Low-nickel and high-strength bi-phase stainless steel material and preparation method thereof

A duplex stainless steel, high-strength technology, applied in the field of stainless steel materials, can solve the problems of insufficient mechanical properties, low cost of duplex stainless steel materials, etc., and achieve important application value and promotion value, high mechanical properties and corrosion resistance. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

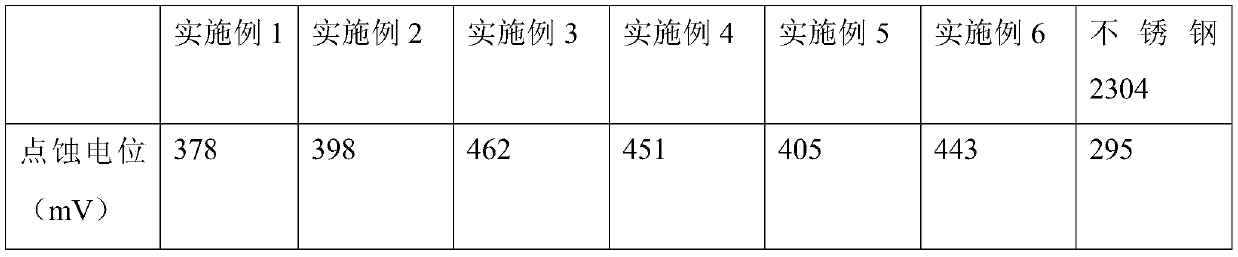

Examples

Embodiment 1

[0026] A low-nickel high-strength duplex stainless steel material, including the following components in mass percentage: C: 0.025%; Cr: 23.5%; Ni: 1.18%; Mo: 0.61%; Si: 0.82%; Mn: 0.87%; Cu : 1.89%; N: 0.31%, Ti: 0.11%, P: 0.023%, S: 0.002%, Al: 0.07%; the balance is Fe and unavoidable impurities; the volume fraction of ferrite in duplex stainless steel materials is 48%, the rest is austenite.

[0027] The preparation method of the above-mentioned low-nickel high-strength duplex stainless steel material comprises the following steps:

[0028] (1) Melting: According to the above chemical composition and content, the ingredients are mixed, melted in an intermediate frequency furnace, and the temperature reaches 1550°C, and molten steel is obtained by melting;

[0029] (2) Refining: Refining the molten steel obtained by smelting in an AOD furnace, the refining temperature is 1600°C, and the refining time is 2 hours, and at the same time reduce the oxygen content and hydrogen co...

Embodiment 2

[0033] A low-nickel high-strength duplex stainless steel material, including the following components in mass percentage: C: 0.021%; Cr: 23.8%; Ni: 1.03%; Mo: 0.53%; Si: 0.71%; Mn: 1.24%; Cu : 2.21%; N: 0.32%, Ti: 0.23%, P: 0.019%, S: 0.003%, Al: 0.05%; the balance is Fe and unavoidable impurities; the volume fraction of ferrite in duplex stainless steel materials is 50%, the rest is austenite.

[0034] The preparation method of the above-mentioned low-nickel high-strength duplex stainless steel material comprises the following steps:

[0035] (1) Melting: According to the above chemical composition and content, the ingredients are mixed, melted in an intermediate frequency furnace, and the temperature reaches 1560°C, and molten steel is obtained by melting;

[0036] (2) Refining: Refining the molten steel obtained by smelting in an AOD furnace, the refining temperature is 1650°C, the refining time is 2h, and at the same time reduce the oxygen content and hydrogen content in ...

Embodiment 3

[0040] A low-nickel high-strength duplex stainless steel material, including the following components in mass percentage: C: 0.026%; Cr: 24.3%; Ni: 0.55%; Mo: 0.46%; Si: 0.79%; Mn: 0.95%; Cu : 4.55%; N: 0.46%, Ti: 0.17%, P: 0.016%, S: 0.002%, Al: 0.06%; the balance is Fe and unavoidable impurities; the volume fraction of ferrite in duplex stainless steel materials is 45%, the rest is austenite.

[0041] The preparation method of the above-mentioned low-nickel high-strength duplex stainless steel material comprises the following steps:

[0042] (1) Melting: According to the above-mentioned chemical composition and content, the ingredients are mixed, melted in an intermediate frequency furnace, and the temperature reaches 1553°C, and the molten steel is melted;

[0043] (2) Refining: Refining the molten steel obtained by smelting in an AOD furnace, the refining temperature is 1688°C, the refining time is 2h, and at the same time reduce the oxygen content and hydrogen content in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com