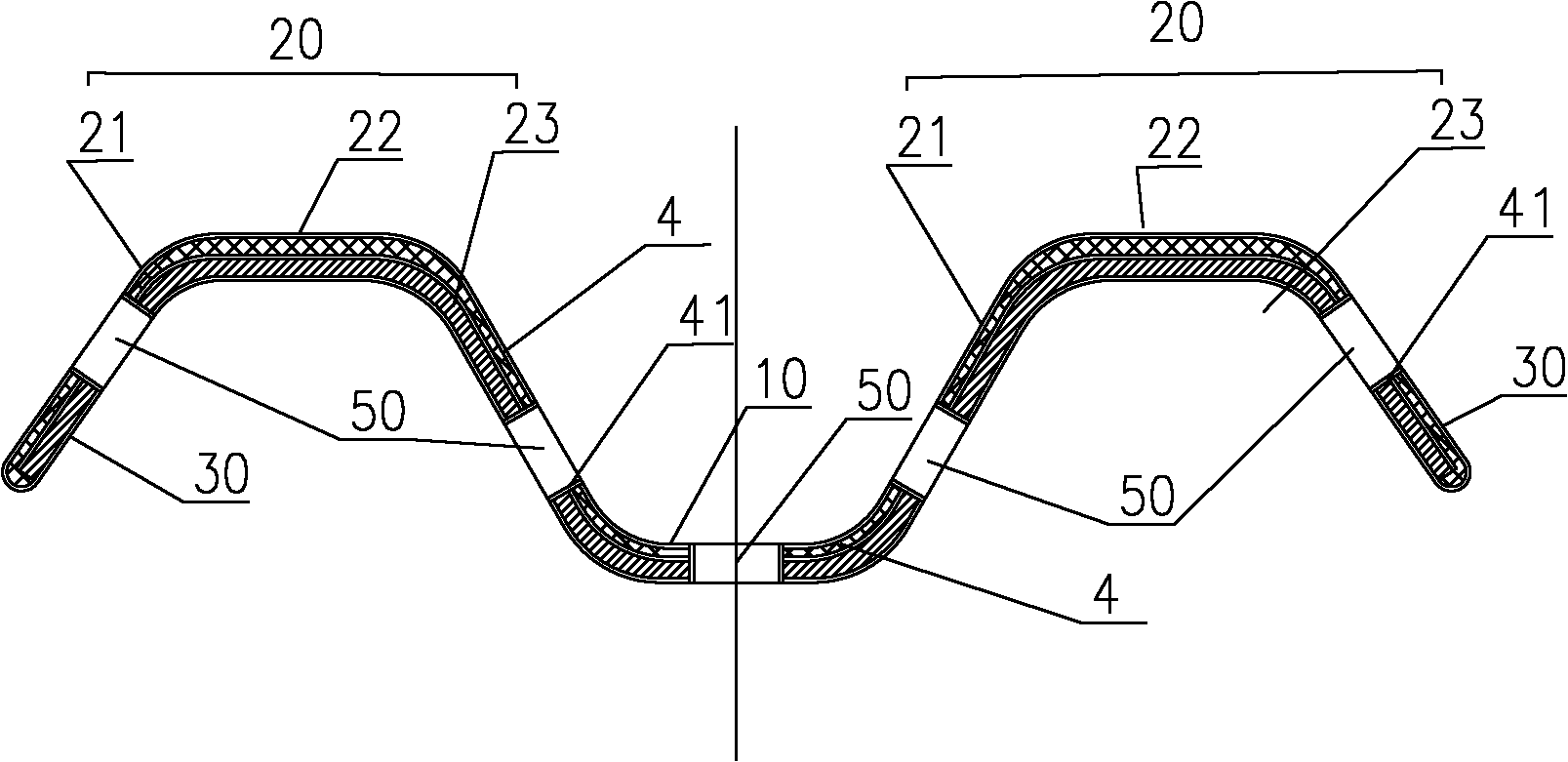

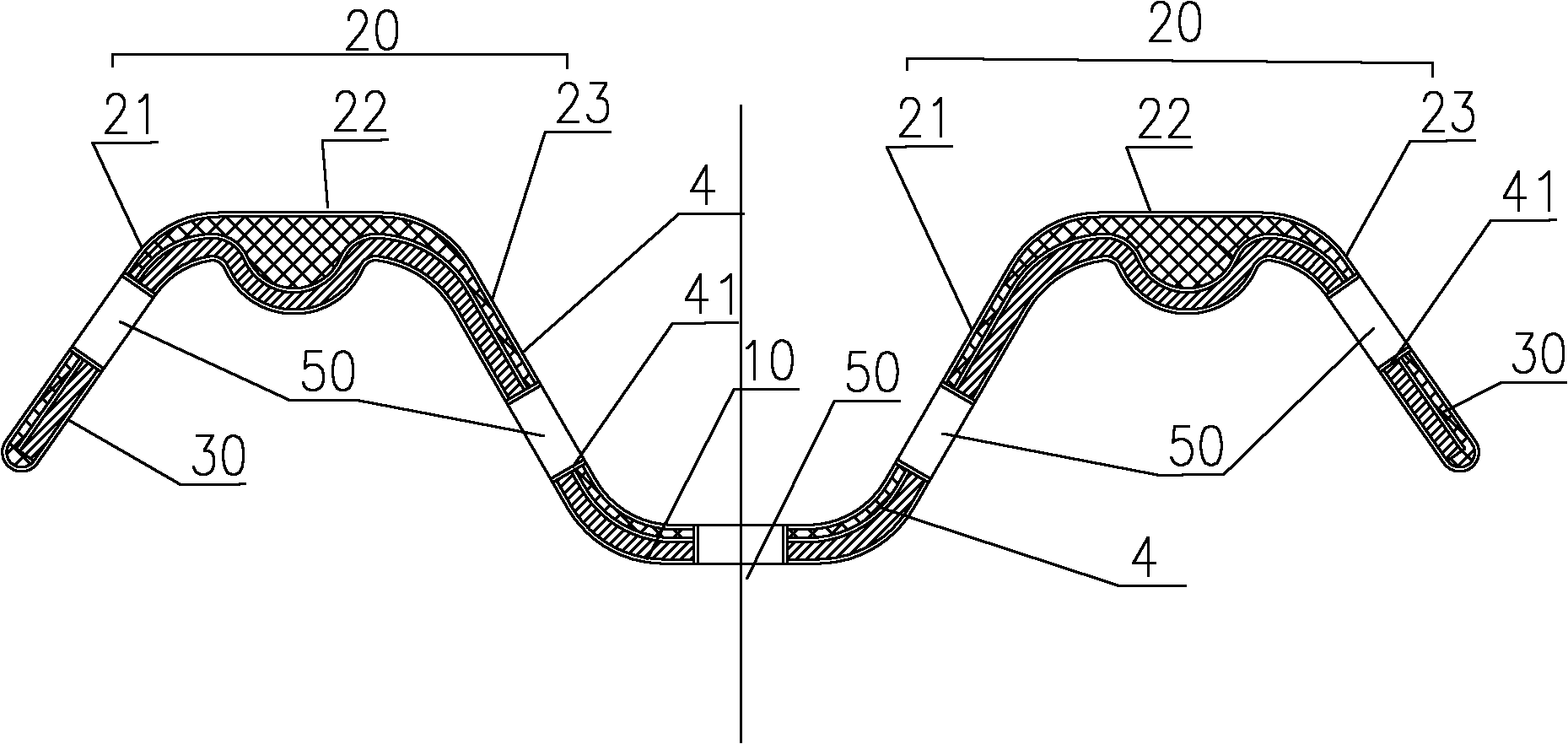

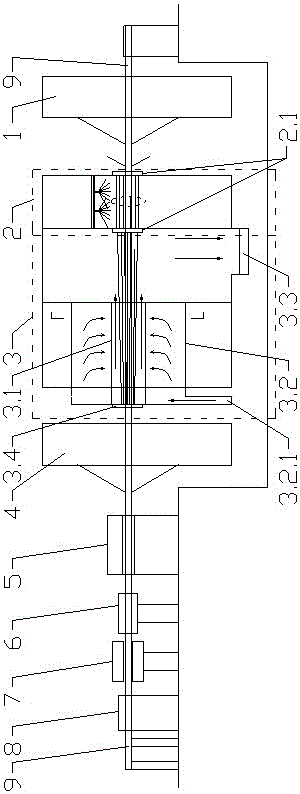

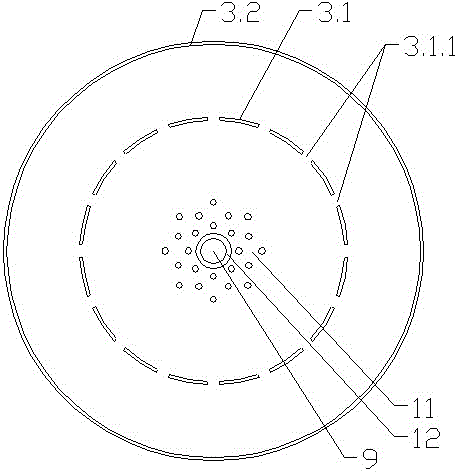

High-strength fiber weaving, winding, pulling and extruding pipeline and production technology thereof

InactiveCN106273579ATear resistanceSolve the impact resistanceTubular articlesInternal pressureFiber

The invention relates to a high-strength fiber weaving, winding, pulling and extruding pipeline and a production technology thereof. The production technology of the pipeline comprises an inner-layer braiding machine (1), a glue spraying region (2), an outer-layer braiding machine (4), a glue dipping tank (5), a thermal curing mould (6), a traction machine (7), a cutting machine (8) and a mould core (9). The high-strength fiber weaving, winding, pulling and extruding pipeline comprises an outer braid layer (10), a middle layer (11) and an inner braid layer (12). The production technology of the pipeline is characterized by also comprising a lap joint nail spraying region (3), and the lap joint nail spraying region (3) is arranged between the glue spraying region (2) and the outer-layer braiding machine (4). The high-strength fiber weaving, winding, pulling and extruding pipeline and the production technology thereof have compression resistance, bending resistance and internal pressure resistance, also have stronger tear resistance and impact resistance and are wide in application range.

Owner:CHANGZHOU LYJIA ENVIRONMENTAL EQUIP

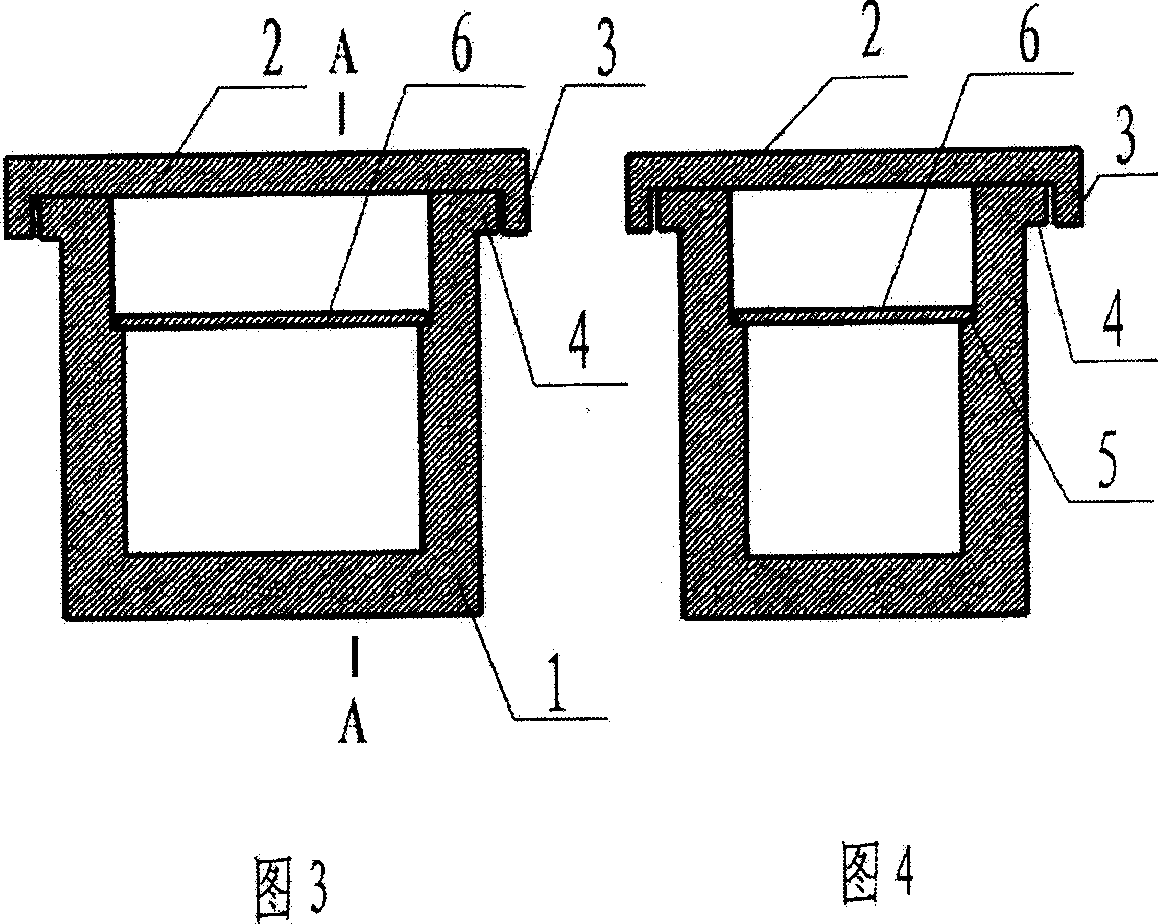

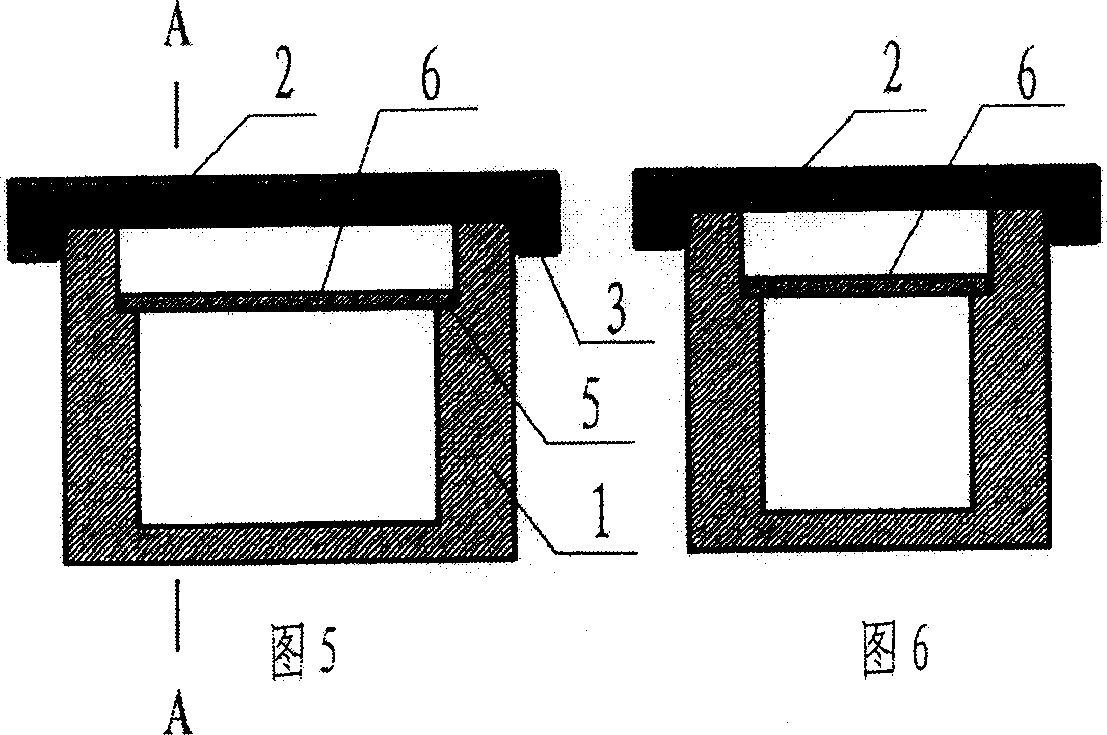

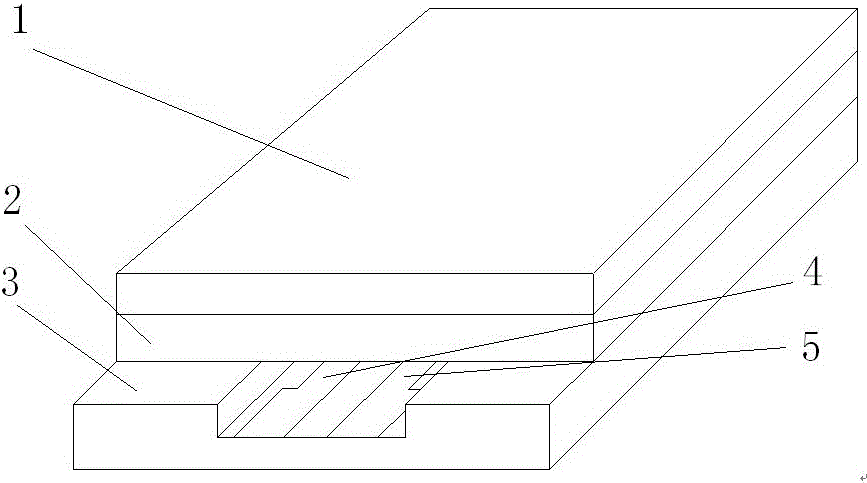

Novel bulletproof and anti-smash laminated glass

InactiveCN106515106ASolve the impact resistanceGlass/slag layered productsUltravioletUltimate tensile strength

The invention discloses novel bulletproof and anti-smash laminated glass. The laminated glass comprises a first glass layer (1) and a third glass layer (3). The laminated glass is characterized in that a second glass layer (2) is arranged between the first glass layer (1) and the third glass layer (3); a glue layer (4) is arranged between the first glass layer (1) and the second glass layer (2); another glue layer (4) is arranged between the second glass layer (2) and the third glass layer (3); an ultraviolet-proof layer (5) is arranged on the upper surface of the first glass layer (1); and a nano layer (6) capable of improving the strength is arranged on the ultraviolet-proof layer (5). The problem that in the prior art, laminated glass is poor in impact resistance and cannot resist ultraviolet can be solved.

Owner:SUZHOU BIHAI SAFE GLASS IND

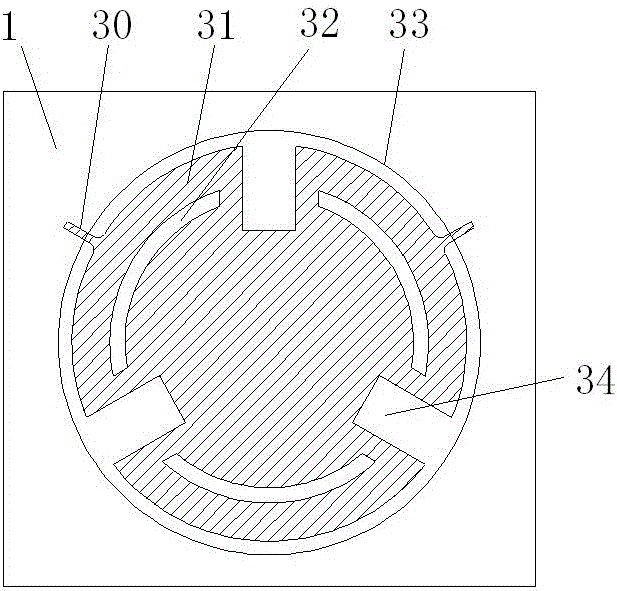

A roller device for an airport container trailer

InactiveCN109204868AImprove impact resistancePlay a supporting roleFreight handling installationsCushioningIndustrial engineering

The invention discloses a roller device for an airport container trailer and relates to the technical field of trailers. The device includes a chassis, wherein a bearing is movably connected to that chassis, both ends of the bearing are fixedly connected with nuts, a groove is formed in the middle circumferential direction of the bearing, a support rod is arranged in the groove, one end of the support rod is fixedly connected with a limit block, the limit block is connected with the groove through a compression spring, the other end of the support rod penetrates the bearing and is fixedly connected with a buffer plate, both ends of the buffer plate are movably connected with a pulley, the axial direction of the bearing is provided with a sleeve, and the inner wall of the sleeve is connected with the pulley. The roller device is provided with the support rod playing a role of supporting the sleeve. The cushioning plate and the compression spring are arranged to achieve a cushioning function, improving the impact resistance of the roller device. The pulley is arranged to enable the sleeve to rotate by setting a pulley, reduce the frictional force, and improve the transportation performance by setting a rotating ring.

Owner:宿迁泰达空港设备有限公司

Advanced ceramic pipe type defueling pump

InactiveCN101649828AEasy clearanceAvoid direct abrasionPositive displacement pump componentsFlexible member pumpsAlloy coatingZirconia Toughened Alumina

The invention relates to an advanced ceramic pipe type defueling pump, comprising a pump cylinder, a plunger piston, an upper traveling valve assembly, a lower traveling valve assembly and a strandingvalve assembly. The advanced ceramic pipe type defueling pump is characterized in that the inner wall of a steel-based pipe of the pump cylinder is provided with an advanced ceramic protection layerwith high temperature resistance, abrasion resistance and corrosion resistance, which is used as an lining; the outer surface of a rod body of the plunger piston is previously provided with grooves atintervals, alloy coatings with abrasion resistance and corrosion resistance is sprayed on the grooves, and zirconia toughening alumina ceramic rings are embedded into the surfaces of the alloy coatings inside the grooves.

Owner:吉林省大多天盛金属陶瓷技术有限公司

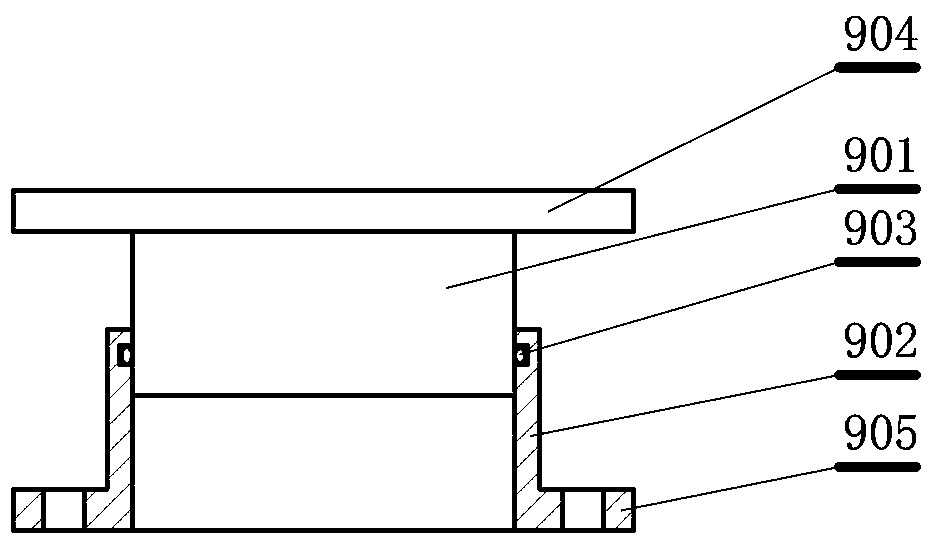

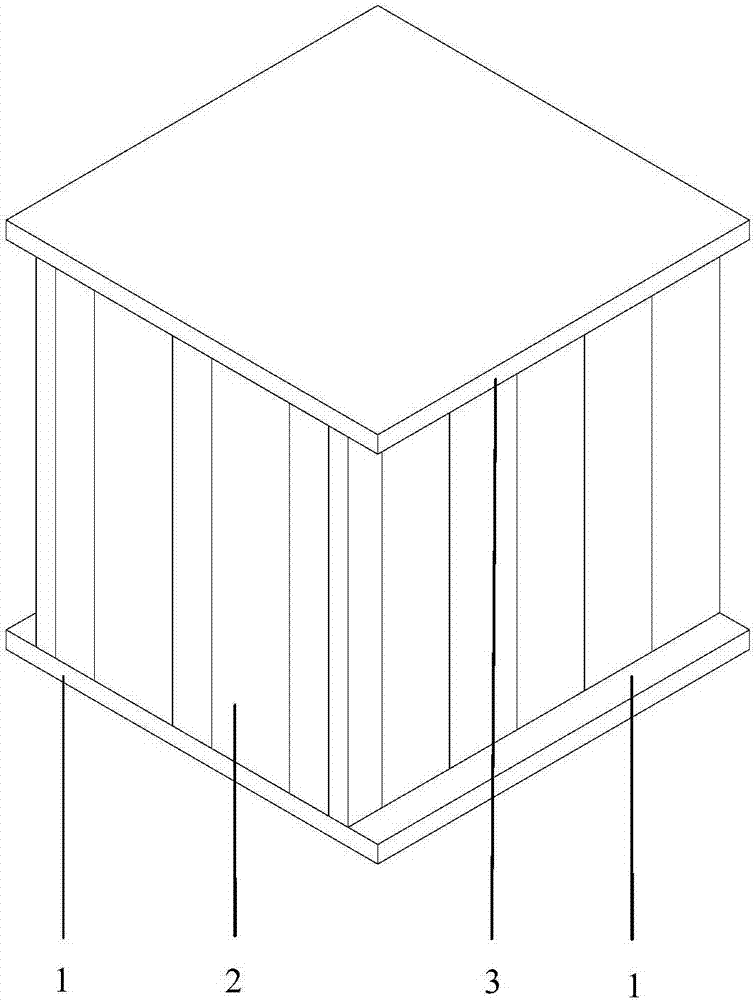

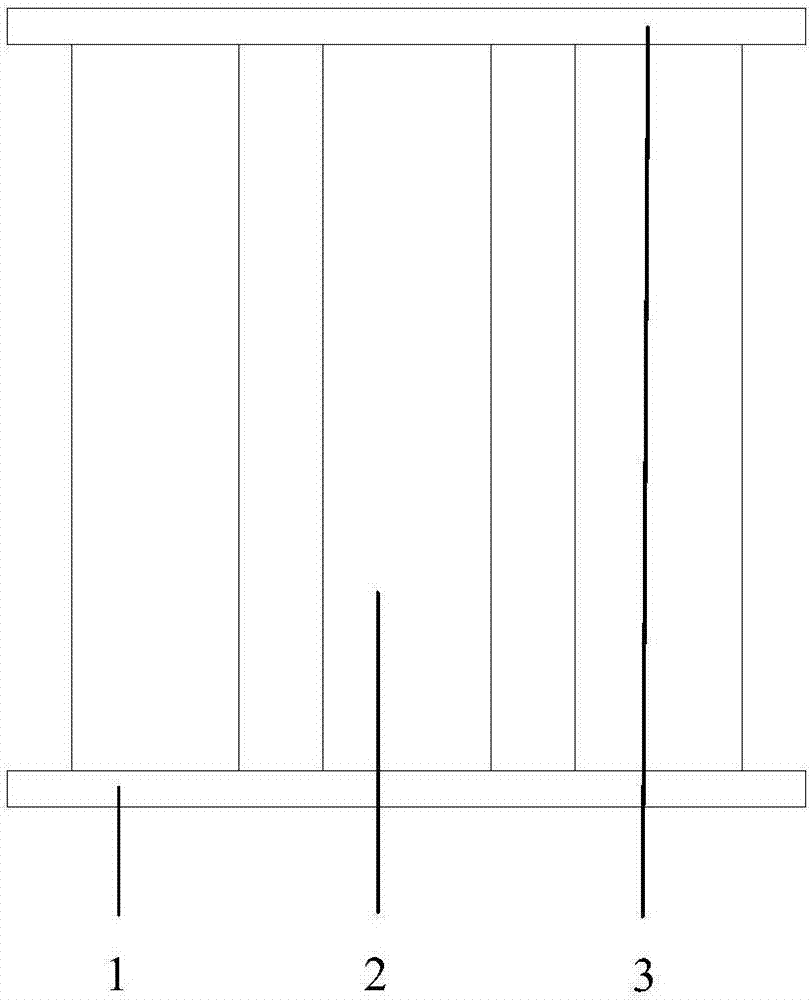

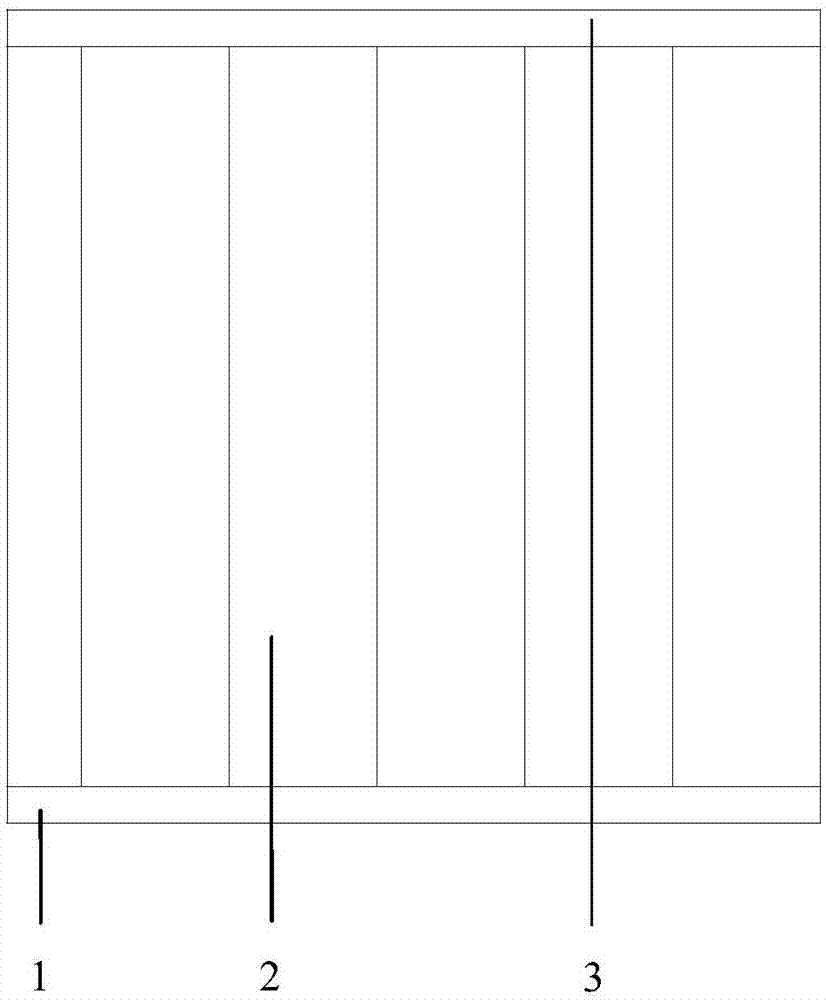

Anti-impact anti-explosion seismic-reduction-and-isolation pile based on elasticity cement materials and use method of anti-impact anti-explosion seismic-reduction-and-isolation pile

PendingCN107313527ASolve the impact resistanceSafe and Quick RescueNon-rotating vibration suppressionProtective buildings/sheltersShock resistanceAluminium

The invention provides an anti-impact anti-explosion seismic-reduction-and-isolation pile based on elasticity cement materials. The anti-impact anti-explosion seismic-reduction-and-isolation pile comprises a bottom plate, a top plate and an aluminum skeleton connected between the bottom plate and the top plate, wherein the aluminum is provided with a plurality of parallel cylindrical spaces, the axial directions of the cylindrical spaces are perpendicular to the bottom plate and the top plate, and the cylindrical spaces are filled with elasticity cement. According to the anti-impact anti-explosion seismic-reduction-and-isolation pile based on the elasticity cement materials, the aluminum skeleton and the elasticity are combined into a whole, when the device is encountered with an earthquake, an explosion or other impacts, energy of impact and explosion can be absorbed, consumed and stored through joint deformation of the elasticity cement and the aluminum skeleton, after the gusty load effect finishes, the elasticity cement in a compressed state can return to an original position, and thus the safety of structures, equipment and other objects is protected.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION

Flame retarding type PVC double-wall pipe and manufacturing method thereof

InactiveCN108976659AImprove flame retardant performanceImprove temperature resistanceRigid pipesAluminium hydroxidePolymethyl methacrylate

The invention relates to a flame retarding type PVC double-wall pipe, and the pipe wall of the double-wall pipe is formed by a double-layer structure. The inner layer comprises the following raw materials: polyvinyl chloride, chlorinated polyvinyl chloride, polymethyl methacrylate, aluminium hydroxide, polypropylene carbonate, a plasticizer, light calcium carbonate; the outer layer comprises the following raw materials: polyvinyl chloride, polybutyl ester, methacrylic acid-butadiene-styrene copolymer, sodium polyacrylate, aluminium hydroxide, polypropylene carbonate, polyethylene-acrylate rubber, aromatic polycarbonate, a plasticizer, etc. Both the inner and outer layer materials of the pipe are added with flame retarding and high temperature-resistant materials. Polypropylene carbonate will be decomposed to generate a large amount of carbon dioxide when heated in a burning condition so as to dilute the oxygen around to achieve the flame retarding purpose. The sodium polyacrylate playsroles in moisture absorption and preservation so as to increase humidity in the small environment around the PVC pipe to some degree, reduce temperature, and improve the heat resistance and flame retarding property of the PVC pipe.

Owner:JIANGSU NOBEL PLASTICS CO LTD

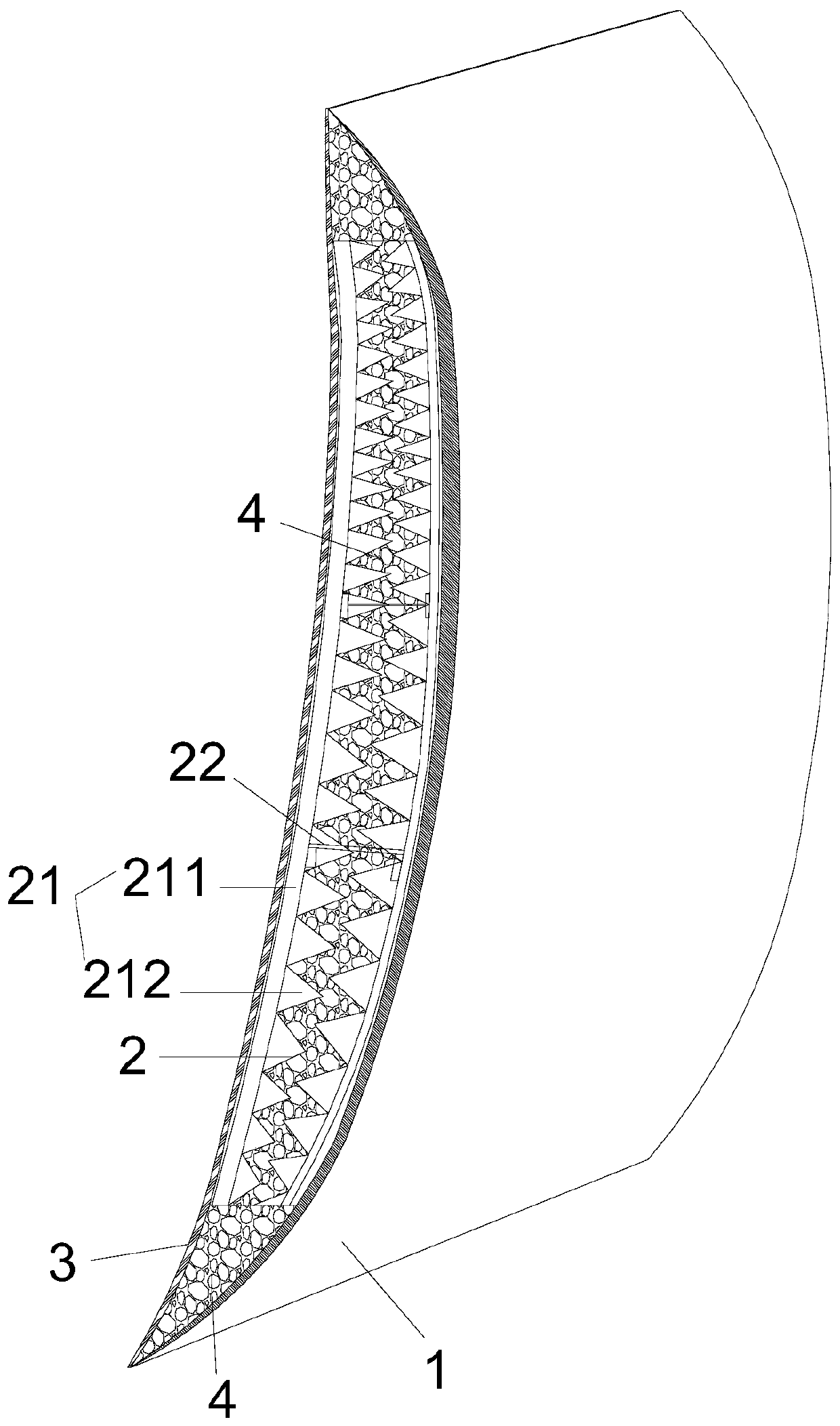

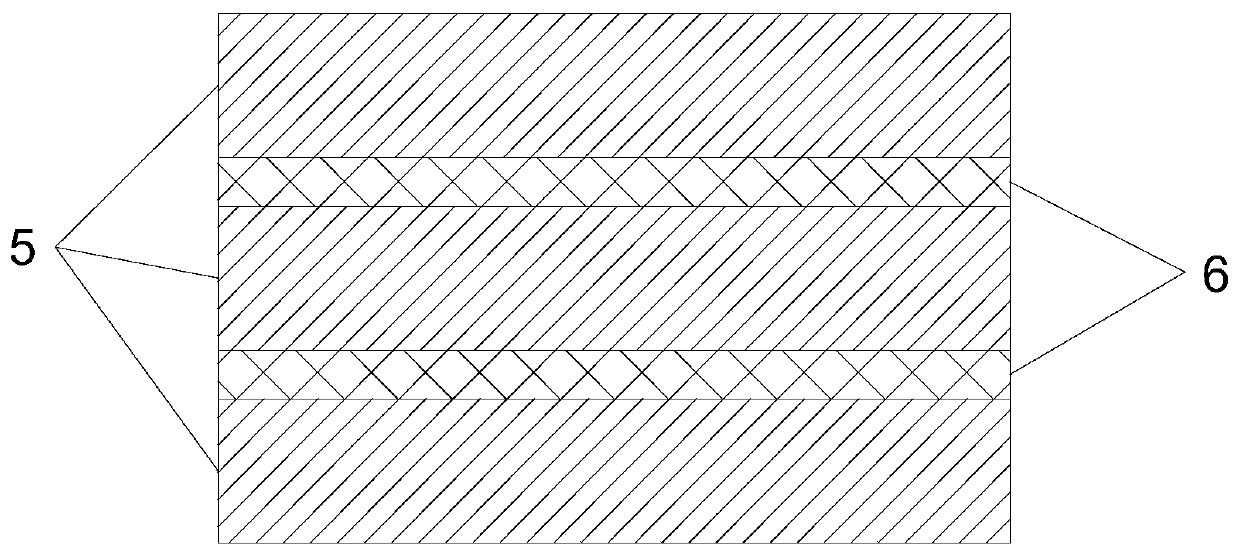

Composite metal structure with interlayer core material and preparation method thereof

ActiveCN111347736AEffective absorptionPrevents the risk of penetrating the bodyworkSynthetic resin layered productsAxle-box lubricationEnergy absorptionMetallic materials

The invention provides a composite metal structure with an interlayer core material and a preparation method of the composite metal structure, the composite metal structure sequentially comprises an outer skin, the interlayer core material and an inner skin from outside to inside, and the interlayer core material is formed by mutually clamping and matching two sawtooth-shaped panels; the smooth side of each sawtooth-shaped panel is fixedly connected with the inner side of the corresponding outer skin and the inner side of the corresponding inner skin, and the space between the two sawtooth-shaped panels is filled with foam metal materials. According to the composite metal structure, certain impact resistance and sound insulation and noise reduction characteristics can be achieved through the interlayer core material, and better sound insulation performance and electromagnetic wave absorption characteristics are achieved through the foam metal structure bonded between the two sawtooth-shaped panels; and due to the porous structure of the foam metal, the foam metal has excellent impact resistance and energy absorption characteristics when bearing pressure, and can be used for solvingthe problems of sound insulation, noise reduction, impact resistance and the like in the high-speed running process of a train. The preparation method is simple to operate and suitable for industrialproduction.

Owner:西安泰利达新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com