Patents

Literature

102results about How to "Raise the electrode potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combination of disinfectors and its applications used in aquiculture

InactiveCN1430896AInhibits and hinders synthesisStunted growthBiocideAnimal repellantsDisinfectantAdhesive

A composite disinfectant for culturing aquatic products contains potassium (or sodium) perferrite, excipient, and / or pH regulator, stabilizer, adhesive, talc powder and magnesium stearate. Its advantages are high effect on disinfecting, enriching oxygen in water, and removing heavy metals, organic substances and harmful suspended substances, and no poison.

Owner:王永东

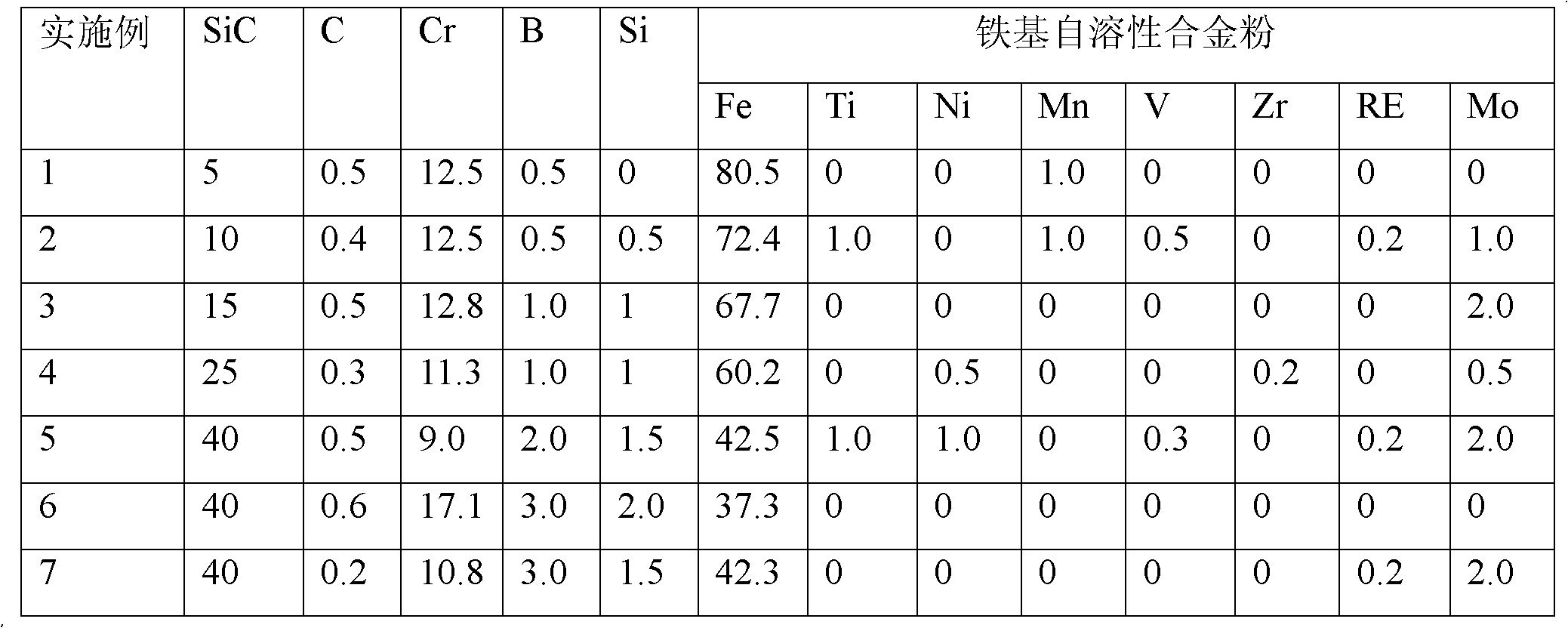

Composite material coated with SiC-Fe based alloy layer and preparation method of composite material

InactiveCN102218857ALow costGood value for moneyMolten spray coatingMetal layered productsHardnessPrice ratio

The invention discloses a composite material coated with a SiC-Fe based alloy layer and a preparation method of the composite material. The composite material coated with the SiC-Fe based alloy layer is formed by coating the SiC-Fe based alloy layer on the surface of a steel base material, wherein the steel base material is carbon steel or alloy steel of which the carbon content is 0.2 to 0.7 weight percent, and the raw material of a SiC-Fe composite material layer is SiC powder and iron-based autolytic alloy powder. The preparation method of the composite material comprises the following steps of: mixing the iron-based autolytic alloy powder with the SiC powder; and spraying the mixture on the surface of the steel base material. The composite material coated with the SiC-Fe based alloy layer has excellent performances of high hardness, good wearing resistance, low brittleness, capability of being subjected to heat treatment and machining, low cost, high performance price ratio and the like, and can obviously improve the surface property of the steel base material.

Owner:HEFEI JINSIDA TECH

High-sag-resistance brazing composite aluminum alloy foil for heat exchanger

InactiveCN102676884AReduce corrosion potentialImproved Brazing Welding AbilityLaminationLamination apparatusManganeseImpurity

The invention discloses high-sag-resistance brazing composite aluminum alloy foil for a heat exchanger, which consists of a core and a clad. The thickness of the clad accounts for 8-15% of the total thickness of the composite aluminum alloy foil. The core comprises the following components by weight: 1.4-1.6% of manganese, 0.4-0.6% of silicon, 0.50-0.90% of iron, 1.00-1.60% of zinc, 0.10-0.50% of vanadium, 0.05-0.30% of zirconium, 0.05-0.30% of titanium, and the balance of aluminum and inevitable impurities, wherein the contents of copper and magnesium in the impurities are both smaller than 0.05%. The alloy provided by the invention can be rolled into controlled atmosphere brazing (CAB) composite aluminum alloy foils for heat exchangers. The composite aluminum alloy foil disclosed by the invention has reasonable component ratio, easy manufacturing, good corrosion resistance, and high sag resistance after brazing, and is suitable for large-scale industrial production.

Owner:长沙众兴新材料科技有限公司

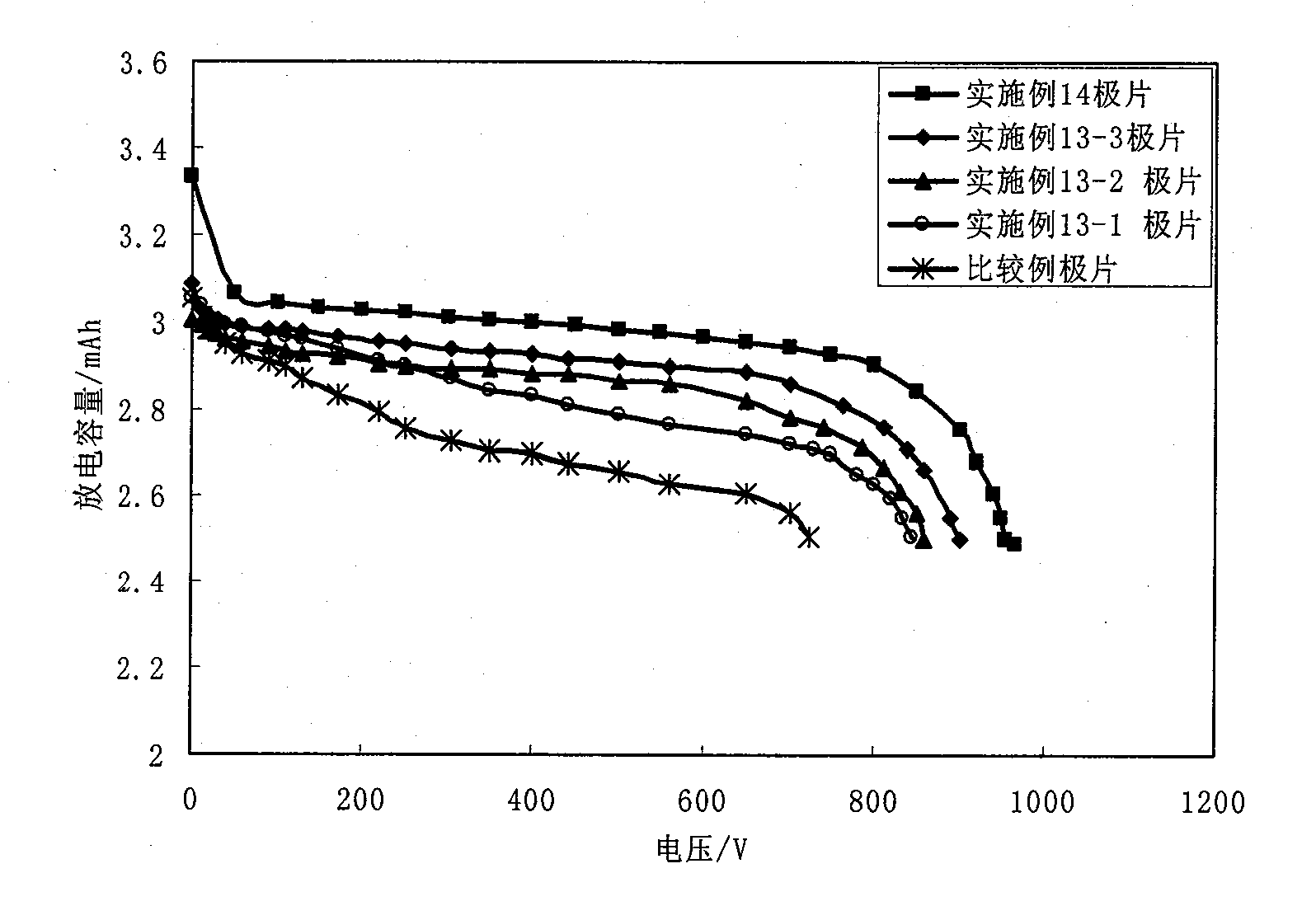

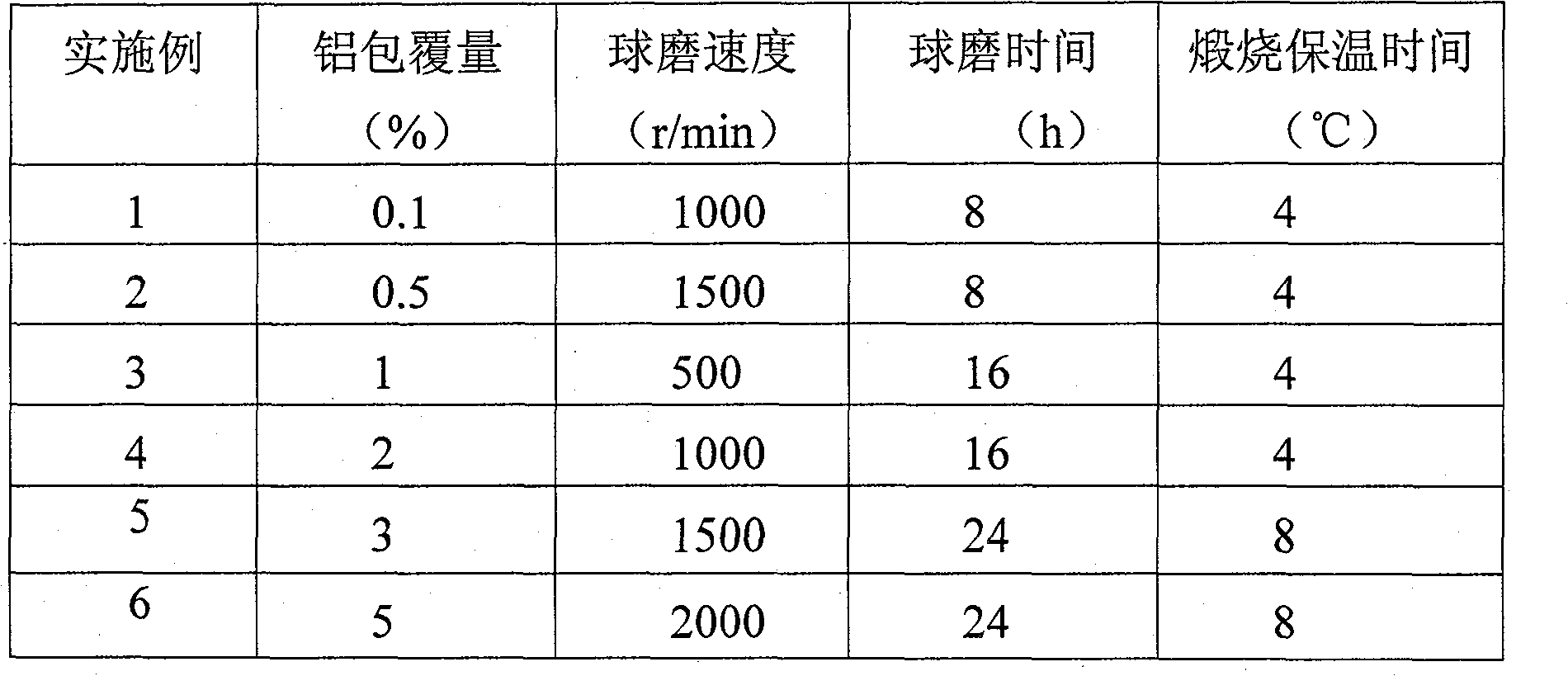

Preparation method of LiFePO material, lithium ion battery and positive plate thereof

ActiveCN101891179ALower internal resistanceImprove high current charge and discharge performanceCell electrodesSecondary cellsAluminium-ion batteryInternal resistance

The invention discloses a preparation method of a LiFePO material, a lithium ion battery using the material and a positive plate thereof. The preparation method comprises the following steps: sintering to prepare LiFePO powder; cladding aluminum on the surface of the LiFePO powder particle to form a LiFePO-Al composite material. Compared with the prior art, the LiFePO material prepared by the invention and the cladding aluminum can carry out homodisperse and surface cladding at the molecule level; the conductivity of the electrode plate prepared by the invention is improved by 101-10001 times; and the internal resistance of the LiFePO lithium ion battery is reduced greatly, and the large-current charge-discharge property is obviously improved, thus the material is particularly suitable for a high power lithium ion battery. Compared with the other cladding elementary metal, Al metal is cheaper, has lighter mass, lower melting point, more stable electrochemistry property and the like; and in additional, the aluminum in the composite material and a positive pole current collector are made of the same material, so that primary battery corrosion effect can not be formed.

Owner:STARZEON ELECTRONICS DONGGUAN +1

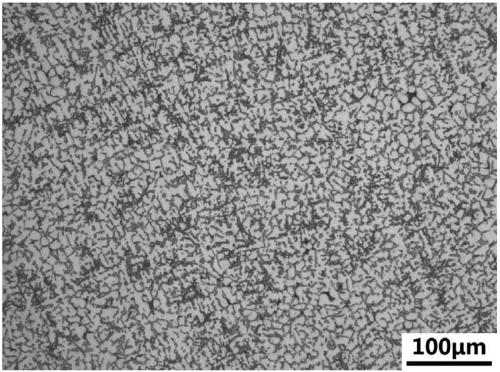

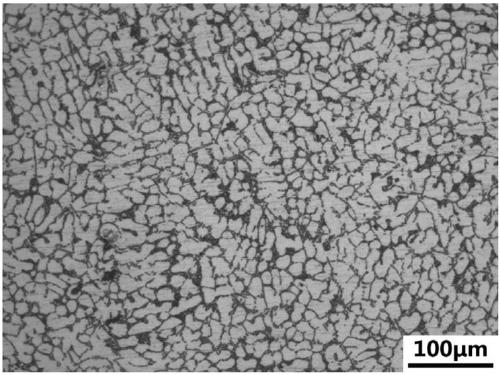

High-heat-conductivity high-corrosion-resistance cast aluminum alloy and preparation method thereof

The invention discloses high-heat-conductivity high-corrosion-resistance cast aluminum alloy and a preparation method thereof. The high-heat-conductivity high-corrosion-resistance cast aluminum alloycomprises the raw material components of, by weight, 7-9% of Si, 0.6-1.0% of Fe, 0.2-0.6% of Zn, 0.1-0.5% of Co, 0.05-0.15% of B, 0.2-0.5% of RE, 0.05-0.2% of Sr and the balance Al. In the preparationprocess, the aluminum alloy containing the elements of Si, Fe and Co is melted at the high temperature at first, and then is subjected to still standing and cooled; pure Zn, Al-RE intermediate alloy,Al-B intermediate alloy and Al-Sr intermediate alloy are added into the melt for further alloying; and the melt is subjected to refining and slag removal, and molding is achieved through casting. According to the alloy preparation process, the technology effect is remarkable, the Co, B, Sr and RE multi-element compound synergistic effect is sufficiently realized, and thus, the alloy casting piecehas the excellent heat conductivity, high mechanical property and good corrosion resistance.

Owner:SOUTH CHINA UNIV OF TECH +1

Rust-preventing aluminum alloy

The invention discloses a rust-proof aluminum alloy, which not only comprises 51 to 97.95 weight percent of aluminum, 0.01 to 2 weight percent of manganese, 0.01 to 2 weight percent of magnesium, and 0.01 to 3 weight percent of copper, but also comprises 1 to 19 weight percent of chromium, 0.01 to 9 weight percent of nickel, 0.01 to 4 weight percent of silicon, and 1 to 47.95 weight percent of aluminum oxide. The aluminum oxide forms a corundum-like substance in an aluminum alloy body to obviously improve the overall corrosion resistance and wear resistance of the aluminum alloy.

Owner:冷博

SnBiSb-series low-temperature lead-free solder and preparation method thereof

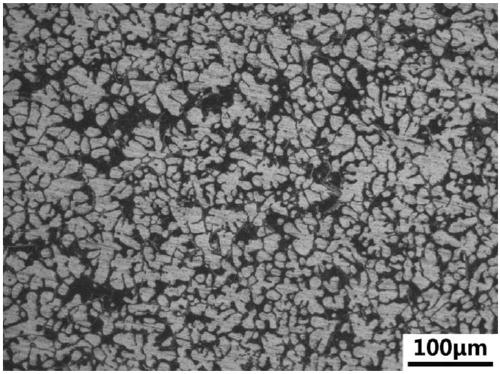

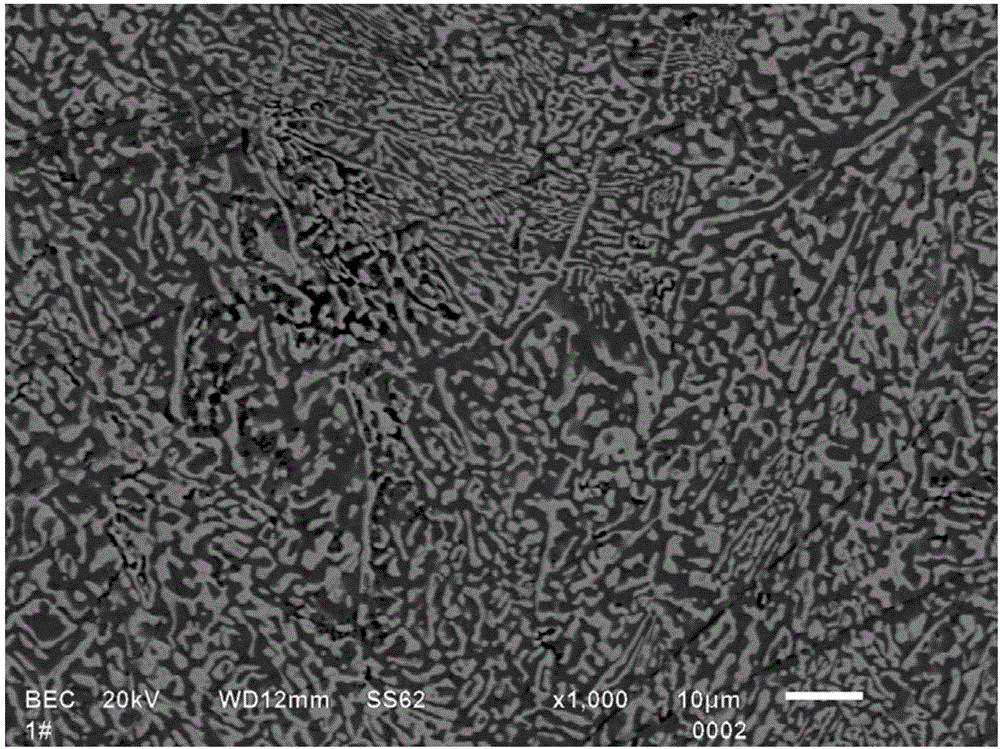

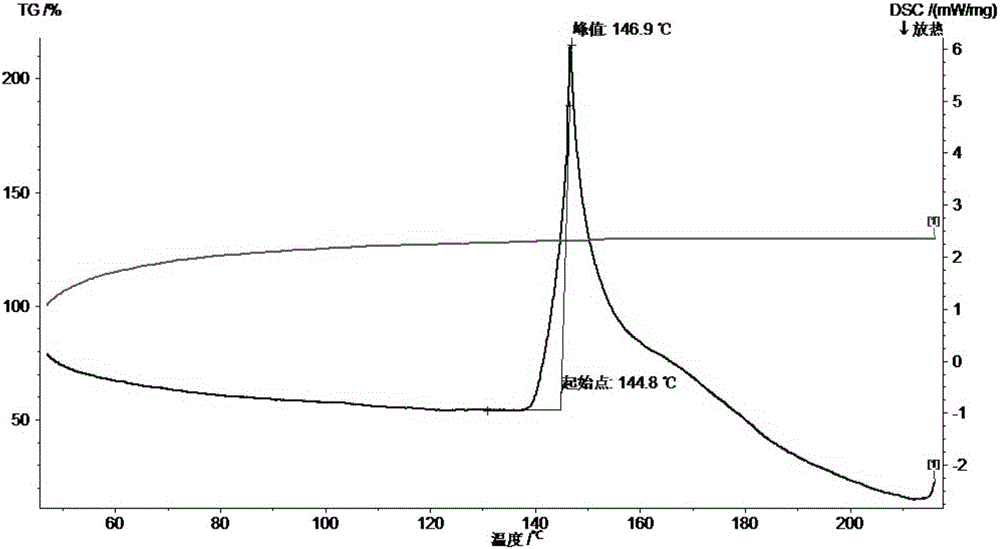

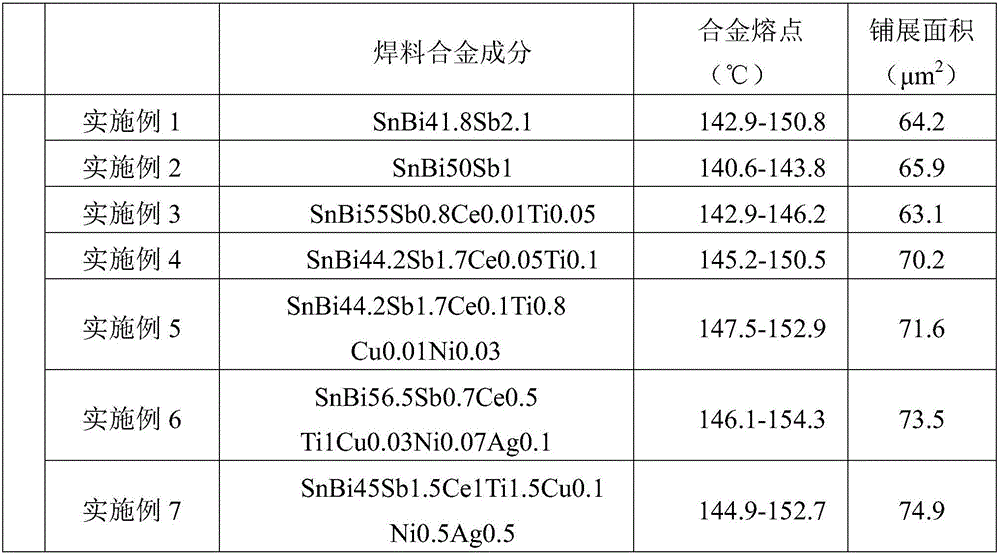

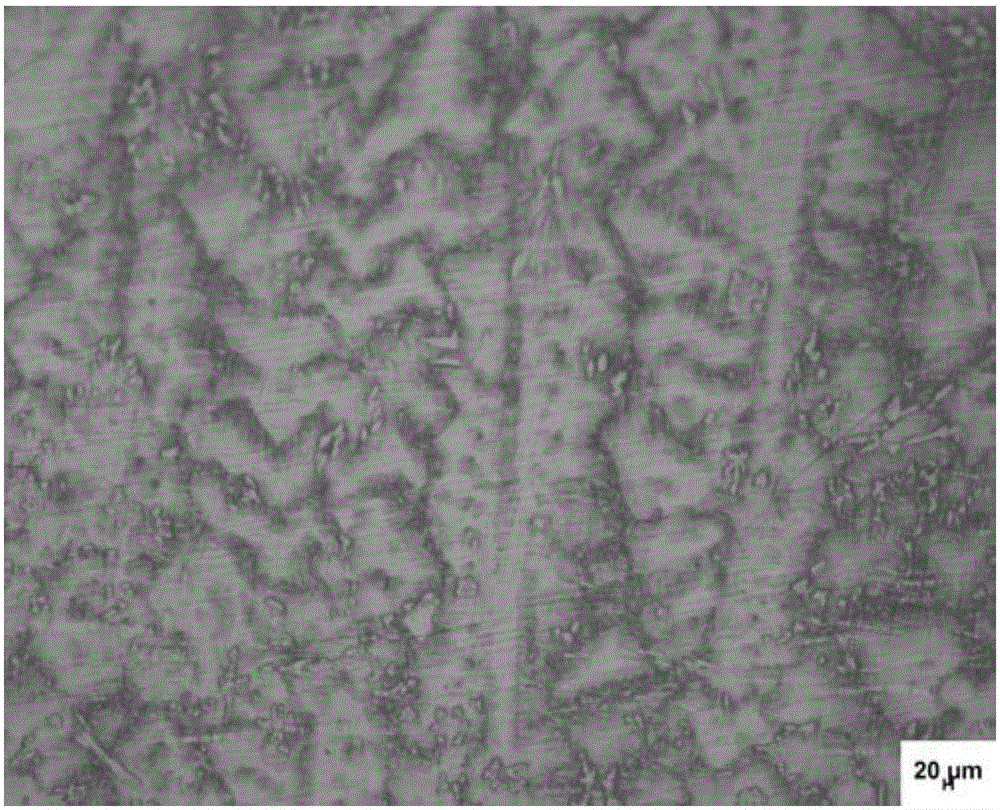

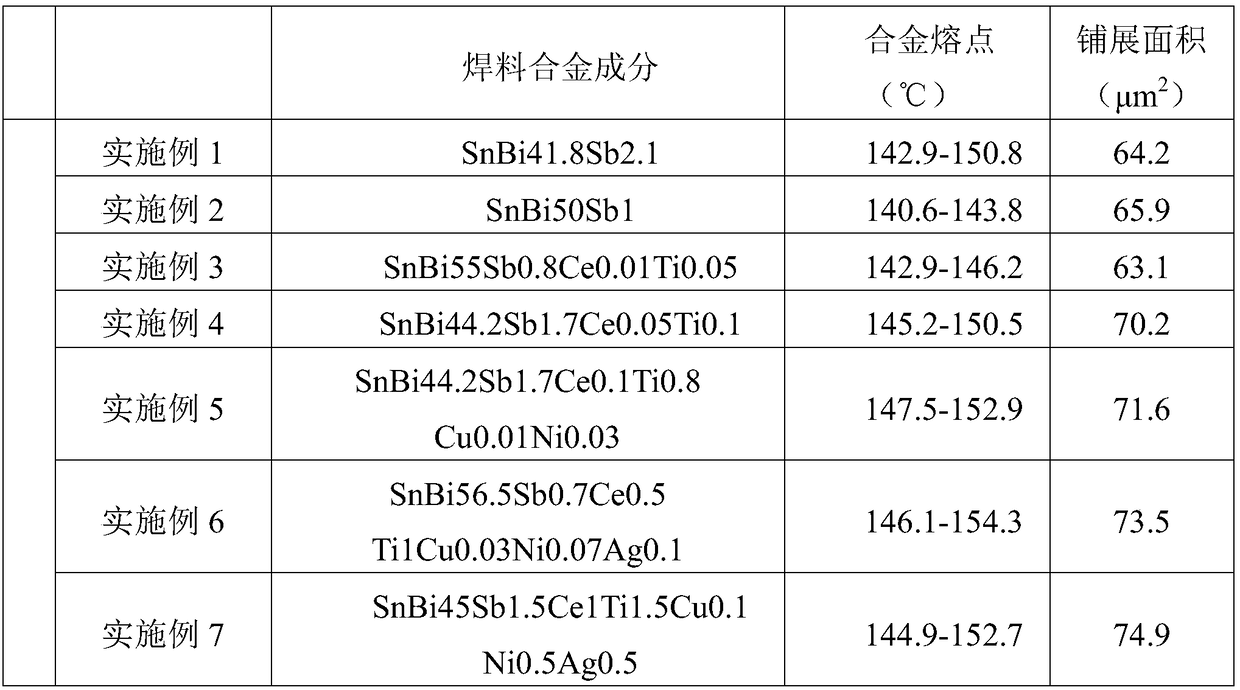

ActiveCN106216872AFine grainSmall grainWelding/cutting media/materialsSoldering mediaMechanical propertyMechanical properties of carbon nanotubes

The invention discloses SnBiSb-series low-temperature lead-free solder and a preparation method thereof, and belongs to the technical field of low-temperature soft solder. The SnBiSb-series low-temperature lead-free solder consists of the following components in percentage by weight: 32.8-56.5% of Bi, 0.7-2.2% of Sb, the balance Sn, wherein weight percentage of Bi and Sb meets a relation b=0.006 a<2>-0.0672a+19.61+c, a is weight percentage of Bi, b is weight percentage of Sb, and c is greater than or equal to c, and smaller than or equal to 1.85. The invention further discloses a preparation method for the lead-free solder. Solder alloy of the SnBiSb-series low-temperature lead-free solder is a ternary eutectic or near-elliptic eutectic structure, is low in melting point, has excellent mechanical property and reliability, and is suitable for the low-temperature solder field.

Owner:BEIJING COMPO ADVANCED TECH

Manufacturing technique for alloy mold

InactiveCN105671371AIncrease chromium contentImprove performanceElectrode potentialElectrical conductor

A manufacturing process of an alloy mold according to the present invention is characterized in that the manufacturing process includes the following steps: firstly weigh and batch the raw materials according to the weight ratio, then add the prepared raw materials into the smelting furnace, and after complete melting, the alloy aluminum liquid Transfer to the holding furnace for refining and degassing, then die-casting production, then preheating, cooling, injection, final molding, preheating, and heat preservation. When in use, the present invention increases the chromium content in the mold material, increases the chromium content, can increase the electrode potential of the iron in the mold steel, and improves the corrosion resistance. At the same time, the alloy aluminum liquid is poured into the production cavity through the side pouring method of double-layer runners, which realizes smooth filling and good feeding effect, and the produced conductor castings meet the process requirements of air tightness and conductivity at the same time. The filling time of alloy aluminum liquid is 0.01-0.2 seconds, and the cavity can be filled, and high-quality castings with good appearance and internal quality can be produced stably, rhythmically and efficiently.

Owner:SHANGHAI YADELIN NONFERROUS METAL

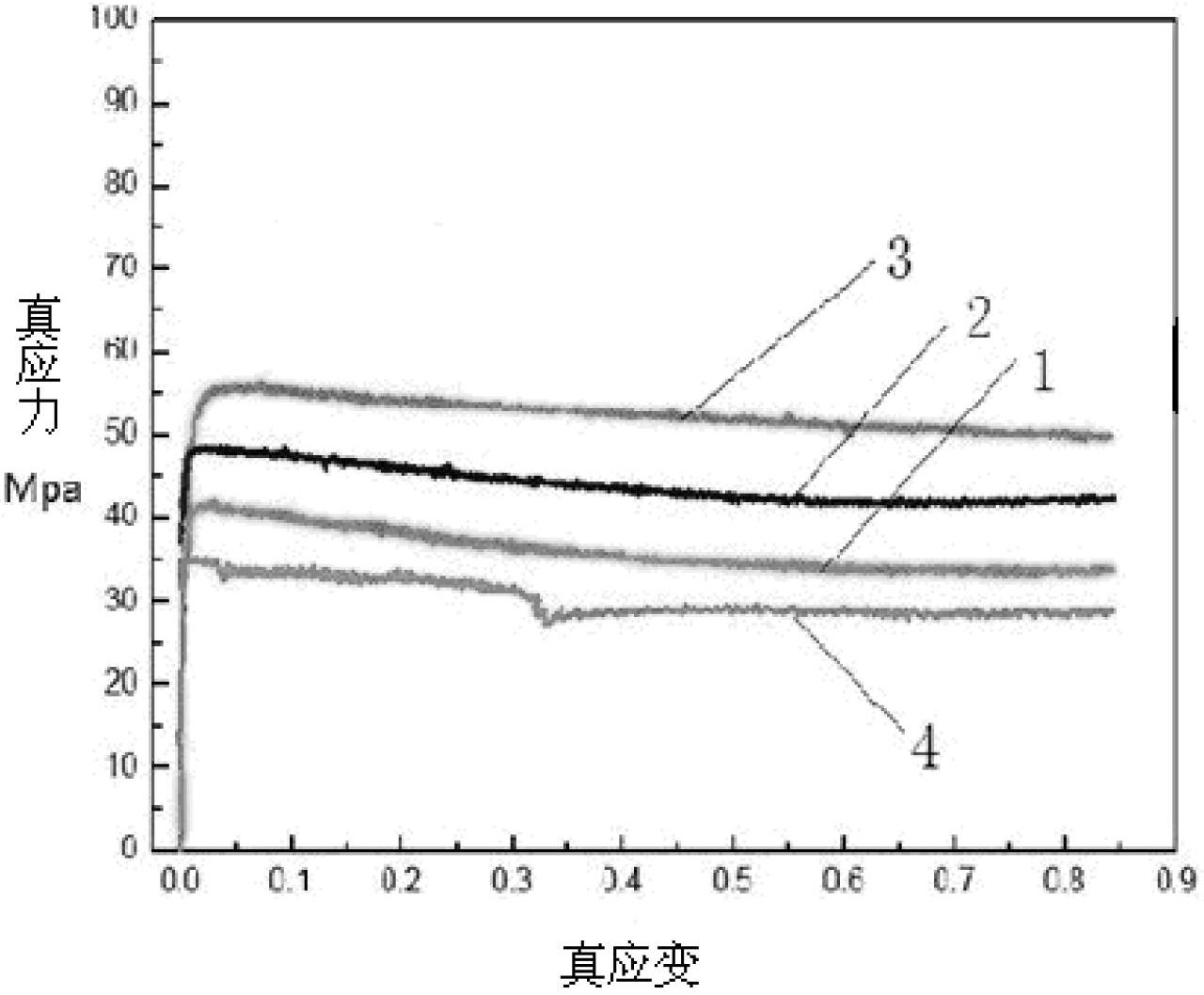

Degradable biomedical Mg-Nd-Sr magnesium alloy as well as preparation method and application thereof

InactiveCN105154735ADegradation without toxic effectGood biocompatibilityBiocompatibility TestingIntravascular stent

The invention belongs to the technical field of biomedical materials and particularly relates to degradable biomedical Mg-Nd-Sr magnesium alloy as well as a preparation method and application thereof. The degradable biomedical Mg-Nd-Sr magnesium alloy comprises the following components in percentage by weight: 1.00-3.00% of Nd, 0.10-3.00% of Sr and the balance of Mg and unavoidable impurity elements. The preparation method of the alloy comprises the thermal treatment technology and the hot extrusion processing technology, Mg, Mg-Nd intermediate alloy and Mg-Sr intermediate alloy are sequentially smelted under the condition of covering agent protection, a refining agent is added for refining after the smelting, and after component detection, casting moulding is performed to obtain cast-condition degradable biomedical Mg-Nd-Sr magnesium alloy. Through reasonable thermal treatment technology and hot extrusion processing technology, polymorphic Mg-Nd-Sr magnesium alloy with excellent biocompatibility and different mechanical properties can be obtained, and the obtained polymorphic Mg-Nd-Sr magnesium alloy can be applicable to orthopaedic implant materials and intravascular stent medical materials of different occasions as demanded.

Owner:SOUTH CHINA UNIV OF TECH

Wear-resistant white cast iron material and preparation method thereof

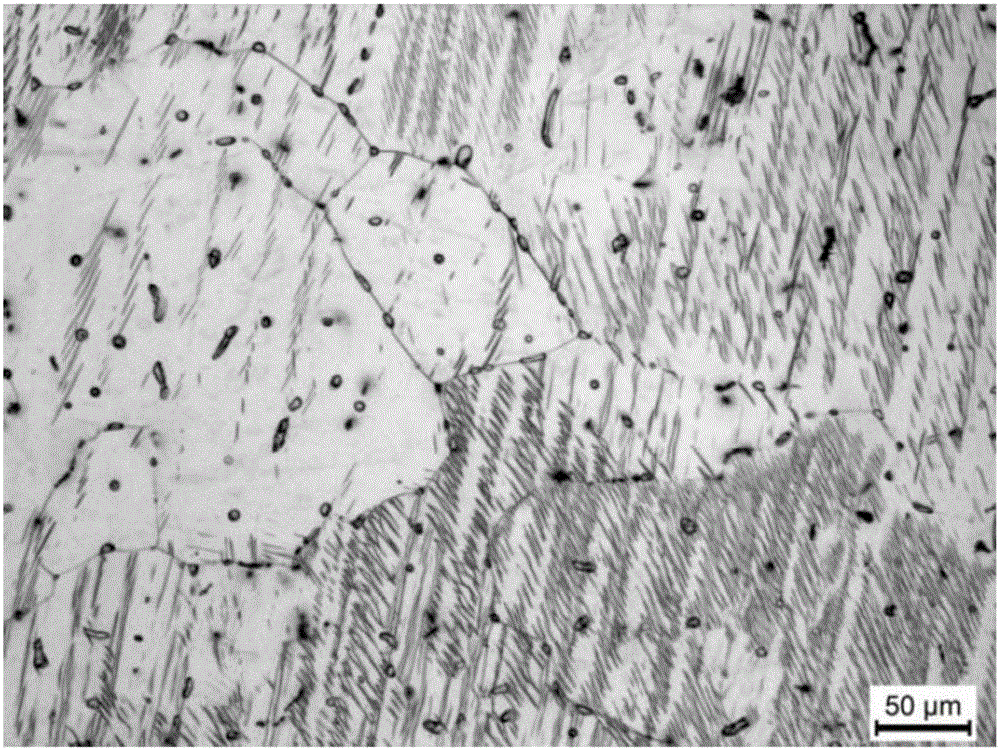

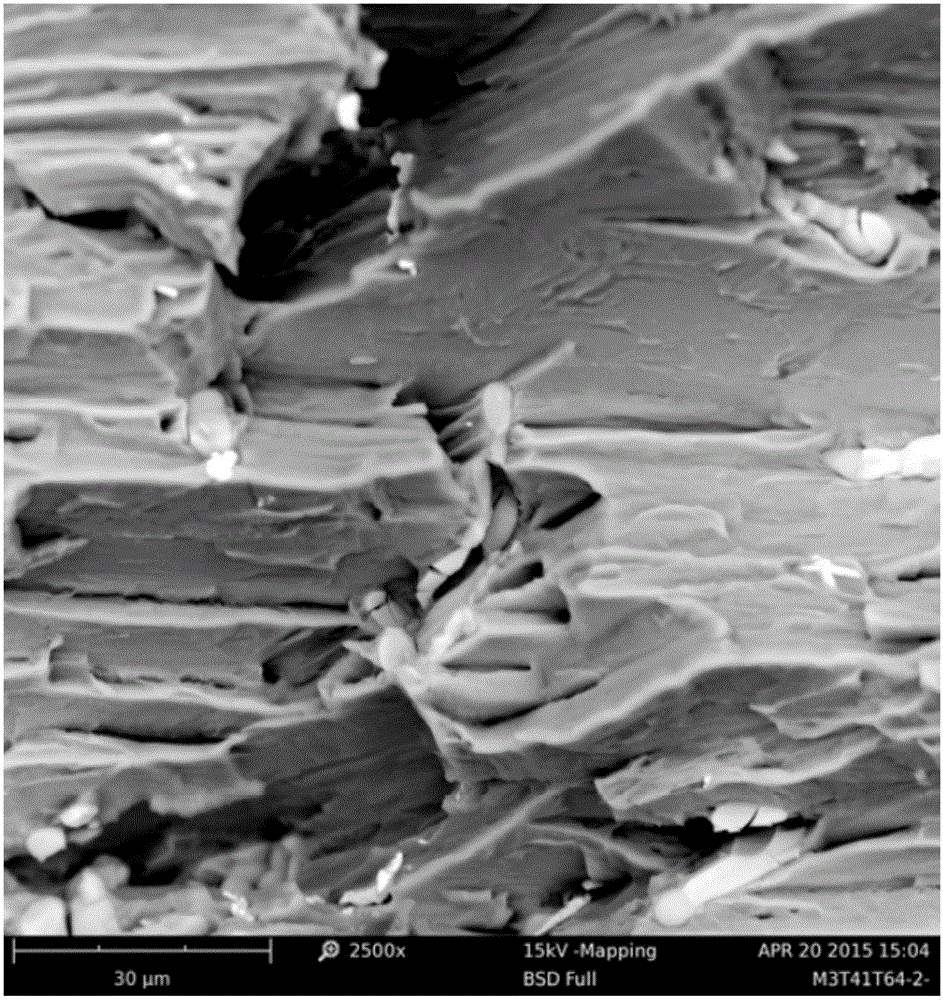

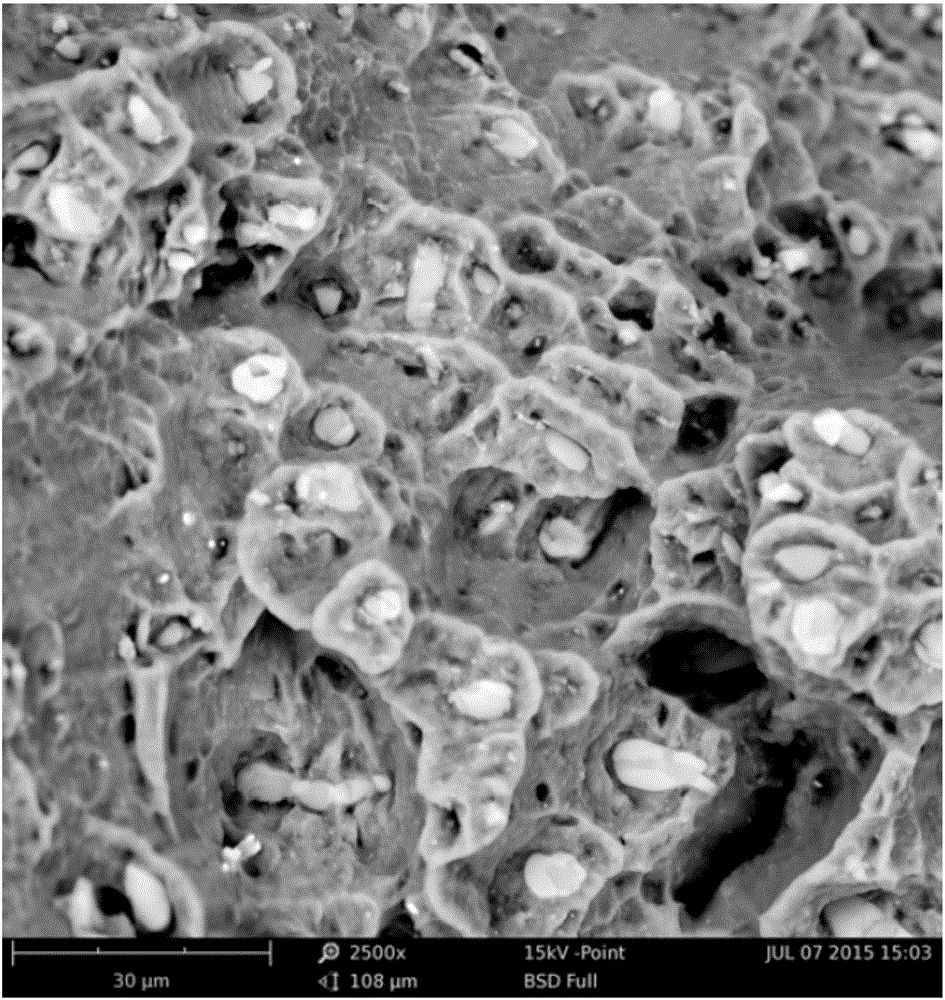

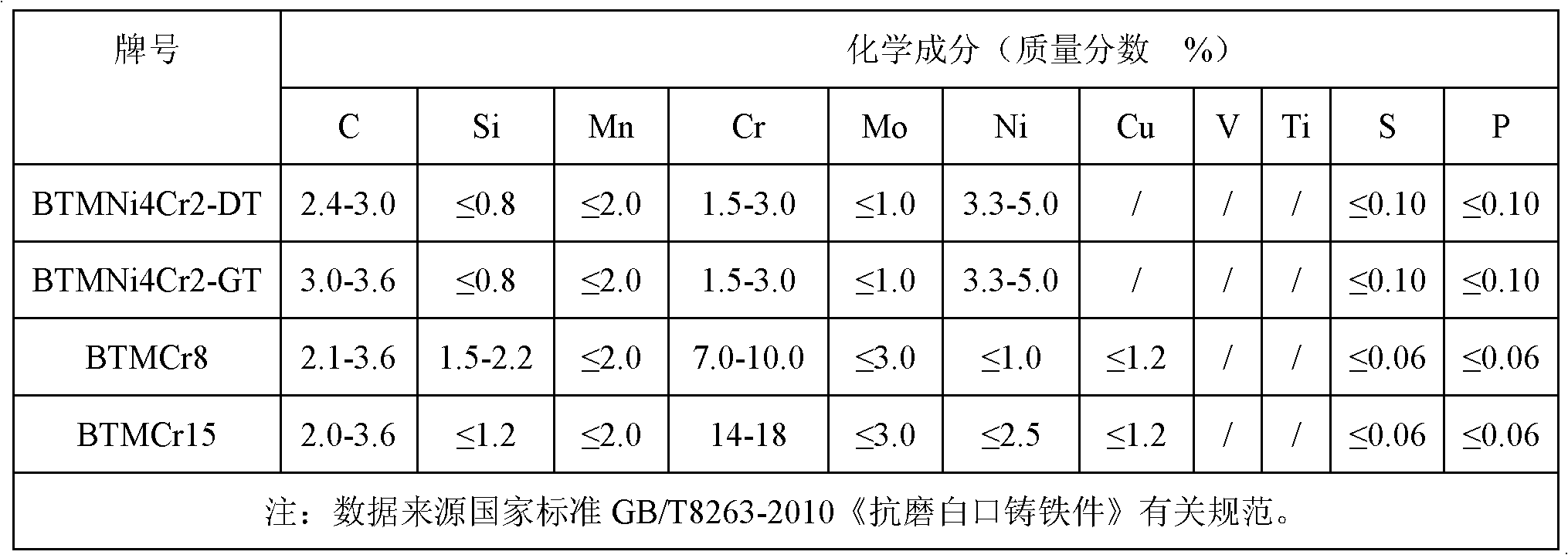

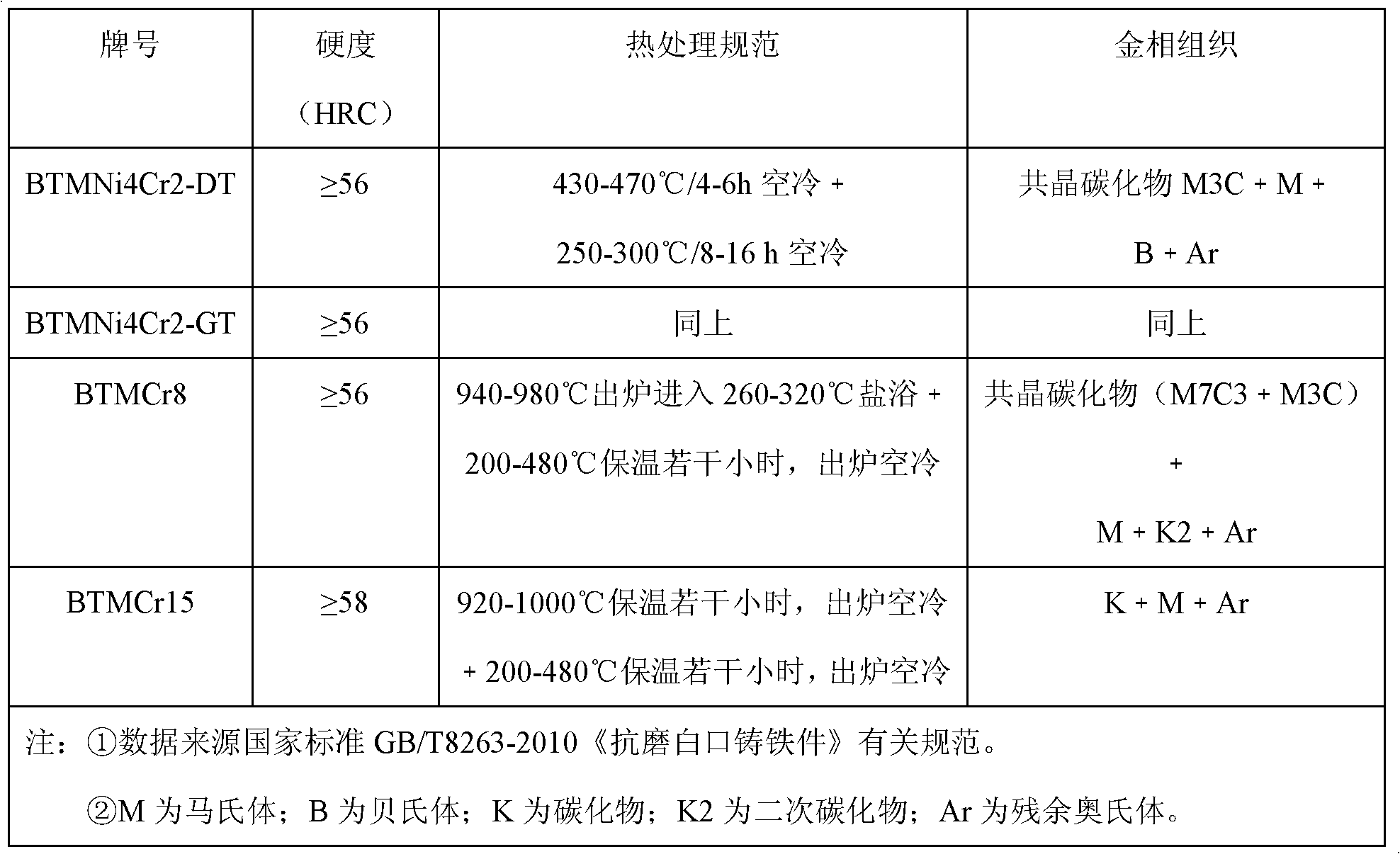

The invention discloses a wear-resistant white cast iron material, which consists of the following elements in percentage by weight: 2.2 to 3.2 percent of C, less than or equal to 1.2 percent of Si, 2.0 to 3.5 percent of Mn, 7.0 to 10.0 percent of Cr, 0.2 to 1.2 percent of Cu, 0.06 to 0.3 percent of V, 0.02 to 0.15 percent of Ti, 0.001 to 0.003 percent of B, 0.02 to 0.06 percent of Al, 0.02 to 0.15 percent of RE, less than or equal to 0.06 percent of S, less than or equal to 0.06 percent of P, and the balance of Fe. The wear-resistant white cast iron material has the hardness (HRC) of more than or equal to 56, the impact toughness aK of more than or equal to 6J / cm<2>, and a metallographic structure consisting of martensite, carbide (M7C3+a small amount of M3C), secondary carbide and a small amount of retained austenite. The wear-resistant white cast iron material does not contain noble metals such as molybdenum, nickel and the like; and compared with the traditional medium-chromium cast iron material, the wear-resistant white cast iron material has the advantages that the production cost can be greatly saved and the material has good economic benefit.

Owner:驻马店市三山耐磨材料有限公司

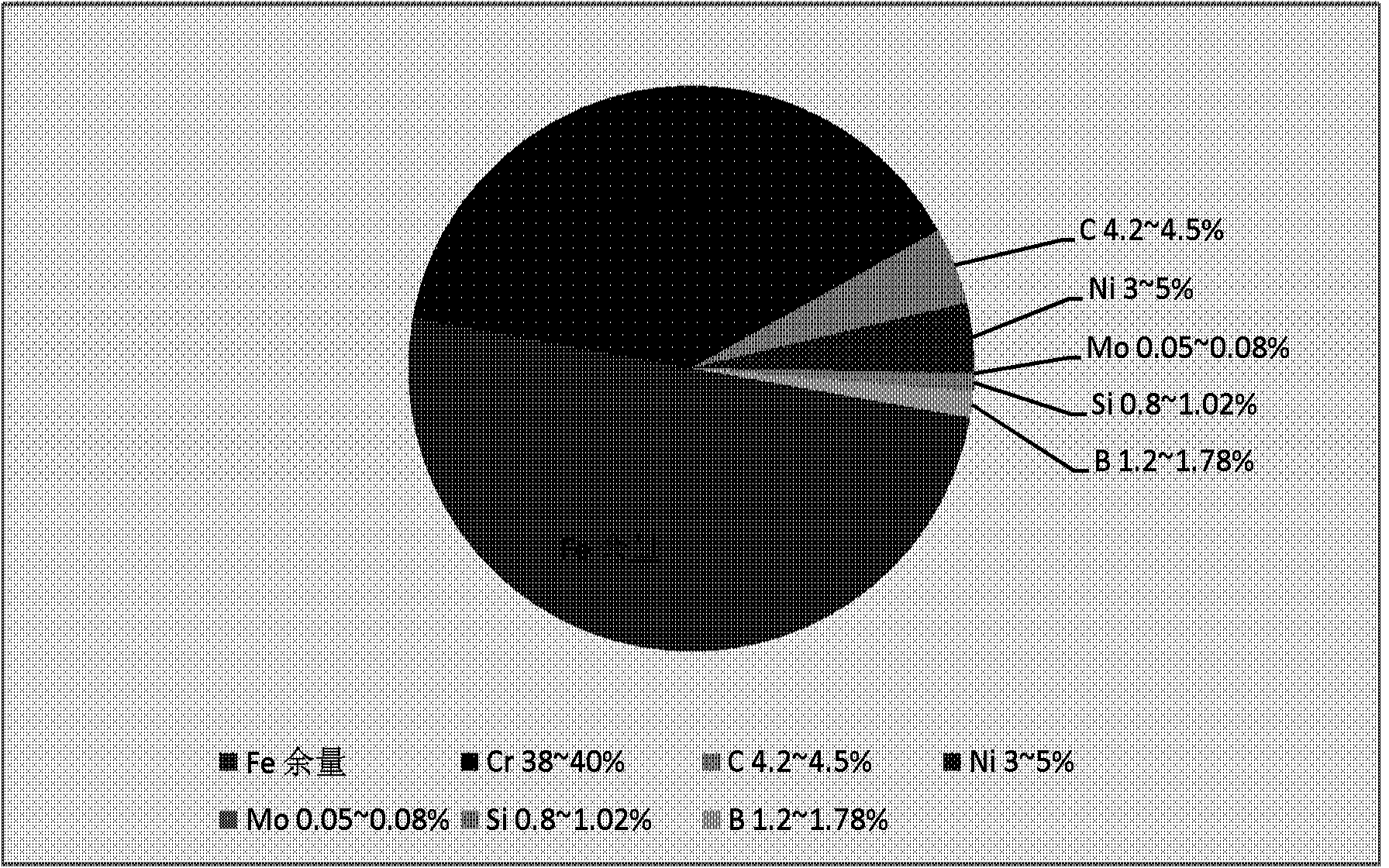

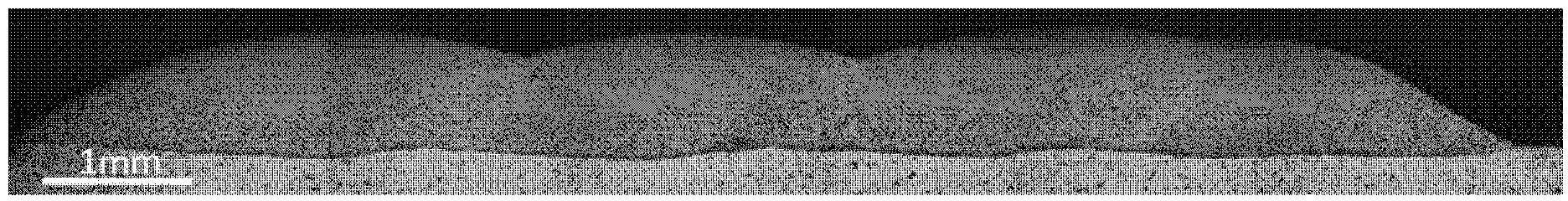

Iron-based composite powder high in chromium content for laser cladding

ActiveCN103752818AHigh hardnessImprove wear resistanceMetallic material coating processesCrack freeHardness

The invention discloses iron-based composite powder high in chromium content for laser cladding. The iron-based composite powder high in chromium content for laser cladding is composed of the chemical compound of Cr3C2, Cr and Fe, Ni, Mo, Si and B. The iron-based composite powder high in chromium content for laser cladding comprises, by mass, 38%-40% of Cr, 4.2%-4.5% of C, 3%-5% of Ni, 0.05%-0.08% of Mo, 0.8%-1.02% of Si, 1.2%-1.78% of B and the balance Fe. The particle size of the iron-based composite powder is between +140 meshes and -325 meshes. The iron-based composite powder is high in carbon content and chromium content, the hardness of a coating can be effectively improved, requirements of the laser cladding technology of iron-based base materials such as carbon steel and stainless steel can be met, a cladding layer of a sample of the iron-based composite powder is free of cracks and macroscopic pores, all the components are distributed evenly, the hardness of the iron-based composite powder can reach HV0.21000 and is five times that of a base body, the corrosion resistance of the iron-based composite powder cladding layer is improved due to the high chromium content, and the iron-based composite powder is suitable for normal temperature, high temperature, abrasion resistance and corrosion resistance working conditions.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

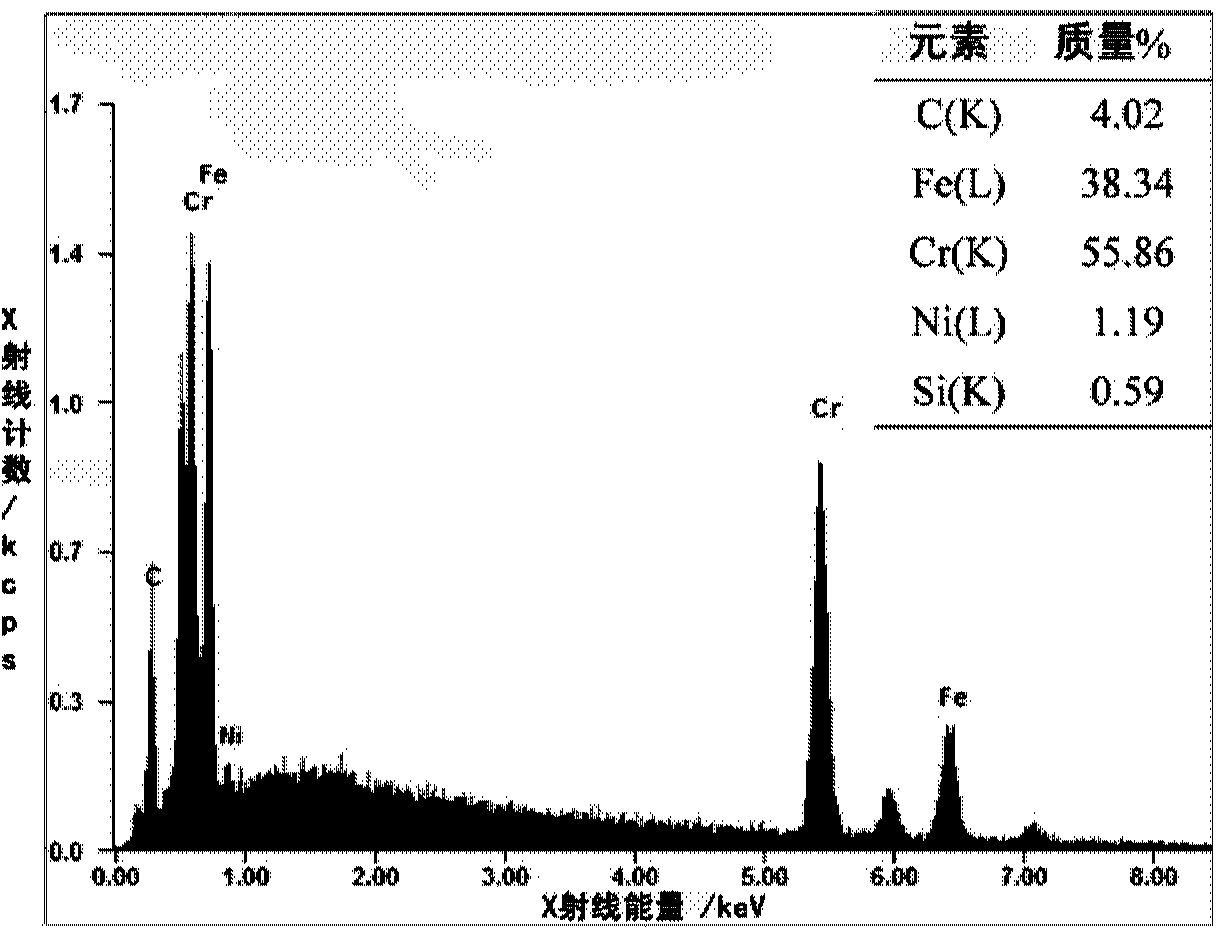

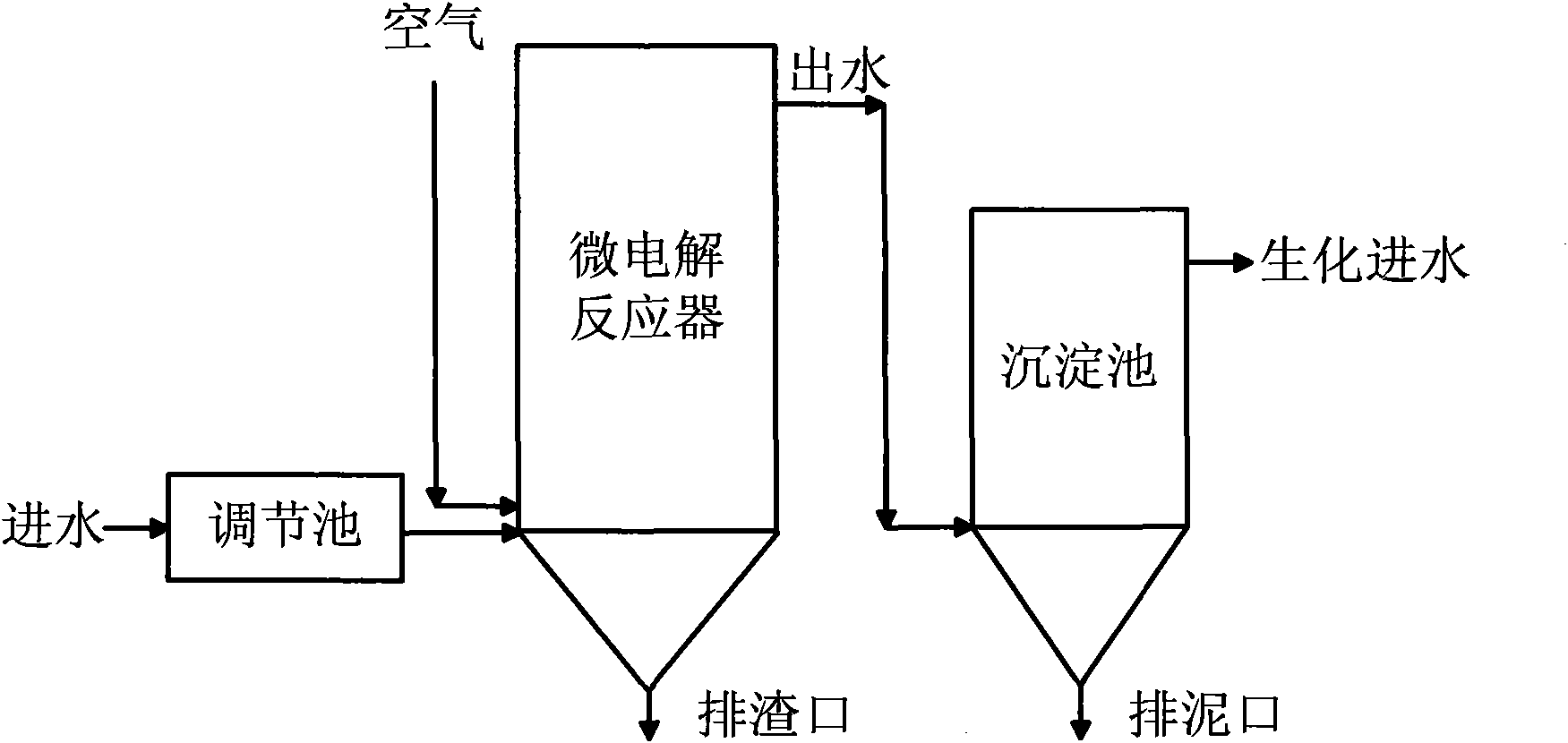

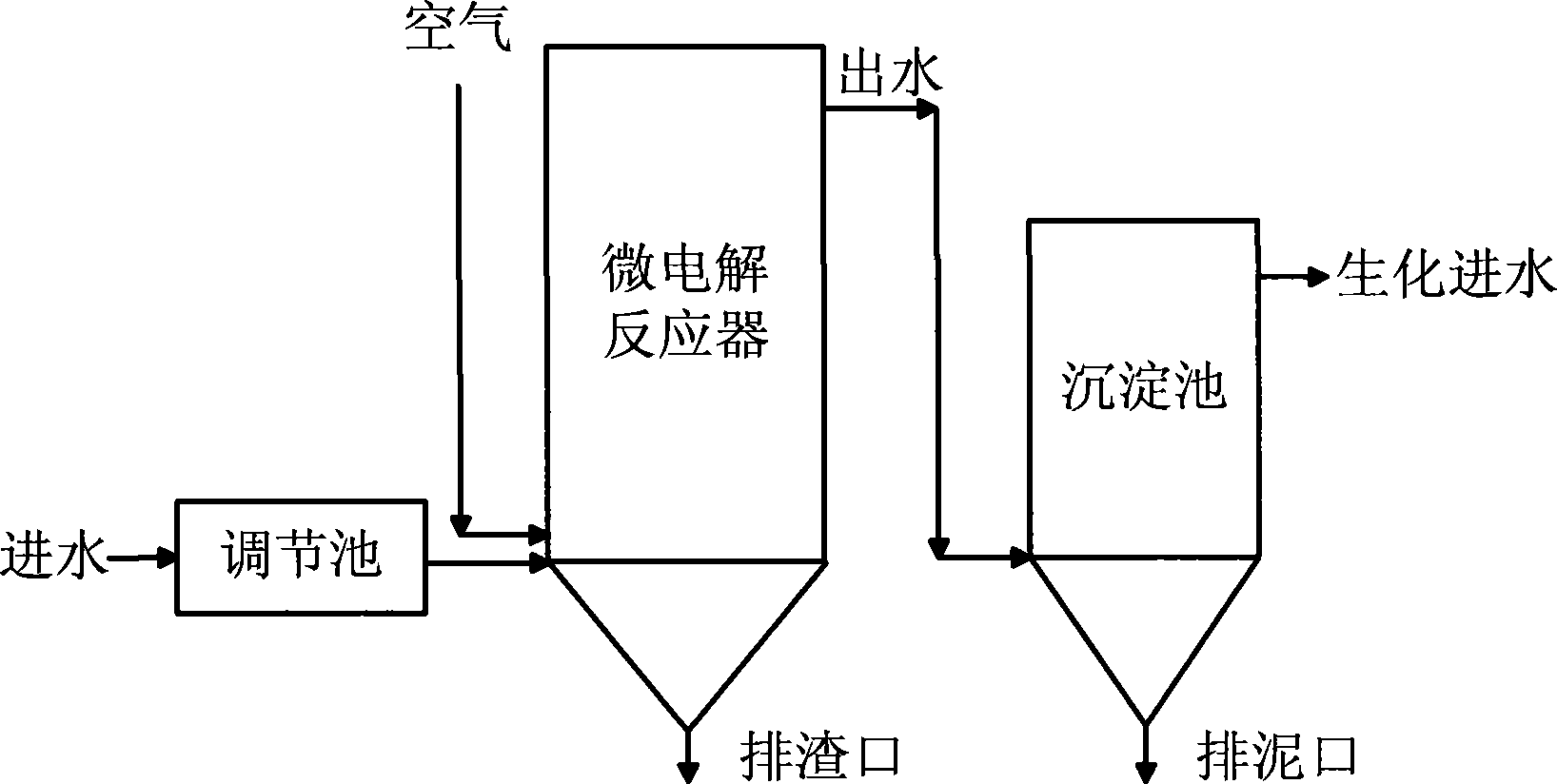

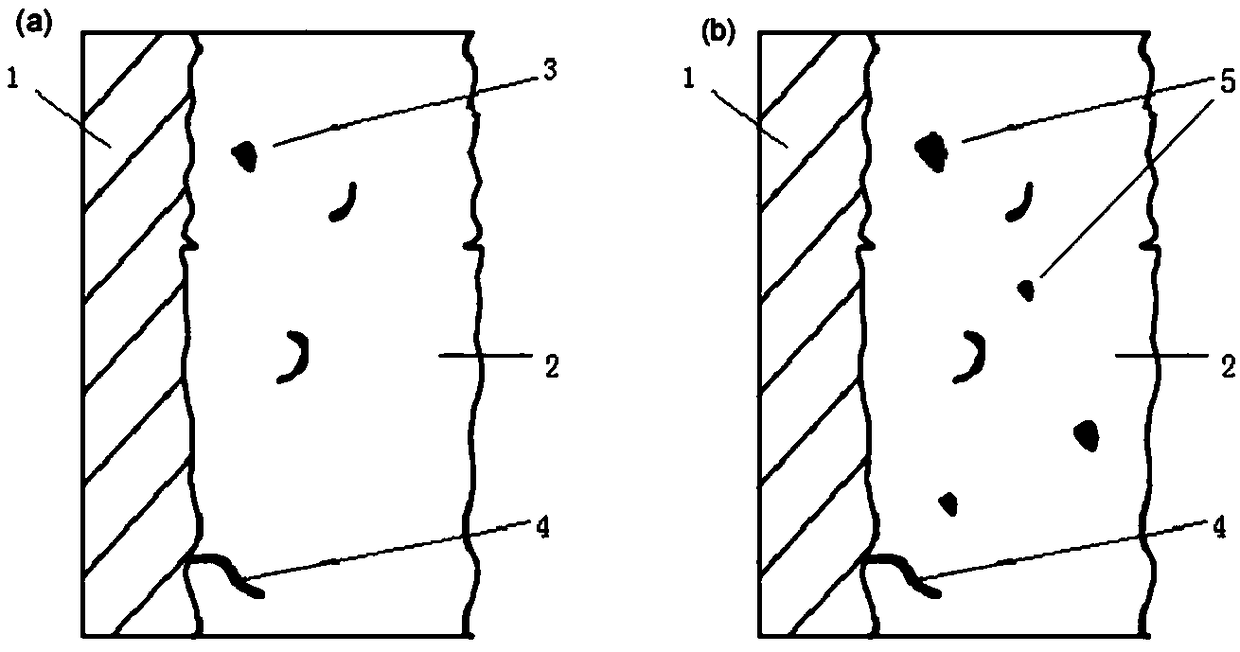

Coking wastewater pretreatment method

InactiveCN101913721AEasy to handleRaise the electrode potentialWater/sewage treatmentMultistage water/sewage treatmentElectrolysisPretreatment method

Owner:南京洁水科技有限公司 +1

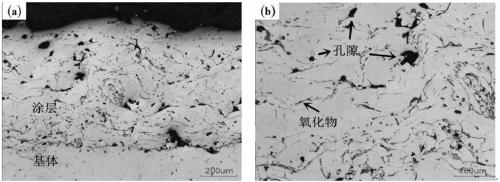

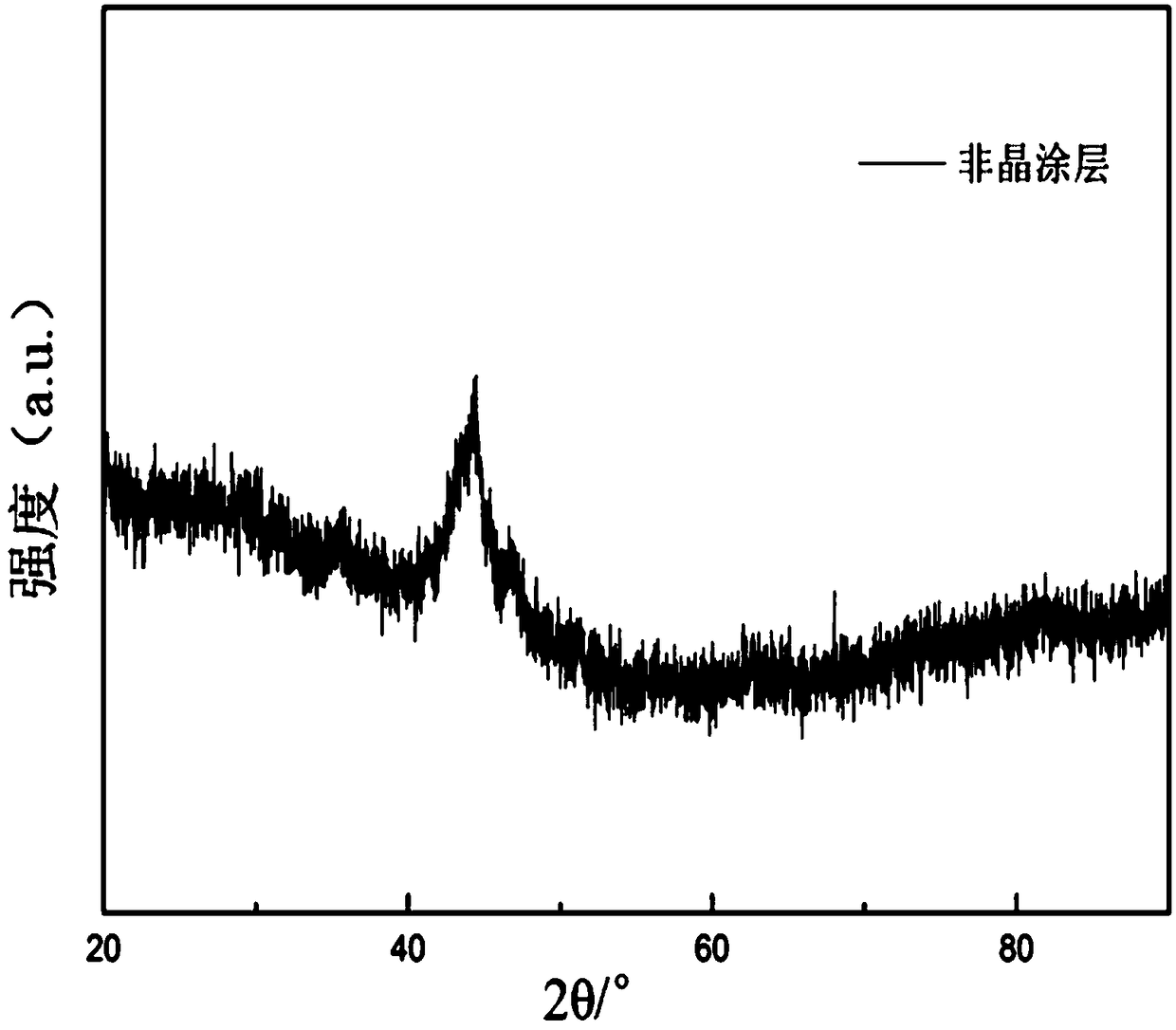

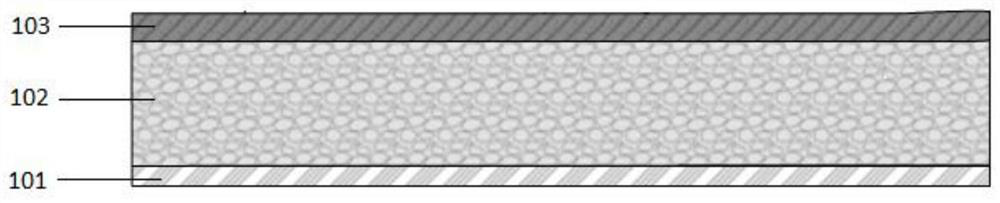

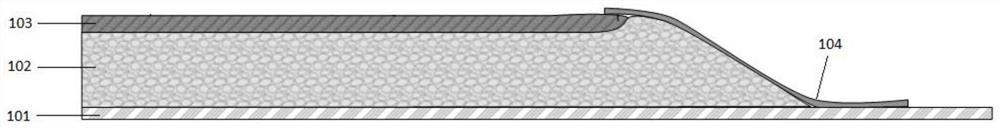

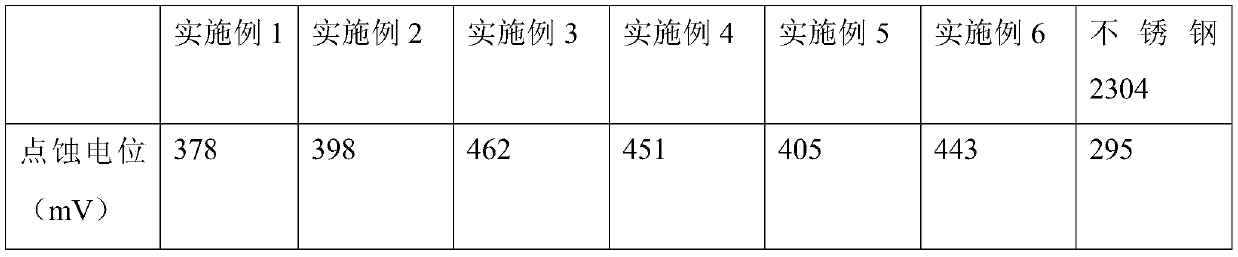

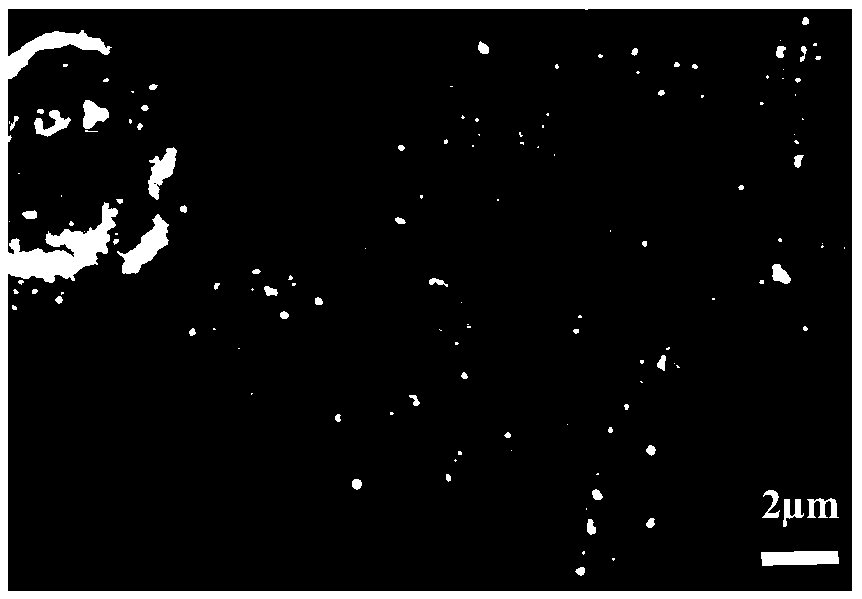

Amorphous protection corrosion resisting steel bar and preparing method thereof

The invention discloses an amorphous protection corrosion resisting steel bar and a preparing method thereof. A powder core wire used in a coating on the steel bar comprises following components including, by weight percent, 25-28 wt% of Cr, 11-13 wt% of B, 0.2-0.7 wt% of C, 0.5-2.5 wt% of P, 3-4.5 wt% of Cu, 1.5-3.5 wt% of Ni, 5-10 wt% of Mo, 2-4 wt% of Mn, 0.35-0.57 wt% of Ti and the balance Fe.After the components are dried and placed in a powder mixing machine according to the proportion to be evenly mixed, the components are placed in a U-shaped 304 stainless steel strip groove, the U-shaped groove is sealed, and drawing is conducted to form filaments through a wire drawing die. A steel bar body is pretreated, the powder core wire serves as the raw material, the coating is prepared through the supersonic speed arc spraying technology, and hole sealing treatment is conducted. The coating is high in amorphous content and bonding strength, low in porosity, high in corrosion resistance and low in cost, and a new path is provided for steel bar corrosion resisting.

Owner:HOHAI UNIV

Negative plate and application thereof

ActiveCN112397685AIncrease the potential of the negative electrodeRaising the nucleation barrier of lithium metalNegative electrodesSecondary cells servicing/maintenanceMetallic lithiumElectrode potential

The invention provides a negative plate and application thereof. According to the negative plate provided by the invention, the safety functional layer containing metal and ceramic is coated on the negative active layer, so the negative electrode potential of the lithium ion battery in the low-temperature high-rate charging process and the nucleation energy barrier of metal lithium are effectivelyimproved, the negative lithium precipitation phenomenon is avoided, and meanwhile, as the ceramic has good heat insulation performance, the thermal runaway phenomenon of the acupuncture experiment can be effectively prevented, and the safety performance of the battery is improved. The negative plate is applied to the lithium ion battery, and the obtained lithium ion battery has the advantages ofgood cycle performance and high safety.

Owner:ZHUHAI COSMX BATTERY CO LTD

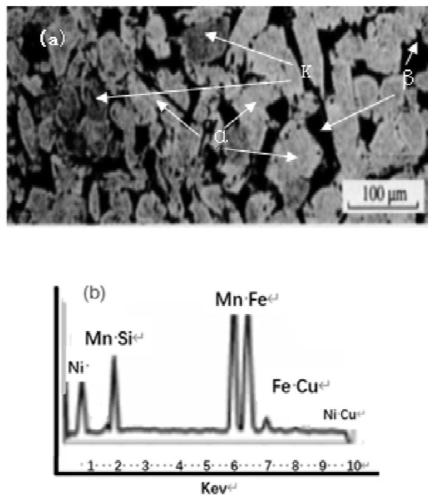

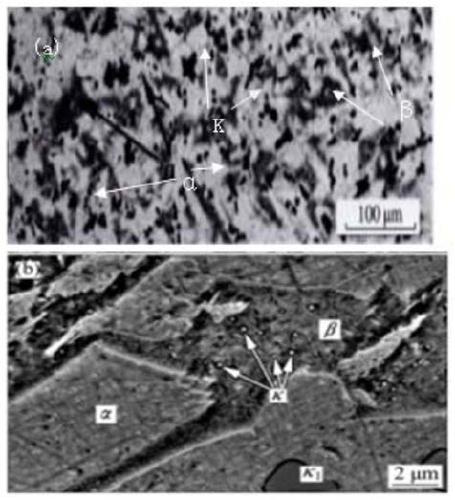

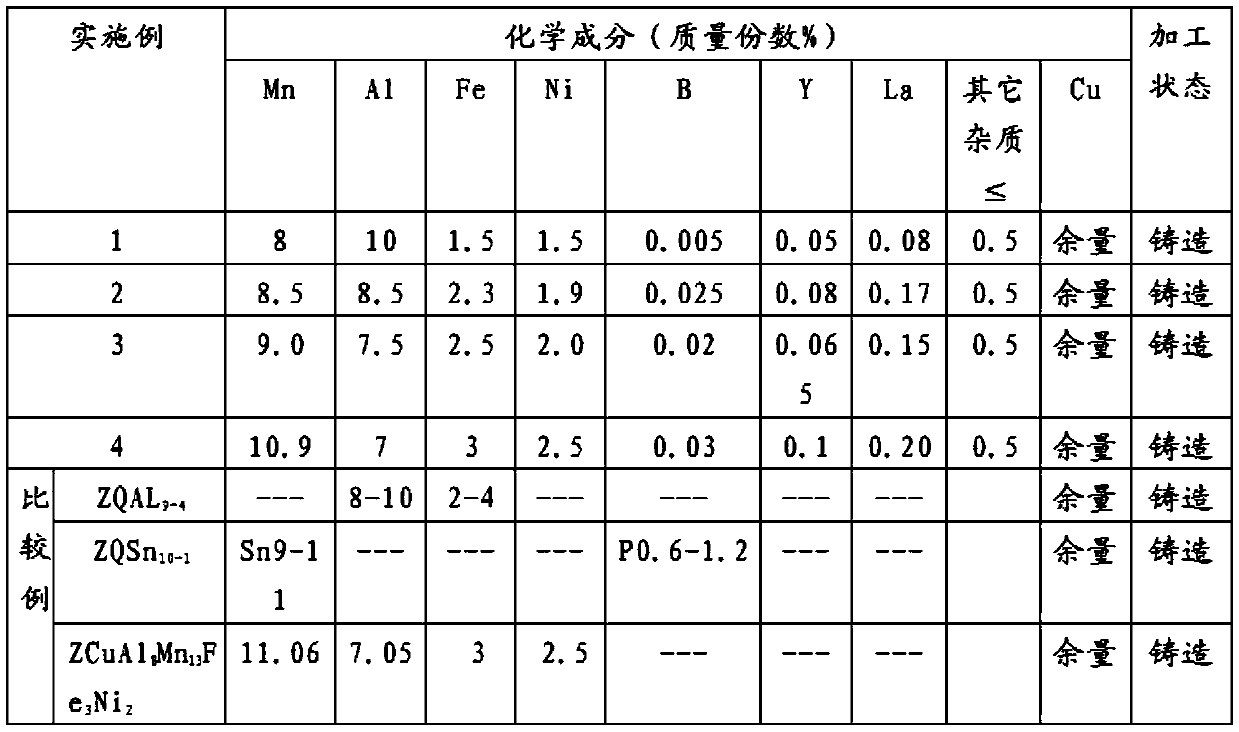

Wear-resistant corrosion-resistant multi-element manganese-aluminum bronze brazing alloy and preparation method thereof

The invention belongs to the field of alloy manufacturing, and particularly relates to a wear-resistant corrosion-resistant multi-element manganese-aluminum bronze brazing alloy and a preparation method thereof. The wear-resistant corrosion-resistant multi-element manganese aluminum bronze brazing alloy is prepared from the following components in parts by weight: 7-10% of Al; 8-11% of Mn; 1.5 to3.0% of Fe; 1.5 to 2.5% of Ni; 0.005-0.03% of B; 0.05 to 0.1 of Y; 0.08-0.20% of La, and the weight ratio of the three elements of B to Y to La is 1: 10: 15-1: 3: 6, and other impurities are less thanor equal to 0.5 percent. The balance is Cu. The wear-resistant corrosion-resistant multi-element manganese-aluminum bronze brazing alloy disclosed by the invention is composed of Al, Mn, Fe, Ni, B, Y, La and Cu, the casting temperature is equal to or lower than 1050 DEG C, and the mechanical property is good. The alloy material is used for cladding an inner wall of a cylinder in a hydraulic support, has bright surface, less deformation, hardness of more than HB240, good wear resistance and corrosion resistance, the operation up to now has always been 2 times of the life of the original material, and the alloy material is still normally used.

Owner:TIANJIN JINLONG WELDING MATERIAL

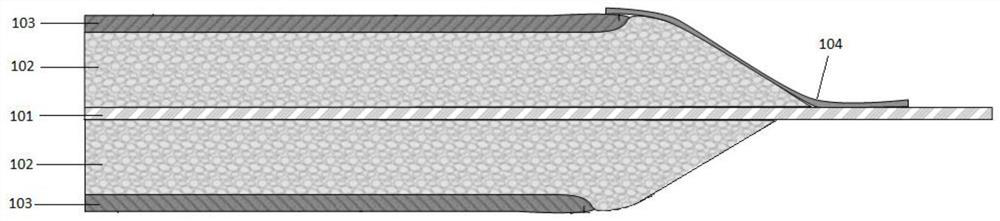

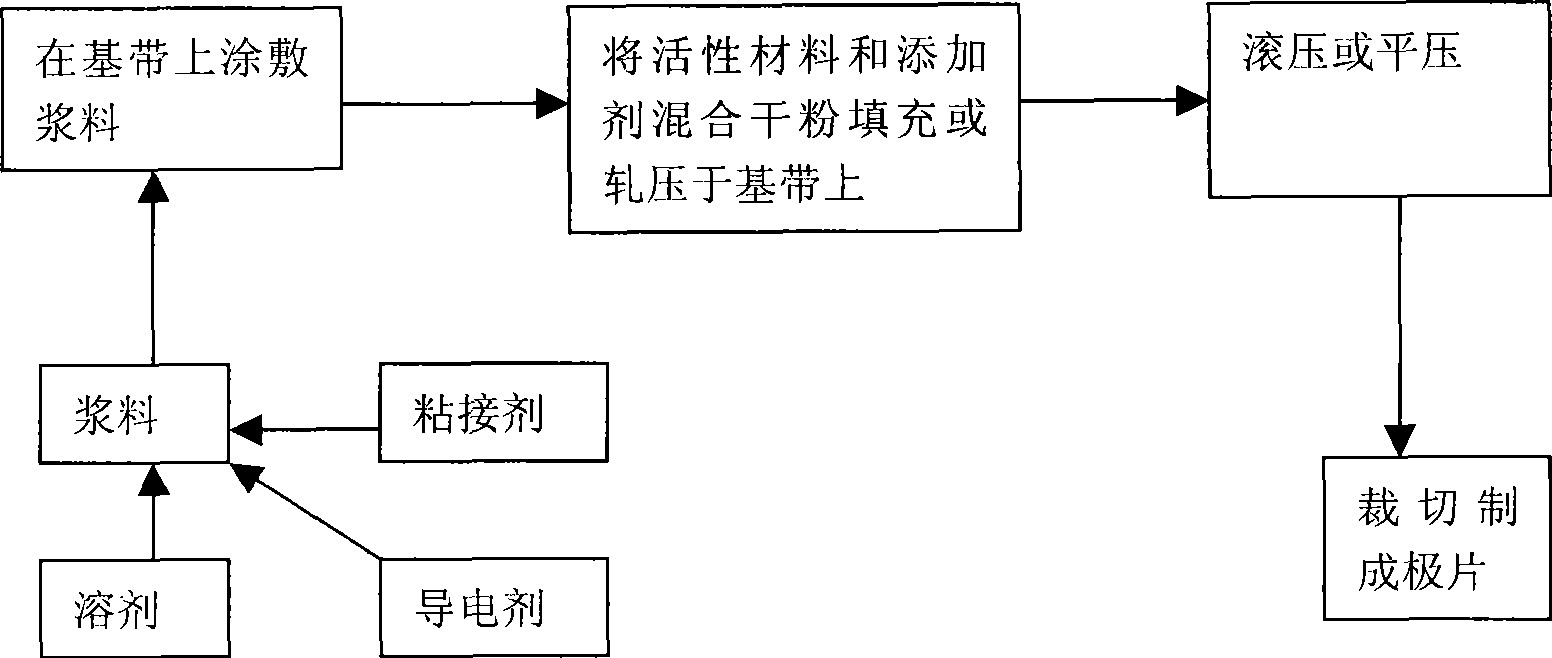

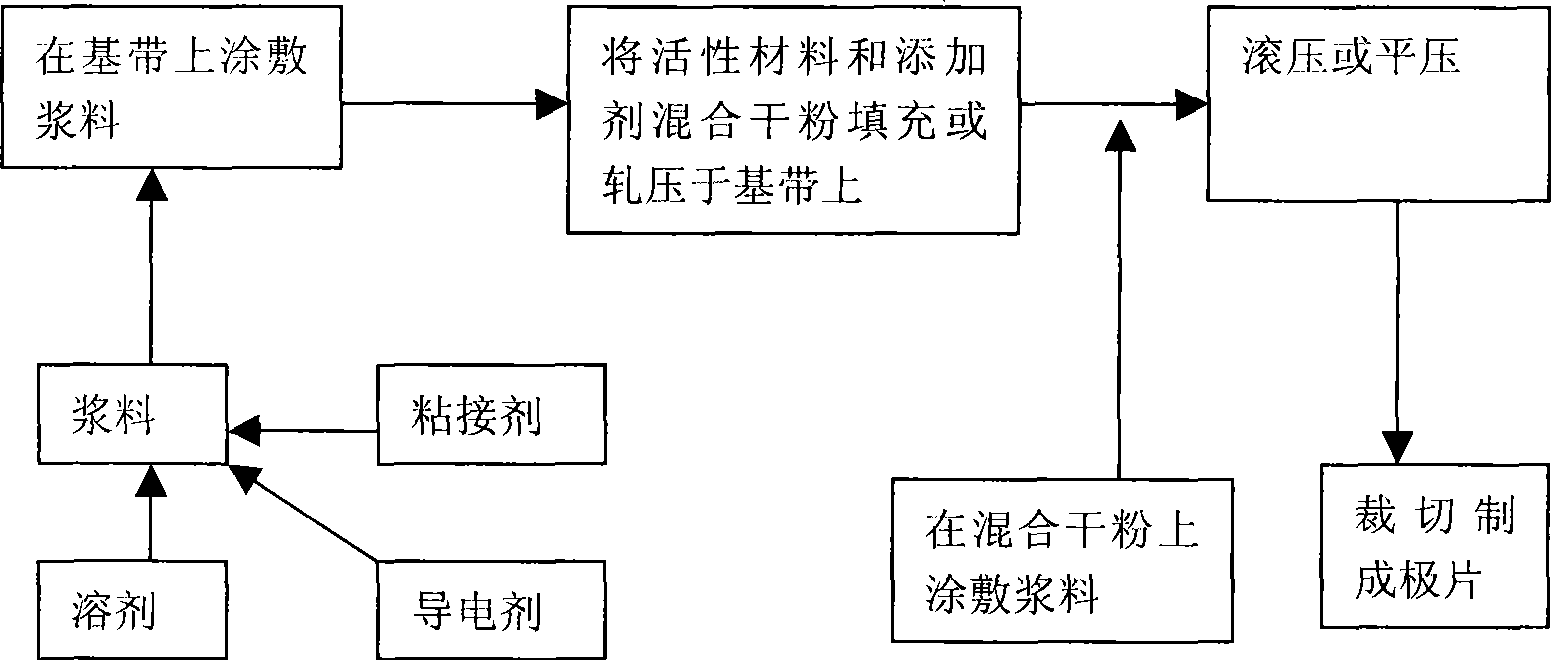

Manufacturing process for battery pole piece

InactiveCN101478036AIncrease energy densityHigh bonding strengthLiquid surface applicatorsElectrode manufacturing processesElectrical batteryEngineering

The invention discloses a battery electrode tab fabrication method, which comprises the following steps: (1) applying a paste on a battery base strip; (2) filling or compressing the mixture powder of an active substance and an additive on the battery base strip; and (3) rolling or flattening, and cutting into the battery electrode tabs. The paste contains a solvent, and also can contain a bonding agent and a conductive agent. The paste applied on the battery base strip can improve the bonding strength between the base strip and the mixture powder of the active substance and the additive to prevent falling off of the base strip, and can also soften the base strip, so as to obtain softer and thinner electrode tabs, thereby improving the energy density of the battery. The mixture powder of the active substance and the additive has little possibility to fall off during coiling; the bonding agent can improve the bonding effect; and the conductive agent can improve the conductive effect. Accordingly, the electrode tab fabricated by the method can achieve better comprehensive performance when used for producing batteries.

Owner:极致动力科技(天津)有限公司

0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube and production process thereof

The invention discloses a 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube. The 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube comprises the following chemical components in percentage by mass: 0.029-0.031% of C, 0.55-0.59% of Si, 1.12-1.14% of Mn, 0.001-0.003% of S, 0.015-0.017% of P, 17.55-17.75% of Cr, 10.15-10.25% of Ni, 0.33-0.35% of Nb, 0.022-0.024% of Mo, 0.04-0.06% of N, 0.149-0.151% of Ti, 0.0013-0.0015% of Sb, 0.0007-0.0009% of Pb, 0.0012-0.0014% of Ce, 0.08-0.12% of rare earth elements and the balance of Fe and unavoidable impurities. The invention further discloses a production process of the 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube. The 0Cr18Ni10Ti small-diameter seamless stainless steel capillary tube has good flexibility, corrosion resistance, high temperature resistance, wear resistance, tensile strength and water resistance and also has excellent electromagnetic shielding performance.

Owner:WUXI XINCHANG STEEL PIPE

Low-nickel and high-strength bi-phase stainless steel material and preparation method thereof

The invention discloses a low-nickel and high-strength bi-phase stainless steel material and a preparation method thereof. The low-nickel and high-strength bi-phase stainless steel material is prepared from the following components in percentage by mass: 0.01-0.04% of C, 17.0-28.0% of Cr, 0.5-1.5% of Ni, 0.2-0.70% of Mo, smaller than or equal to 1.5% of Si, smaller than or equal to 2.0% of Mn, 1.50-5.00% of Cu, 0.05-0.70% of N, smaller than or equal to 0.50% of Ti and the like. The preparation method comprises the steps: blending is conducted, and the low-nickel and high-strength bi-phase stainless steel material is prepared through smelting, refining, centrifugal casting and high-temperature solid solution heat treatment. Mechanical properties of the prepared low-nickel and high-strengthbi-phase stainless steel material can meet mechanical property requirements of X2CrNiN23-4 hot-rolled stainless steel in EN 10088-2 2005 of the sheet steel / steel plate and belt material standard of European corrosion-resistant steel, and the low-nickel and high-strength bi-phase stainless steel material is low in raw material cost and more stable in comprehensive mechanical property.

Owner:SICHUAN WEIZHEN PETROCHEM EQUIP

Hot galvanized high-strength steel plate with high surface quality and excellent corrosion resistance and manufacturing method thereof

ActiveCN110760773AIncrease contactIncreasing the thicknessHot-dipping/immersion processesSuperimposed coating processChemical compositionUltimate tensile strength

The invention discloses a hot galvanized high-strength steel plate with high surface quality and excellent corrosion resistance and a manufacturing method thereof. The hot galvanized high-strength steel plate sequentially comprises a substrate, a pre-metallization layer and Fe-Al barrier layer and a galvanized layer from bottom to top, wherein the chemical composition of the substrate comprises the following chemical components of, in percentage by weight, 0.15 wt% to 0.25wt% of C, 1.00 wt% to 2.00 wt% of Si, 1.50 wt% to 3.00 wt% of Mn, less than or equal to 0. 015 wt% of P, less than or equalto 0.012 wt% of S, 0.03 wt% to 0.06 wt% of Al and the balance Fe and inevitable impurities, and the pre-metallization layer is a metal Ni layer. The hot galvanized high-strength steel plate is good in surface quality, uniform and complete in plating layer, and better in corrosion resistance compared with a conventional hot galvanized product; and the yield strength of the hot galvanized steel plate is 600-900 MPa, the tensile strength is 980 MPa or above, the elongation is 15-22%, the surface quality and corrosion resistance are superior to those of conventional hot galvanized high-strength steel, and the hot galvanized teel plate is suitable for automobile structural parts and outer plates with higher requirements on surface quality, corrosion resistance and formability.

Owner:BAOSHAN IRON & STEEL CO LTD

High temperature-resistant anti-oxidant alloy steel for resistor and preparation method thereof

InactiveCN106636975AImprove corrosion resistanceImprove high temperature oxidation resistanceMetallurgyRare earth

The invention discloses high temperature-resistant anti-oxidant alloy steel for a resistor. The high temperature-resistant anti-oxidant alloy steel for the resistor comprises the following components in percentage by weight: 0.1 to 0.2 percent of C, 0.6 to 1.1 percent of Si, 4.2 to 8.6 percent of Mn, 16.8 to 22.4 percent of Cr, less than or equal to 0.04 percent of P, less than or equal to 0.04 percent of S, 0.02 to 0.08 percent of V, 0.05 to 0.15 percent of Nb, 0.02 to 0.06 percent of Pb, 3.2 to 4.6 percent of Al, 0.2 to 0.6 percent of Ti, 0.6 to 1.2 percent of Mo, 6.8 to 8.6 percent of Cu, 0.2 to 0.6 percent of Y, 4.5 to 8.5 percent of Ni, 0.12 to 0.24 percent of W, 0.02 to 0.08 percent of rare earth, and the balance of Fe and unavoidable impurities. The invention also discloses a preparation method for the high temperature-resistant anti-oxidant alloy steel for the resistor. The alloy steel for the resistor prepared by the preparation method has excellent high temperature-resistant anti-oxidant performance.

Owner:ANHUI RUIXIN AUTOMATION INSTR

Manufacturing method of auto tire mold

InactiveCN106626163AIncrease chromium contentIncrease contentTyresElectrode potentialElectrical conductor

The invention discloses a manufacturing method of an auto tire mold. The manufacturing method comprises the following steps that (A), the mold molded face is designed through a combination method of CAD and CAE; (B), materials are prepared, specifically, the raw materials are weighed and prepared from the raw materials including, by weight, 60-65% of Al, 5-10% of Cr, 2-3% of Si, 3-4% of Cu, 5-9% of Fe, 0.5-1.0% of Mn, 1-2% of Zn, 1-3% of Mg, 0.5-1.0% of Ni, 1.0-3.0% of Sn, 0.1-0.13% of Ti and 0.1-0.18% of Pb; and (C), smelting is conducted, specifically, the prepared raw materials are added into a smelting furnace, the temperature of the smelting furnace is controlled to be 850-900 DEG C, and after complete smelting, the temperature falls to 650-700 DEG C. According to the manufacturing method of the auto tire mold, the chromium content in the mold materials is increased; through increasing of the chromium content, electrode potential of iron in mold steel and corrosion resistance can be improved; and meanwhile, alloy molten aluminum is poured into a fabrication mold cavity in a double-layer pouring way side pouring mode, so that smooth and steady mold filling and the good feeding effect are achieved, the technical requirements of air impermeability and electrical conductivity of a produced conductor casting are simultaneously met, and the service life of the mold is remarkably improved.

Owner:JIANGSU YUYAN MOLDING CO LTD

Nickel-based alloy with high grain-boundary strength and preparation method thereof

The invention relates to a nickel-based alloy with high grain-boundary strength and a preparation method thereof. The nickel-based alloy consists of the chemical components in percentage by weight; 20-25 percent of chromium, 0.2-0.7 percent of copper, 0.01-0.2 percent of carbon, 8.0-10.0 percent of molybdenum, 10-15 percent of cobalt, 0.5-1.5 percent of aluminum, 0.2-0.6 percent of titanium, 0.01-0.02 percent of boron, 0.01-0.03 percent of tungsten, 0.01-0.3 percent of tantalum, 0.02-0.06 percent of rare earth and the balance of nickel and other unavoidable trace impurity elements. The preparation method for the nickel-based alloy with high grain-boundary strength comprises the following steps of (1) preparing raw materials: preparing a proper amount of Incone1617 main material and a small amount of Re, B, Ta and W for component adjustment; and (2) feeding the materials for smelting: putting the materials Cr, Mo, Ta and W which have high smelting points to the bottom of a crucible, then adding the Incone1617 furnace material, sequentially adding the rest of the raw materials, covering the materials with a slag removal agent, and smelting the materials in a vacuum smelting furnace. By the adding of B, Ta and the rare earth elements, the nickel-based alloy is low in environment sensitivity and can achieve effects of purifying the grain boundary and effectively improving the grain-boundary bonding strength.

Owner:CHANGZHOU UNIV

Iron-containing magnesium-based composite material as well as preparation method and application thereof

InactiveCN105177383ASolve storage problemsNo pollution in the processFluid removalHydrogen productionPorosityGeneration rate

The invention discloses an iron-containing magnesium-based composite material as well as a preparation method and an application thereof. The mass fraction of Fe in the composite material is 0.01 to 10 percent, and the balance is magnesium, and the material density is 1.37 to 2.35g / cm<3>. The preparation method of the iron-containing magnesium-based composite material comprises the following steps: (1) ball milling magnesium powder and iron powder to form a uniform mixture, wherein the mass fraction of the Fe powder in the mixture is 0.01 to 10 percent, and the balance is magnesium powder; (2) placing the uniform mixture processed in the step 1 into a forming mold, and pre-pressing and forming under the conditions that the temperature is 25 to 150 DEG C and the pressure is 50 to 300 MPa; and (3) sintering the material pressed and formed in the step (2) under the argon protection condition, wherein the sintering temperature is 580 to 600 DEG C, the sintering time is 2 to 5 hours, and the pressure is 100 to 300 MPa. The iron-containing magnesium-based composite material can be used as a hydrogen evolution reaction raw material and a fracturing ball during the petroleum exploitation process. The iron-containing magnesium-based composite material is simple in preparation process and high in hydrogen generation and dissolving rate; and moreover, the hydrogen generation rate can be controlled by virtue of porosity and the surface area, and the application of the product produces no pollution.

Owner:CHONGQING UNIV

Scale and corrosion resistant rare earth-Ag-Zn alloy and its preparation method

The invention discloses a scale and corrosion resistant rare earth-Ag-Zn alloy and its preparation method. The alloy is obtained through melting metallic elements having different electronegativities and comprising 40-65wt% of Ag, 15-35wt% of Zn, 5-25wt% of Ni, 2-15wt% of Sn, 0.5-4wt% of Mn, 1-5wt% of Ti, 1.5-10wt% of Mo, 0.5-5wt% of Pb, 0.5-2.5wt% of Nd and 0.5-2.5wt% of Sm. The rare earth-Ag-Zn alloy is mainly used for the scale and corrosion resistance of producing well oil tubes and pipelines in the petrochemical industry, is also used for the boiler scale resistance in the heat supply industry, the electric power industry and the like, and is a scale and corrosion resistant product having the advantages of excellent scale and corrosion resistances, safety, environmental protection and resource saving.

Owner:HUANGSHI BOHUI TECH CO LTD

Degradable ultrafine needle piece

The invention relates to the technical field of medical cosmetology instruments, in particular to a degradable ultrafine needle piece. The degradable ultrafine needle piece consists of degradable magnesium alloy. The magnesium alloy comprises the following chemical elements in parts by weight: 2-5 parts of neodymium, 0.1-0.5 part of zinc, 0.2-0.7 part of zirconium and the balanced magnesium metal. The magnesium alloy has lower corrosion potential, is easy to be corroded in the body of a person, and can be degraded completely and absorbed by the body of the person after being corroded slowly; magnesium is a necessary nutrient element of persons, and participates in energy metabolism of the body of the person; after the magnesium is absorbed by the body of the person, the circumstance that the content of serum magnesium is increased obviously is avoided; and the magnesium alloy has the neodymium which serves as a low alloying element, by the neodymium, the magnesium alloy has a good ageing precipitation strengthening and solution strengthening effect, electrode potential of an alloy matrix is improved, and homogeneous corrosion resistance of the magnesium alloy is improved. By the small amount of the zinc, the strength of the alloy and plastic working capability can be improved.

Owner:陈彦彪

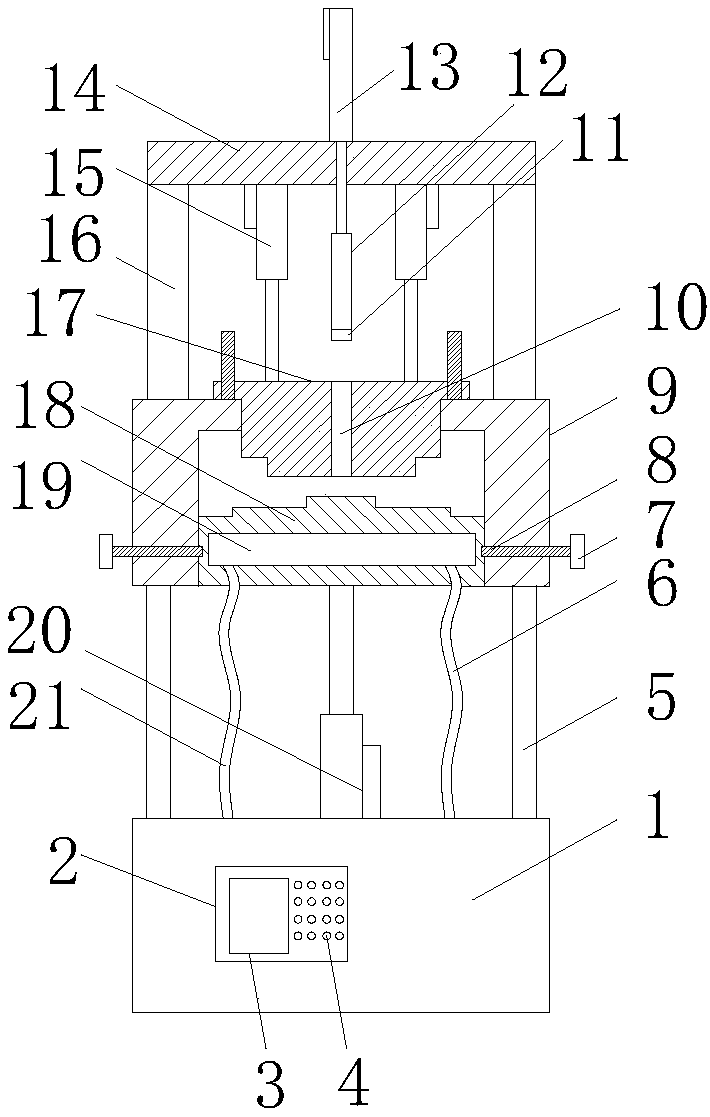

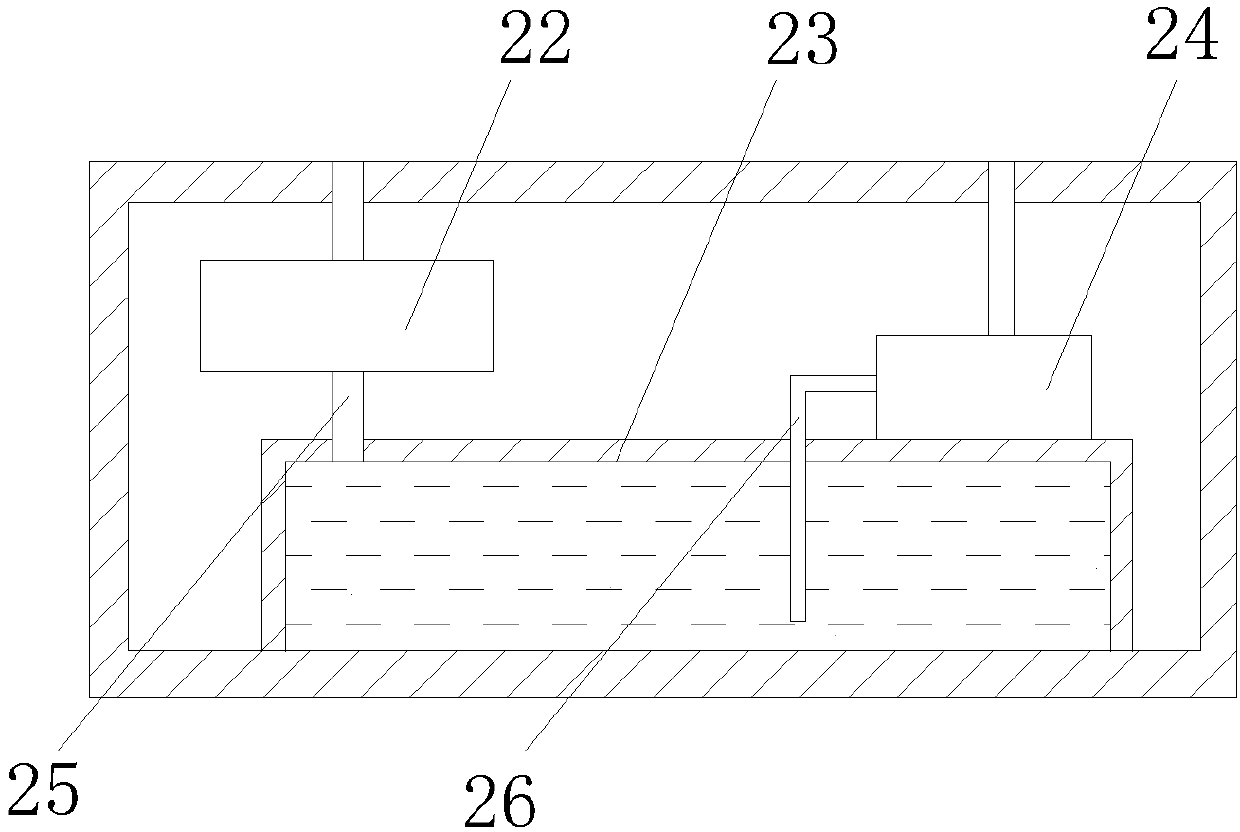

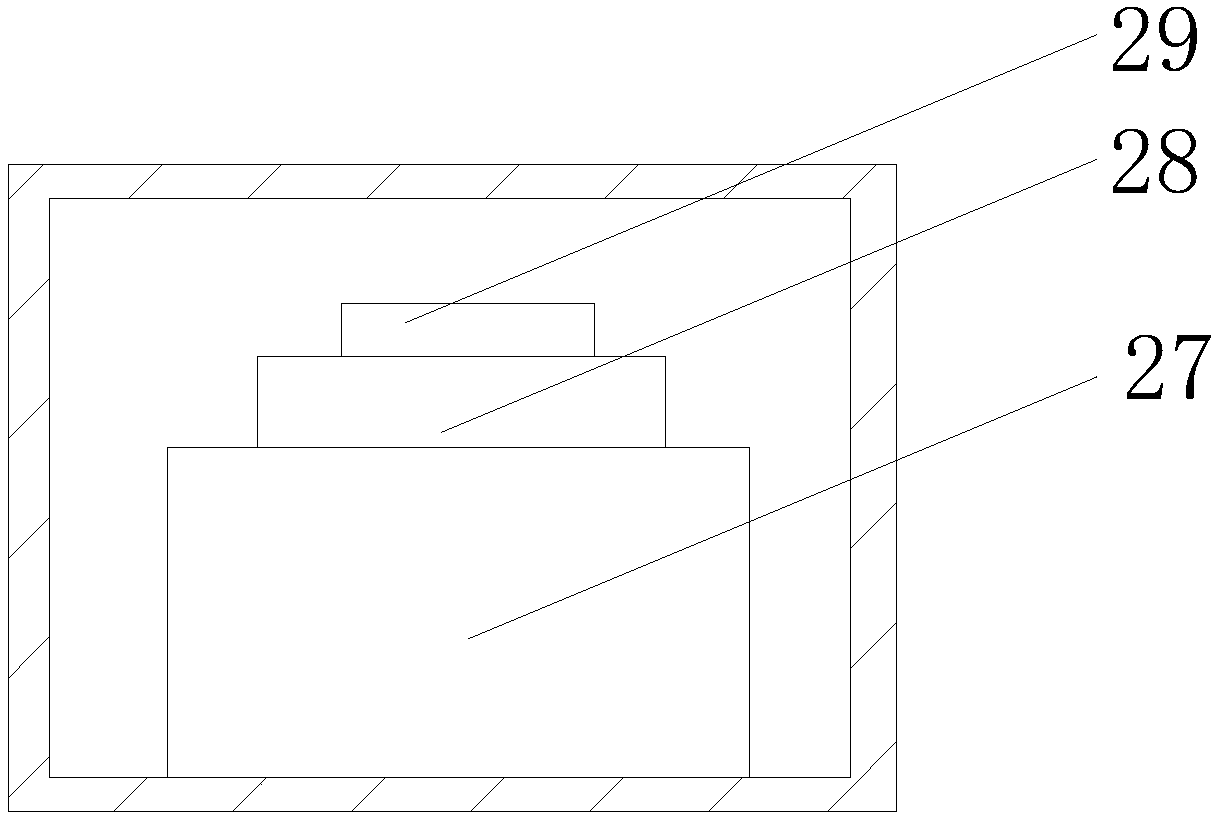

Automobile part mold good in cooling effect

The invention discloses an automobile part mold good in cooling effect. The automobile part mold comprises a base. A control panel is embedded to the base. A display screen is mounted on the control panel. Operation buttons are mounted on one side of the display screen. A storage battery is mounted in the control panel. A circuit mainboard is mounted on the storage battery and provided with a PLC.First supporting rods are mounted on the edges of the two sides of the top of the base. A first mold is mounted on the first supporting rods. Second supporting rods are mounted on the edges of the two sides of the top of the first mold. A top plate is mounted at the top ends of the first supporting rods. A hydraulic rod is mounted in the center of the top of the base. A second mold is mounted atthe top end of the hydraulic rod. A water tank is mounted in the base. A water pump is mounted at the top of the water tank. A cavity is formed in the second mold. The water pump is connected with thecavity through a first water pipe. One end of the cavity is connected with a cooling box through a second water pipe. The automobile part mold is compact in structure and high in cooling efficiency.

Owner:徐九威

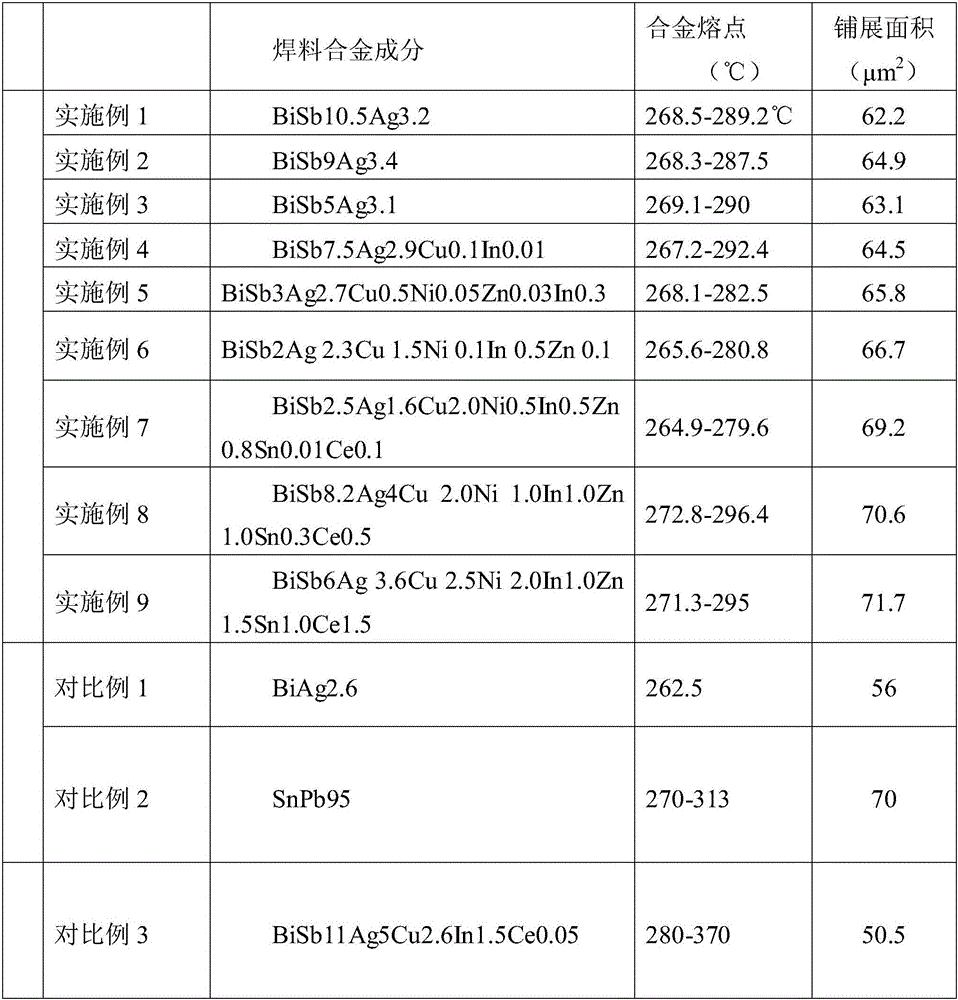

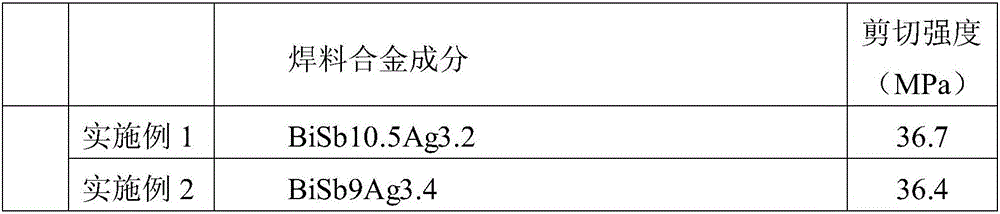

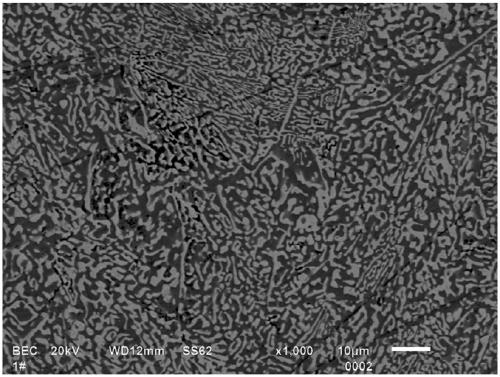

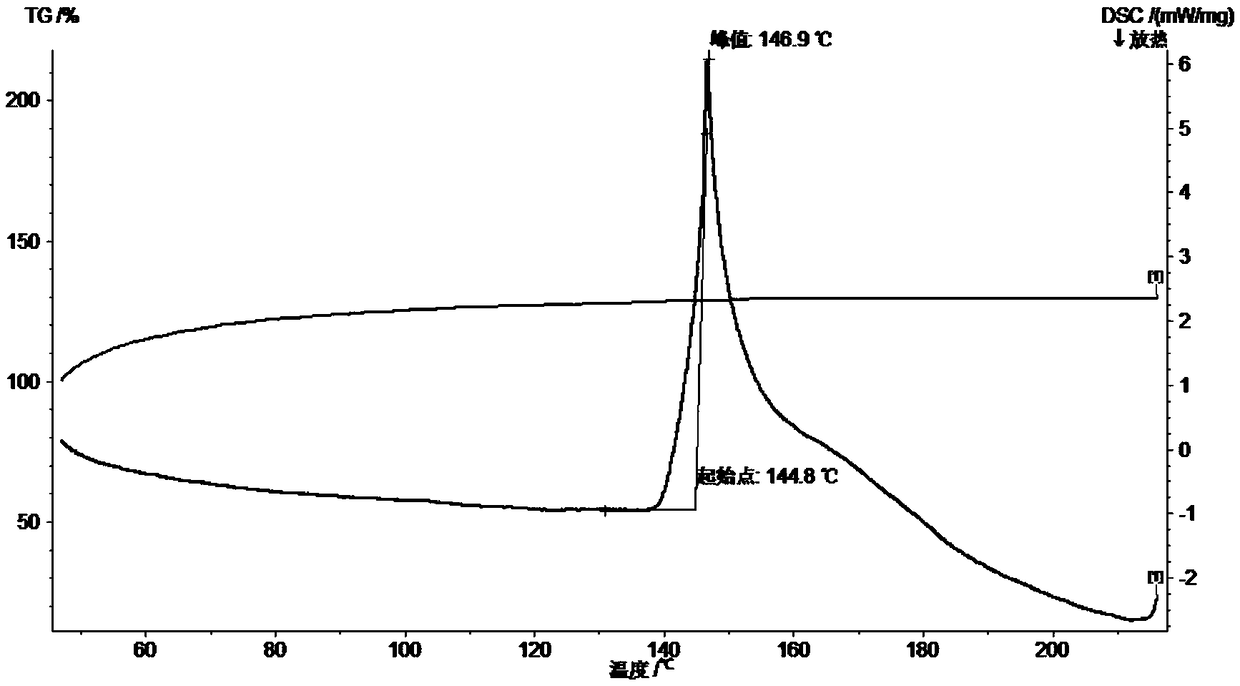

BiSbAg-series high-temperature lead-free solder and preparation method thereof

ActiveCN106392366ASolve the brittleness problemImprove brittlenessWelding/cutting media/materialsSoldering mediaMechanical propertyImpurity

The invention discloses a BiSbAg-series high-temperature lead-free solder and a preparation method thereof and belongs to the technical field of high-temperature soft solders. The lead-free solder contains the following components in percentage by weight: 2.0-10.5% of Sb, 1.6-4.0% of Ag and the balance of Bi and a small number of unavoidable impurities, and the weight percentages of Sb and Ag in the solder alloy meet a relational expression, namely b=-0.046a<2>+0.67a+1.11+c, wherein the value of a is the weight percentage of Sb, the value of b is the weight percentage of Ag, and the value of c is larger than or equal to 1.0 and smaller than or equal to 1.0. The invention also discloses a preparation method of the lead-free solder. A microstructure of the solder alloy disclosed by the invention is a quasi-peritectic or approximate quasi-peritectic structure, and the solder alloy is small in melting range, favorable in mechanical property and reliability and suitable for the field of high-temperature soft solders.

Owner:BEIJING COMPO ADVANCED TECH

A kind of snbisb series low-temperature lead-free solder and preparation method thereof

ActiveCN106216872BFine grainSmall grainWelding/cutting media/materialsSoldering mediaMechanical propertyMaterials science

The invention discloses a SnBiSb low-temperature lead-free solder and a preparation method thereof, belonging to the technical field of low-temperature solder. The weight percentage composition of this lead-free solder is: Bi 32.8-56.5%, Sb 0.7-2.2%, the rest is Sn, and the weight percentage of Bi and Sb satisfies the relationship b=0.006a 2 ‑0.672a+19.61+c, wherein a is the weight percentage of Bi, b is the weight percentage of Sb, and the range of c is ‑1.85≤c≤1.85. The invention also discloses a preparation method of the lead-free solder. The solder alloy of the invention is a pereutectic or near-eutectic structure, has a low melting point, has excellent mechanical properties and reliability, and is suitable for the field of low-temperature soldering.

Owner:BEIJING COMPO ADVANCED TECH

Seamless self-protection flux-cored wire for low-nitrogen non-magnetic naval vessel steel welding

ActiveCN112404795AFast solidificationEasily ionizedWelding/cutting media/materialsSoldering mediaSilica fumeNitriding

The invention relates to a seamless self-protection flux-cored wire for low-nitrogen non-magnetic naval vessel steel welding. According to the technical scheme, the seamless self-protection flux-coredwire is composed of 70 wt%-80 wt% of a stainless steel strip and 20 wt%-30 wt% of flux-cored powder, and the stainless steel strip is filled with the flux-cored powder. The stainless steel strip comprises the following chemical components of, in percentage by weight, 0.03-0.08 wt% of C, less than or equal to 1wt% of Si, less than or equal to 2 wt% of Mn, 18-20 wt% of Cr, 8-11 wt% of Ni, less thanor equal to 0.03 wt% of S, less than or equal to 0.03 wt% of P and the balance Fe and inevitable impurities. The flux-cored powder comprises the following chemical components of, in percentage by weight, 40-43 wt% of barium fluoride, 5-8 wt% of marble, 8-10 wt% of aluminum powder, 2-4 wt% of silicon powder, 7-10 wt% of manganese powder, 2-5 wt% of manganese nitride, 10-13 wt% of nickel powder, 5-7 wt% of chromium powder and the balance iron powder. According to the seamless self-protection flux-cored wire, weld metal formed by welding the low-nitrogen non-magnetic naval vessel steel is high in strength, good in ductility and toughness, non-magnetic and excellent in seawater corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

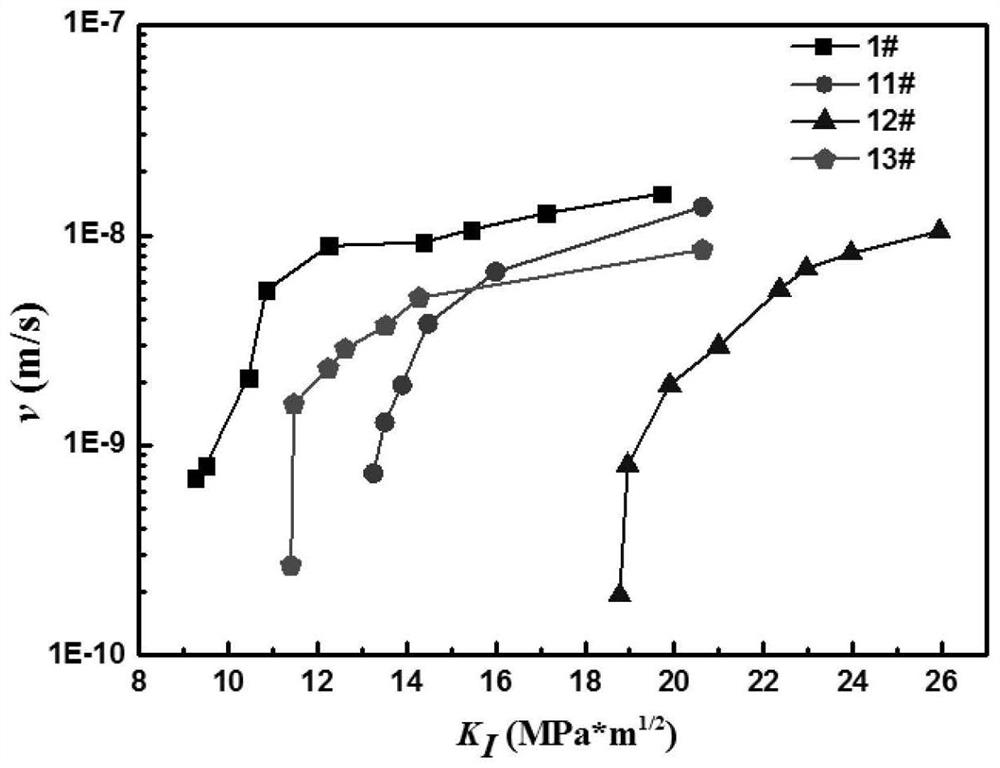

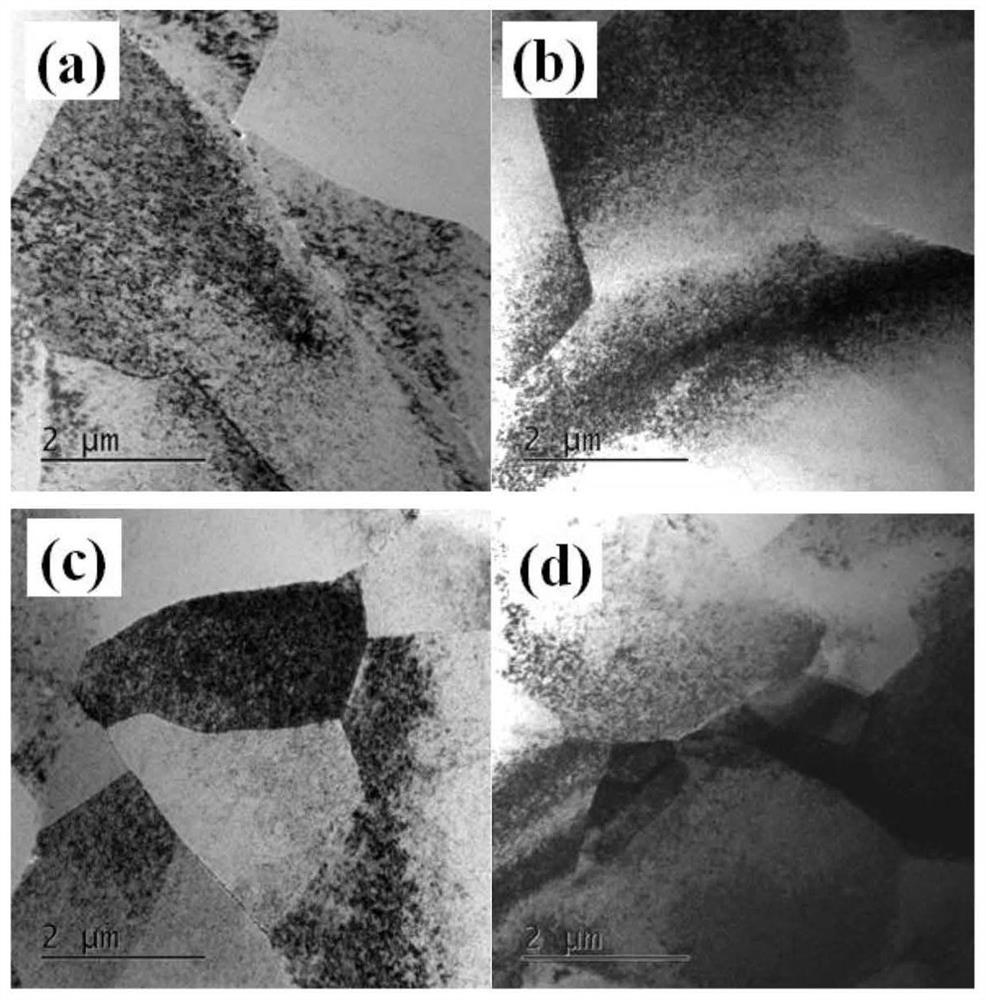

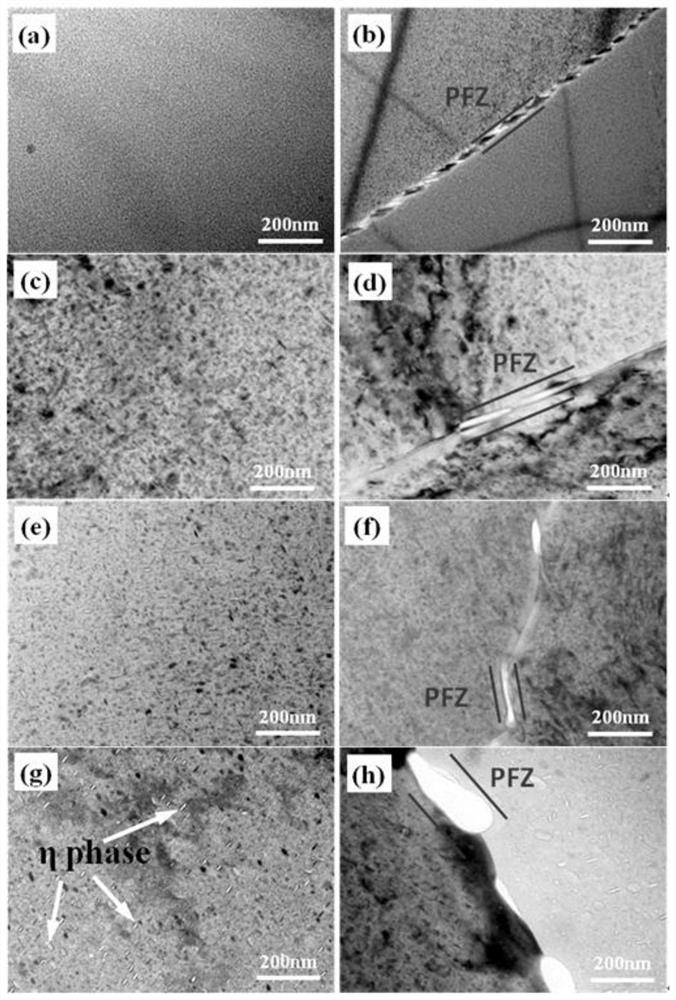

Thermomechanical treatment method for improving stress corrosion resistance of 7xxx series aluminum alloy

PendingCN114134436AImprove stress corrosion resistanceIncrease contentFurnace typesHeat treatment furnacesElectrode potentialAnodic dissolution

The invention provides a thermomechanical treatment method for improving stress corrosion resistance of a 7xxx-series aluminum alloy. The 7xxx-series aluminum alloy is subjected to solid solution-water quenching and then sequentially subjected to precooling deformation and three-stage artificial aging heat treatment. According to the thermomechanical treatment method, pre-cooling deformation is adopted firstly, a large number of dislocations are formed in alloy grains and at the grain boundary, different-degree precipitation of an intragranular precipitated phase and a grain boundary precipitated phase can be promoted, and then it is guaranteed that coarsening of the intragranular precipitated phase is not obvious by shortening the subsequent overaging time; the grain boundary precipitated phase is obviously coarsened and distributed with high discretization, and the effect of blocking an anode dissolution channel is achieved; besides, dislocation generated by pre-cooling deformation provides a channel for diffusion of intragranular Cu atoms to a grain boundary, the content of Cu atoms in a grain boundary precipitated phase is promoted to be greatly increased, the electrode potential is increased accordingly, and the effect of increasing the anode dissolution barrier is achieved. Through the synergistic effect of the two effects, the 7xxx series aluminum alloy has high strength and good corrosion resistance at the same time.

Owner:湖南中创空天新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com