Preparation method of fine-crystal spume aluminium alloy

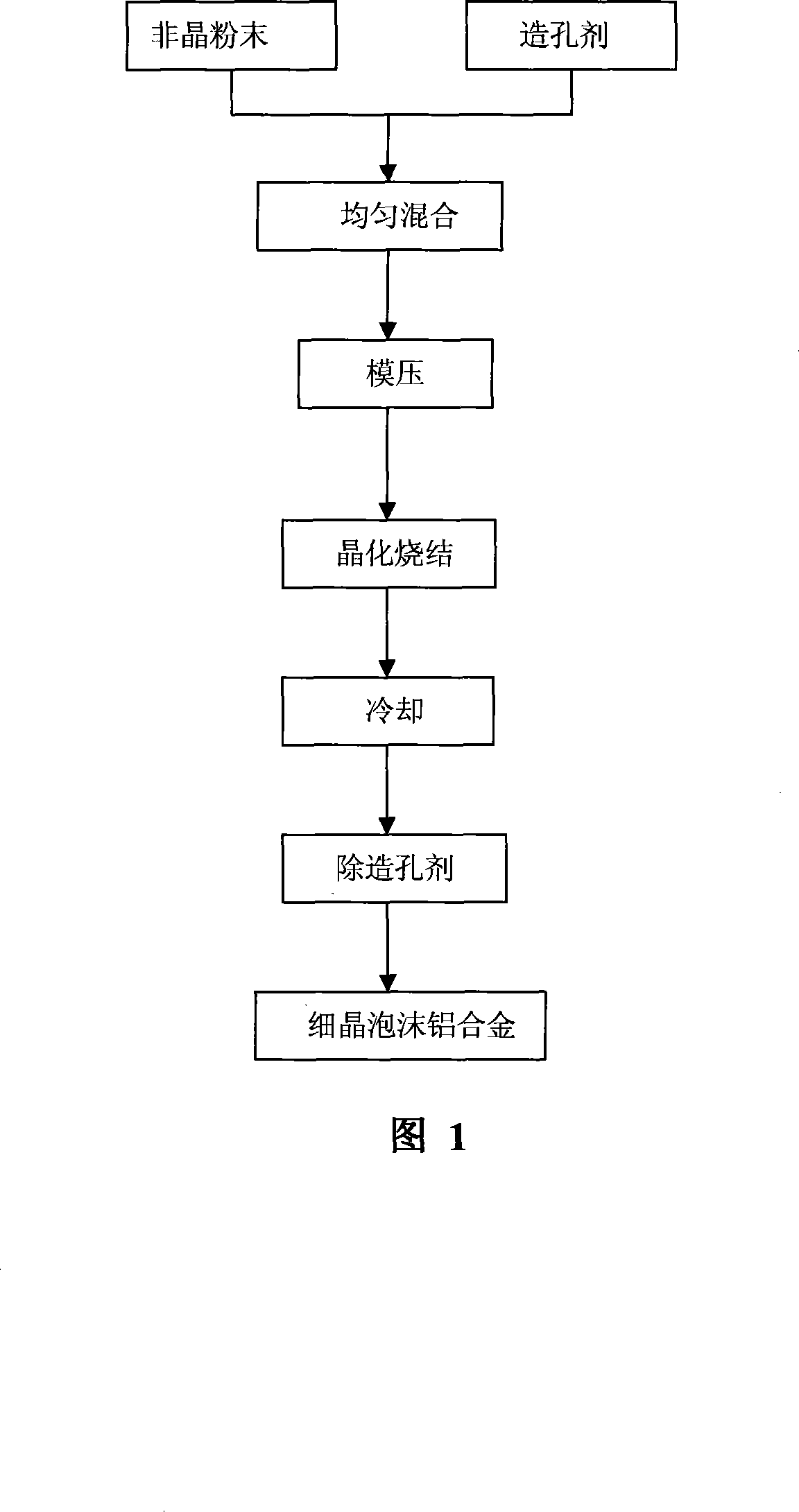

A foamed aluminum alloy and fine-grained technology, which is applied in the field of preparation of fine-grained foamed aluminum alloy, can solve problems such as large grain size, and achieve the effects of improving strength and simple equipment conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The grain size-200 purpose Al90Y3Nd2Co5 (Al92wt.%, Y2wt.%, Nd2wt.%, Co4wt.%) amorphous powder and the grain size-200 purpose NaCl particle are mixed with the volume ratio of 1: 2, mix in the mixer ( Mixing time: 40 minutes, rotation speed: 100rpm), the mixed powder is put into the die, compacted on the press (pressure 500MPa), and then subjected to isothermal crystallization and sintering treatment (420°C, 35min., Ar gas protection), air cooling and water Rinse for 15 minutes to remove NaCl, and obtain a fine-grained foamed aluminum alloy with a porosity of 67%, a pore diameter of 0.1 mm to 1 mm, a matrix grain size of 600 nm to 800 nm, a yield strength of 30 MPa, and a densified compressive strain of 63%.

Embodiment 2

[0012] The particle size-200 purpose Al85Y4Nd4Co7 (Al85wt.%, Y4wt.%, Nd4wt.%, Co7wt.%) amorphous powder and the particle size-200 purpose NaCl particle are mixed with the volume ratio of 1: 3, mix in the mixer ( Mixing time: 20 minutes, rotation speed: 180rpm), the mixed powder is put into the die, compacted on the press (pressure 700MPa), and then subjected to isothermal crystallization and sintering treatment (355°C, 60min., Ar gas protection), air cooling and water Rinse for 30 minutes to remove NaCl, and obtain a fine-grained foamed aluminum alloy with a porosity of 75%, a pore diameter of 0.1-1mm, a matrix grain size of 300nm-600nm, a yield strength of 23MPa, and a densified compressive strain of 65%.

Embodiment 3

[0014] The particle size-200 mesh Al90Y3Nd2Co5 (Al90wt.%, Y3wt.%, Nd2wt.%, Co5wt.%) amorphous powder and the particle size-200 mesh NaCl particles are mixed with a volume ratio of 1:5, and mixed uniformly in a mixer ( Mixing time: 30 minutes, rotation speed: 140rpm), the mixed powder is put into the die, compacted on the press (pressure 900MPa), and then subjected to isothermal crystallization and sintering treatment (390°C, 40min., Ar gas protection), air cooling and water Rinse for 20 minutes to remove NaCl, and obtain a fine-grained foamed aluminum alloy with a porosity of 85%, a pore diameter of 0.1 mm to 1 mm, a matrix grain size of 500 nm to 700 nm, a yield strength of 13 MPa, and a densified compressive strain of 66%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com