Zinc alloy coating of LNG (Liquefied Natural Gas) opening-frame vaporizer

An open-frame gasifier, zinc alloy technology, applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of no patents, etc., to prolong the service life, good erosion and corrosion resistance, and improve the forming performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

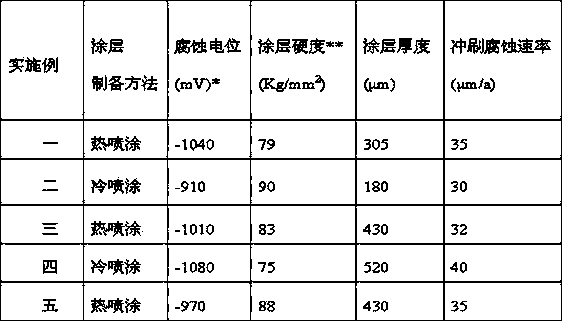

[0023] Zn-Al master alloy, Al-Cu master alloy, Al-Y master alloy, and pure Zn particles are distributed according to the chemical composition Al 5.3wt%, Cu4.0wt%, Y 0.5wt%, and the balance is the target composition of Zn, through Alloy ingots are produced by smelting. The ingot is extruded and drawn to make Ф3mm Zn-Al-Cu wire, and a long-term sacrificial anode coating is sprayed on the aluminum alloy by thermal spraying. The corrosion potential, microhardness, thickness, and Corrosion rates are shown in Table 1.

Embodiment 2

[0025] The Zn-Al master alloy, Al-Cu master alloy, Al-Y master alloy, and pure Zn particles are prepared by mechanical mixing according to the target ingredients of the chemical composition Al 35.4wt%, Cu6.2wt%, and the balance being Zn. Pseudo-alloy powder. The pseudo-alloy powder was cold sprayed on the aluminum alloy substrate to prepare a long-lasting sacrificial anode coating. The corrosion potential, microhardness, thickness and corrosion rate of the coating in seawater are shown in Table 1.

Embodiment 3

[0027] The Zn-Al master alloy, Al-Cu master alloy, Al-Y master alloy, and pure Zn particles are distributed according to the chemical composition Al 20.3wt%, Y 5.1wt%, and the balance is Zn, and the alloy ingot is prepared by , the ingot is made into Ф3mm Zn-Al-Cu wire after extrusion and wire drawing, and a long-term sacrificial anode coating is prepared on the aluminum alloy by thermal spraying. The corrosion potential, microhardness and thickness of the coating in seawater , The corrosion rate is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com