Patents

Literature

56results about How to "Reduce corrosion potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium alloy foil and its producing method

InactiveCN1473949ARaise the recrystallization temperatureImprove welding strengthMetal rolling arrangementsManganeseCopper

The present invention discloses a kind of aluminum alloy foil for heat exchanger of air conditioner, cooler, heater unit, radiator, etc. in automobile and its production process. The aluminum alloy foil is produced with Al, Fe, Si, Mn, Zn, Cu, Mg, Zr and Ti, and through smelting, casting, homogenizing, cutting, milling, heating, rolling, annealing, finish rolling and other steps. The aluminum alloy foil thus produced has no deformation, subsidence and collapse.

Owner:沈健生

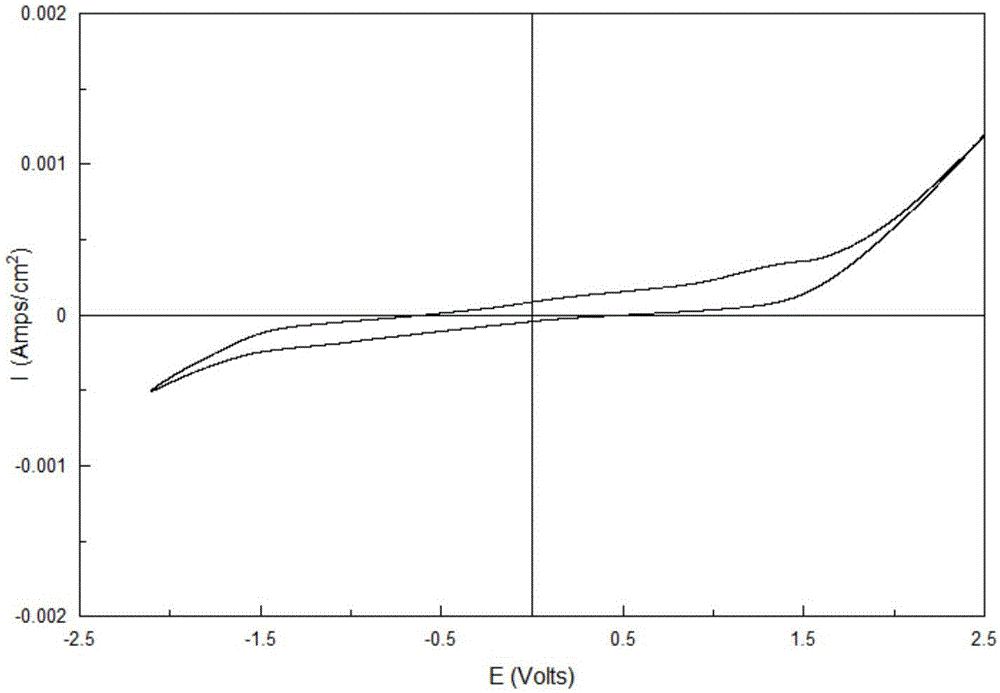

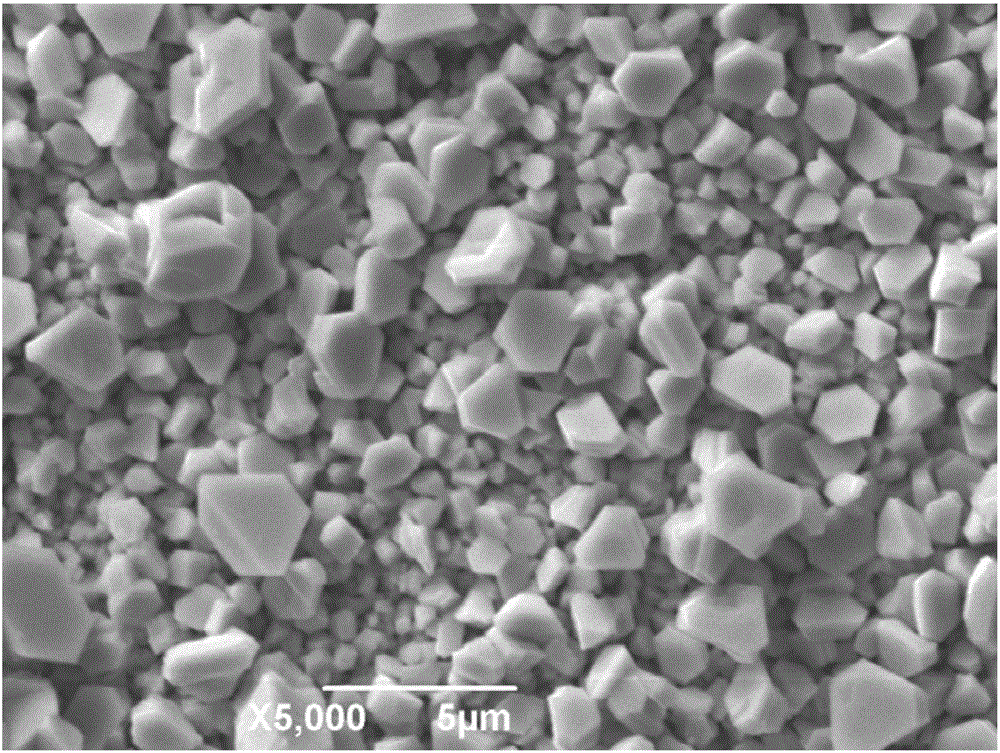

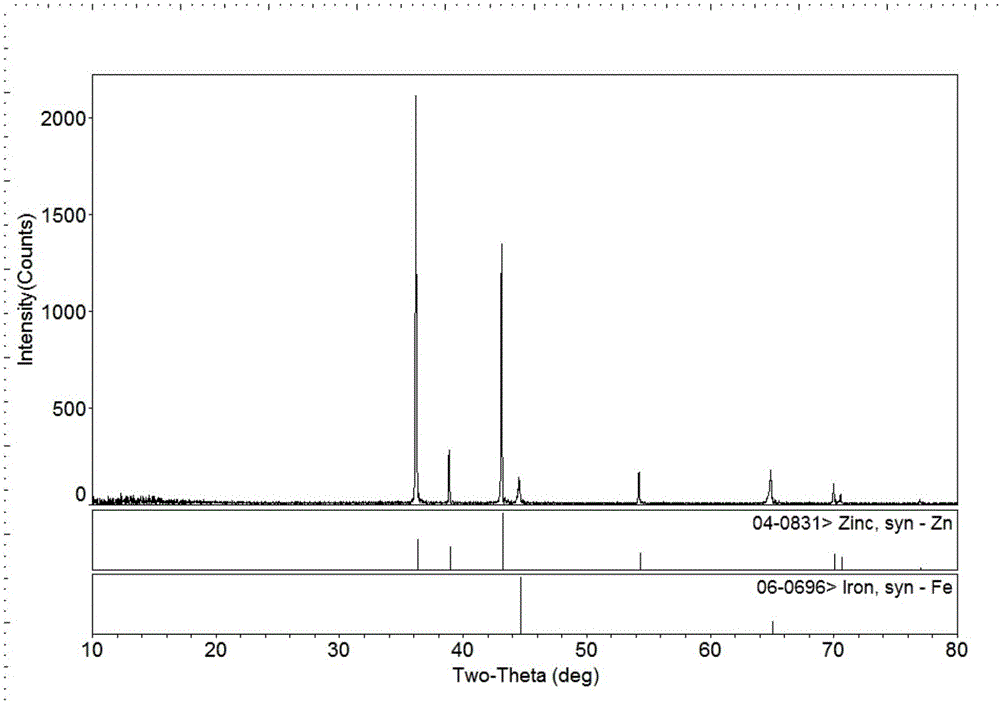

Electrogalvanizing method based on glycine betaine-urea-water deep-eutectic solvent

The invention discloses an electrogalvanizing method based on a glycine betaine-urea-water deep-eutectic solvent and belongs to the technical field of electroplating. The method includes the steps that firstly, glycine betaine, urea and distilled water are stirred at the constant temperature to obtain a transparent deep-eutectic solvent; then zinc chloride is added into the deep-eutectic solvent for constant temperature stirring to obtain a zinc containing deep-eutectic solvent which serves as electroplating liquid; and a pure zinc board used as an anode and low-carbon steel used as a cathode are immersed into the electroplating liquid for continuous current electroplating. The deep-eutectic solvent prepared from the glycine betaine, urea and water has the characteristics that an electrochemical window is wide, the galvanization process is safe, free of toxicity and environmentally friendly, and the problem of environmental pollution occurring in the processes of borofluoride galvanization, halide galvanization and the like is solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

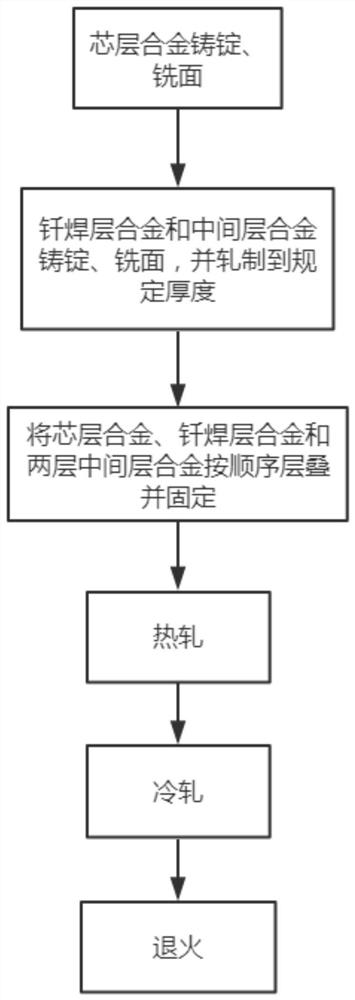

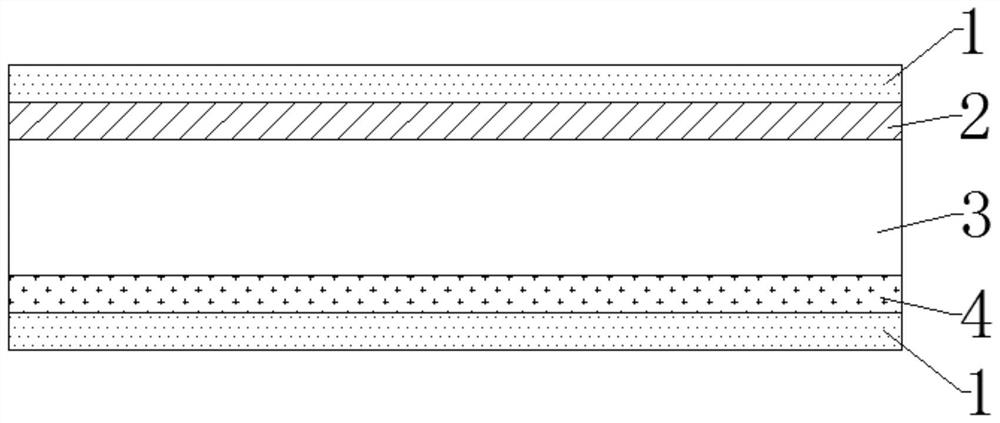

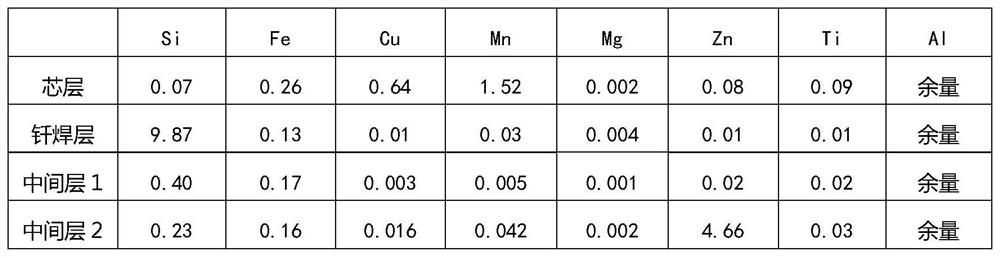

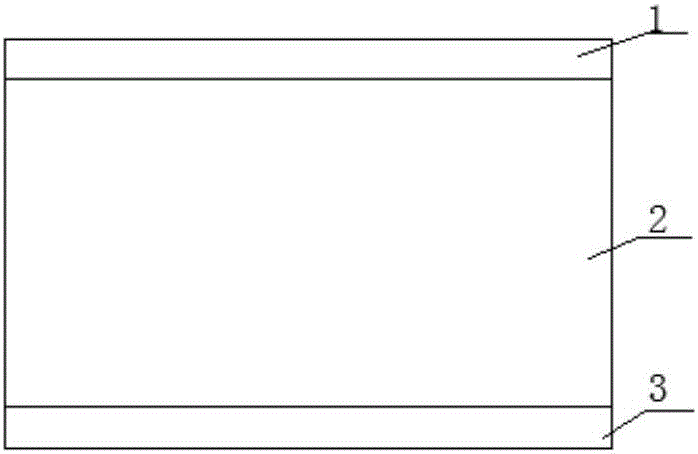

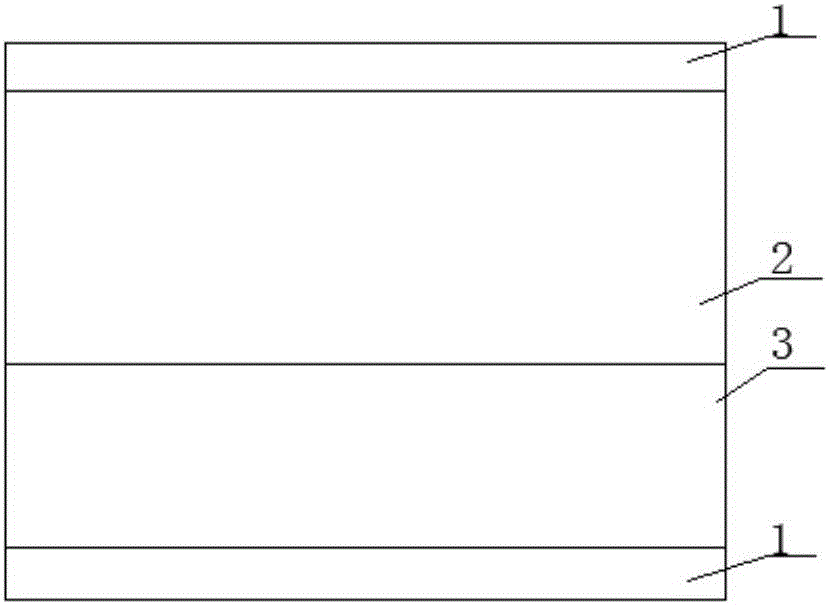

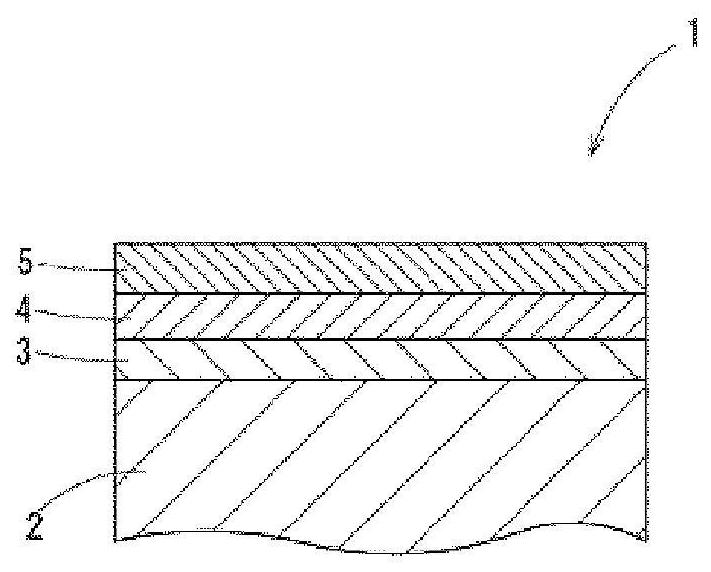

Multi-layer material brazing aluminum material with excellent internal and external corrosion performance and preparation method of multi-layer material brazing aluminum material

ActiveCN111906471AGuaranteed brazeabilityHigh strengthWelding/cutting media/materialsSoldering mediaMaterials scienceTi element

The invention discloses a multi-layer material brazing aluminum material with excellent internal and external corrosion performance and a preparation method of the multi-layer material brazing aluminum material. The multi-layer material brazing aluminum material is formed by sequentially stacking brazing layer alloy, first intermediate layer alloy, core layer alloy, second intermediate layer alloyand brazing layer alloy and then carrying out hot rolling compounding; the first intermediate layer alloy consists of the following elements of, in percentage by mass, less than or equal to 0.6% of Si, less than or equal to 0.7% of Fe, less than or equal to 0.2% of Cu, less than or equal to 1.5% of Mn, less than or equal to 0.1% of Mg, 0.8%-5% of Zn and the balance Al; and the second intermediatelayer alloy consists of the following elements of, in percentage by mass, less than or equal to 0.5% of Si, less than or equal to 0.3% of Fe, less than or equal to 0.2% of Cu, less than or equal to 0.1% of Mn, less than or equal to 0.45% of Mg, less than or equal to 0.1% of Zn, less than or equal to 0.1% of Ti and the balance Al. The multi-layer material brazing aluminum material has the beneficial effects that the first intermediate layer contains a certain amount of zinc and has very low corrosion potential, so that the core layer alloy is protected by sacrificing the first intermediate layer; and the second intermediate layer alloy with extremely low zinc content can play a very good role in protecting a low-PH 1.2-1.8 solution environment through an internal test due to the fact thatthe relatively pure components of the 1-series aluminum alloy are adopted, and therefore an excellent anti-corrosion effect is achieved on the cooled medium side.

Owner:ALCOA KUNSHAN ALUMINUM PROD COMPANY

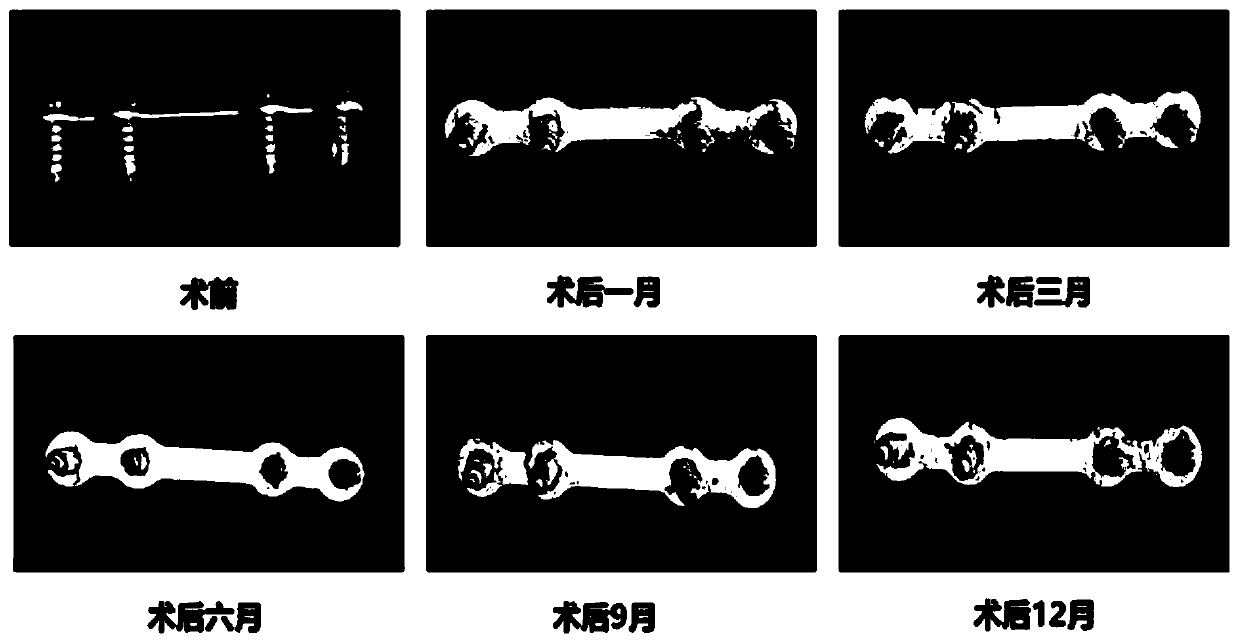

Degradable Zn-Ag series zinc alloy and preparing method and application thereof

InactiveCN110241330AReduce corrosion potentialImprove corrosion resistanceSurgeryTrace element compositionZinc alloys

The invention provides a degradable Zn-Ag series zinc alloy and a preparing method and application thereof. The zinc alloy is composed of Zn, Ag and a microelement. The mass percent of the Zn ranges from 89.85 to 99.4%, the mass percent of the Ag ranges from 0.01 to 10%, and microelement comprises one or multiple of Fe, Mg, Ca, Sr and Li. The mass percent of the microelement ranges from 0.01 to 0.55%. The method comprises the steps of heating metal zinc to be molten after burdening, adding metal silver, performing stirring until the metal silver is molten, adding the microelement, performing stirring, standing and pouring, and obtaining a zinc alloy cast ingot; and performing heat treatment and heat preservation on the zinc alloy cast ingot, and finally performing extrusion forming. The made zinc alloy has the higher strength and ultra-high plasticity, good anti-bacterium effect is achieved, and the alloy can serve as a degradable medical device implant to be applied into the human body to be subjected to non-toxic degradation.

Owner:湖南华耀百奥医疗科技有限公司

Zinc-aluminum-magnesium rare earth corrosion-resistant coating

InactiveCN102534305AImprove the effect of cathodic protectionReduce porosityMolten spray coatingRare earthZinc

The invention discloses a zinc-aluminum-magnesium rare earth corrosion-resistant coating, which contains the following components in percentage by weight: 5-23 percent of Al, 0.05-0.1 percent of Mg, 0.05-1 percent of rare earth metal RE and the balance of Zn. In the zinc-aluminum-magnesium rare earth corrosion-resistant coating, the rare earth metal RE is at least one of La and Ce. The zinc-aluminum-magnesium rare earth corrosion-resistant coating in accordance with the invention has wide application range, and meets the steel and iron corrosion resistance requirements under different environments; and brine corrosion resistance performance is over 2 times that of a pure zinc layer.

Owner:STATE GRID CORP OF CHINA +1

Rare earth polishing liquor for organic alkaline corrosive medium

ActiveCN1807540AIncrease oxidation rateReduce corrosion potentialOther chemical processesSemiconductor/solid-state device manufacturingChemistryOrganic base

The invention provides a rare earth polishing liquid of organic base corrosive medium, which comprises (by weight percent) cerium dioxide 0.5-5%, triethanolamine 0.05-1.0% and balancing H2O. The polishing liquid can also contain 0.25-1.0% of potassium ferricyanide as the oxidizing agent, or 5-15wt% of hydrogen peroxide.

Owner:BEIJING UNIV OF TECH

Method for preparing aluminum part surface zincing powder and method for coating aluminum part surface zincing powder

InactiveCN102002665AImprove corrosion resistanceAvoid direct contactSolid state diffusion coatingCorrosionZinc

The invention discloses a method for preparing aluminum part surface zincing powder and a method for coating the aluminum part surface zincing powder. The aluminum part surface zincing powder comprises the following components in percentage by weight: 14.9 to 84.5 percent of zinc powder, 84.9 to 14.5 percent of inert metal oxide powder, 0.1 to 0.5 percent of activating agent and 0.1 to 0.5 percent of auxiliary agent. The coating method of the aluminum part surface zincing powder comprises the following steps of: placing the aluminum part surface zincing powder prepared by the preparation method and an aluminum part to be zinced in the same sealed steel can; heating the steel can; controlling the temperature to 400 + / -10 DEG C; after keeping the temperature for 60 to 180 minutes, cooling to the room temperature; and zincing and coating the surface of the aluminum part. The corrosion resistance of an aluminum plate processed by the method is obviously improved, and particularly the marine atmospheric environment corrosion resistance is greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

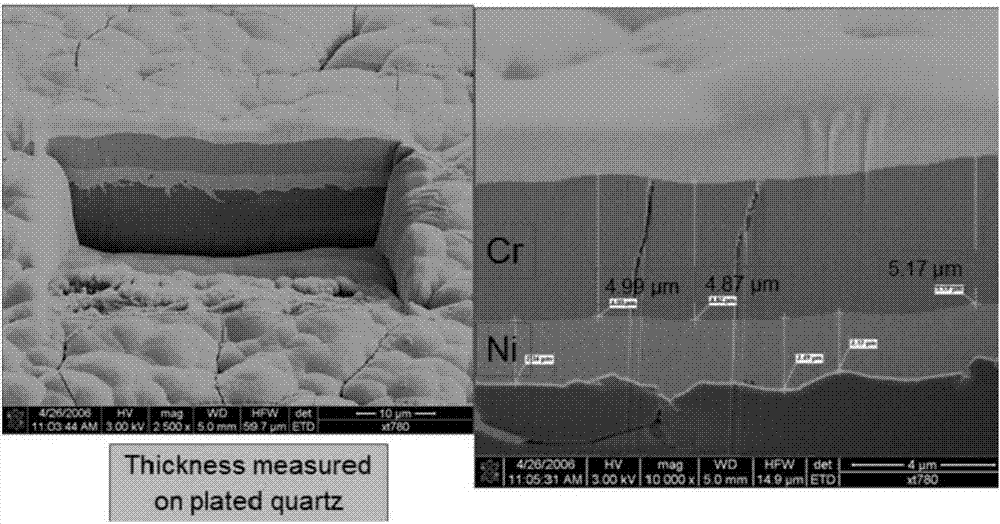

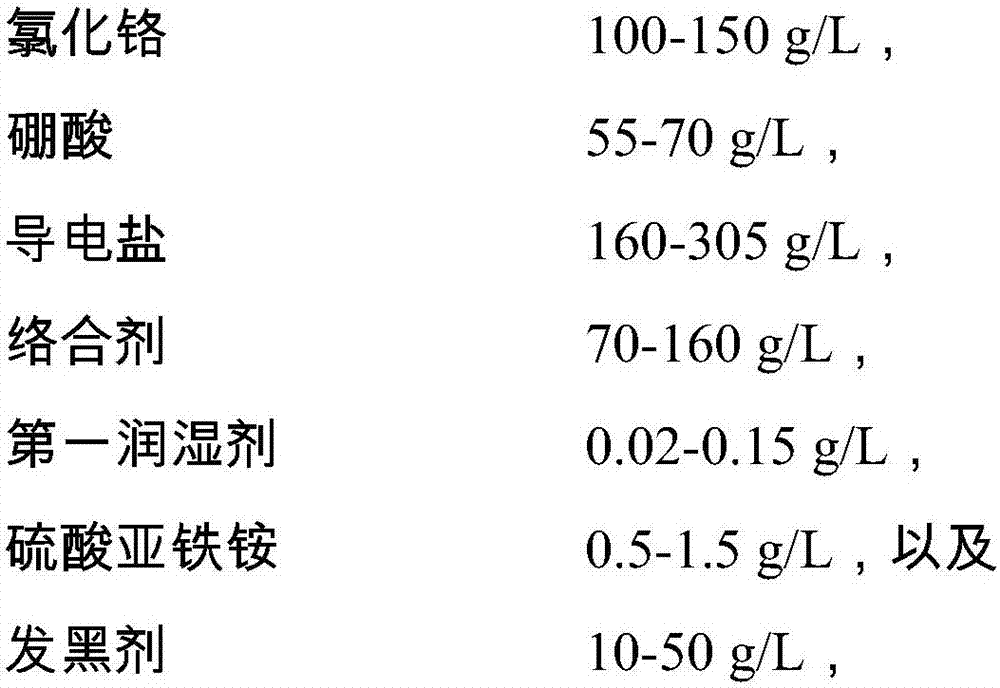

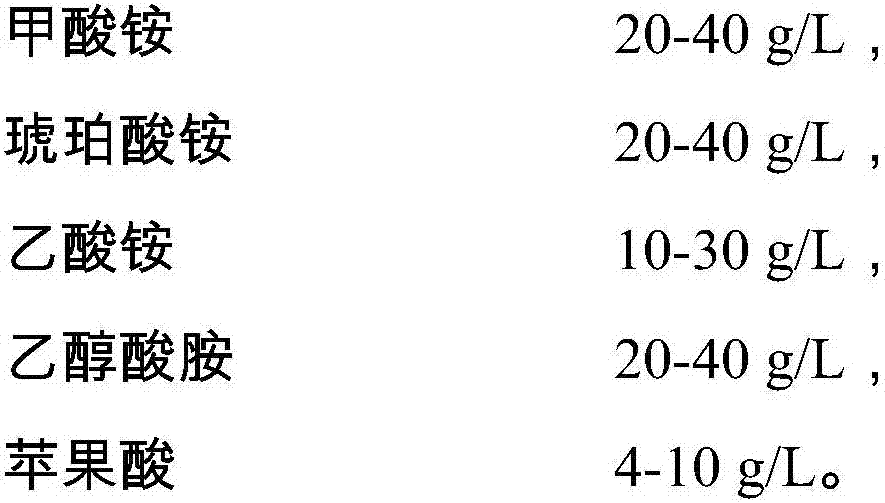

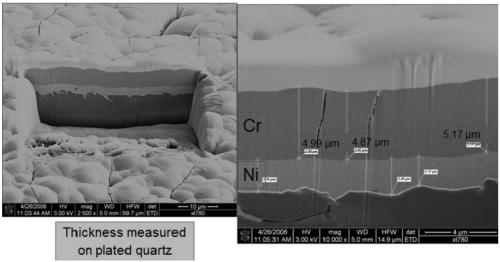

Black chromium plating solution, composite plating layer and preparing method thereof

ActiveCN107099824AUniform colorImprove coverage uniformityAmmonium ferrous sulfatePotassium thiocyanate

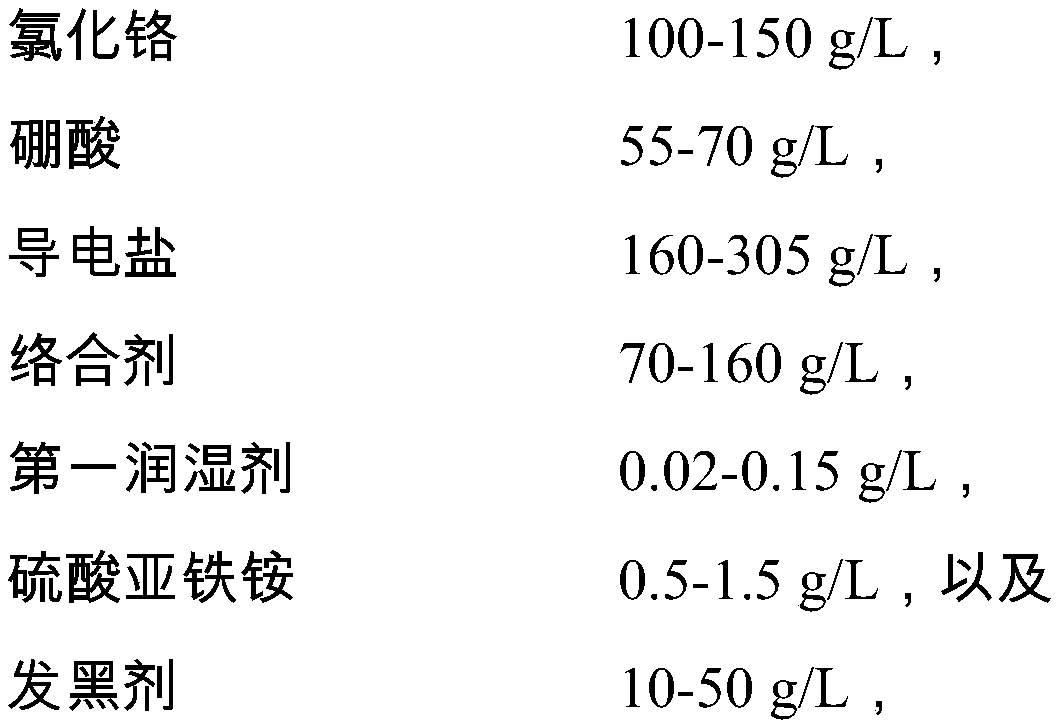

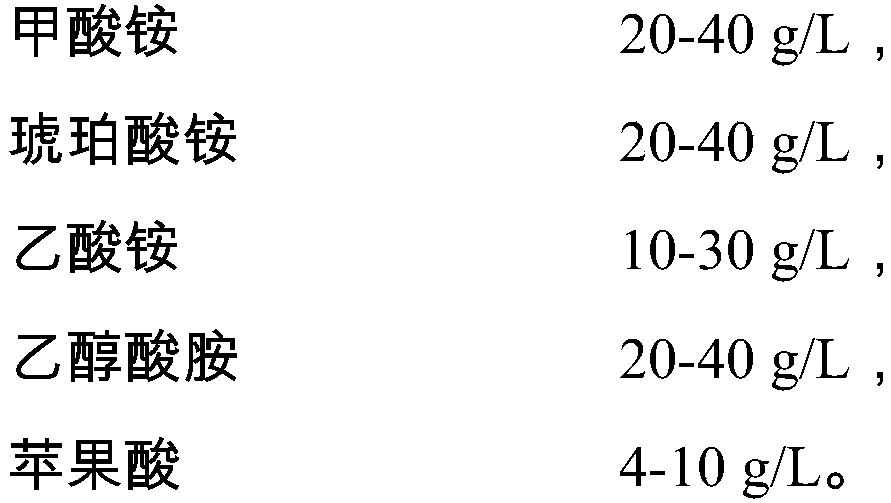

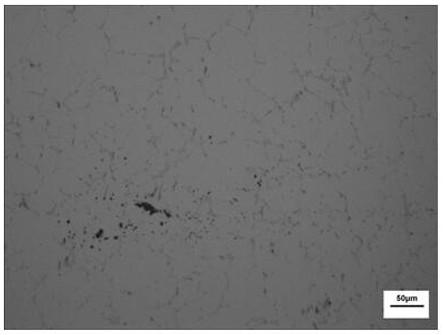

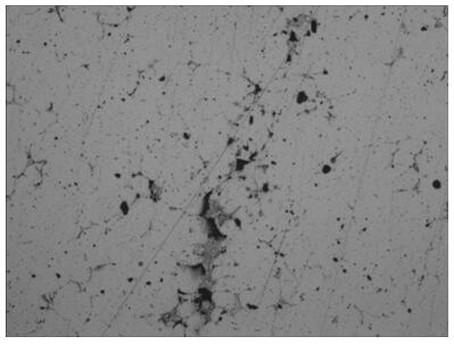

The invention relates to a black chromium plating solution, a composite plating layer and a preparing method thereof. The black chromium plating solution comprises water solutions of the following components of 100-150 g / L of chromic chloride, 55-70 g / L of boric acid, 160-305 g / L of conducting salt, 70-160 g / L of complexing agents, 0.02-0.15 g / L of wetting agents, 0.5-1.5 g / L of ammonium ferrous sulfate and 10-50 g / L of blackening agents, wherein the blackening agents are mixtures of methionine, potassium thiocyanate and aspartic acid. The trivalent black chromium plating layer formed by plating through the black chromium plating solution is in deep black, is strong in uniform covering capacity and can be matched with a bright copper layer, a semi-bright nickel layer, a bright nickel layer, a micro-porous nickel layer and a passivation film layer to enable the obtained composite plating layer to have high abrasion resistance and be in uniformly deep black.

Owner:SWELL MARUI GUANGZHOU AUTOMOBILE PARTS

Fin material for aluminum alloy heat radiator

The invention provides a fin material for an aluminum alloy heat radiator, which can effectively solve the problems that the conventional fin material for the aluminum alloy heat radiator, which is machined by using the traditional 3003 aluminum alloy, has the defects of low strength and poor collapse resistance. Meanwhile, with the adoption of the fin material for the aluminum alloy heat radiator provided by the invention, the material thickness can be greatly reduced; and the raw material cost is reduced; and a heat radiator pipe can be prevented from being corroded, so that the service life of the entire heat radiator can be prolonged. The fin material for the aluminum alloy heat radiator is characterized by comprising the following materials according to the total parts by weight of 100: 0.5-0.8 parts of silicon (Si), less than or equal to 0.6 parts of ferrum (Fe), less than or equal to 0.1 parts of copper (Cu), 1.4-1.8 parts of manganese (Mn), less than or equal to 0.03 parts of magnesium (Mg), 2.3-2.7 parts of zinc (Zn), 0.05-0.2 parts of zirconium (Zr), and the balance of aluminum (Al) and other unavoidable impurity trace elements.

Owner:YINBANG CLAD MATERIAL

A kind of black chromium electroplating solution, composite coating and preparation method thereof

The invention relates to a black chromium electroplating solution, a composite coating and a preparation method thereof. The black chromium electroplating solution includes an aqueous solution of the following concentration components: chromium chloride 100-150g / L, boric acid 55-70g / L, conductive salt 160-305g / L, complexing agent 70-160g / L, wetting agent 0.02 -0.15g / L, ferrous ammonium sulfate 0.5-1.5g / L and blackening agent 10-50g / L; wherein said blackening agent is a mixture of methionine, potassium thiocyanide and aspartic acid. The trivalent black chromium coating formed by electroplating with this black chromium electroplating solution has deep black color and strong uniform coverage, and can be matched with bright copper layer, semi-bright nickel layer, bright nickel layer, microporous nickel layer and passivation film layer , so that the composite coating obtained as a whole has strong corrosion resistance and is uniform and dark black.

Owner:SWELL MARUI GUANGZHOU AUTOMOBILE PARTS

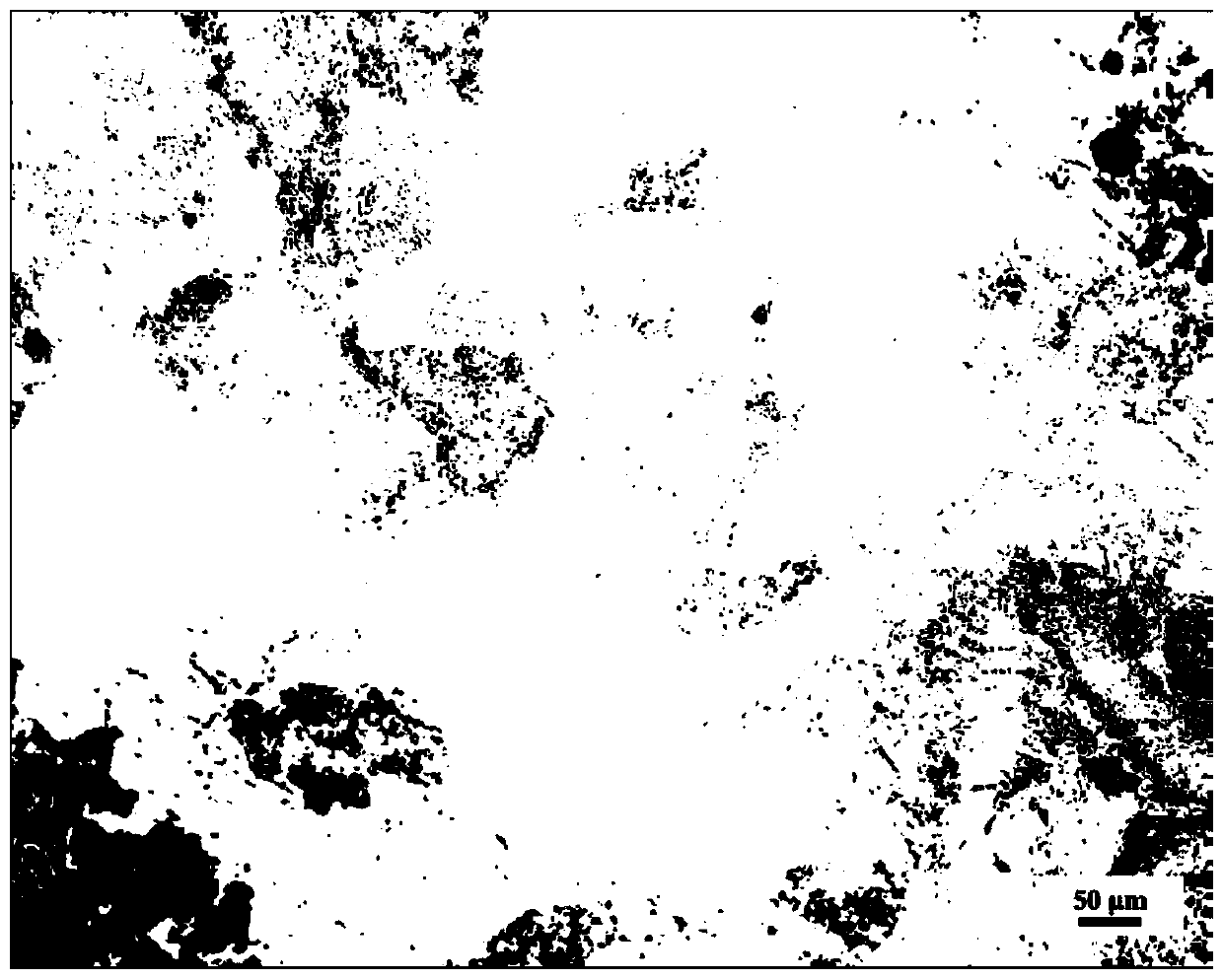

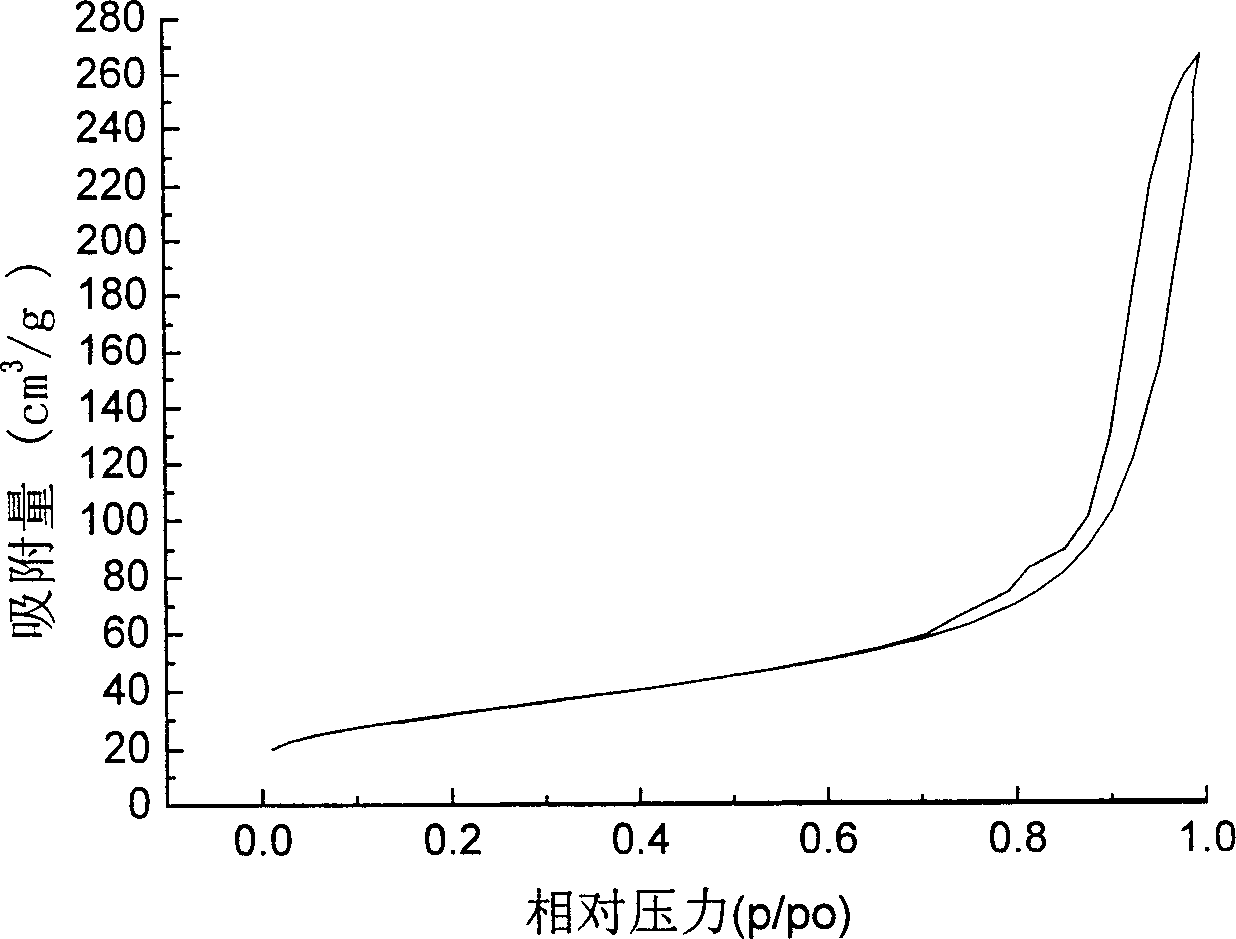

Preparation method of aluminum foil for automobile radiator

ActiveCN111101035AReduce corrosion potentialReduce solubilityHeat exchange apparatusMetal rolling arrangementsAlloyAluminum foil

The invention discloses a preparation method of an aluminum foil for an automobile radiator. The preparation method comprises the following steps of preparation of an aluminum melt; continuous castingand rolling, wherein during the continuous casting and rolling, a layer of nanometer silica powder is uniformly sprayed on a contact interface between a steel belt and a casting blank of a casting machine; homogeneous annealing; cold rolling; and finished product annealing. Through the adoption of the method for producing the aluminum foil for the automobile radiator by continuous casting and rolling provided by the invention, more options are provided for the production of the aluminum foil for the automobile radiator with a 7072 alloy.

Owner:广西润泰铝业有限公司

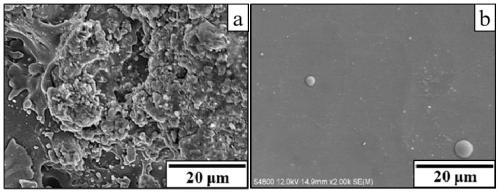

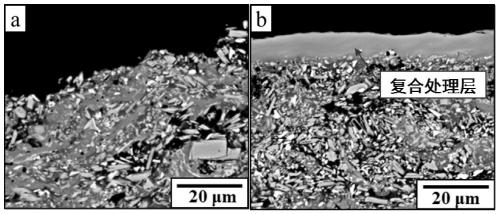

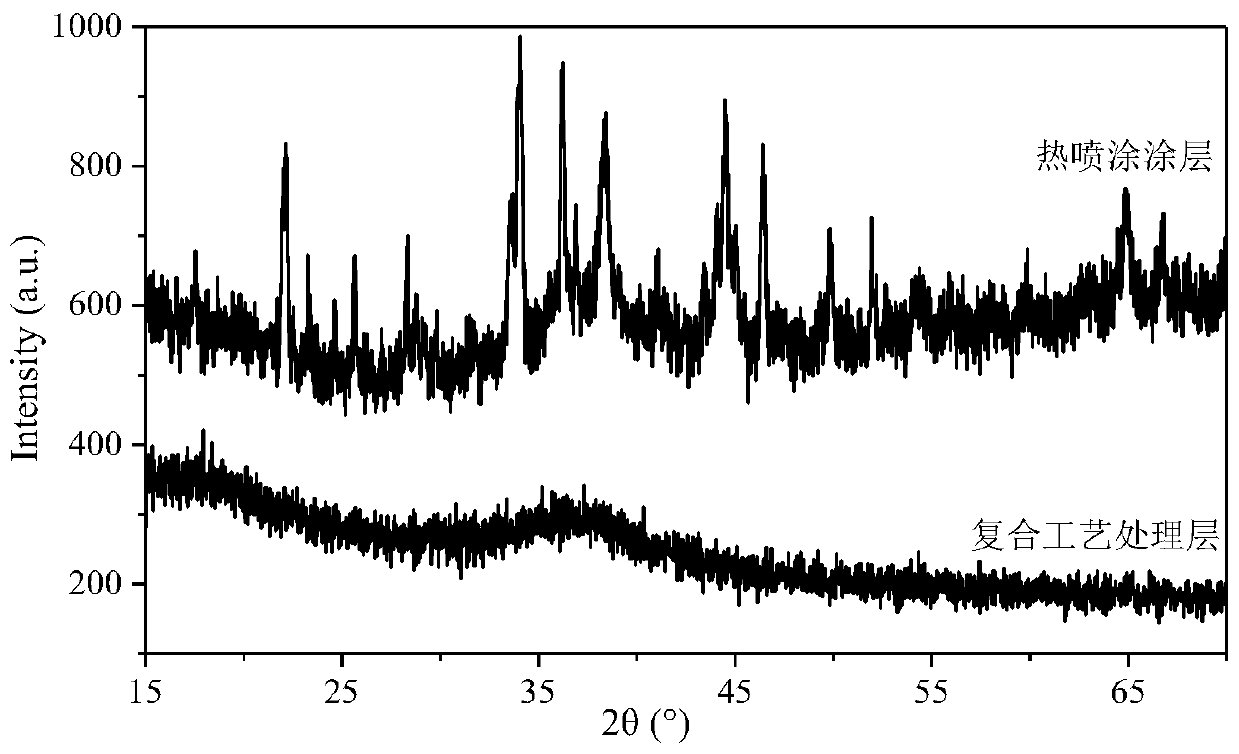

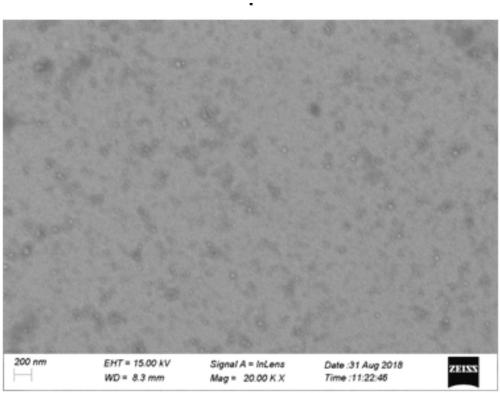

Method for preparing aluminum-based amorphous layer by jointly adopting hot spraying and electron beam remelting technologies

ActiveCN110306148AReduce corrosion potentialStrong Amorphous Formation AbilityMolten spray coatingThermal sprayingSpray coating

The invention discloses a method for preparing an aluminum-based amorphous layer by jointly adopting hot spraying and electron beam remelting technologies, and relates to the technical field of preparation of an aluminum-based amorphous coating. The method comprises the steps of preparing an Al-Co-Ce alloy, carrying out a gas atomization process on the alloy so as to powder, then utilizing a supersonic speed flame for hot-spraying a substrate surface so as to prepare an Al-Co-Ce alloy protection coating, and finally adopting a high-current pulse electron-beam for carrying out surface modification on the prepared Al-Co-Ce alloy protection coating, wherein the Al-Co-Ce alloy is prepared from 4.0 to 8.0 at percent of Co, 6.0 to 8.0 at percent of Ce and the balance Al. According to the methodfor preparing the aluminum-based amorphous layer by jointly adopting the hot spraying and electron beam remelting technologies provided by the invention, surface modification is carried out on the surface of a hot-spraying coating, so that the amorphous alloy layer with a flat surface and a compact structure is generated, and the corrosion resistance of the hot-spraying coating is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

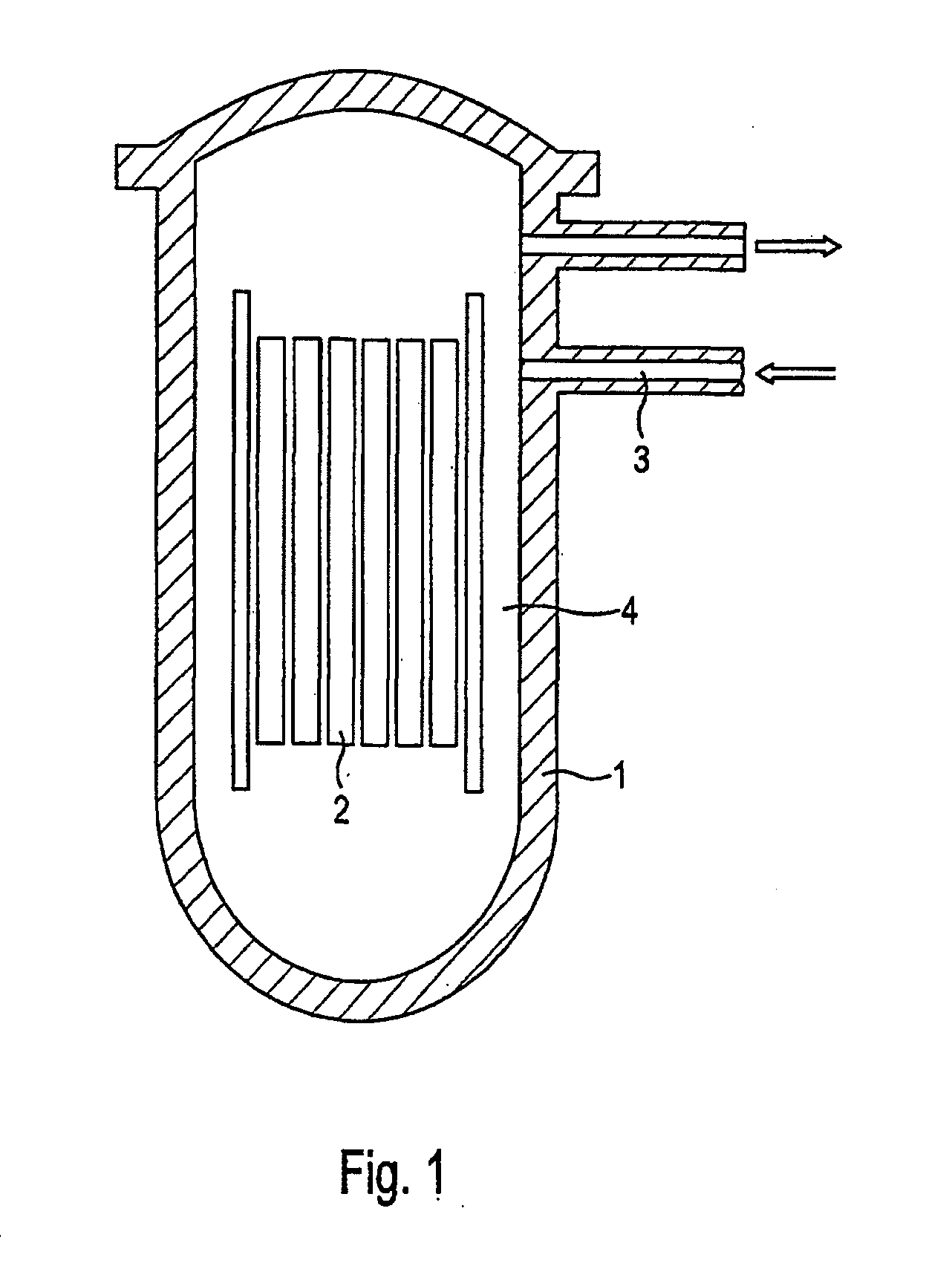

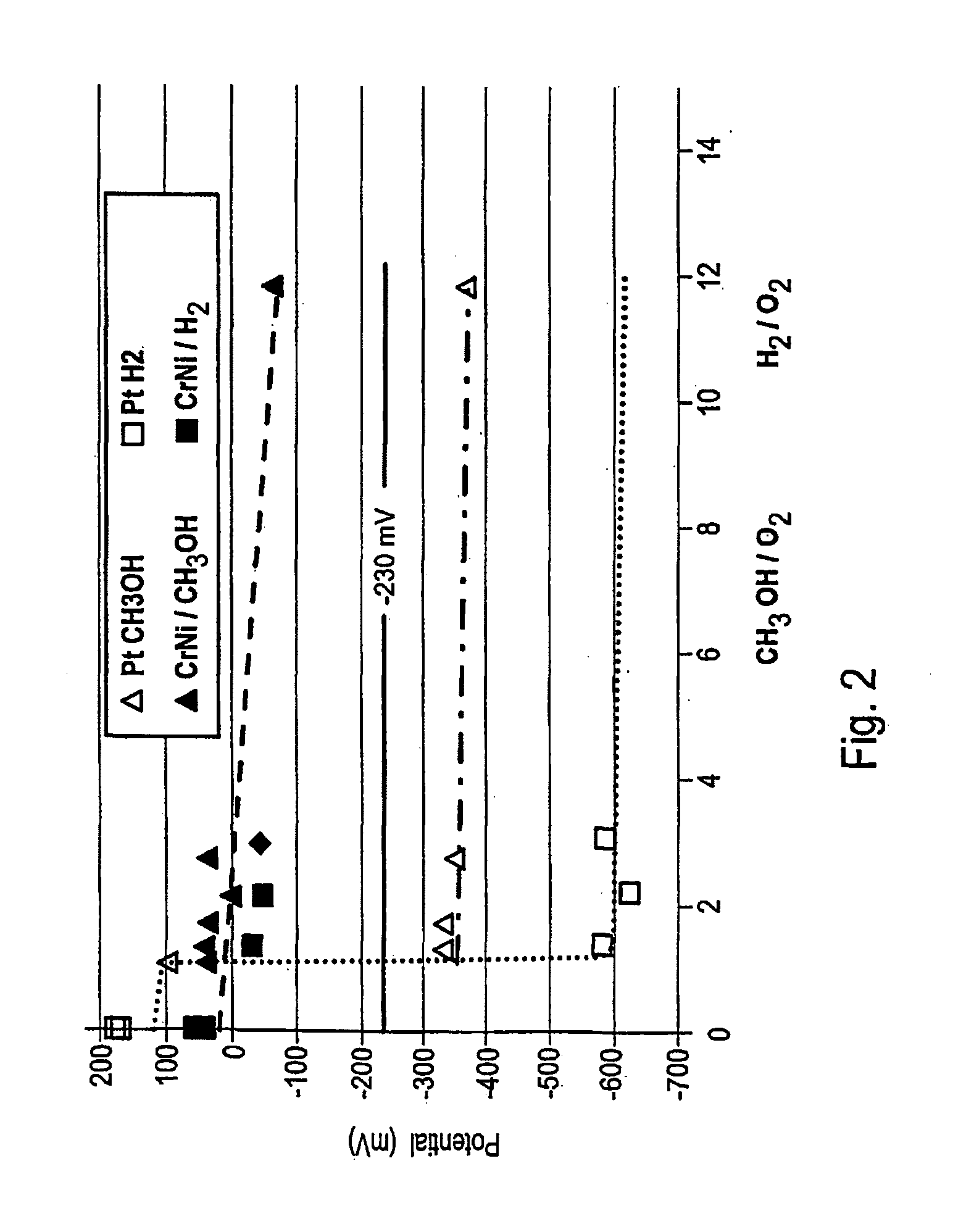

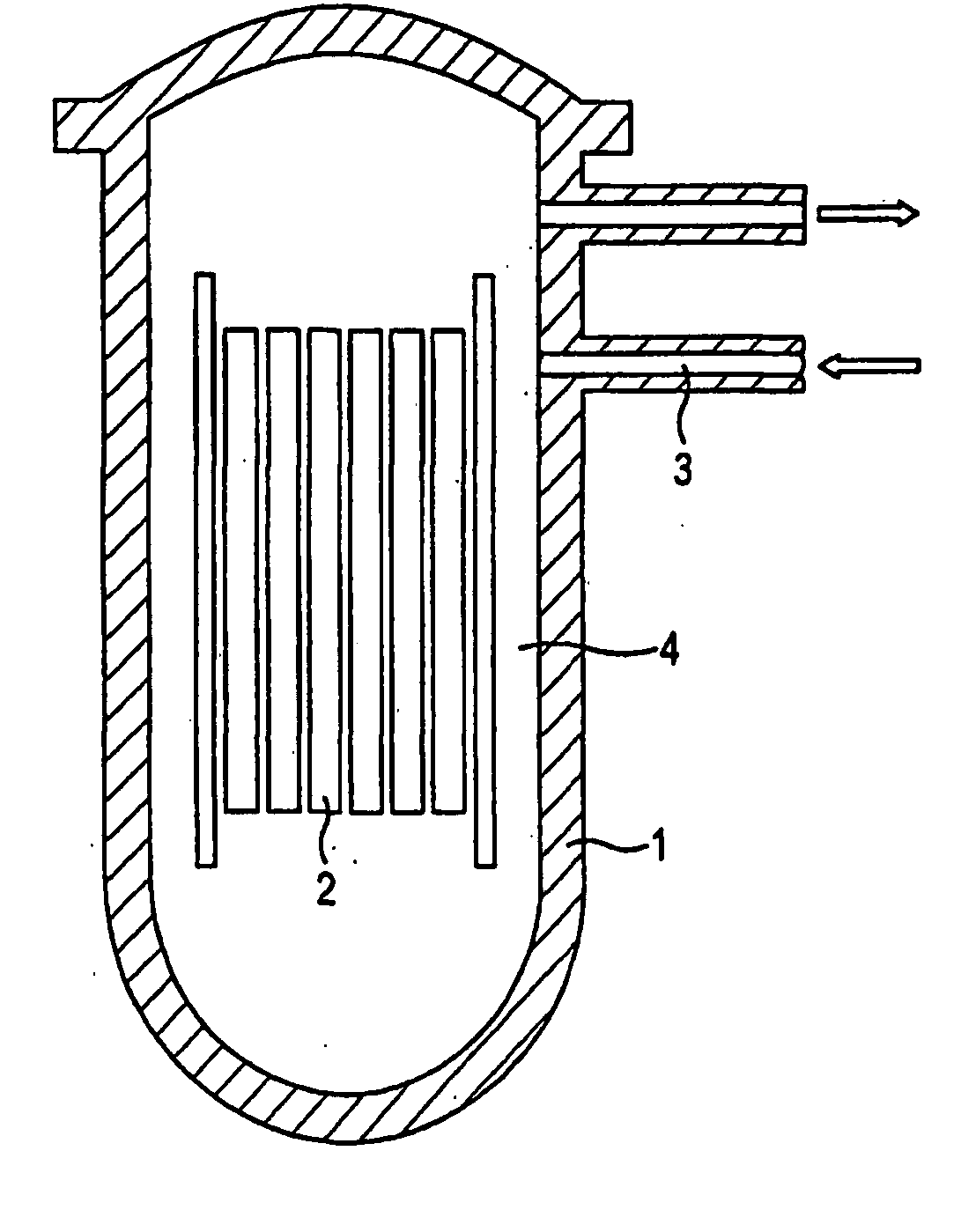

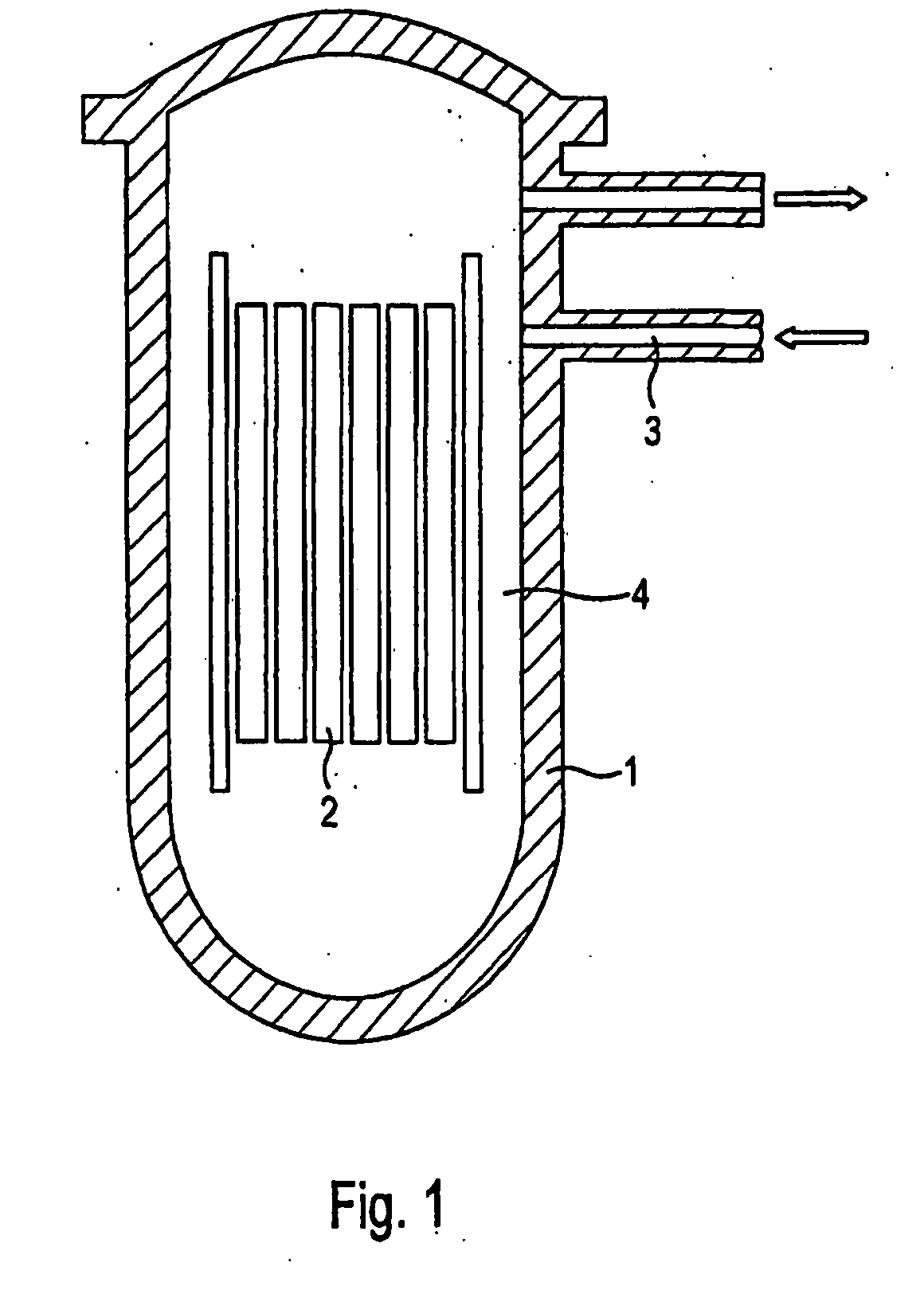

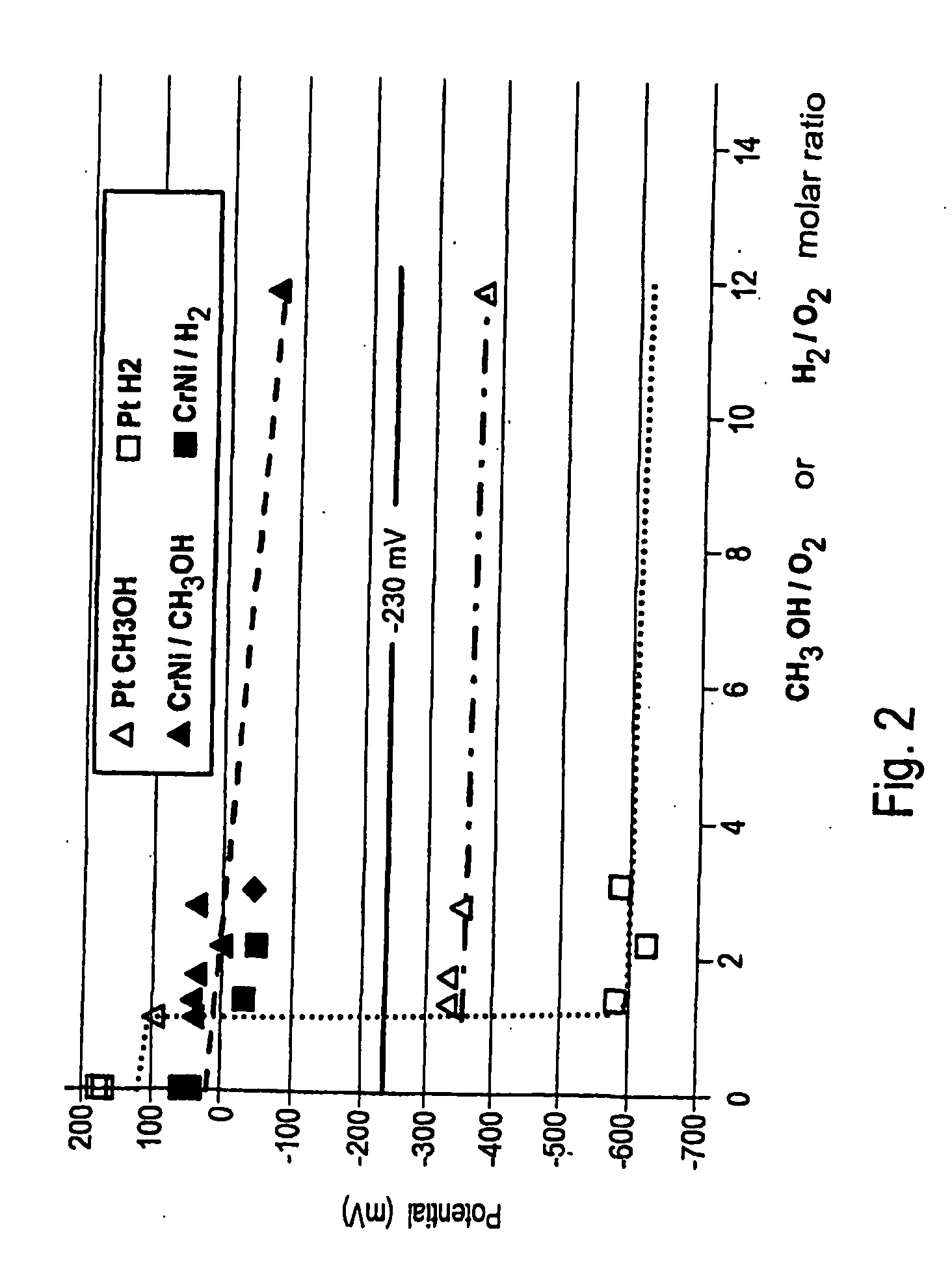

Method for protecting components of a primary system of a boiling water reactor in particular from stress corrosion cracking

InactiveUS20130272476A1Effective protectionPrevent bulk materialPlant parameters regulationNuclear energy generationAlcoholStress corrosion cracking

A method for protecting the components of the primary system of a boiling water reactor, especially against stress cracking corrosion, includes feeding a reducing agent into the primary coolant in order to reduce the number of substances having a oxidizing effect or in order to modify the electrochemical potential of the component surfaces covered with an oxide layer to negative values. An alcohol that can be oxidized in the conditions of a reactor is fed in as a reducing agent, preferably in a liquid form, into the primary coolant. The component surfaces are provided with a blank coating or a single intrinsic oxide coating.

Owner:AREVA INC

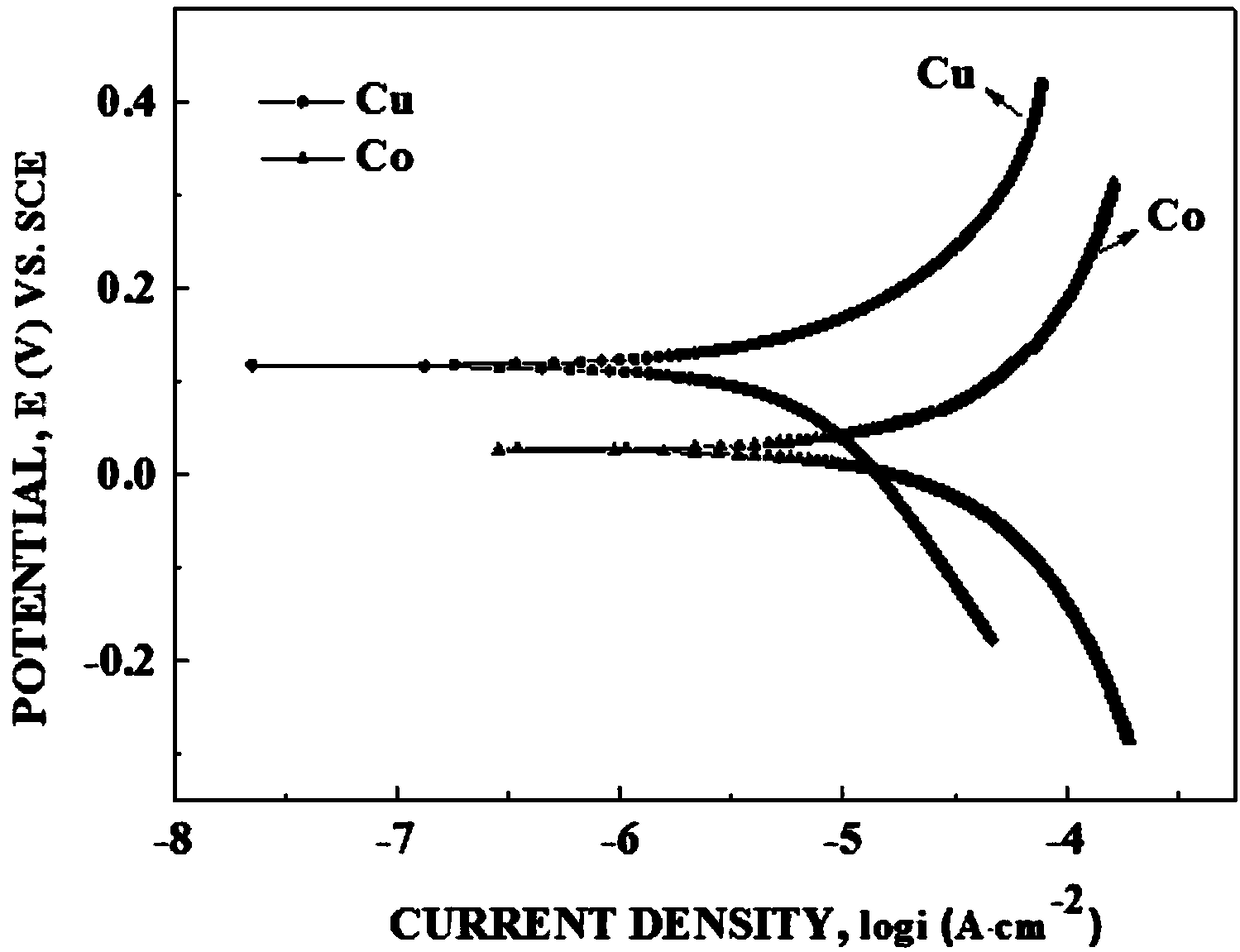

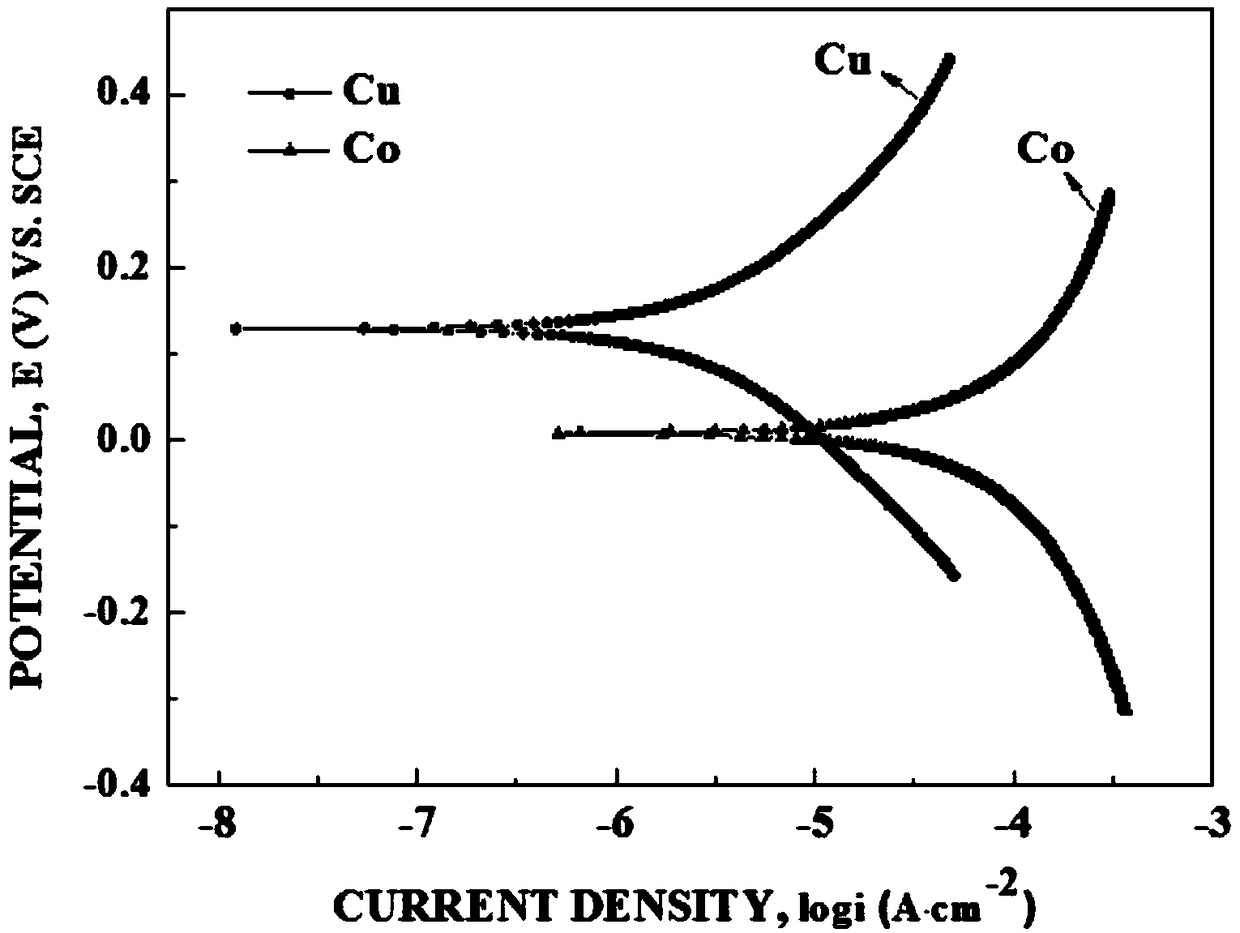

Polishing slurry for inhibiting galvanic corrosion of copper-cobalt barrier layer and corrosive pitting of cobalt surface

InactiveCN109370439AReduce corrosion potentialReduce corrosion potential differencePolishing compositions with abrasivesHydrogenAntioxidant

The invention belongs to the field of polishing liquid and in particular relates to polishing slurry for inhibiting galvanic corrosion of a copper-cobalt barrier layer and corrosive pitting of a cobalt surface. The polishing slurry is prepared from the following components in parts by weight: 1 to 20 parts of grinding particles, 0.001 to 5 parts of a cobalt surface protection agent, 0.001 to 5 parts of an azole compound, 0.1 to 6 parts of a complexing agent and 0.01 to 3 parts of an antioxidant; and the pH (Potential of Hydrogen) value of the polishing slurry is 7.0 to 11.0. The polishing slurry provided by the invention can be used for reducing the corrosion potential difference of cobalt and copper, and copper-cobalt galvanic corrosion density, so that the galvanic corrosion of the cobalt, which is used as an anode in a chemical and mechanical polishing process, is inhibited. Meanwhile, the corrosion potential of the copper is not obviously lower than that of the cobalt and galvaniccorrosion occurs at one side of the copper. Furthermore, the slurry also can be used for effectively inhibiting the generation and development of the corrosive pitting of the cobalt surface, and the reliability and yield of devices are improved.

Owner:HEBEI UNIV OF TECH

Method for improving corrosion resistance of carbon fiber reinforced aluminum matrix composite

ActiveCN112962035AImprove corrosion resistanceIncreased corrosion potentialElectrochemical responseFiber

The invention relates to a method for improving the corrosion resistance of the carbon fiber reinforced aluminum matrix composite, and particular to a method for improving the corrosion resistance of the carbon fiber reinforced aluminum composite. The invention aims to solve the technical problem that the composite material is easy to corrode due to interface reaction and electrochemical reaction of the conventional carbon fiber / aluminum composite. The method comprises the following steps: step 1, performing weighing; step 2, mixing and melting raw materials to obtain an aluminum-yttrium alloy melt; step 3, putting carbon fibers into a mold to be preheated, and then infiltrating the aluminum-yttrium alloy melt through a pressure infiltration method; and step 4, performing heat treatment. According to the method, a matrix and a reinforcement body are compounded through the pressure infiltration method, and carbon fibers and aluminum are prevented from interface reaction through precipitation of the element Y at the interface of the carbon fibers and the aluminum alloy so that the corrosion resistance of the carbon fiber reinforced aluminum matrix composite is improved. The carbon fiber reinforced aluminum composite prepared by the method can be applied to various fields of aviation, aerospace, medical treatment, sports equipment and the like.

Owner:HARBIN INST OF TECH

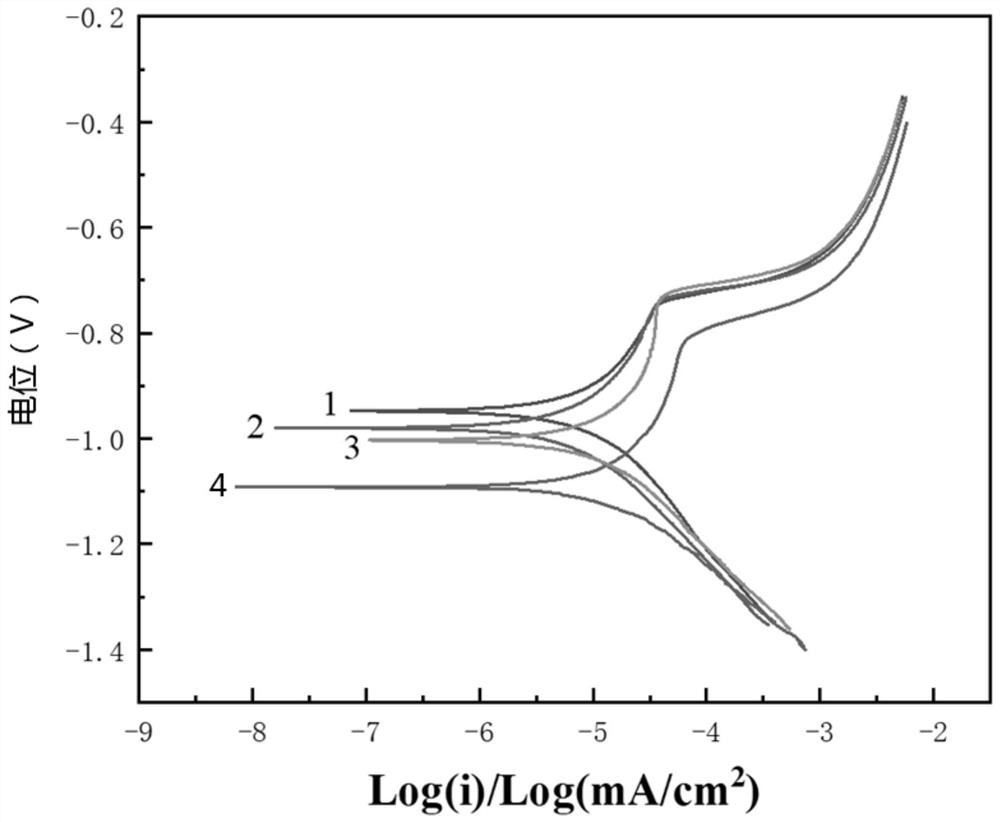

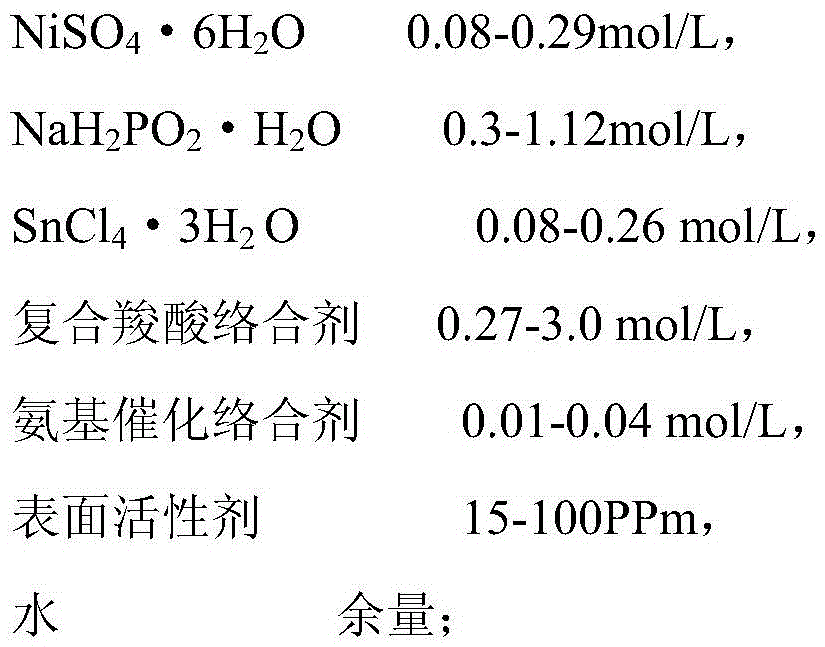

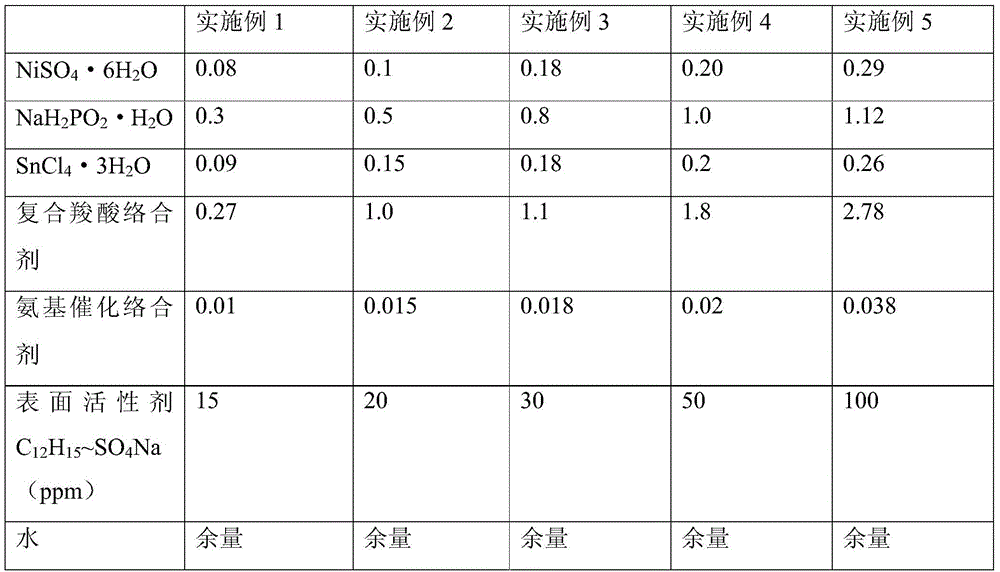

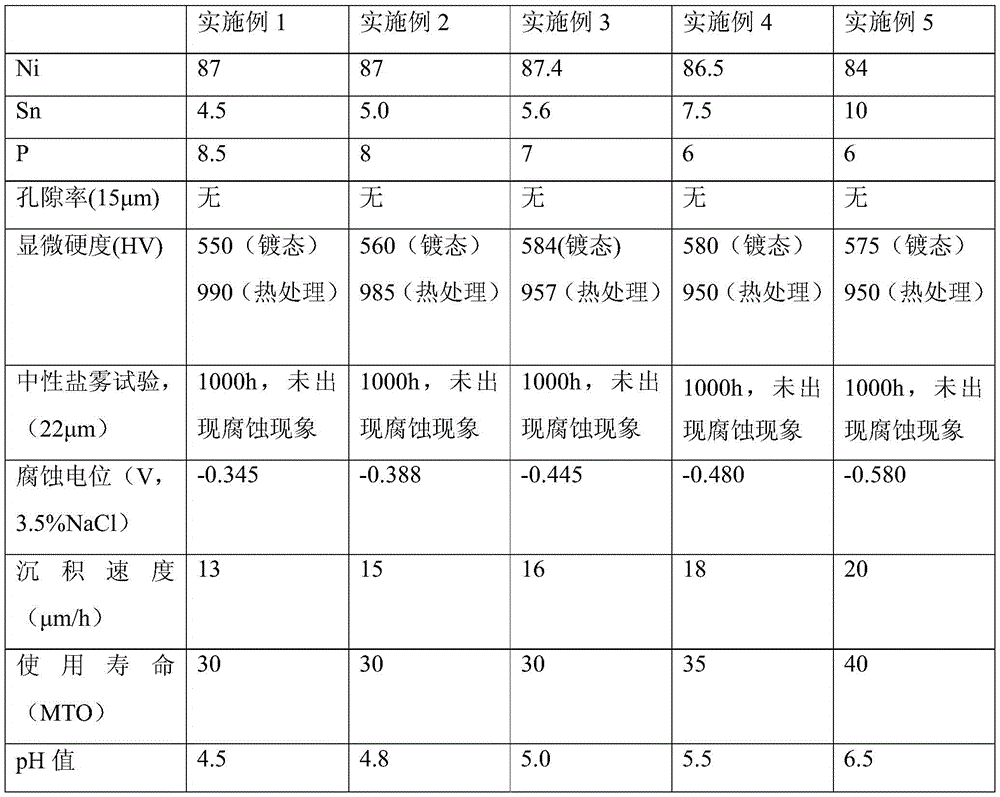

Electroless nickel-tin-phosphorus alloy bath

ActiveCN104018142BImprove stabilityFast depositionLiquid/solution decomposition chemical coatingElectroless nickelChemical plating

The invention belongs to the field of chemical plating solutions, and in particular relates to a chemical-plated multifunctional nickel-tin-phosphorus alloy plating solution and a plating layer thereof. The plating solution is composed of the following components: 0.08-0.29mol / L of NiSO4.6H2O, 0.3-1.12mol / L of NaH2PO2.H2O, 0.08-0.26mol / L of SnCl4.3H2O, 0.04-3.0mol / L of composite carboxylic acid complexing agent, 0.01-0.04mol / L of amino catalytic complexing agent, 15-100PPm of surfactant and the balance of water. The plating solution is free from Pb and Cd heavy metal ions and more environment-friendly and has high stability and high deposition speed. Due to the increase of the Sn ions, the ductility of the plating layer is greatly improved, the hydrogen sulfide, chloride and carbon dioxide corrosive resistance of the plating layer is improved, the corrosion potential is more negative, the conductivity is better, and the plating layer can be used as a better invisible material.

Owner:林忠华

High-strength aluminum alloy composite plate for gas-carrying soldering and cladding material

InactiveCN106626601AImprove corrosion resistanceImprove internal corrosion performanceMetal layered productsAlloy compositeHigh intensity

The invention relates to a high-strength aluminum alloy composite plate for gas-carrying soldering and a cladding material. The cladding material is an aluminum alloy which contains the following components in percentage by mass: 0.8-1.2% of Zn, 0.3-0.6% of Mg, 0.1-0.6% of Mn and 0.1-0.7% of Fe. A core material of the composite plate made of the cladding material is AA3003, and the cladding material is composited on one side of the core material. According to the high-strength aluminum alloy composite plate for the gas-carrying soldering and the cladding material disclosed by the invention, on the premises that the requirements for the corrosion properties of the material are met, and the welding effect of the gas-carrying soldering is not influenced, the strength of the composite plate alloy is improved.

Owner:YINBANG CLAD MATERIAL

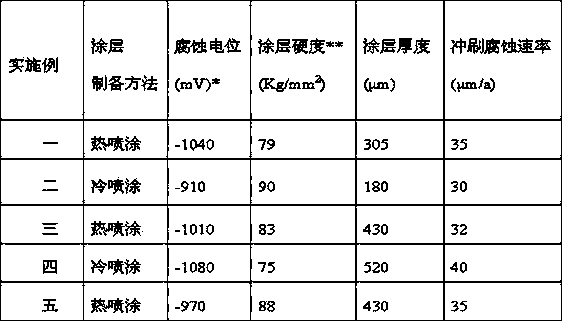

Zinc alloy coating of LNG (Liquefied Natural Gas) opening-frame vaporizer

ActiveCN103409751AImprove the effect of cathodic protectionGood erosion and corrosion resistanceMolten spray coatingAlloy elementSeawater

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP +2

Method for preparing aluminum part surface zincing powder and method for coating aluminum part surface zincing powder

InactiveCN102002665BAvoid direct contactImprove corrosion resistanceSolid state diffusion coatingRoom temperatureZinc

The invention discloses a method for preparing aluminum part surface zincing powder and a method for coating the aluminum part surface zincing powder. The aluminum part surface zincing powder comprises the following components in percentage by weight: 14.9 to 84.5 percent of zinc powder, 84.9 to 14.5 percent of inert metal oxide powder, 0.1 to 0.5 percent of activating agent and 0.1 to 0.5 percent of auxiliary agent. The coating method of the aluminum part surface zincing powder comprises the following steps of: placing the aluminum part surface zincing powder prepared by the preparation method and an aluminum part to be zinced in the same sealed steel can; heating the steel can; controlling the temperature to 400 + / -10 DEG C; after keeping the temperature for 60 to 180 minutes, cooling to the room temperature; and zincing and coating the surface of the aluminum part. The corrosion resistance of an aluminum plate processed by the method is obviously improved, and particularly the marine atmospheric environment corrosion resistance is greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

Fast directional biodegradation hemostatic clamp and preparation method thereof

ActiveCN108525022AGood biocompatibilityImprove toughnessSurgeryPharmaceutical delivery mechanismSurface modificationHemostatics

The invention belongs to the field of an implanted medical appliance product, and particularly relates to a fast directional biodegradation hemostatic clamp and a preparation method thereof. The outersurface and the side surfaces of the hemostatic clamp are subjected to laser surface modification treatment; the outer surface and the side surfaces of the hemostatic clamp have laser modification layers after the laser surface modification; the degradation speed is higher than that at the inner side; the directional degradation from the outside to the inside can be realized.

Owner:烟台浩忆生物科技有限公司

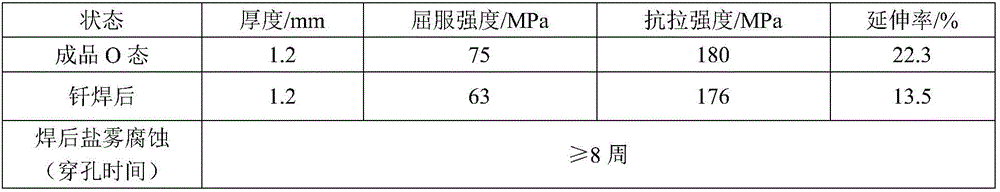

Aluminium alloy radiator fin material

InactiveCN105333763AExtended service lifeHigh strengthHeat exchange apparatus2014 aluminium alloyManganese

Owner:YINBANG CLAD MATERIAL

Method for protecting components of a primary system of a boiling water reactor in particular from stress corrosion cracking

InactiveUS20070263761A1Efficiently protectEffective protectionPlant parameters regulationNuclear energy generationElectrochemical responseOxide coating

A method for protecting the components of the primary system of a boiling water reactor, especially against stress cracking corrosion, includes feeding a reducing agent into the primary coolant in order to reduce the number of substances having a oxidizing effect or in order to modify the electrochemical potential of the component surfaces covered with an oxide layer to negative values. An alcohol that can be oxidized in the conditions of a reactor is fed in as a reducing agent, preferably in a liquid form, into the primary coolant. The component surfaces are provided with a blank coating or a single intrinsic oxide coating.

Owner:AREVA NP SAS

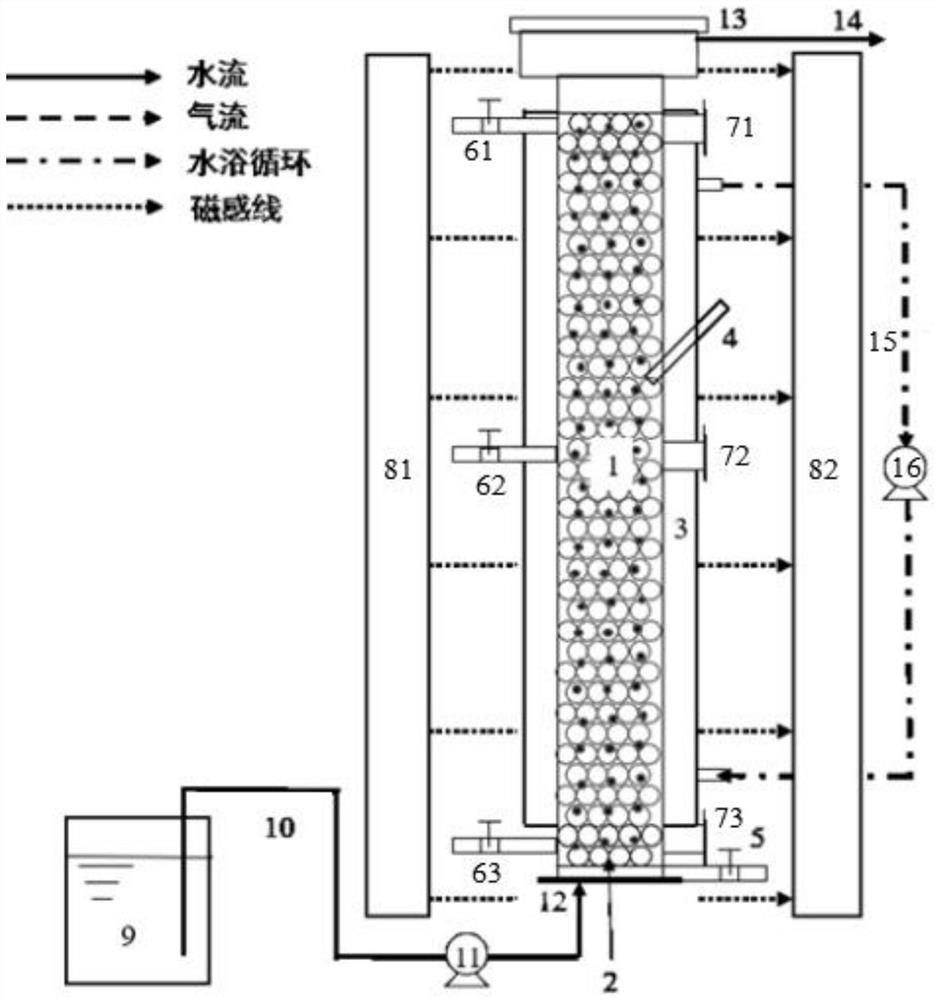

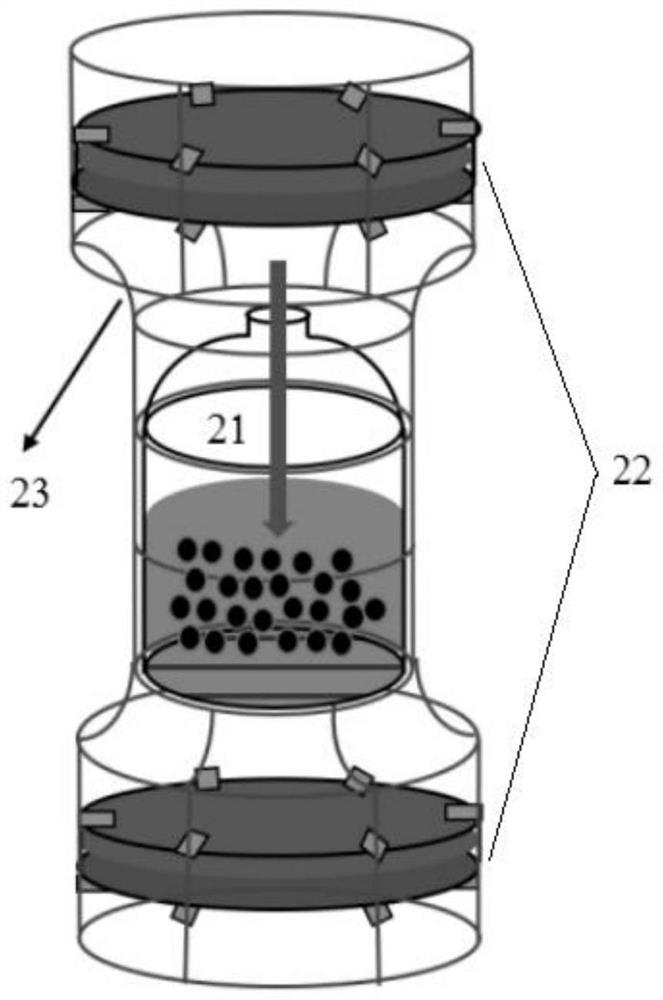

Method and device for removing nitrate nitrogen pollutants by intensifying iron-carbon micro-electrolysis through low-intensity magnetic field

InactiveCN113620413AIncrease the reflux ratioReduce corrosion potentialWater treatment parameter controlTreatment by combined electrochemical biological processesMicrobial inoculationMagnetic field gradient

The invention provides a method and a device for removing nitrate nitrogen pollutants by intensifying iron-carbon micro-electrolysis through a low-intensity magnetic field, and belongs to the technical field of denitrification. Under the action of a low-intensity magnetic field, microorganisms are inoculated on an iron-carbon carrier, nitrate-nitrogen-containing inlet water is introduced, iron-carbon micro-electrolysis corrosion hydrogen evolution and iron-carbon micro-electrolysis autotrophic denitrification are carried out, and nitrate-nitrogen-removed outlet water is obtained. Iron-carbon micro-electrolysis autotrophic denitrification is carried out under the condition of a low-intensity magnetic field, the activity of microorganisms and related enzymes can be improved, the corrosion potential of an iron-carbon carrier can be reduced, the iron-carbon micro-electrolysis corrosion hydrogen evolution rate is increased, the precipitation position and the precipitate attribute can be changed through the Lorentz force and the magnetic field gradient force effect, therefore, the formation of an iron-carbon carrier passivation film is relieved, and the nitrate nitrogen removal effect of microorganisms is effectively improved.

Owner:BEIJING JIAOTONG UNIV

Processing technology of aluminum alloy for cooling device

ActiveCN106947897AImprove support strengthHigh yield strengthMetallic material coating processesQuenchingHeat sink

The invention discloses a processing technology of an aluminum alloy for a cooling device. The technologies of composition optimization, blank making, extrusion, quenching, stretcher straightening, aging treatment, cleaning and coating are sequentially carried out; and according to a prepared aluminum alloy cooling fin, the room-temperature tensile strength is not smaller than 320 MPa, the yield strength is not smaller than 230 MPa, the postwelding yield strength is not smaller than 120 MPa, corrosion resistance is high, and the antimicrobial property is good.

Owner:山东创新精密科技有限公司

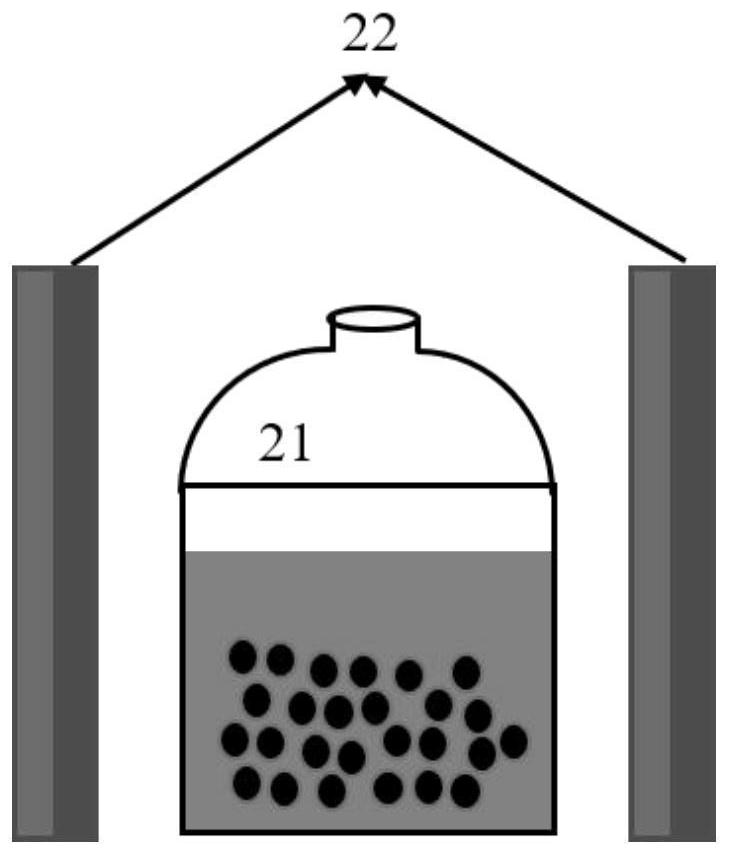

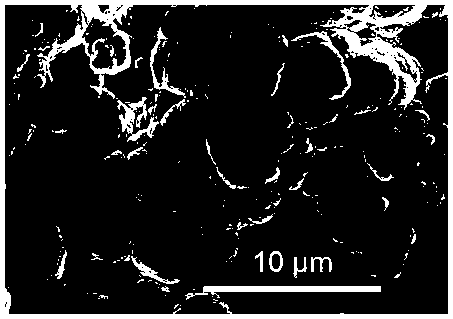

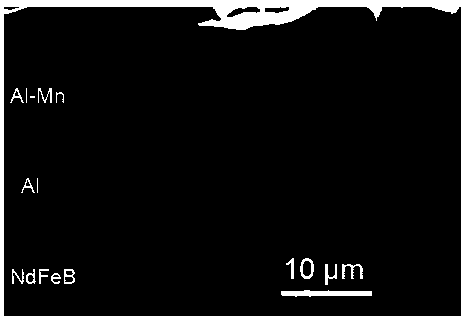

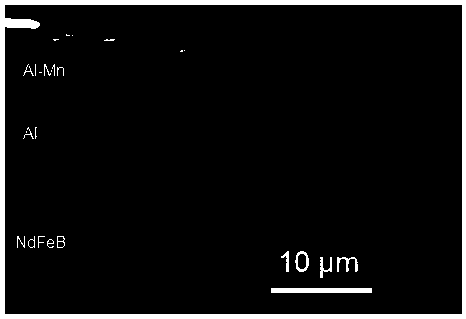

DdFeB magnet surface composite metal protection layer and preparing method thereof

The invention discloses a DdFeB magnet surface composite metal protection layer and a preparing method thereof. By means of the method, after pretreatment, ionic liquid aluminum plating, ionic liquidamorphous Al-Mn alloy plating and aftertreatment are conducted in sequence, then the composite metal protection layer with the total thickness ranging from 5 microns to 20 microns is obtained, whereinthe outer layer of the composite metal protection layer is an amorphous Al-Mn alloy plating layer, and the inner layer of the composite metal protection layer is an Al plating layer. The flexible Alplating layer serves as the transition layer of bristle NdFeB and the amorphous Al-Mn alloy plating layer, cracking of the Al-Mn alloy plating layer can be prevented, and colliding damage of NdFeB corners can be prevented. The amorphous Al-Mn alloy plating layer serves as the outer layer so that the scratching and abrasion resisting performance of the plating layer can be improved. The corrosion potential of the amorphous Al-Mn alloy plating layer is lower than that of the Al plating layer and a NdFeB base body, and therefore sacrificial anode type protection can be formed on NdFeB through theabove protection plating layer, and therefore good corrosion resisting performance is achieved.

Owner:ZHEJIANG UNIV

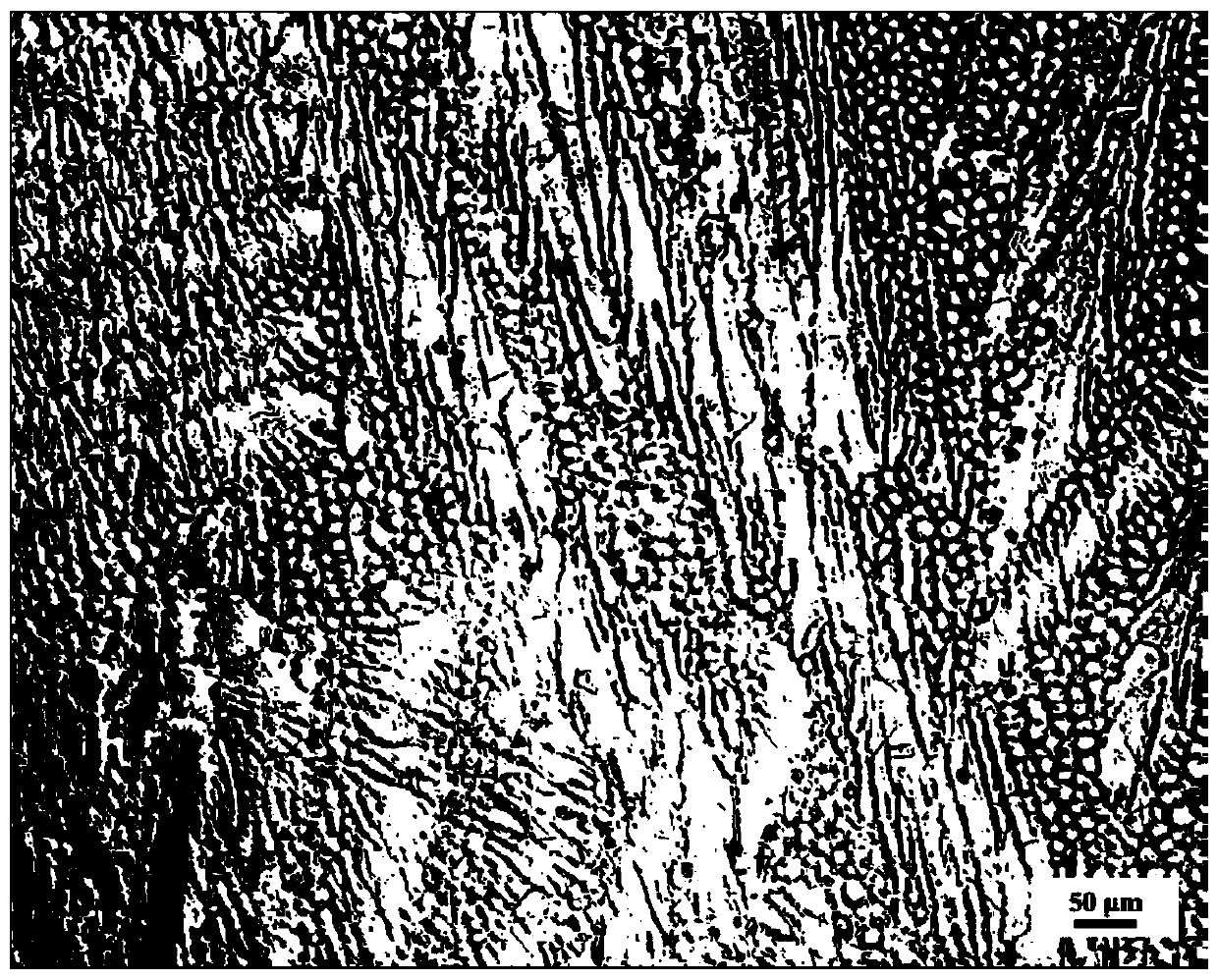

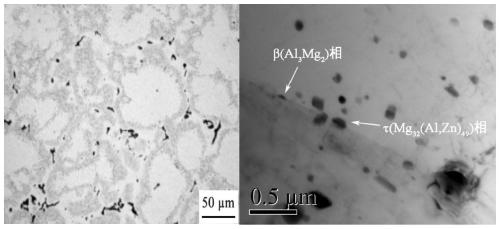

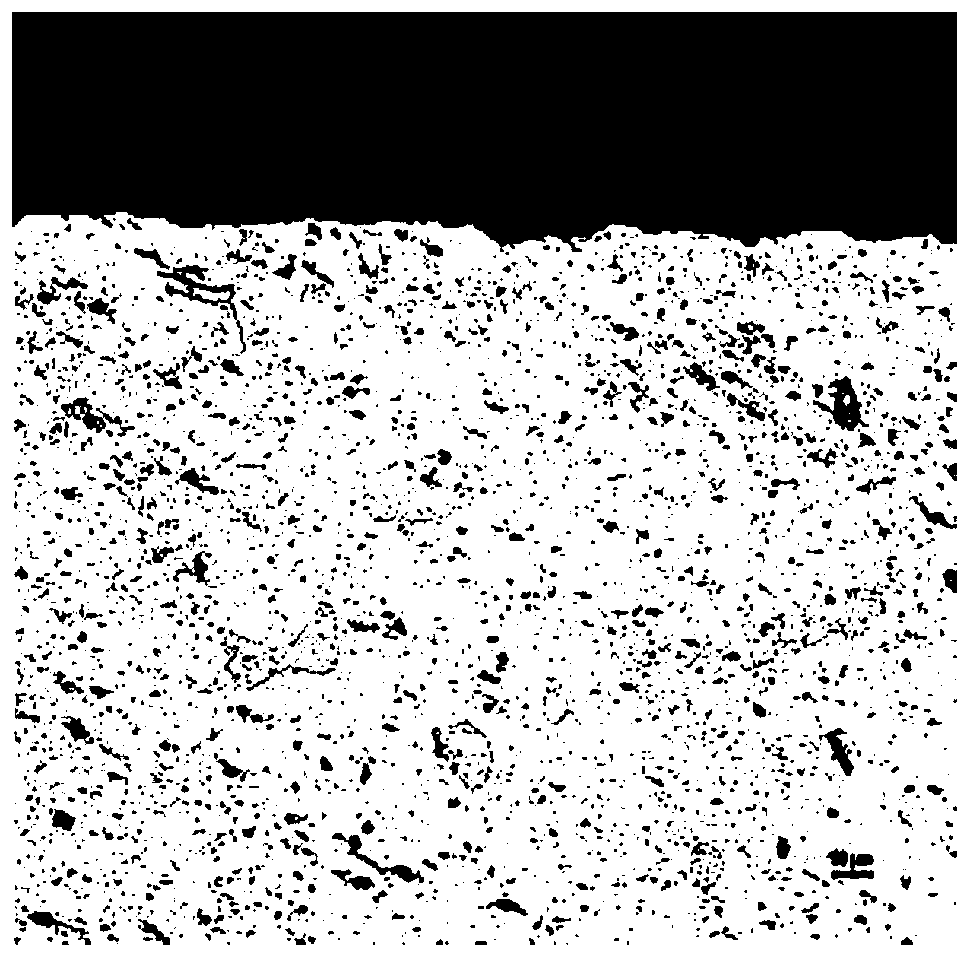

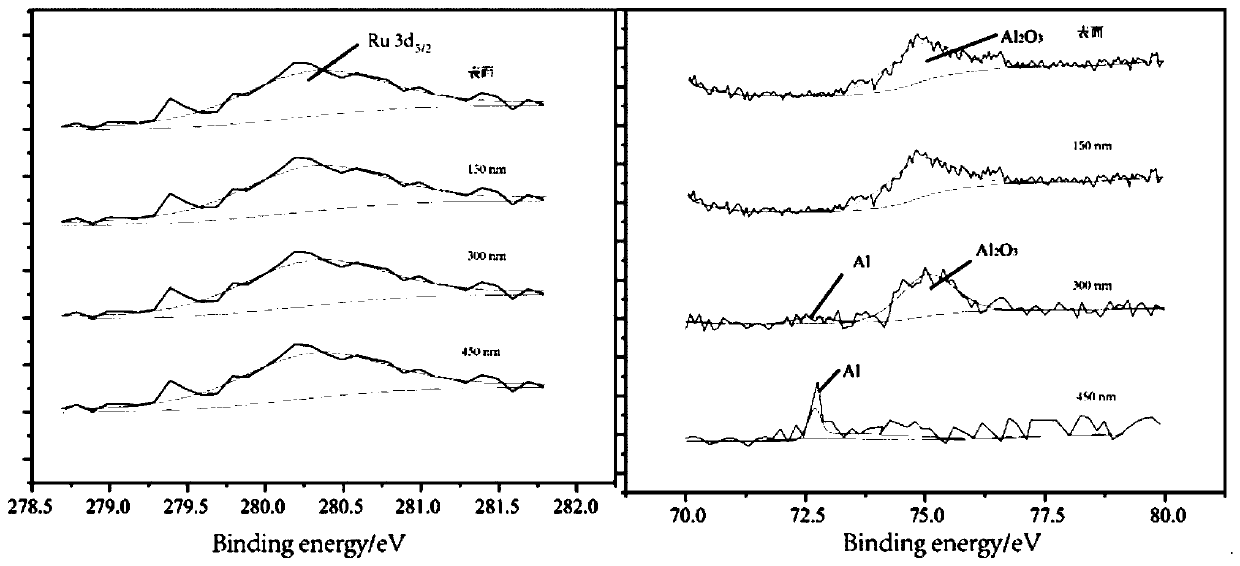

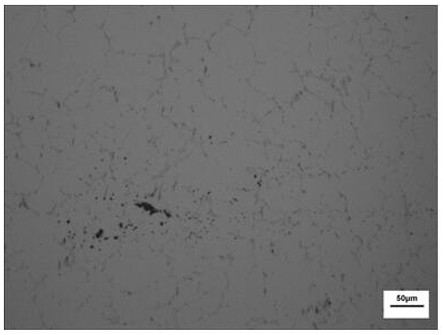

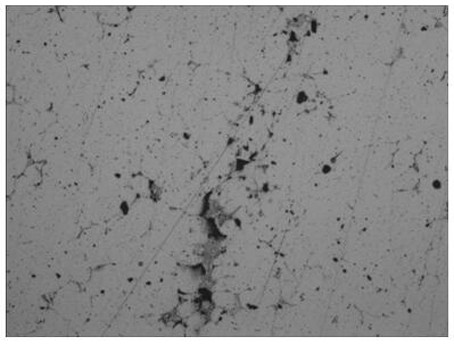

Al-Mg alloy with high intergranular corrosion resistance and preparation method thereof

InactiveCN110205528AImprove intergranular corrosion resistanceReduce potential differencePotential differenceCathode reaction

The invention discloses an Al-Mg alloy material with high intergranular corrosion resistance. The alloy comprises Ru, Mg, Mn, Zn, Ti and Al. According to the alloy, in a corrosive medium, Ru can increase the current density of a cathode reaction, so that an alpha(Al) surface spontaneously generates Al2O3.3H2O with the thickness of 300 nm and a compact, self-repairing high-corrosion-resistance passivation film. The erosion of the corrosive medium to a beta(Al3Mg2) phase is effectively blocked, and the intergranular corrosion resistance of the alloy is greatly improved. By adjusting the proportion of M(Mg) to M(Mn) to M(Zn), a tau(Mg32(Al,Zn)49) phase can be separated out from the alloy, separation of the beta(Al3Mg2) phase is inhibited, the potential difference between a second phase and analuminum matrix is reduced, and the intergranular corrosion resistance of the alloy is further improved.

Owner:CENT SOUTH UNIV

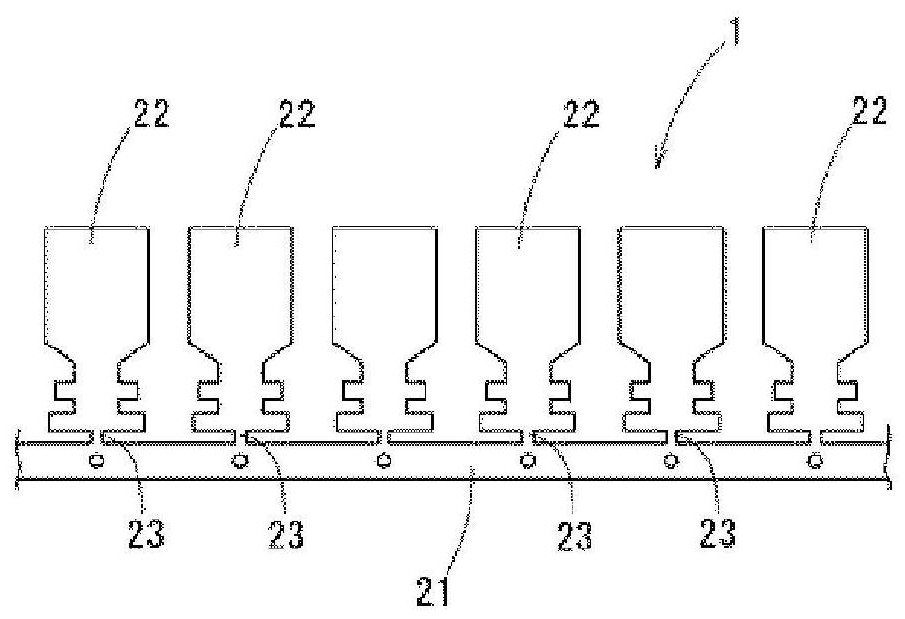

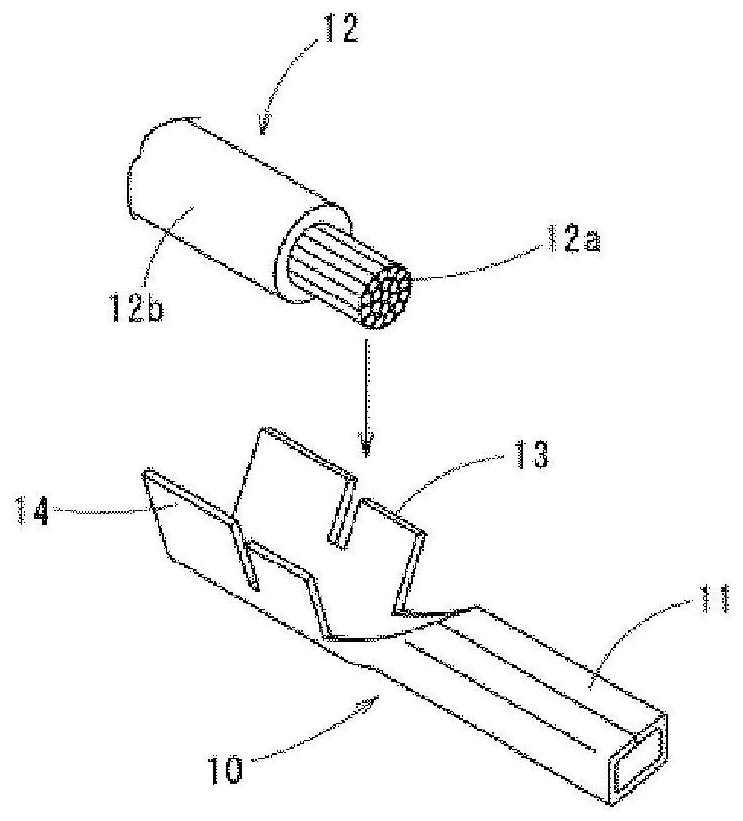

Tin-plated copper terminal material, terminal and wire end structure

ActiveCN110603349BHas anti-corrosion effectLower the resistance valueConductive materialCoupling contact membersTin platingZinc alloys

The present invention provides a tinned copper terminal material, a terminal made of the terminal material, and an electric wire end structure using the terminal. The tinned copper terminal material has: a base material, which is made of copper or a copper alloy; an intermediate zinc layer, formed on the base material and composed of a zinc alloy, and having a thickness of 0.10 μm or more and 5.00 μm or less; and a tin layer formed on the intermediate zinc layer and composed of tin or a tin alloy, and having a small-tilt grain boundary length The tin-plated copper terminal material effectively suppresses galvanic corrosion when the ratio to the total grain boundary length is 2% or more and 30% or less.

Owner:MITSUBISHI MATERIALS CORP

A kind of preparation method of aluminum foil for automobile radiator

ActiveCN111101035BReduce corrosion potentialReduce solubilityHeat exchange apparatusMetal rolling arrangementsSilicon oxideAluminum foil

The invention discloses a method for preparing aluminum foil for automobile radiators, which comprises the following steps: preparing aluminum melt; continuous casting and rolling, during continuous casting and rolling, the contact interface between the steel strip of the casting machine and the slab is uniformly sprayed with a layer of nano-scale carbon dioxide Silicon powder; homogenization annealing; cold rolling; finished annealing. The invention provides a method for producing aluminum foil for automobile radiators by means of continuous casting and rolling, and provides more choices for producing aluminum foil for automobile radiators with 7072 alloy.

Owner:广西润泰铝业有限公司

A preparation process of aluminum alloy for power equipment in marine environment

ActiveCN106978554BResistance to corrosion damageImprove corrosion resistanceAnodisationElectric power equipmentAcid washing

The invention discloses a preparation technique of aluminum alloy for power equipment in the marine environment. The preparation techniques comprises the steps of composition optimization, homogenizing, squeezing, quenching, drawing, aging, cooling, cleaning, alkali washing, acid washing, oxidation and hydrophobic surface manufacturing. As for aluminum alloy products obtained through the technique, the tensile strength is larger than or equal to 420 MPa, the yield strength is larger than or equal to 320 MPa, the elongation is larger than or equal to 18%, the Brinell Hardness is larger than or equal to 100 HB, the electrical conductivity is larger than or equal to 27 MS / m, the corrosion resistance and weather resistance are good, corrosion damage of high-humidity corrosive saline ions to aluminum alloy workpieces can be effectively resisted, and the production process is stable.

Owner:SHANDONG INNOVATION METAL TECH

A kind of 3003 aluminum alloy for aluminum alloy heat sink

ActiveCN103334036BReduce corrosion potentialImprove collapse resistanceHeat exchange apparatusManganeseCopper

The invention provides a 3003 aluminum alloy for aluminum alloy cooling fin. The 3003 aluminum alloy can effectively improve yield strength of the cooling fin after brazing, enhance overall strength of a radiator core body, and prolong service life. The 3003 aluminum alloy is characterized by containing the following materials in a total weight part of 100:0.7-1 part of silicon (Si), no more than 0.3 part of iron (Fe), no more than 0.05 part of copper (Cu), 0.8-1.2 parts of manganese (Mn), no more than 0.3-0.6 part of magnesium (Mg), 1.2-1.8 parts of zinc (Zn), 0.1-0.2 part of zirconium (Zr) and the balance of aluminum (Al) and inevitable impurities.

Owner:YINBANG CLAD MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com