Split-type large water hammer pump and starting method thereof

A water hammer pump, split type technology, applied in the direction of pumps, engine components, machines/engines, etc., can solve the problems of large-scale water hammer pumps, etc., to solve the impact resistance, save electric energy and petrochemical energy, reduce interference and damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

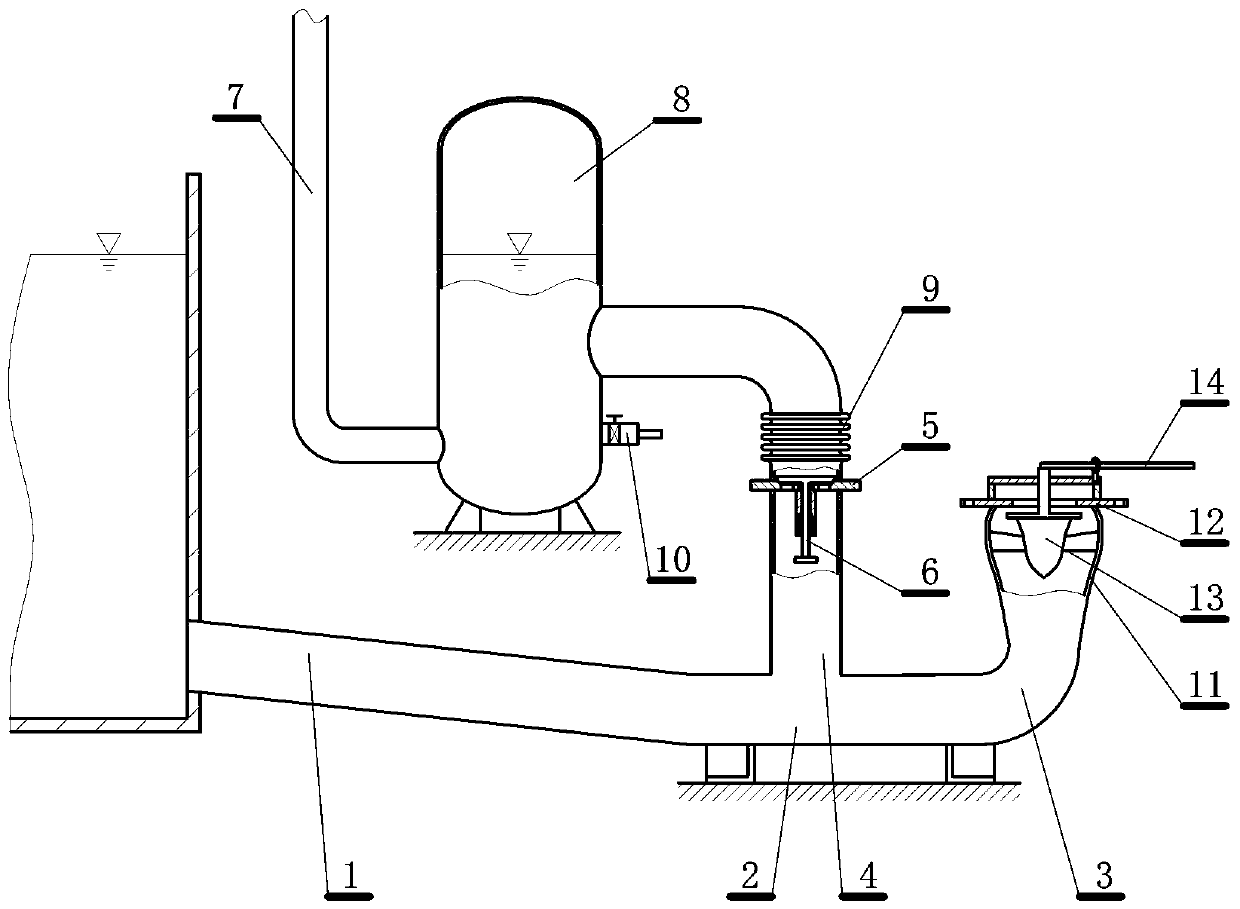

[0036] This embodiment is a split type large water hammer pump, such as figure 1 shown. This embodiment includes: a power pipe 1, the power pipe is connected to the pump body fixed on the foundation 2, the pump body is connected to the elbow 3, and the bottom of the vertical water inlet pipe 4, and the water inlet pipe is connected to the water delivery valve 5 connection, the water delivery valve is provided with a spring limit facility 6, the water delivery valve is connected to the air tank 8 fixed on the foundation with the water pumping pipe 7 through a connecting pipe, the connecting pipe is A detachable telescopic joint 9 is provided, and the air tank is provided with an air supply facility 10, and the elbow is connected to the small end of a different-diameter pipe 11 with one end large and the other end small, and the large end of the different-diameter pipe The end is connected with the drain valve 12, and the drain valve disc of the drain valve is provided with a d...

Embodiment 2

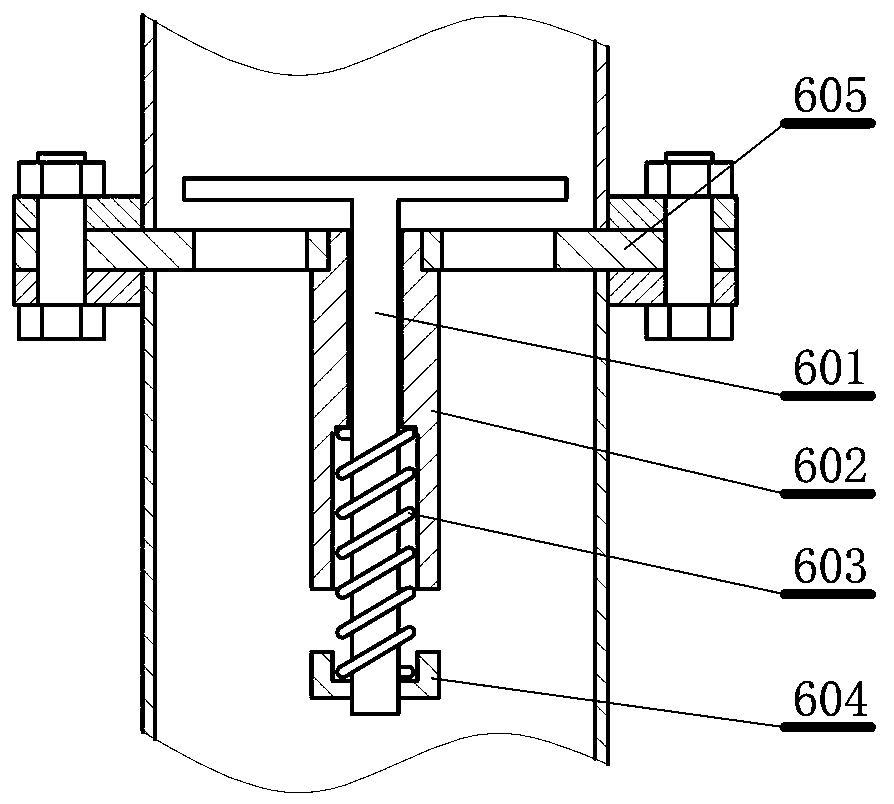

[0047] This embodiment is an improvement of the first embodiment, and it is a refinement of the first embodiment on the spring limit mechanism on the water transfer. The spring limiting mechanism described in this embodiment includes: a valve stem 601 fixed at the center of the valve disc, and a sleeve 602 fixedly connected with the valve seat is sleeved on the valve stem. A spring 603 is set, and the valve stem is provided with a limit block 604 that limits the excessive compression of the spring, such as figure 2 shown.

[0048] Limiting the compression and release length of the spring to prolong the service life of the spring is the main purpose of using the spring limit mechanism. The biggest difficulty in manufacturing a large water hammer pump is how to prolong the service life of the drain valve and water delivery valve of the water hammer pump, so that these two valves can work for a long time without damage. The spring limiting mechanism adopted in this embodiment ...

Embodiment 3

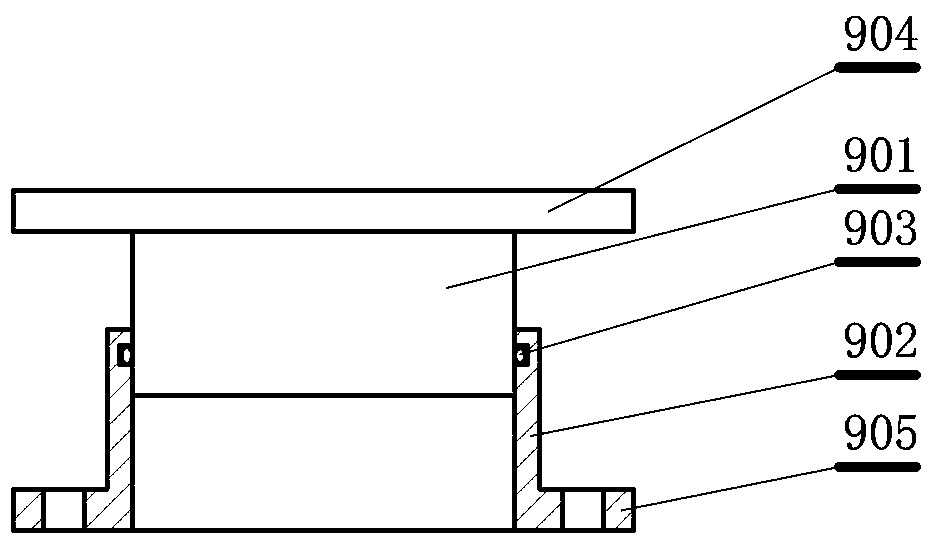

[0051] This embodiment is an improvement of the above embodiment, and is a refinement of the above embodiment on the expansion joint. The expansion joint described in this embodiment includes: an inner 901 and an outer sleeve 902 that can slide and expand each other, a sealing ring 903 is provided between the inner and outer sleeves, and the inner and outer sleeves are connected to their respective docking flanges 904, 905 connection, such as image 3 shown.

[0052] There are many forms of telescopic joints, and this embodiment only enumerates one of them. In this embodiment, two casings which are nested together and can move with each other are used, and a sealing member is arranged between the two casings so that the sliding surfaces of the two can be sealed. Since the sliding surface only slides during installation, there is no dynamic sealing problem, and the general O-ring can achieve a good sealing effect.

[0053] Different from the traditional water hammer pump des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com