Patents

Literature

74results about How to "Does not reduce toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High performance nano polyurethane micropore elastomer composite material and preparation thereof

ActiveCN101486834AImprove mechanical propertiesHigh tensile strengthFoaming agentPolyether polyurethane

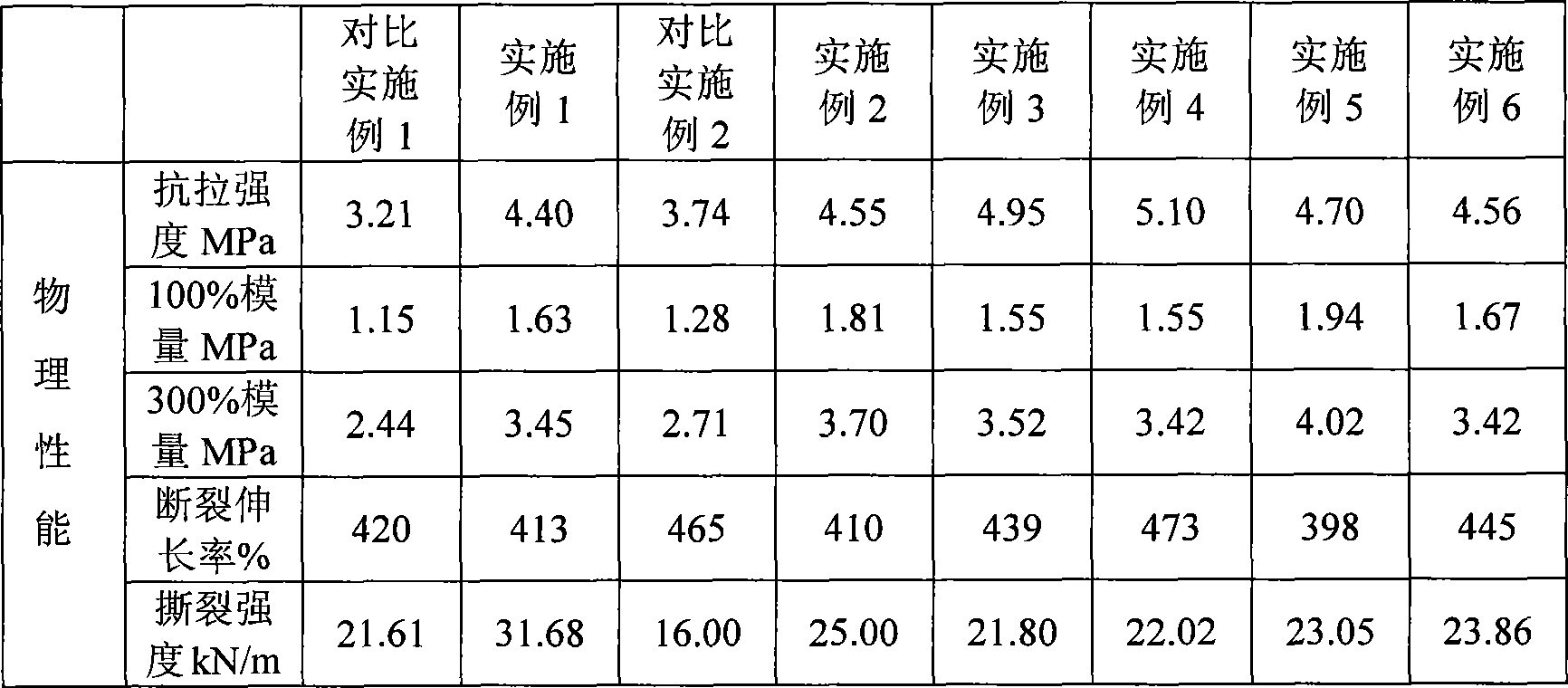

The invention discloses a high-performance nanometer polyurethane microcellular elastomer composite material and a preparation method thereof. Organic montmorillonite is added into polyether glycol I, heated and stirred, thus obtaining stably dispersed colloidal fluid; then polyether glycol II, an alcohols chain-extender, a foaming agent, a foam stabilizer and a catalyst are added, fully and evenly mixed, thus obtaining component A. B component is a performed polymer prepared by the reaction of the polyether glycol I, vulcabond or polyisocyanates at the temperature between 60 and 90 DEG C, with NCO percentage controlled between 17 and 26 percent by weight. The components A and B are mixed at high speed according to the weight mixture ratio that A:B equals to 0.5:1 to 3:1 by using a casting machine and at the temperature of 30-55 DEG C, and injected into a mould for injection moulding, consequently, the high-performance nanometer polyurethane microcellular elastomer composite material is obtained. With low cost, the invention improves a plurality of mechanical properties of a polyether polyurethane microcellular elastomer, such as the tensile strength, modulus and tear strength and the like, and broadens the application field of materials. The composite material can be used as shoe parts, bottom materials, bearing tires or shock absorption buffering materials, and the like. With a bi-component system and a casting moulding technology adopted simultaneously, the invention is simple and can be easily controlled, thus bringing convenience to production promotion.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

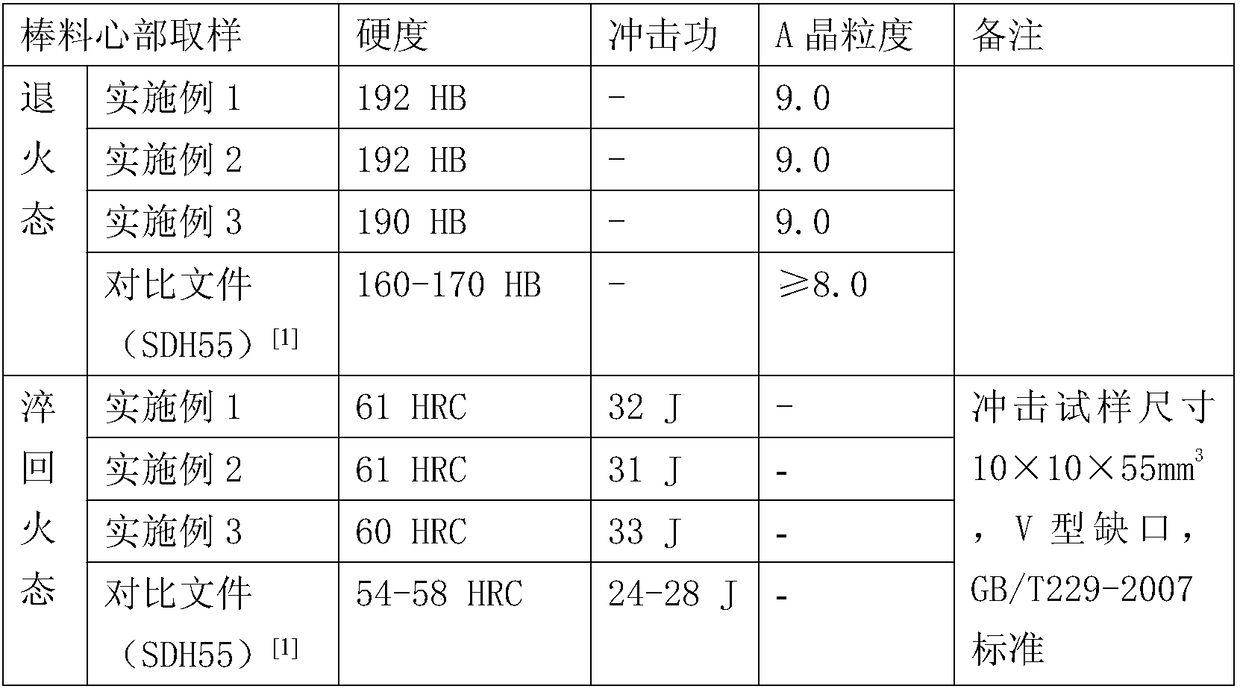

High-strength alloy tool steel

InactiveCN1422972AImprove comprehensive physical and chemical propertiesImprove hardenabilityManganeseQuenching

The invention refers to a kind of high intensity alloy tool steel which is used in cutting knives, stone breaking knives and the model manufacturing field. It includes Fe and alloy elements, the shares and contents of Fe and alloy element is: C 0.4-0.6%, Cr3.5-6%, Mo0.5-2.5%, Si0.4-2.5%, V0.4-2.0%, Mn0.1-1.0% Fe is the residue. The alloy steel in the invention goes through 1100-1200 C degree high temperature quenching and 500-580 C degree backfire process three times, its highest rigidity can reach HRC58-62, gold phase tissue is quenching ma body and evenly, little carbide.

Owner:SINOPEC OILFIELD EQUIP CORP

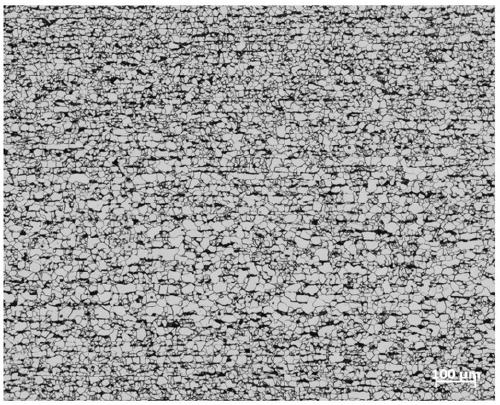

Preparation method of fine-crystal spume aluminium alloy

InactiveCN101182605ADoes not reduce toughnessEquipment condition is simpleRoom temperatureCrystallization temperature

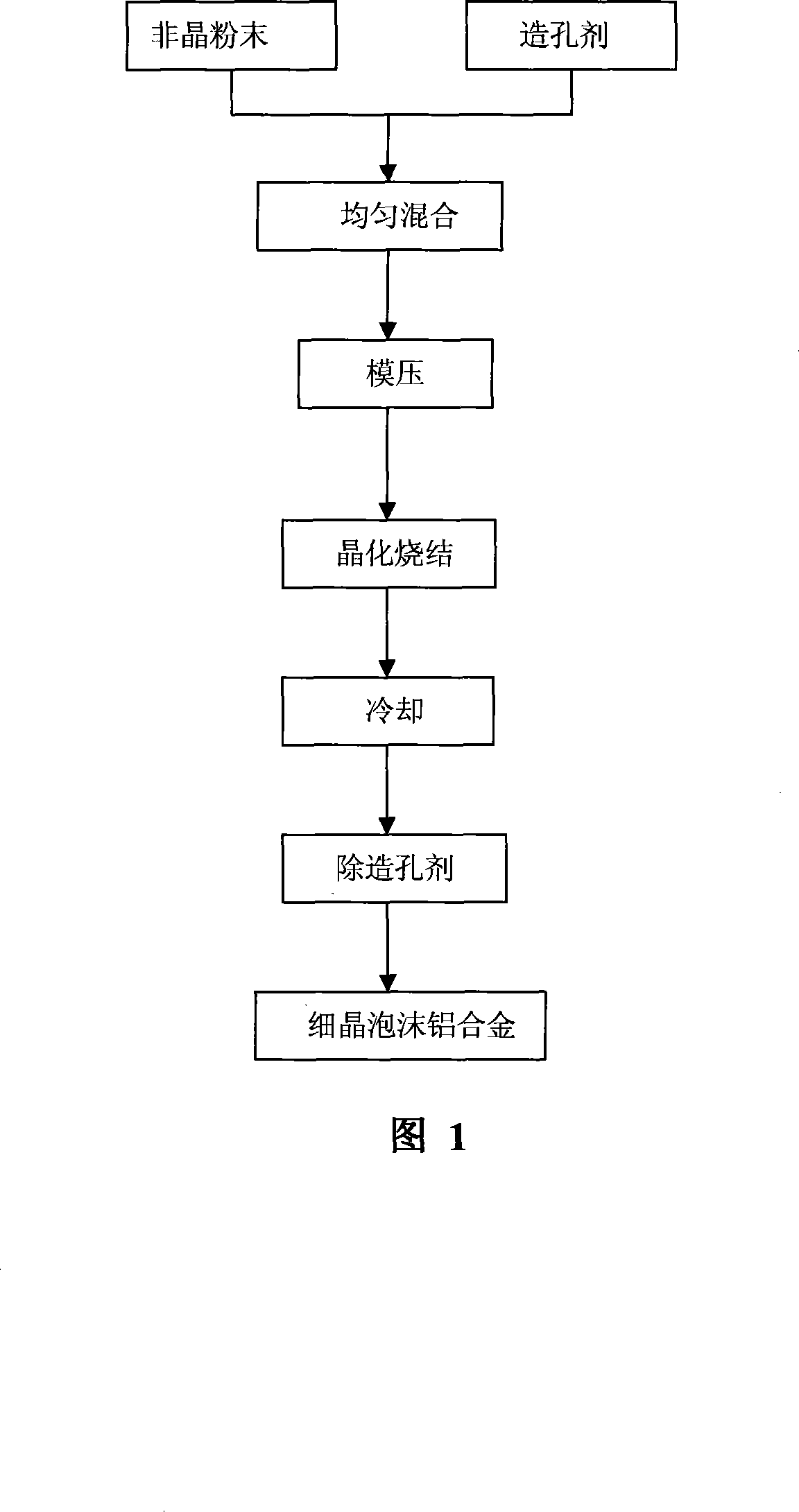

A method for preparing a fine-grained foam aluminum alloy belongs to the porous foam metal material field. According to the method, aluminum base non-crystal powder is evenly mixed with pore forming material and the mixture is compressed compactly to obtain the green compact; under the protection of argon and with the crystallization temperature of the aluminum base non-crystal powder, the process of isothermal annealing and crystallization and at the same time, the metal powder is sintered and cooled to the room temperature; water is used for dissolving the pore forming material and high-strength and tenacity foam aluminum alloy with fined matrix tissue. The invention fines the matrix tissue of the foam aluminum alloy according to the method of crystallization of non-crystal material; with the fine-grained consolidation action, the strength of the foam aluminum alloy is enhanced on the basis of not reducing the tenacity of the foam aluminum alloy.

Owner:KUNMING UNIV OF SCI & TECH

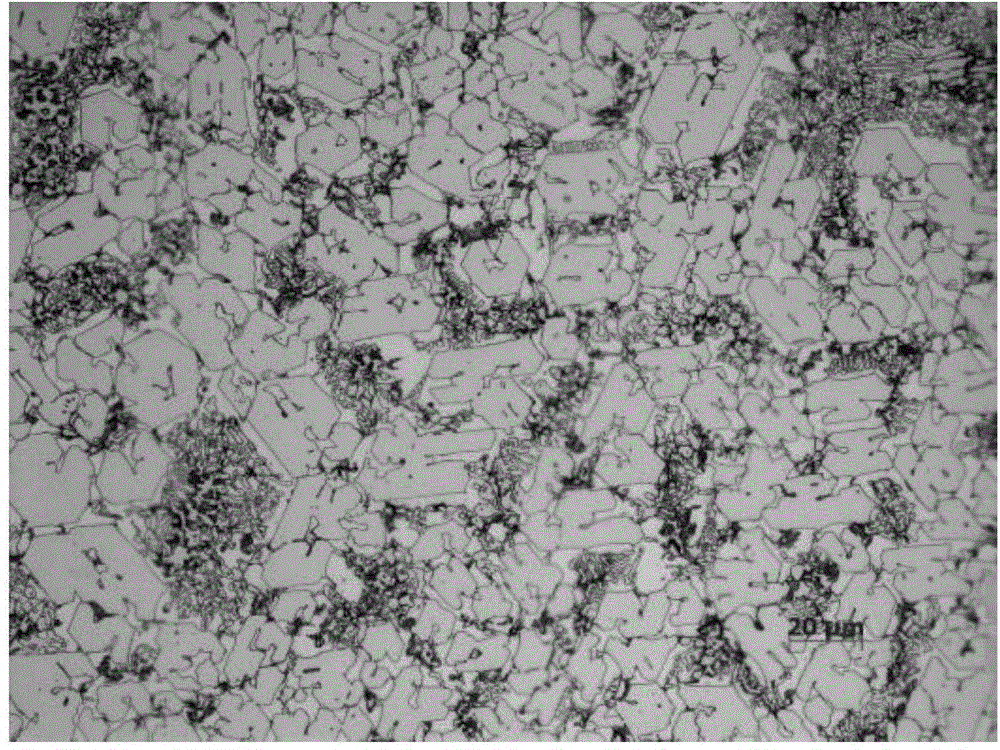

Surface wear-resistant strengthening treatment method for high-carbon cold work die steel

InactiveCN103225055AExtended service lifeDense tissueSolid state diffusion coatingHigh carbonWear resistant

The invention relates to a surface wear-resistant processing technology for a high-carbon cold work die steel, and particularly relates to a preparation method for vanadium-carbon-boron wear-resistant layer of the high-carbon cold work die steel. According to the method, a salt bath formed by mixing borax and BCl2+NaCl+KCl according to a certain proportion is used as a carrier; V2O5, Al and the metal yttrium are added in the salt bath; and the above materials are permeated for 6 hours at a temperature of 1,040-1,060 DEG C. The thickness of the vanadium-carbon-boron wear-resistant layer prepared by the method is 12-15 [mu]m; the hardness is HV2,900-3,3300; the vanadium-carbon-boron wear-resistant layer is compact in microstructure, and has good bonding strength with a matrix, excellent wear resistance, seizure resistance and anti-stripping capacity; and the wear-resistant layer is stable in quality. The high-carbon cold work die steel is directly subjected to quenching (or normalizing) and tempering for 8-10 hours at a temperature of 200-250 DEG C after the vanadium-carbon-boron penetrating treatment, so that toughness of the matrix is not reduced; and service life of the die is increased by a plurality times to ten times. Besides, the method is pollution-free in treatment process and good in energy conservation, and overcomes the disadvantages of unstable quality of vanadizing layer in mixed salt bath.

Owner:WUXI SHENGYUAN METAL PRODS

Ultra-low-carbon cryogenic steel and heat treatment technique thereof

The invention provides ultra-low-carbon cryogenic steel and a heat treatment technique thereof. The ultra-low-carbon cryogenic steel comprises the elements of, by mass, 0.005-0.01% of C, 1.0-4.5% of Ni, 6.0-12.0% of Mn, 1.0-3.0% of Al, 0.5-3.0% of Cu, 0.005% or less of P, 0.003% or less of S, 0.005-0.008% of N, 0.0005-0.002% of O and the balance Fe. According to the ultra-low-carbon cryogenic steel and the heat treatment technique thereof, through the TRIP effect of retained austenite and precipitation hardening of a nano-precipitate phase, the high-strength ultra-low-carbon nickel-saving nano-precipitate reinforced cryogenic steel is prepared and obtained, has good strength, excellent plasticity and good weldability and is low in cost, and the heat treatment technique is simple.

Owner:SHANGHAI JIAO TONG UNIV

High-strength and high-elongation cold-rolled packing steel strip and manufacturing method thereof

The invention provides a high-strength and high-elongation cold-rolled packing steel strip and a manufacturing method thereof. The steel strip is prepared from following chemical components in percentage by mass: 0.20-0.23% of C, 1.50-1.80% of Mn, smaller than or equal to 0.15% of Si, smaller than or equal to 0.015% of S, smaller than or equal to 0.025% of P, larger than or equal to 0.035% of Al, smaller than or equal to 0.0050% of N and the balance iron and inevitable impurities. The manufacturing method includes the procedures of converter smelting, LF furnace refining, continuous casting, casting blank heating, hot rolling, laminar cooling, reeling, acid pickling, cold rolling and annealing blueing. The procedure of hot rolling includes the steps of coarse rolling and fine rolling. According to the method, Nb, Ti, V and other precious alloy elements are not added, and the production cost is effectively reduced; a ferrite matrix is subjected to solution strengthening through a certain manganese content, the strength of steel is guaranteed, and the toughness of the steel is not reduced; and a hot rolling controlled rolling and controlled cooling process is adopted and combined with a follow-up cold rolling hardening process and a low-temperature annealing blueing process, and it is guaranteed that the final product has high strength (tensile strength is larger than or equal to 980 MPa) and has good processing performance (elongation A30 is larger than or equal to 12%).

Owner:TANGSHAN IRON & STEEL GROUP

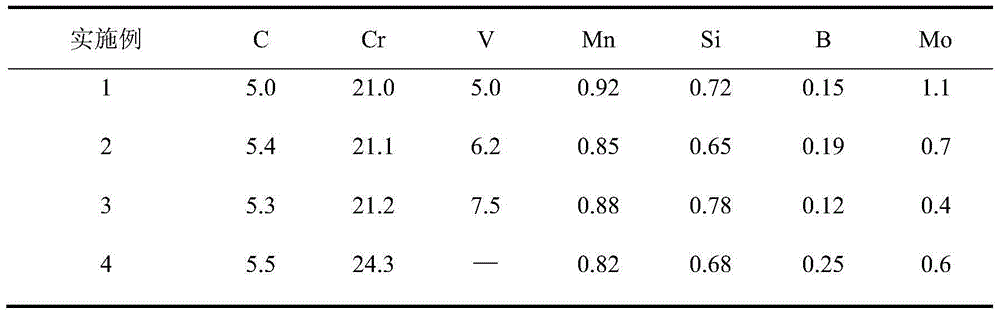

High-carbon high-chrome high-vanadium wearable surfacing self-shielded flux-cored wire

InactiveCN105798484AHigh hardnessImprove wear resistanceWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention discloses a high-carbon high-chrome high-vanadium wearable surfacing self-shielded flux-cored wire. According to the flux-cored wire, the core is prepared from the following components in mass percentage: 5-25% of high carbon ferro-chrome, 30-60% of chromium carbide, 15-35% of ferrovanadium, 0.5-5% of ferromolybdenum, 1-4% of electrolytic manganese, 1-4% of ferrosilicon, 1-4% of ferroboron, 1-5% of graphite, 1-5% of aluminium magnesium, 0-3% of zircon sand, 0-4% of marble, 0-3% of barium fluoride, 0-5% of barium carbonate, 0-3% of sodium fluosilicate, and 0-5% of fluorite; the skin of the flux-cored wire is a mild-carbon steel strip, the diameter is 1.6-4.0mm, and the counterweight ratio is 44-53%. According to the flux-cored wire disclosed by the invention, the rigidity and wearability of surfacing alloy can be greatly improved and the toughness of the surfacing alloy cannot be reduced; and the prepared surfacing alloy can be widely applied to surfacing repair of parts with severe low and intermediate stress abrasion at low temperature, intermediate temperature and high temperature and manufacture of new parts.

Owner:GRIPM ADVANCED MATERIALS CO LTD

345MPa-grade low-yield-ratio weather-resistant steel and preparation method thereof

The invention discloses 345MPa-grade low-yield-ratio weather-resistant steel. The 345MPa-grade low-yield-ratio weather-resistant steel comprises the following components in percentage by mass: 0.04 to0.12 percent of C, 0.50 to 0.75 percent of Si, 0.43 to 0.50 percent of Mn, 0.06 to 0.09 percent of P, 0.010 to 0.020 percent of Ti, less than or equal to 0.004 percent of S, 0.25 to 0.40 percent of Cu, 0.15 to 0.35 percent of Ni, 0.30 to 0.60 percent of Cr, 0.02 to 0.04 percent of Al and the balance of Fe and unavoidable impurities. The preparation method of the weather-resistant steel comprisesthe following steps: (1) smelting: performing smelting, refining, alloying and calcium treatment on raw materials to obtain molten steel; (2) performing continuous casting: performing continuous casting on a molten steel upper plate blank; (3) soaking: performing soaking treatment on the casting blank; (4) performing steel rolling: performing steel rolling after removing phosphorus; (5) performingrelaxation: performing relaxation on a thin steel plate after finishing rolling; and (6) cooling. The preparation method of the weather-resistant steel has low yield ratio, high-temperature and low-temperature toughness, extensibility and high properties.

Owner:NANJING IRON & STEEL CO LTD

Master batch with functions of toughening, chemical corrosion resistance and color matching and preparation method of master batch

InactiveCN104788838AReduce dissolutionImprove corrosion resistanceRefrigerated temperatureColor matching

The invention discloses a master batch with the functions of toughening, chemical corrosion resistance and color matching, and belongs to the technical field of modified plastics. The master batch is prepared from the following raw materials in parts by weight: 0-35 parts of polyolefin resin, 0-20 parts of PS resin, 0-15 parts of a compatilizer, 0-40 parts of a toughening agent, 0-20 parts of a reinforcing agent, 15-35 parts of pigments, 0.5-1 part of an antioxygen and 1-5 parts of a lubricant. The master batch can improve the toughness of an interlayer material and enables the elongation at break to be doubled or higher; by adopting the alloy technology, the dissolution of the interlayer HIPS by a foaming agent is reduced, cracks due to partial dissolution of the material is prevented; the master batch also enables sheet materials to have excellent covering power, and meets the trend of a thinner liner of a refrigerator; color matching can be carried out according to customer requirements.

Owner:ANHUI LIANKE WATER BASED MATERIAL TECH

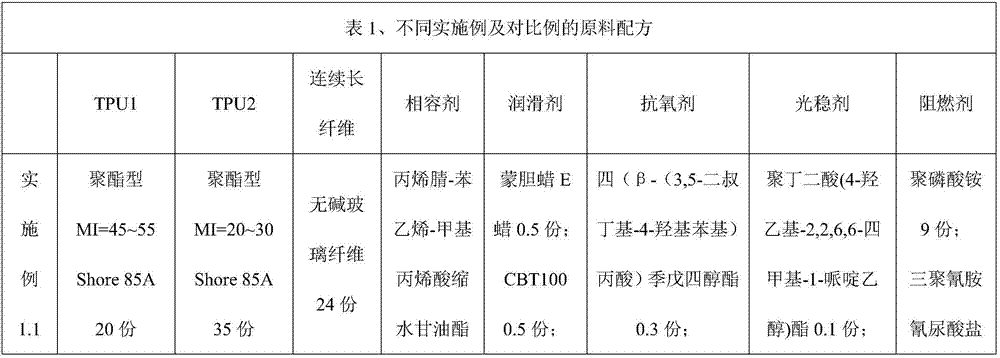

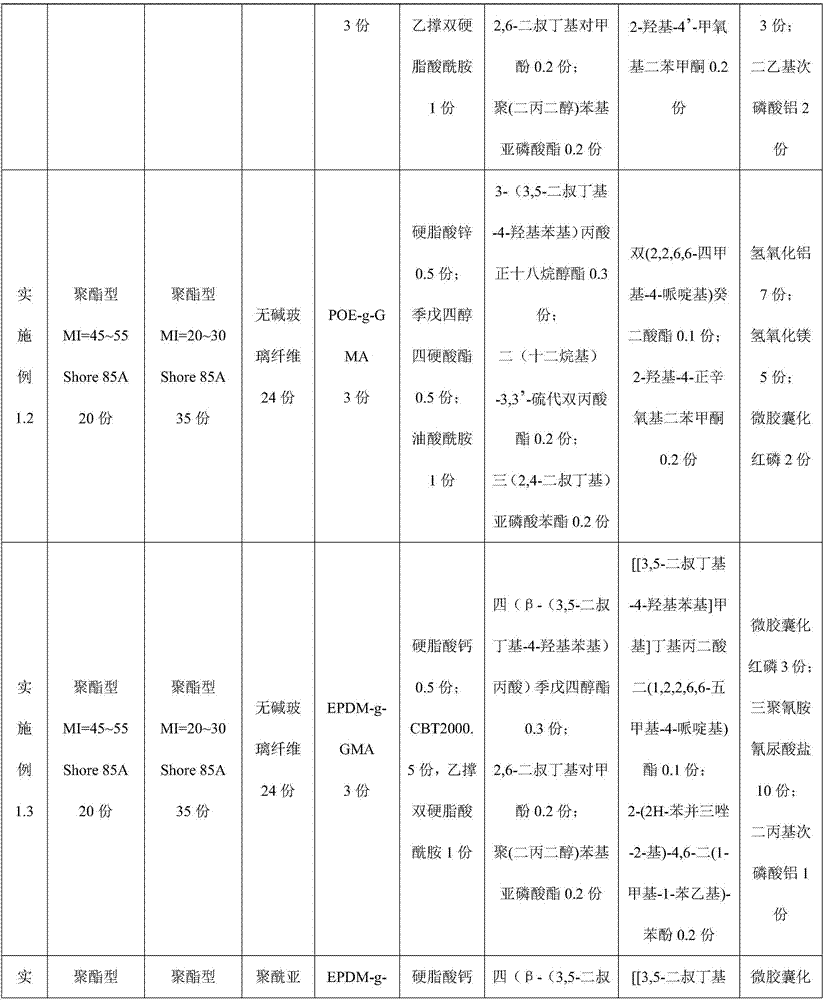

Thermoplastic polyurethane composite material used for cable and optical cable sheaths and preparation method of composite material

ActiveCN108003602AGood weather resistanceHigh tensile strengthPlastic/resin/waxes insulatorsFiberAntioxidant

The invention discloses a thermoplastic polyurethane composite material used for cable and optical cable sheaths. The composite material is mainly prepared from the following raw material components in parts by weight: 15-35 parts of TPU1, 30-60 parts of TPU2, 10-30 parts of continuous long fibers, 0.1-10 parts of a compatibilizer, 0.1-6 parts of a lubricant, 0.2-5 parts of an antioxidant, and 0-35 parts of a flame retardant. The obtained thermoplastic polyurethane composite material provided by the invention has excellent tensile strength, rigidity and wear resistance, has high performance such as toughness, hardness, elasticity, oil resistance, chemical corrosion resistance, weather resistance, tension resistance and extrusion resistance, can form a good product surface, has higher impact resistance and higher wear resistance, can meet the performance requirements of a high-performance cable and optical cable sheath material, and is used in special application fields such as wind energy cables and submarine optical cables. The preparation method of the thermoplastic polyurethane composite material provided by the invention is beneficial for obtaining an excellent-performance material used for the cable and optical cable sheaths, and is convenient for application and promotion of the material, and has remarkable economic benefits.

Owner:河北邦泰氨纶科技有限公司

Super-high-strength steel Q960D for engineering machinery and production method of super-high-strength steel Q960D

ActiveCN106086639AGuaranteed mechanical propertiesImprove cleanlinessProcess efficiency improvementSheet steelImpurity

The invention discloses super-high-strength steel Q960D for engineering machinery and a production method of the super-high-strength steel Q960D. The steel comprises, by mass percentage, 0.13-0.16% of C, 1.40-1.50% of Mn, 0.02-0.04% of Nb, 0.09-0.11% of V, 0.015-0.025% of Ti, 0.45-0.55% of Cr, 0.45-0.55% of Mo, 0.0008-0.003% of B, greater than or equal to 0.03% of Als and the balance Fe and unavoidable residual elements and impurities generated in the production process. According to the super-high-strength steel Q960D and the production method thereof, an LF+RH process is adopted for guaranteeing cleanliness of the steel, and it is guaranteed that internal quality of a steel plate meets the flaw detection requirements; a controlled rolling+(DQ+ACC) cooling + tempering process is adopted for refining grains, low production cost is guaranteed, and meanwhile, the super-high-strength steel Q960D for the engineering machinery is produced; and mechanical performance and internal quality meet the requirements of GB / T16270-2009.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Steel for sucker rod, and making method of sucker rod

The invention discloses a steel for a sucker rod, and a making method of the sucker rod, and belongs to the field of petroleum exploitation apparatuses. The steel for the sucker rod comprises carbon, silicon, manganese, chromium, molybdenum, aluminum, copper, phosphorus, sulfur, nickel and iron. The making method comprises the following steps: machine-shaping the steel for the sucker rod, forging the steel, quenching and tempering the forged steel, carrying out heat straightening to obtain a sucker rod blank, carrying out shot blasting treatment on the surface of the sucker rod, and processing a screw thread on the surface of the sucker rod blank to make the sucker rod. Proper amounts of elements are added to iron in the steel for the sucker rod, so the corrosion resistance and the strength of the sucker rod are improved, especially the corrosion resistance to hydrogen sulfide and chloride ions is improved, thereby the life of the sucker rod is prolonged, and the petroleum exploitation cost is reduced. The making method adopts an aqueous solution of sodium chloride as a medium to cool, so the sucker rod made in the invention is uniformly quenched, and the quenching cracks of the sucker rod are reduced.

Owner:PETROCHINA CO LTD

Ultra-high strength Q800C steel plate used for engineering machinery and producing method thereof

The invention discloses an ultra-high strength Q800C steel plate used for engineering machinery and a producing method thereof. The steel plate comprises, by mass, 0.13-0.16% of C, 1.40-1.50% of Mn, 0.02-0.04% of Nb, 0.09-0.11% of V, 0.015-0.025% of Ti, 0.45-0.55% of Cr, 0.45-0.55% of Mo, 0.0008-0.003% of B, no less than 0.03% of Als, and the balance Fe and unavoidable impurities. The producing method comprises the processes of converter smelting, refining, continuous casting, heating, rolling, quenching+cooling and tempering heat treatment. According to the ultra-high strength Q800C steel plate and the producing method, an LF+RH process is used to guarantee the steel cleanliness, TMCP+DQ on-line quenching+ACC cooling+ tempering processing is adopted for grain refining, and the mechanicalproperties and internal mass of the steel plate meet the GB / T 16270-2009 requirement.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

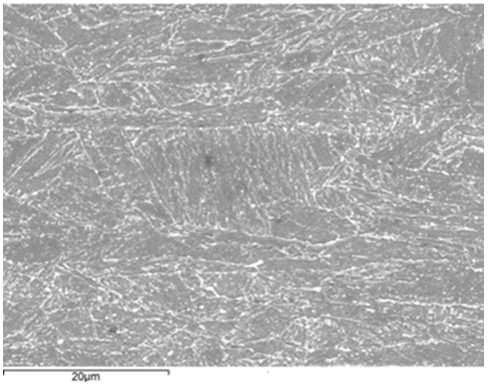

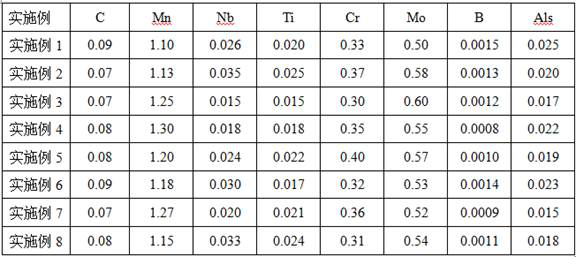

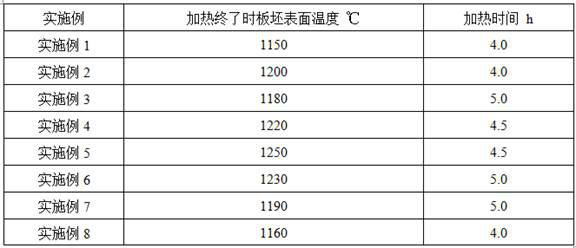

Ultrahigh-strength engineering machinery steel Q890D and production method thereof

ActiveCN111945077AGuaranteed mechanical propertiesReduce toughnessProcess efficiency improvementTemperingMechanical property

The invention discloses ultrahigh-strength engineering machinery steel Q890D and a production method thereof. A steel plate comprises the following components in percentage by mass: 0.07-0.09% of C, 1.10-1.30% of Mn, 0.015-0.035% of Nb, 0.015-0.025% of Ti, 0.30-0.40% of Cr, 0.50-0.60% of Mo, 0.0008-0.0015% of B, no less than 0.015% of Als, and the balance Fe as well as inevitable residual elementsand impurities in the production process; and the online quenching and tempering production technology is adopted in the production process. The mechanical properties of the Q890D steel plate provided by the invention meet the GB / T 16270-2009 requirements, and the low-cost production of such steel is achieved.

Owner:HANDAN IRON & STEEL GROUP +1

P-N fire retardant, flame-retardant master batch, flame-retardant nylon engineering plastic and preparation method thereof

ActiveCN103087312AImprove flame retardant performanceReduce dosagePolymer scienceEngineering plastic

The invention relates to a nylon engineering plastic, particularly relates to a P-N fire retardant, a flame-retardant master batch, and a flame-retardant nylon engineering plastic. In order to solve the defects of poor fire resistance and mechanical property of the flame-retardant nylon engineering plastic in the prior art, the invention provides the P-N fire retardant, the flame-retardant master batch, the flame-retardant nylon engineering plastic and preparation methods thereof. The structural general formula of the P-N fire retardant provided by the invention is shown in the specification, wherein R1 is a benzyl or aryl functional group; R2 and R3 are alkyl or hydrogen; R4 and R5 are alkyl or hydrogen; n is greater than or equal to 2, preferably 2-6; and m represents the polymerization degree of polymer and is an integer greater than or equal to 1. The flame-retardant master batch provided by the invention comprises the fire retardant. The glass fiber reinforced flame-retardant nylon engineering plastic provided by the invention comprises the flame-retardant master batch. The fire retardant and the flame-retardant master batch provided by the invention are good in flame-retardant effect; and the provided nylon has better fire resistance and mechanical property.

Owner:NINGBO CHANGYANG TECH

Low-alloy and high-strength steel Q460C and production method thereof

ActiveCN106086647AReduce manufacturing costLow alloy high strength production costTemperature controlReduction rate

The invention discloses low-alloy and high-strength steel Q460C and a production method thereof. The steel comprises, by mass percent, 0.11%-0.15% of C, 0.20%-0.40% of Si, 1.30%-1.50% of Mn, 0.01%-0.02% of Nb, 0.050%-0.070% of Ti and 0.020%-0.040% of Als. The heating time of a plate blank is longer than or equal to 3.5 h, and temperature at the heating ending moment ranges from 1100 DEG C to 1190 DEGC; a CR manner is adopted for rolling, the temperature-holding thickness at the rolling starting moment is three times or more of the thickness of a finished steel plate, the accumulative reduction rate of finish rolling is larger than or equal to 66%, and the final rolling temperature ranges from 810 DEG C to 850 DEG C; and an ACC cooling manner is adopted, the finish cooling temperature of the steel plate ranges from 630-20 DEG C to 630+20 DEG C. According to the low-alloy and high-strength steel Q460C and the production method thereof, a low-Nb and high-Ti microalloy component system is adopted, toughness is not reduced on the premise that strength is ensured, temperature-control rolling and ACC cooling control processes are optimized, an ideal F+P structure is obtained, and the production cost is low.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

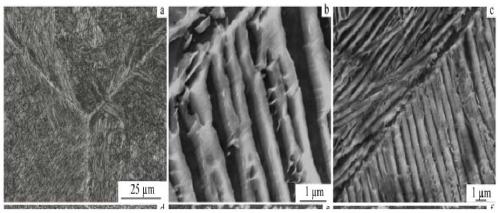

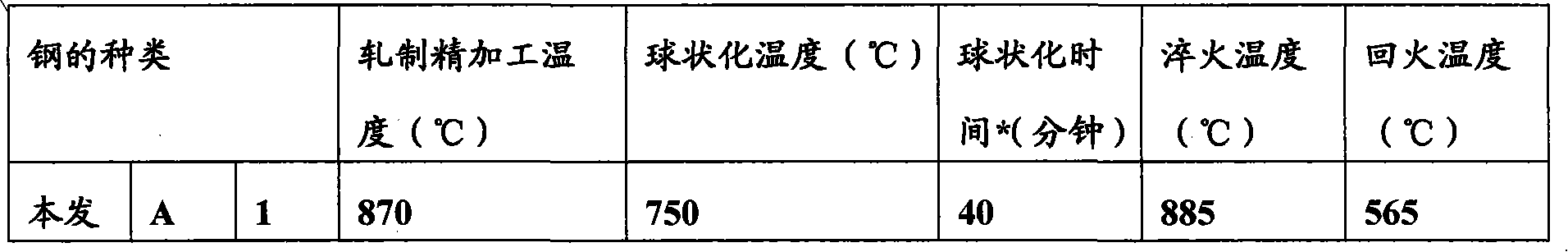

Steel for shield machine cutting tool and manufacturing method thereof

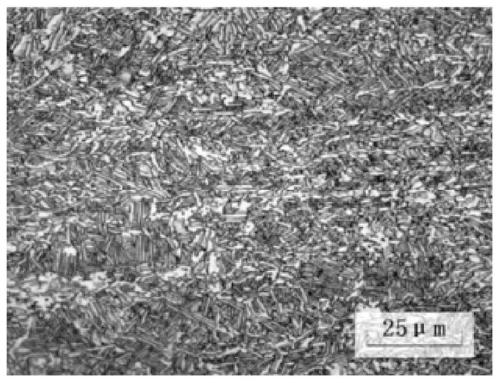

InactiveCN108486499AHigh hardnessImprove wear resistanceFurnace typesHeat treatment furnacesCarbideIngot

The invention discloses steel for a shield machine cutting tool. The steel for the shield machine cutting tool comprises the components of, by mass, 0.70-0.75% of C, 0.15-0.25% of Si, 0.45-0.55% of Mn, 5.00-5.20% of Cr, 2.30-2.40% of Mo, 0.50-0.60% of V, less than 0.020% of P, less than 0.005% of S, and the balance Fe and inevitable impurities. The steel for the shield machine cutting tool is manufactured by melting of an induction furnace, remelting of an electroslag furnace, three-dimensional refinement uniforming, FM forging and post-forging heat treatment. The steel has high abrasion performance, high hardness and good tenacity. Large sized carbides in a steel ingot are thoroughly fragmented by the FM forging, and existence of tensile stress in a forge piece is avoided.

Owner:HUBEI SHANGDA MODEL MATERIAL TECH

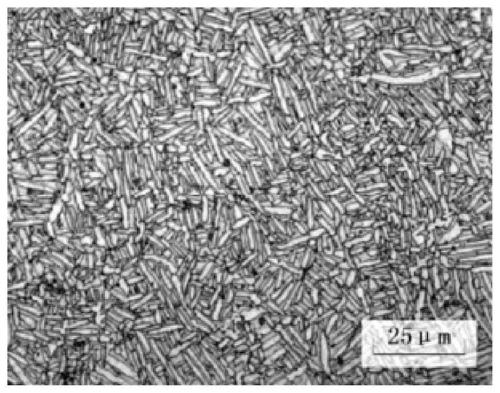

Preparation method of high-strength and high-toughness titanium alloy material cutter

InactiveCN110129700AHigh strengthImprove corrosion resistanceVacuum evaporation coatingSputtering coatingFine structurePunching

The invention relates to the technical field of cutters, in particular to a preparation method of a high-strength and high-toughness titanium alloy material cutter. The preparation method comprises the following steps that S1, raw materials are prepared; S2, punching is carried out, wherein the prepared titanium alloy materials are fed into a punching workshop for cutting, and a cutter blank is cut according to the size of the cutter, and the size and the thickness of a cutter sample; S3, heat treatment is carried out, and specifically heat treatment is carried out on the cut cutter blank; S4,surface hydrogen permeation is carried out; and S5, film coating is carried out, wherein a Ti-DLC film is plated on the surface of the cutter blank by using a magnetron sputtering method, microporesin the DLC film layer are plugged through fluorine-containing acrylate monomers, so that the wear resistance of the cutter is improved, the toughness of a substrate is not reduced, the coating has a fine structure, so that the compressive stress is produced inside the coating, the anti-crack propagation capability is high, and the service performance of the cutter is improved.

Owner:阳江十八子刀剪制品有限公司

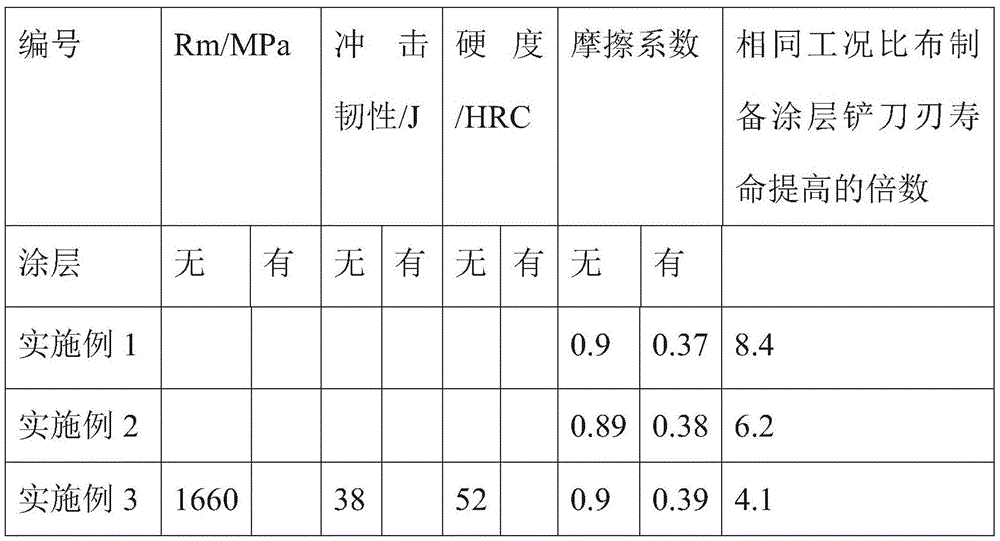

High-wear-resistance cermet coating

InactiveCN105603420AHigh surface hardnessReduce coefficient of frictionMetallic material coating processesWear resistantAlloy

The invention provides a high-wear-resistance cermet coating which comprises 10-20 wt.% of Ni-base alloy and 80-90 wt.% of Si-Al-C-N amorphous particles. The invention also provides a laser cladding preparation method of the high-wear-resistance cermet coating. The Si-Al-C-N superhard amorphous particles coated with the Ni-base alloy are used as the cermet coating for perching knife blades; the hardness of the coating can reach HV2000 or above, and the friction factor is lower than 0.4; the laser cladding preparation technique does not lower the strength and toughness of the steel; and by using the cermet coating, plain steel has favorable compatibility among hardness, strength, toughness and friction factor, and has favorable service performance and very long service life. By using the Ni-base alloy as the laser cladding coating material of the Si-Al-C-N amorphous particles, so that the cost of the wear-resistant special steel is obviously lowered.

Owner:苏州范德雅特新材料科技有限公司

High tensile steel for deep drawing and manufacturing method thereof

InactiveCN101849028AHigh strengthInhibit deteriorationFurnace typesHeat treatment furnacesUltimate tensile strengthDeep drawing

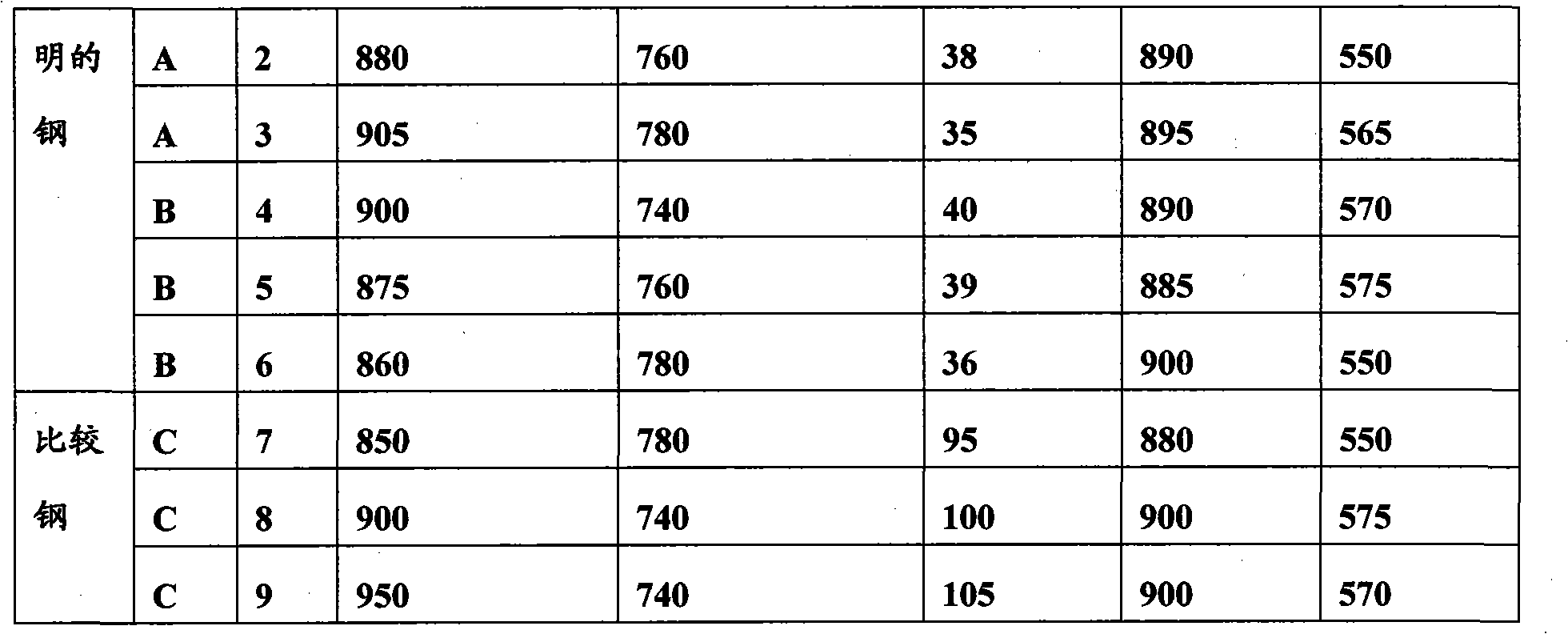

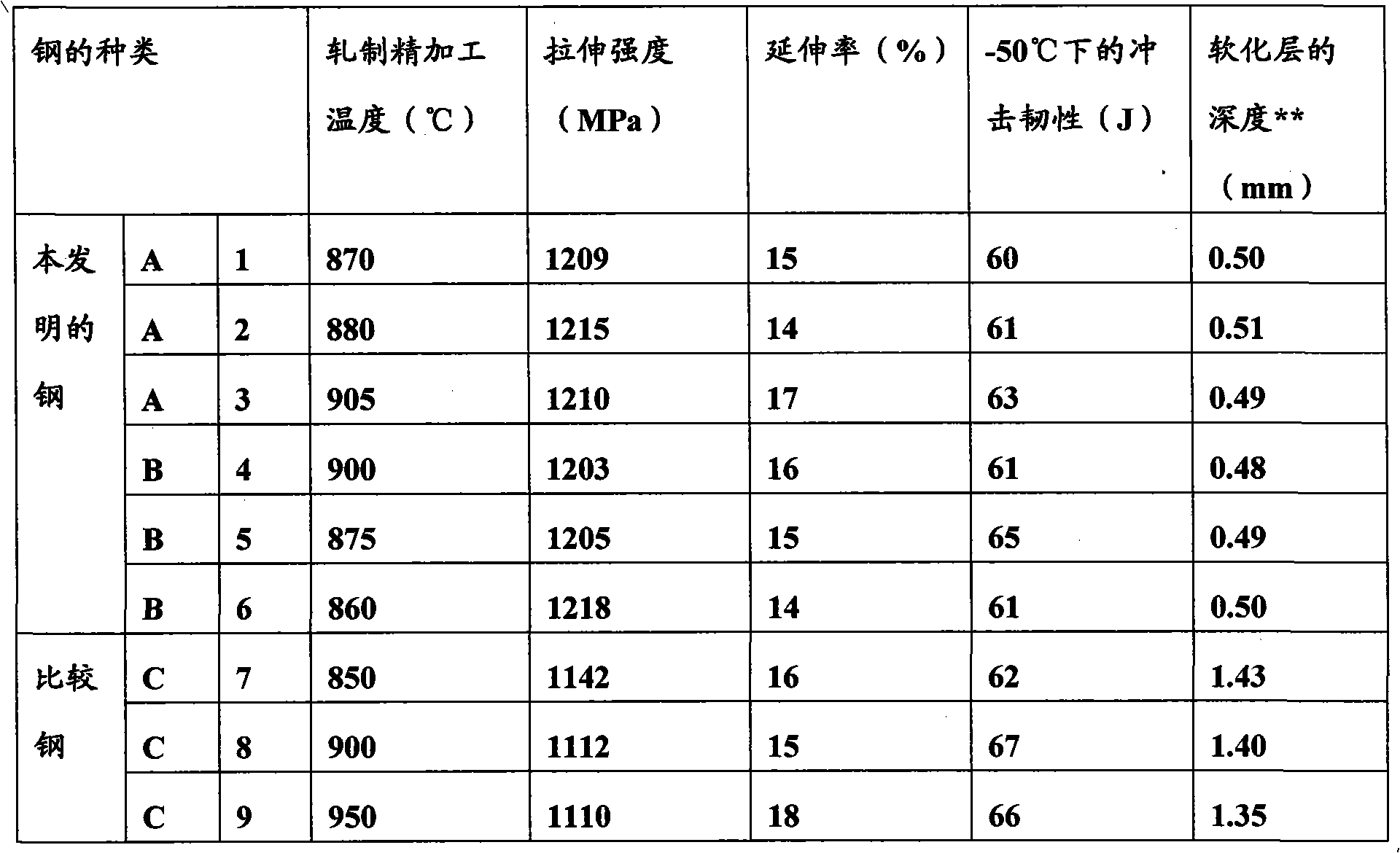

There are provided a steel for deep drawing, and a method for manufacturing the steel and a high pressure container. The steel for deep drawing includes, by weight: C: 0.25 to 0.40%, Si: 0.15 to 0.40%, Mn: 0.4 to 1.0%, Al: 0.001 to 0.05%, Cr: 0.8 to 1.2%, Mo: 0.15 to 0.8%, Ni: 1.0% or less, P: 0.015% or less, S: 0.015% or less, Ca: 0.0005 to 0.002%, Ti: 0.005 to 0.025%, B: 0.0005 to 0.0020% and the balance of Fe and inevitable impurities, wherein a microstructure of the steel has a triphase structure of ferrite, bainite and martensite. The steel for deep drawing may be useful to further improve the strength without the deterioration of the toughness by adding a trace of Ti and B, compared to the conventional steels having a strength of approximately 1100 MPa. Also, the a method for manufacturing a steel may be useful to save the manufacturing cost and time by significantly curtailing time used in the spheroidization heat treatment during the deep drawing process, and to manufacture a steel for deep drawing that is used for a low-temperature, high-pressure container having a tensile strength of approximately 1200 Mpa by reducing a depth of the softening layer to prevent the deterioration in strength of the steel.

Owner:POHANG IRON & STEEL CO LTD

Sc-Al alloy foamed aluminum material and preparation method thereof

The invention relates to the technical field of foamed aluminum and preparation thereof, in particular to an Sc-Al alloy foamed aluminum material and a preparation method thereof. With the total weight of 1 of the foamed aluminum material as reference, the Sc-Al alloy foamed aluminum material comprises, by weight, 2.6-5.2% of Mg, 0.16-0.22% of rare earth element, 0.002-0.008% of Fe, 0.05-0.15% ofSc, 0.23-0.59% of Si, 0.01-0.026% of C, 0.56-1.21% of Ti, 0.01-0.05% of precious metal, 0.12-0.28% of N, and the balance Al; and the precious metal is composed of at least two of gold, silver, platinum, palladium, ruthenium and rhodium. According to the Sc-Al alloy foamed aluminum material and the preparation method thereof, microcrystalline metal element is added in aluminum alloy, matrix grainsof the foamed aluminum alloy is greatly refined, and through the refined grain strengthening action, while the toughness of the foamed aluminum alloy is not reduced, the strength of the foamed aluminum alloy is improved.

Owner:安徽省一鸣新材料科技有限公司

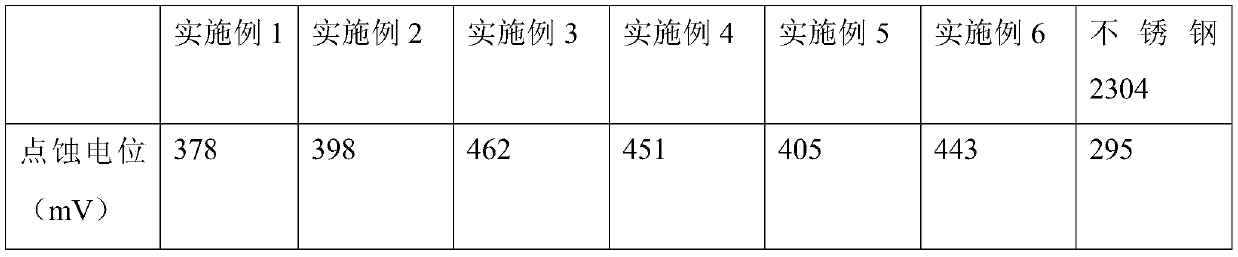

Low-nickel and high-strength bi-phase stainless steel material and preparation method thereof

The invention discloses a low-nickel and high-strength bi-phase stainless steel material and a preparation method thereof. The low-nickel and high-strength bi-phase stainless steel material is prepared from the following components in percentage by mass: 0.01-0.04% of C, 17.0-28.0% of Cr, 0.5-1.5% of Ni, 0.2-0.70% of Mo, smaller than or equal to 1.5% of Si, smaller than or equal to 2.0% of Mn, 1.50-5.00% of Cu, 0.05-0.70% of N, smaller than or equal to 0.50% of Ti and the like. The preparation method comprises the steps: blending is conducted, and the low-nickel and high-strength bi-phase stainless steel material is prepared through smelting, refining, centrifugal casting and high-temperature solid solution heat treatment. Mechanical properties of the prepared low-nickel and high-strengthbi-phase stainless steel material can meet mechanical property requirements of X2CrNiN23-4 hot-rolled stainless steel in EN 10088-2 2005 of the sheet steel / steel plate and belt material standard of European corrosion-resistant steel, and the low-nickel and high-strength bi-phase stainless steel material is low in raw material cost and more stable in comprehensive mechanical property.

Owner:SICHUAN WEIZHEN PETROCHEM EQUIP

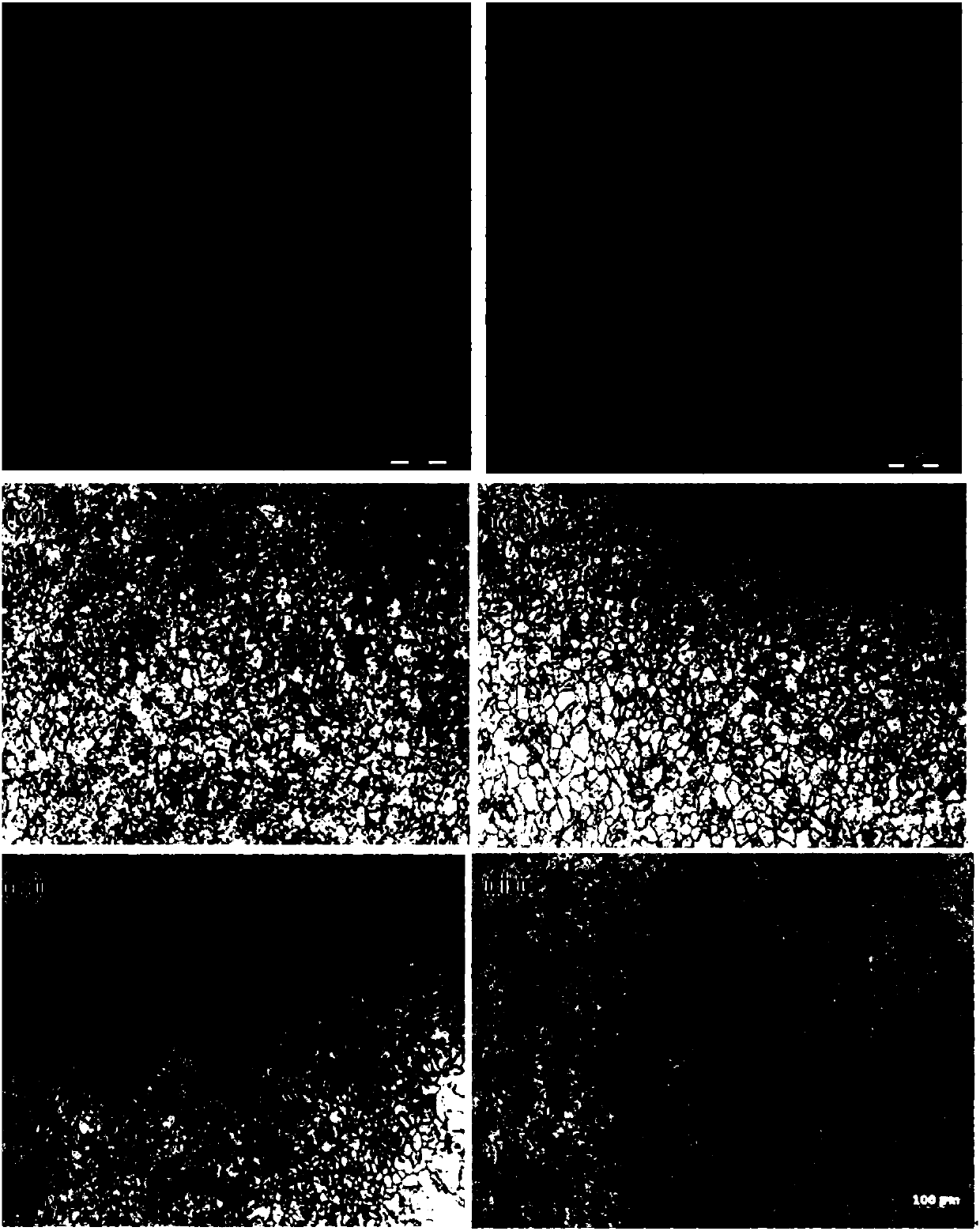

Rare earth-containing superpure high-chromium ferrite anti-wrinkle stainless steel and preparation method thereof

InactiveCN107746938AImprove wrinkle resistanceImprove surface wrinkle defectsRare-earth elementWrinkle skin

The invention relates to a rare earth-containing superpure high-chromium ferrite anti-wrinkle stainless steel and a preparation method thereof. The rare earth-containing superpure high-chromium ferrite anti-wrinkle stainless steel is prepared from the following chemical components in percentage by weight: less than 0.015% of C+N (carbon+nitrogen), less than or equal to 1.0% of Si (silicon), less than or equal to 1.0% of Mn (manganese), less than or equal to 0.04% of P (phosphor), less than or equal to 0.03% of S (sulfur), 25.0% to 28.0% of Cr (chromium), 3.0% to 4.0% of Mo (molybdenum), 1.0% to 3.5% of Ni (nickle), 0.2% to 1.0% of Ti+Nb (titanium+niobium), less than 0.1% of rare earth element, and the balance of Fe (iron) and unavoidable impurities. The rare earth-containing superpure high-chromium ferrite anti-wrinkle stainless steel has the characteristics that the ferrite stainless steel with high chromium grade and low carbon and nitrogen content and containing Nb, Ti and rare elements is obtained, and the anti-wrinkle property is excellent; especially, the condensing tissues are fined, the segregation due to columnar crystals in the condensing process of casting ingots or casting blanks is reduced, the defect of surface wrinkles in the superpure high-chromium ferrite stainless steel in the rolling process is relieved, and the high-efficiency smelting of the super ferrite stainless steel is realized.

Owner:NORTHEASTERN UNIV

Printing and dyeing finishing agent

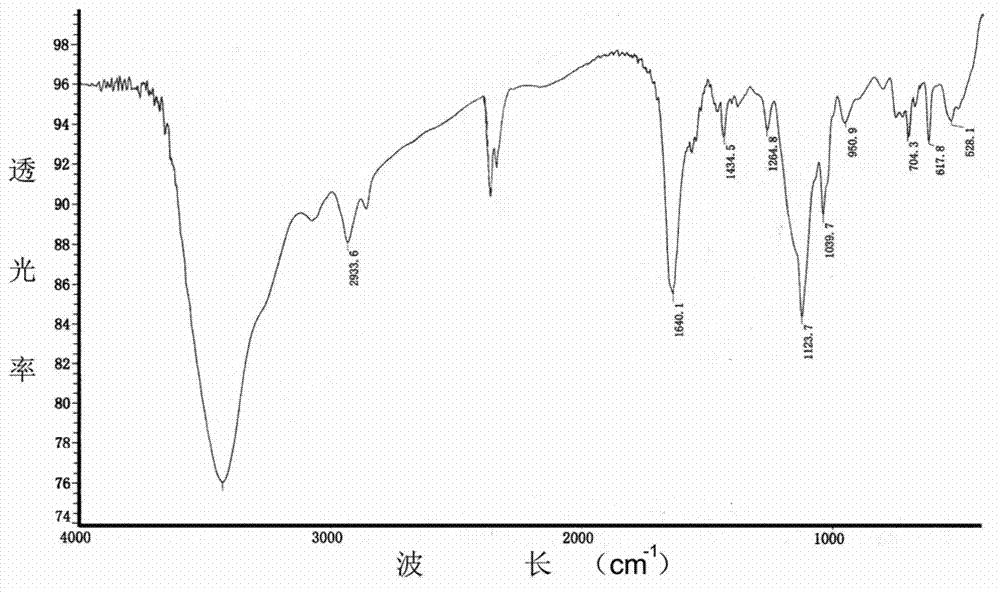

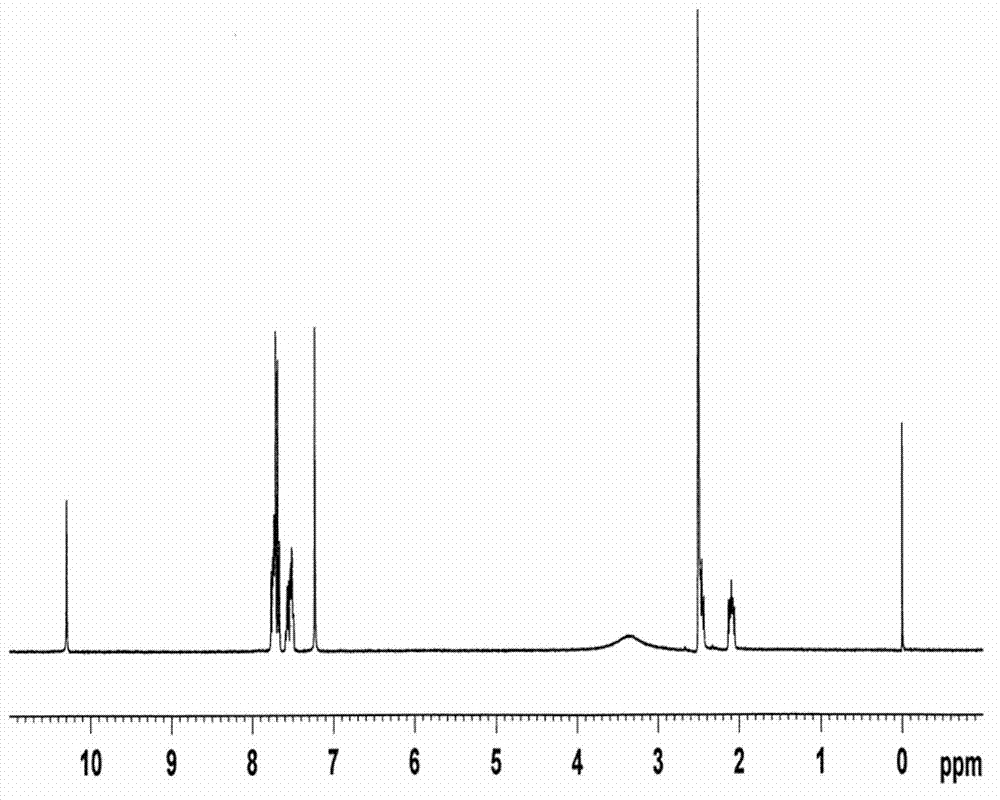

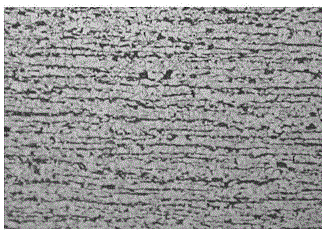

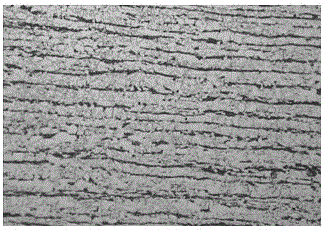

InactiveCN103147279AImprove surface propertiesDoes not reduce toughnessFibre treatmentSulfonateAcetyl chloride

The invention discloses a printing and dyeing finishing agent. The finishing agent comprises the following components of 3-5 parts of sodium chloride, 3-5 parts of sodium sulfonate, 6-8 parts of magnesium oxide, 15-25 parts of titanium dioxide, 15-22 parts of aluminium oxide, 6-10 parts of silicon dioxide, 8-15 parts of p-hydroxyphenylacetyl chloride, 3-8 parts of o-nitrophenol sodium, and 20-26 parts of sodium sulfate. The finishing agent disclosed by the invention has the beneficial effect that the surface performance of the fabric is improved so that the coloring is easier; and meanwhile, the damage to the internal structure of the fabric is small, the toughness of the fabric cannot be lowered.

Owner:WUXI SINTEX PRINTING & DYEING CO LTD

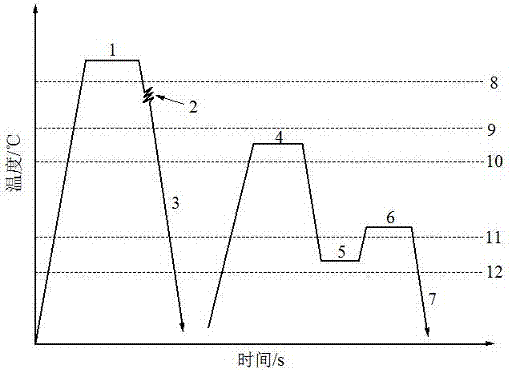

Manufacturing method for reverted austenite hot-stamped steel plate

InactiveCN107245554AEasy to operateIncreased strength and plasticityQuenching agentsMartensite transformationHot stamping

The invention relates to a manufacturing method for a reverted austenite hot-stamped steel plate. The method comprises the following steps: (1) heating materials to a certain temperature of greater than Ac3 (a finishing temperature of austenite transformation) at a certain heating speed and insulating heat for a certain time; (2) carrying out primary quenching: transferring a steel plate into a stamping die and carrying out hot-stamping formation, and then carrying out water quenching to achieve room temperature; (3) carrying out heat insulation in a reverted austenite area: re-heating the steel plate quenched to the room temperature to a certain temperature between As (a beginning temperature of reverted austenite formation) and Ac1 (a beginning temperature of austenite transformation) and keeping constant temperature for a period of time; (4) carrying out secondary quenching: rapidly quenching the steel plate to a certain temperature between Ms (a beginning temperature of martensite phase transformation) and Mf (a finishing temperature of martensite phase transformation) and insulating heat for a certain time; (5) partitioning: heating the steel plate to a temperature of greater than Ms and insulating heat for element partitioning; and (6) carrying out tertiary quenching: quenching the steel plate to room temperature.

Owner:SHANDONG JIANZHU UNIV

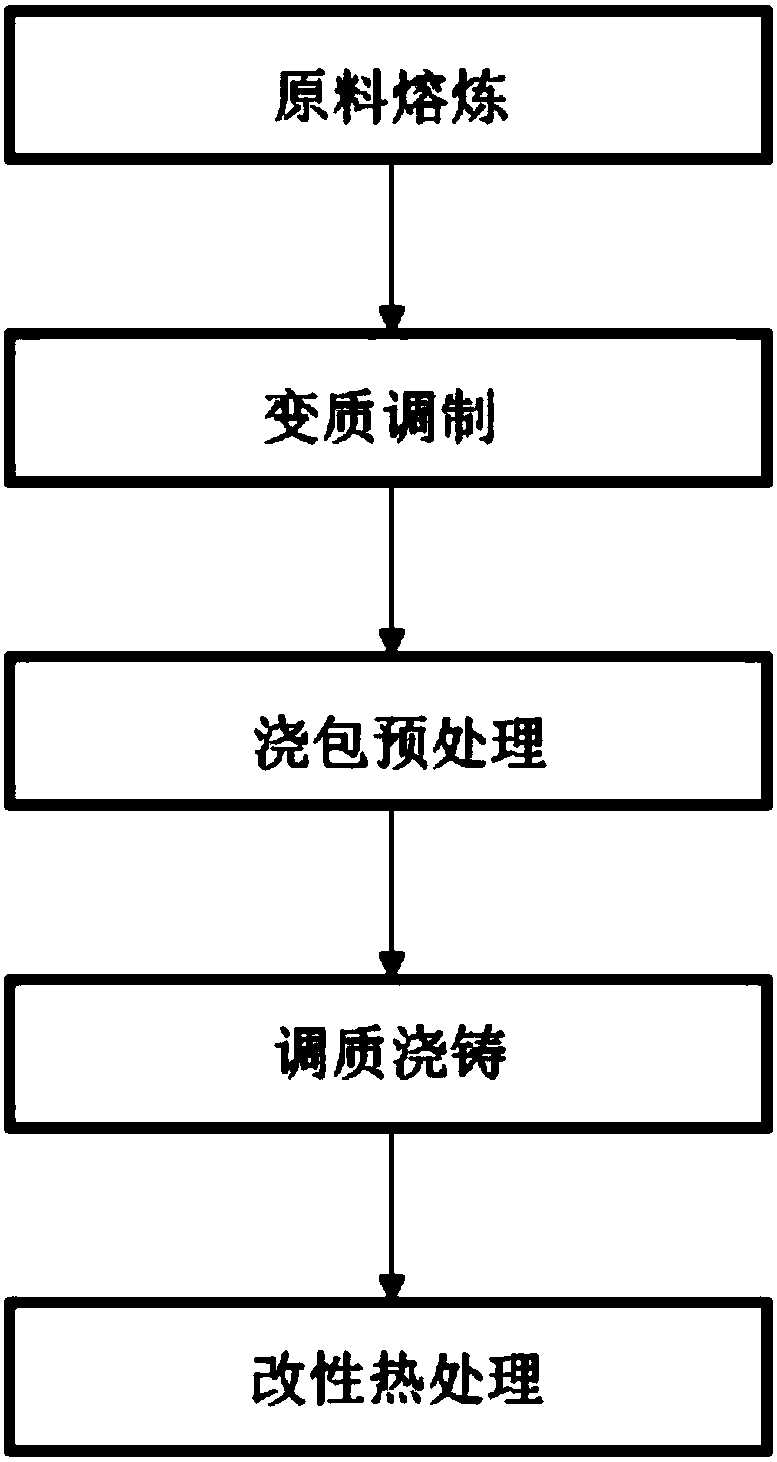

High-strength and high-temperature resistance nodular cast iron, and casting technology of nodular cast iron pipe

The invention relates to a high-strength and high-temperature resistance nodular cast iron. The high-strength and high-temperature resistance nodular cast iron comprises, by weight, 10-25% of foundryreturn, 10-25% of primary iron, 0.1-1% of iron-nickel alloy, 0.5-3.5% of manganese-iron alloy, 1-7.5% of tungsten-molybdenum alloy, 1-3.5% of a carburant, 1.1-3.6% of a modifier, 1-3% of a spheroidizer, 1-3% of an inoculant, 0.5-2% of rare earth, and the balance of scrap steel. The casting method includes the following steps: raw material melting, modifying tempering, ladle pretreatment, temperingcasting and modifying heat treatment. Rare earth elements are used to improve the distribution uniformity of the metallographic structure in nodular cast iron in order to improve the hardness of thenodular cast iron without lowering the elongation and toughness, modifying and tempering treatments are performed to comprehensively improve the fatigue resistance and the wear resistance of a spheroidal graphite cast iron workpiece, and a casting technology of the nodular cast iron can effectively reduce the internal stress concentration, cracks, small holes and other defects of the nodular castiron workpiece and improve the product quality and the structural strength of the nodular cast iron workpiece.

Owner:WUHU JINMAO FLUID TECH CO LTD

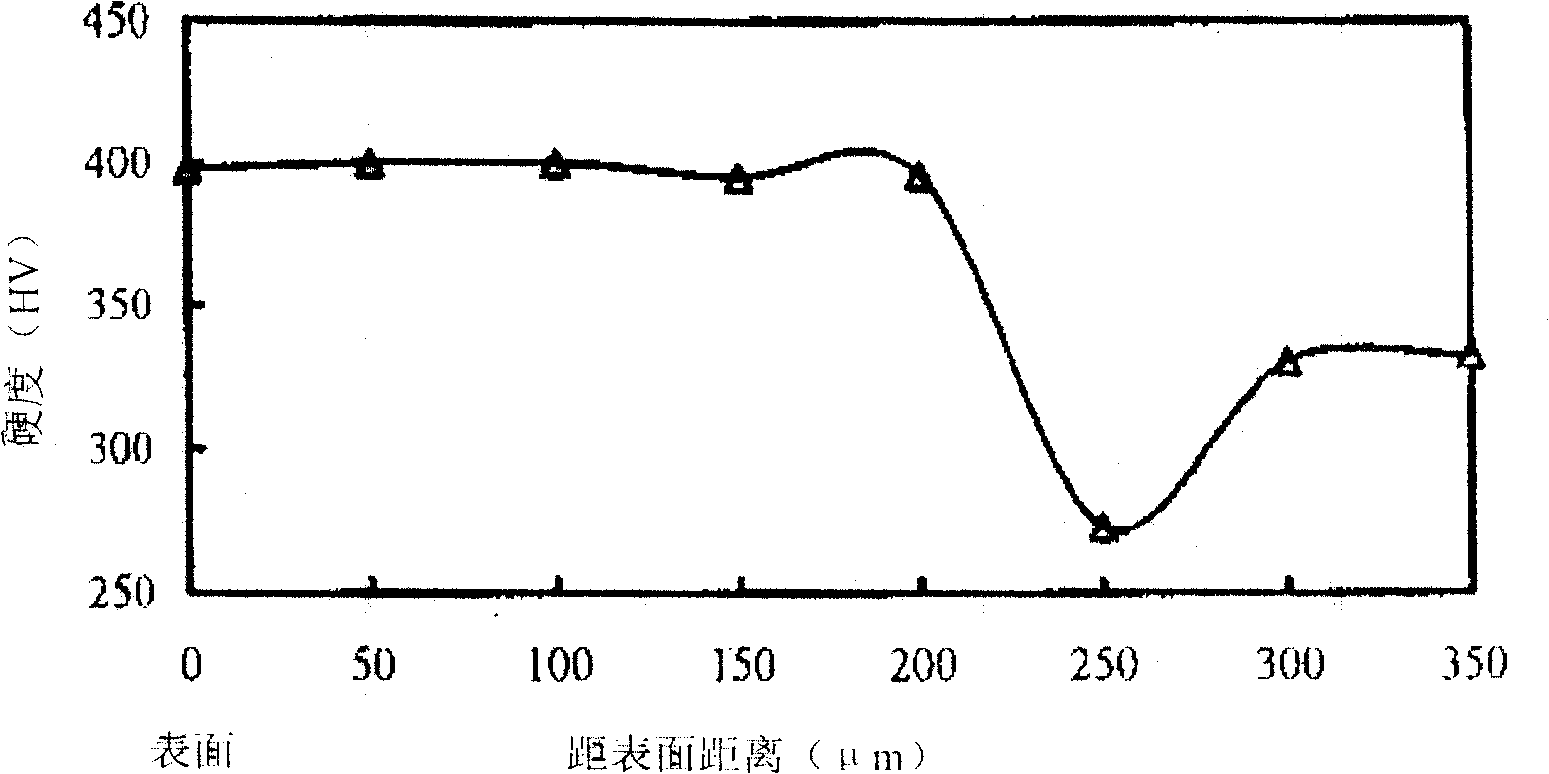

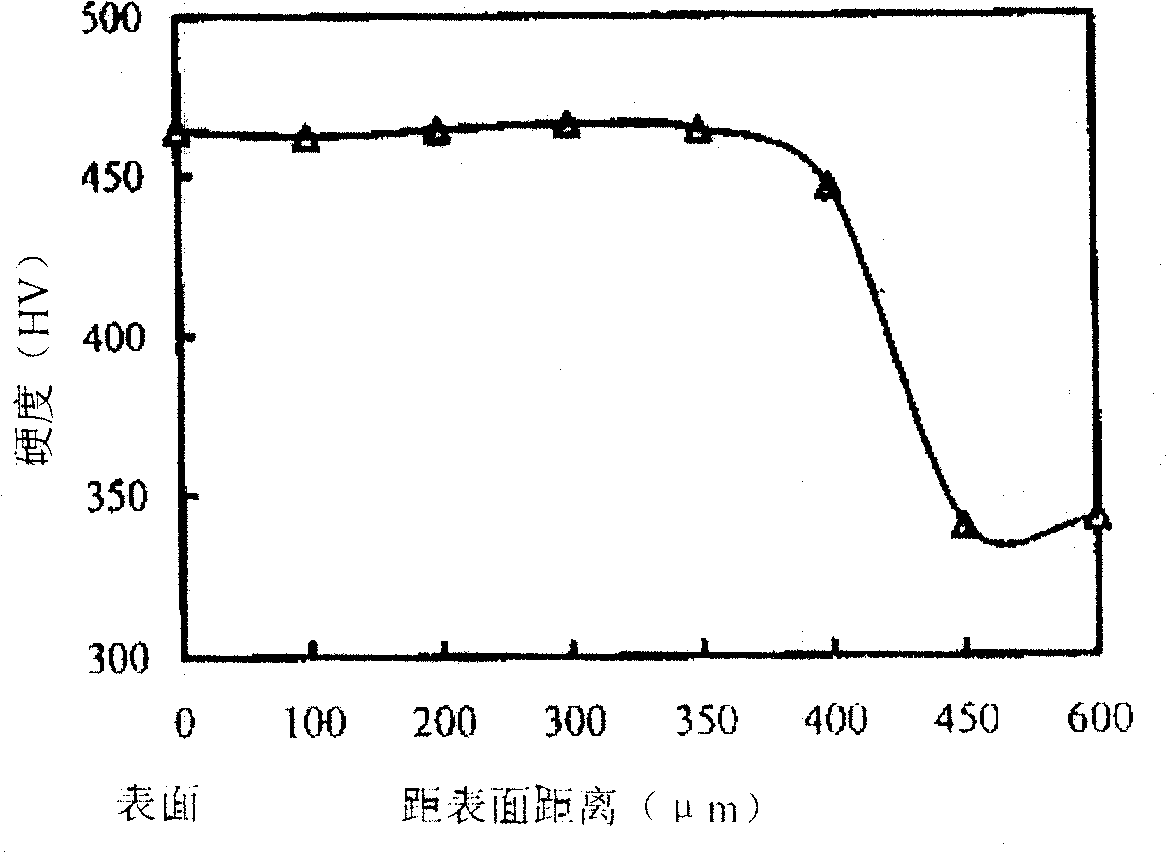

Hardening technology for precipitation hardening stainless steel laser surface

InactiveCN100443597CHigh hardnessMechanical properties unchangedHeat treatment process controlShielding gasCase hardening

In the invention, a specific wave-length laser is used for scanning radiation on the surface of the precipitation hardening stainless steel within a certain condition, so, making the surface of said steel to smelt. Low temperature shield gas is used for being cover onto the scanned area, for speeding-up the cooling. After that, the steel is subjected to heat treatment, so the hardness of the surface in a certain thickness is harder than that of the main body of the steel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Toughening functional masterbatch of PS materials and preparation technology thereof

The invention discloses toughening functional masterbatch of PS materials. The toughening functional masterbatch is characterized by being prepared from, by weight, 20-60 parts of SBS resin, 5-40 parts of plasticizers, 5-50 parts of polypropylene, 0.002-1 part of antioxidants, 5-50 parts of packing and 0-25 parts of pigment. The toughening functional masterbatch of the PS materials has the significant chemical corrosion resistance, the toughening function, the dyeing and color mixing properties and the good covering power, is stable in color and good in weather resistance and can be mixed according to the customer requirements.

Owner:ANHUI LIANKE WATER BASED MATERIAL TECH

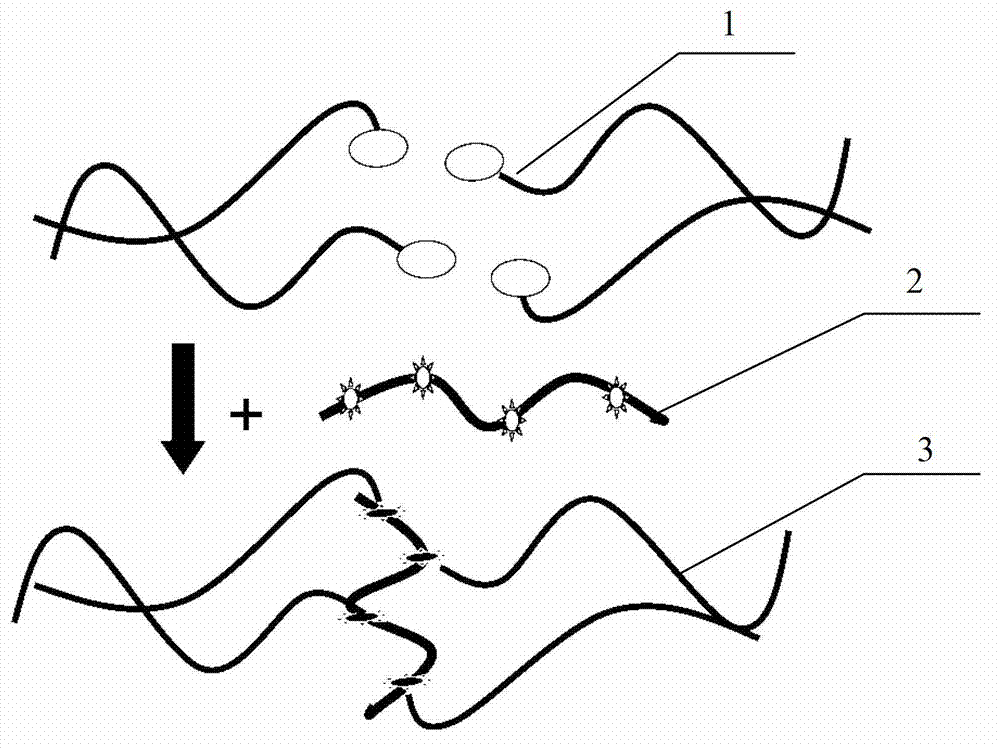

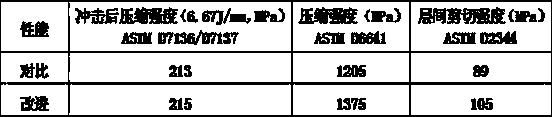

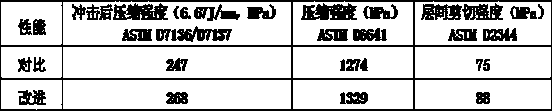

Method used for optimizing epoxy carbon fiber composite material system interface performance

InactiveCN109895469AReduce toughnessResolve compressionSynthetic resin layered productsEpoxyFibrous composites

The invention provides a method used for optimizing epoxy carbon fiber composite material system interface performance. The method is capable of solving problems in the prior art that in moulding of aepoxy carbon fiber composite material system from an intercalation thermoplastic material toughening liquid, interface combination is weak, and compression and interlayer shearing performance are poor. According to the method, an epoxy resin film is adopted between a thermoplastic material and carbon fiber; the epoxy resin film is composed of three components including a matrix resin component, atoughening compound, and an interface modifying component. The original thermoplastic material and carbon fiber interface is changed to be a thermoplastic material-resin film-carbon fiber interface,so that an intercalation thermoplastic material toughened epoxy carbon fiber composite material system is adopted, and reduction interface performance is avoided at the same time.

Owner:HENGSHEN

Metal ceramic material

The invention discloses a metal ceramic material, and belongs to the technical field of metal ceramic materials. The metal ceramic material comprises, by weight, 60-80 parts of a principal phase, 16-20 parts of a binding phase, 5-10 parts of carbide, 3-10 parts of an additive, 5-10 parts of whiskers and 5-10 parts of auxiliaries. SiC and / or TiC serve / serves as the whiskers, and carbon nano tubes serve as the auxiliaries. Through adding of the whiskers Sic and / or TiC and the auxiliary carbon nano tubes, the strength of the metal ceramic material is high, toughness is enhanced, and the application range of a metal ceramic cutter manufactured through a powder metallurgy manner is wide.

Owner:自贡市希力数控工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com