Method used for optimizing epoxy carbon fiber composite material system interface performance

A composite material and interfacial performance technology, which is applied in the field of composite material toughening, can solve the problems of high melt viscosity of thermoplastic materials, low interface bonding strength between thermoplastic materials and carbon fibers, and low performance of composite materials such as compression and interlayer shear. Achieve the effect of improving the interface binding performance and expanding the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

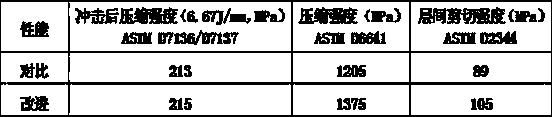

[0033] Comparison: T300 carbon fiber fabric is used, with an areal density of 160g / ㎡; the resin matrix is a medium-temperature curing liquid epoxy (the main epoxy resin component is E-51). A layer of 6g / ㎡ polyester non-woven fabric is used for toughening, and its properties are shown in Table 1 below;

[0034] Improvement: On the basis of the comparison system, an interface improvement layer is added between the polyester non-woven fabric and the carbon fiber fabric. The density of this layer is 8g / ㎡, and its composition is: 80% E-51 epoxy, 18% CTBN, 0.5 %CNT and 1.5% ethylene vinyl acetate grafted maleic anhydride. Its performance is shown in Table 1 below:

[0035] Table 1 Performance comparison

[0036]

[0037] After the improvement, the compression and interlaminar shear properties of the material system are improved to a certain extent, while the compression properties after impact are basically unchanged.

Embodiment 2

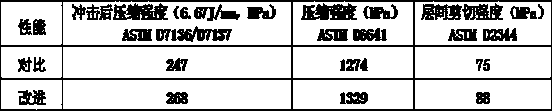

[0039] Comparison: T800 carbon fiber fabric is used with an areal density of 190g / ㎡; the resin matrix is a high temperature curing liquid epoxy (the main epoxy resin component is AG-80). A layer of 6g / ㎡ polyamide non-woven fabric is used for toughening, and its properties are shown in Table 2 below;

[0040] Improvement: On the basis of the comparison system, an interface improvement layer is added between the polyamide non-woven fabric and the carbon fiber fabric. The density of this layer is 14g / ㎡, and its composition is: 55% AG-80 epoxy resin, 40% polyether Sulfone, 1% CNT and 4% SMA. Its performance is shown in Table 2 below:

[0041] Table 2 Performance comparison

[0042]

[0043] After the improvement, the compression, interlaminar shear and post-impact compression properties of the material system are improved to a certain extent.

[0044] Beneficial effects of this embodiment: the problem of poor compression and interlaminar shear properties caused by weak int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com