P-N fire retardant, flame-retardant master batch, flame-retardant nylon engineering plastic and preparation method thereof

A technology of flame retardant masterbatch and engineering plastics, which is applied in the fields of flame retardant masterbatch and flame retardant nylon engineering plastics, P-N type flame retardants, and can solve the problem of poor comprehensive performance of flame retardant nylon engineering plastics in terms of flame retardancy and mechanical properties. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

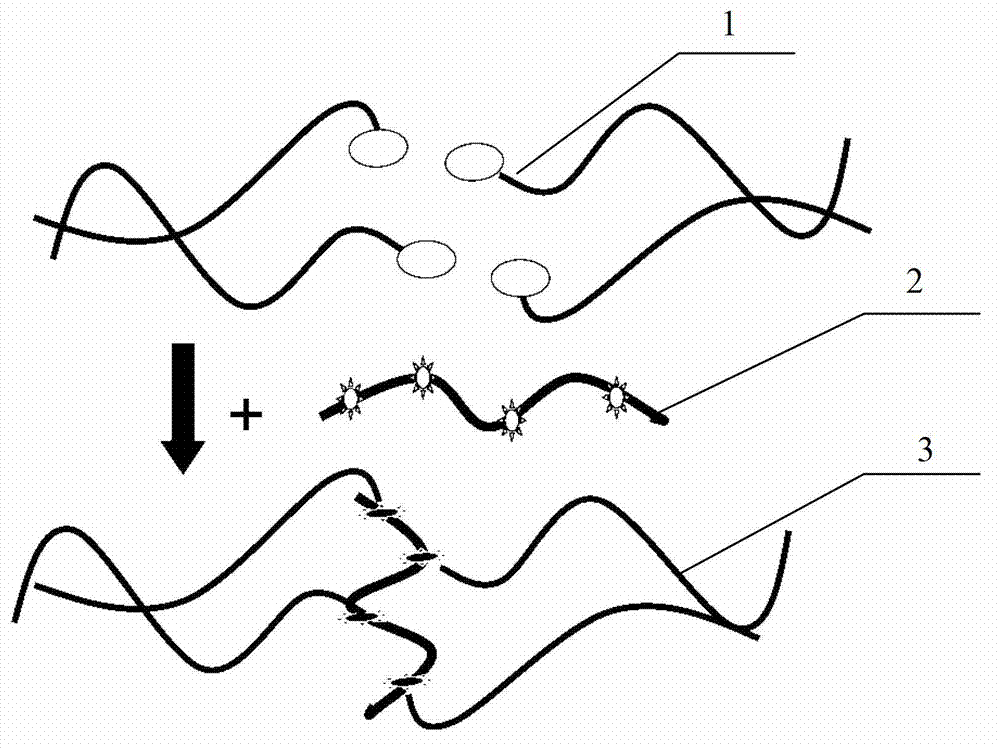

[0085] The preparation method of the P-N type flame retardant masterbatch provided by the invention comprises the following steps:

[0086] (1) Add dibasic acid compounds, such as 3-(hydroxyphenylphosphono)-propionic acid (CEPP) and diamines, such as ethylenediamine, into a reaction vessel, and add them to a beaker with a stirring bar and water respectively In the process, the acid-base neutralization reaction occurs under the stirring of a magnetic stirrer. After the reaction for 0.5-1h, it is poured into a tray and placed under an infrared lamp to evaporate the water completely, and a white solid product is obtained. The molar ratio of the dibasic acid compound to the diamine is 1:1; (2) The product obtained in step (1) is dried and ground into a white powder. Weigh the white powder and put it into a stainless steel reaction kettle with a water circulation jacket, built-in low-speed stirrer, thermal coupling sensor, and intermittent feeding port. Under a nitrogen atmosphere...

Embodiment 1

[0101] The synthetic route of flame retardant 3-(hydroxy-phenyl-phosphoryl)-propionic acid ethylenediamine polymer (CEPP-EA) is as follows:

[0102]

[0103]

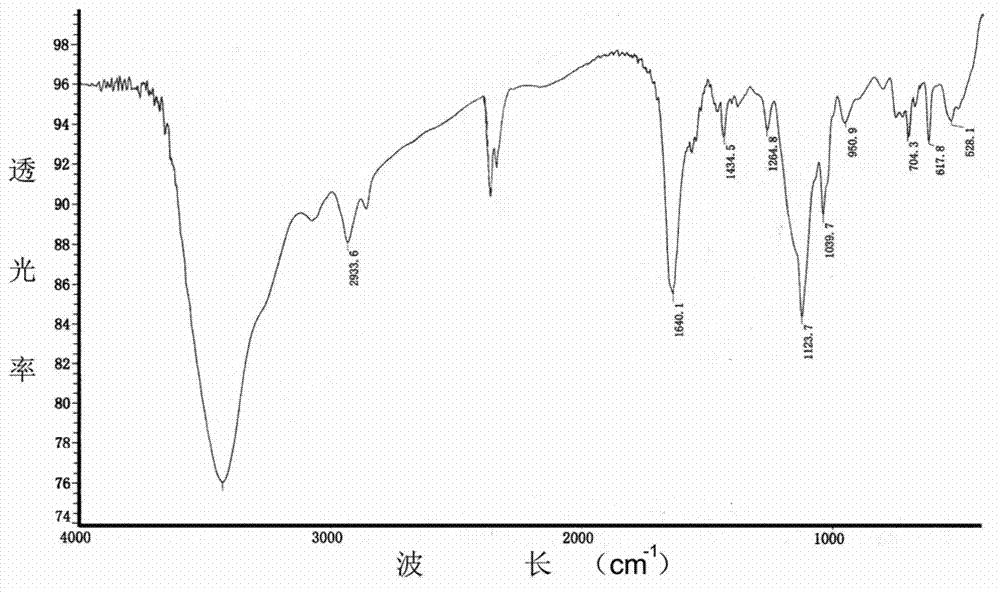

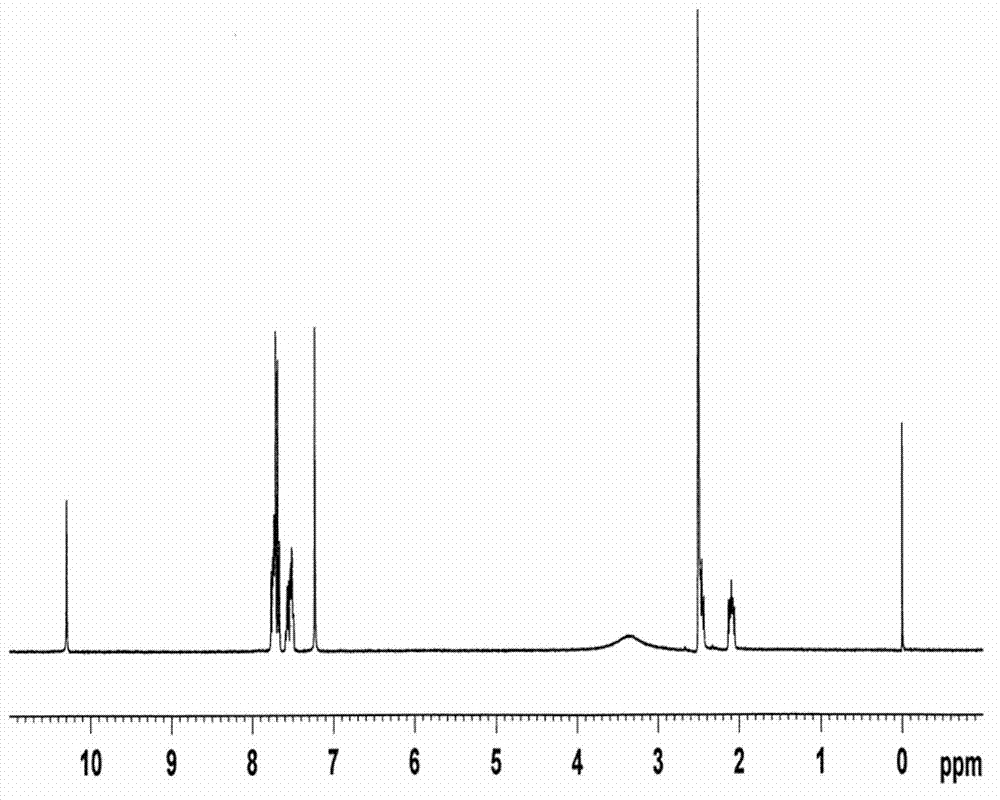

[0104] In a four-neck flask equipped with a stirring device, a thermometer, and a dropping funnel, add 3-(hydroxy-phenyl-phosphoryl)-propionic acid (CEPP) (214g, 1mol) and ethylenediamine (116g, 1mol) respectively , Acid-base neutralization reaction occurs under the stirring of a magnetic stirrer. After 30 minutes of reaction, pour it into a tray and place it under an infrared lamp to evaporate the water to obtain a white solid product (intermediate). Dry and grind the obtained white solid product Fine into white powder. Weigh 320g of white powder (intermediate), put it into a stainless steel reactor with a water circulation jacket, built-in low-speed stirrer, thermal coupling sensor, intermittent feeding port, the reactor is 25L. Under a nitrogen atmosphere, the initial reaction temperature is 220°C, and then th...

Embodiment 2

[0107] The synthetic route of flame retardant 3-(hydroxy-naphthyl-phosphoryl)-propionic acid ethylenediamine polymer (CENP-EA) is as follows:

[0108]

[0109]In a four-neck flask equipped with a stirring device, a thermometer, and a dropping funnel, add 3-(hydroxy-naphthyl-phosphoryl)-propionic acid (CENP) (264g, 1mol) and ethylenediamine (116g, 1mol) respectively. , under the stirring of a magnetic stirrer, an acid-base neutralization reaction occurs. After 40 minutes of reaction, it is poured into a tray and placed under an infrared lamp to evaporate the water completely, and a white solid product is obtained. The product obtained in step (1) is dried and ground into white powder. Weigh 380g of white powder and put it into a stainless steel reaction kettle with a water circulation jacket, built-in low-speed stirrer, thermal coupling sensor, and intermittent feeding port. Under a nitrogen atmosphere, the initial reaction temperature was 210°C, and then a temperature prog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com