Shock resistance and noise reduction integrated lightweight cross-core latticed foam sandwich board and preparation method thereof

A foam sandwich panel, impact-resistant technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of poor impact resistance and noise reduction performance, to improve bearing capacity and impact resistance, Good noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

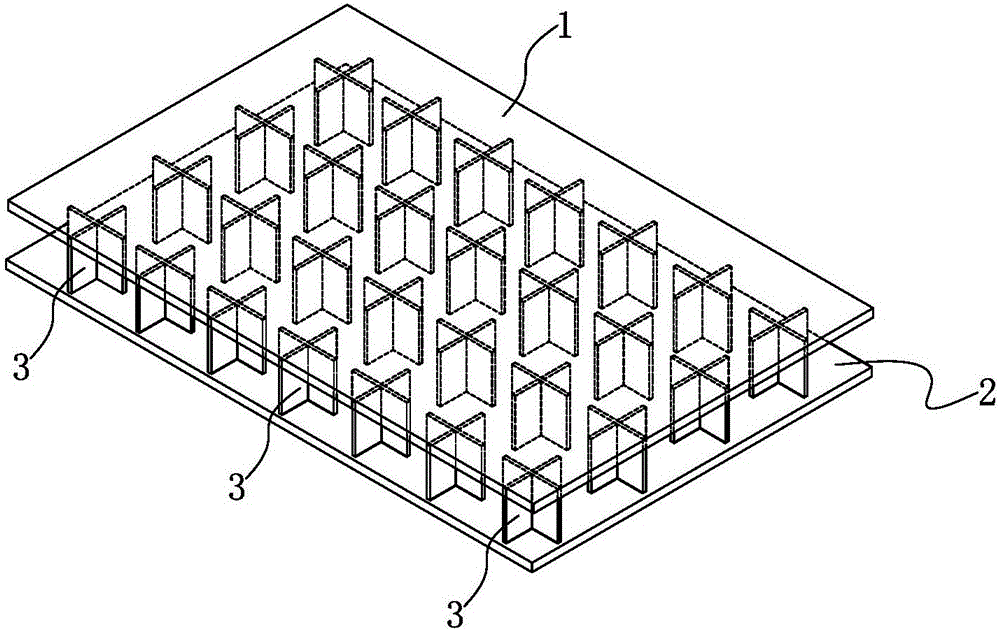

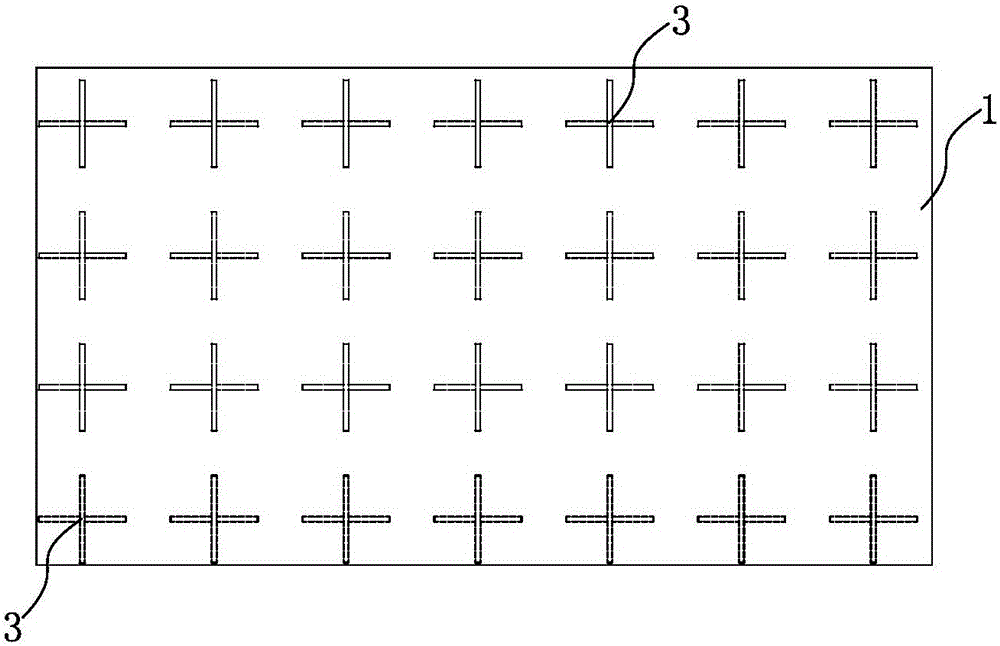

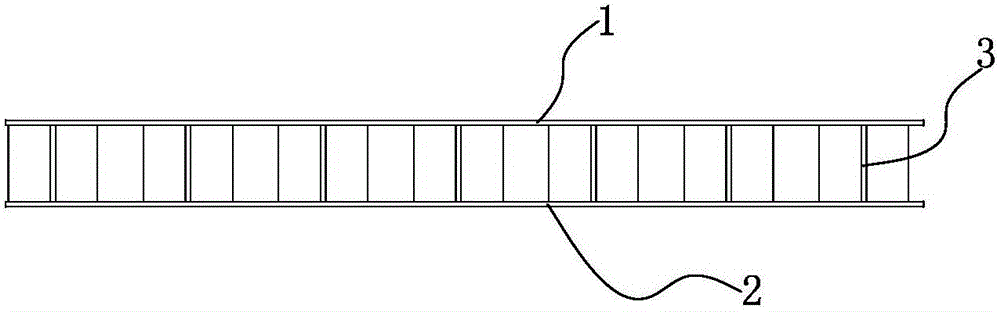

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 A lightweight cross-core lattice foam sandwich panel that integrates impact resistance and noise reduction is shown, including: an upper panel 1 and a lower panel 2 arranged oppositely; the upper panel 1 and the lower panel 2 are both made of metal Made of material; a plurality of skeletons 3 placed between the upper panel 1 and the lower panel 2; the skeleton 3 is in the shape of a cross, with a first metal plate 31 and a second metal plate 32 arranged perpendicular to each other; A plurality of skeletons 3 are arranged in a display style between the upper panel 1 and the lower panel 2; and the foam layer filled in the gap formed between each of the skeletons 3 and the upper panel 1 and the lower panel 2; further, the between the frame 3 and the upper panel 1, and between the frame 3 and the lower panel 2; further, from the center position of the first metal plate 31 to the first metal p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com